| | #61 |

| RCC Addict Join Date: Jun 2008 Location: Monroe, NC

Posts: 1,547

| |

| |  |

| Sponsored Links | |

| | #62 |

| PapaGriz Yo  Join Date: Apr 2004 Location: In the garage building the wife a crawler

Posts: 13,137

|

Man, that is one busy buggy.  |

| |  |

| | #63 | |

| Rock Stacker Join Date: Aug 2008 Location: BC Canada

Posts: 69

| Quote:

It is only 3/16, unless it is solid then heat really isn't necessary. That said, if you go to fast with too much force you will kink brake line because the radius is small and the die (hole saw in this case) does not support the "sides" of the tube while bending. Just try it and you'll see what works. 3/4 is a good "scale" looking radius as most automotive based bend tools are a lot bigger than that and tend to look too big and a bit hoopy (a technical term) IMHO. My pro-tools one shot hydro bender (1:1 so don't start searching the web for it) has a CLR of 7" for 1.75" tube Scale that down to 3/16 BL and it is just under 3/4 (.7). I actually use a 5/8 bolt at the bolt head (ARP) as it is a rounded transition and helps to keep the tube straight or as a reference point when a bend is forming a compound angle. | |

| |  |

| | #64 | |

| RCC Addict Join Date: Jun 2008 Location: Monroe, NC

Posts: 1,547

| Quote:

Justin | |

| |  |

| | #65 |

| RCC Addict Join Date: Jun 2004 Location: Bruiser Heaven!!!!

Posts: 1,463

|

the best looking frame on the site, and since i have been on here. keep up the good work too.

|

| |  |

| | #66 | |

| Quarry Creeper Join Date: Mar 2004 Location: n.e. ohio

Posts: 433

| Quote:

| |

| |  |

| | #67 | ||

| Custom Carbon Fiber  Join Date: Oct 2007 Location: Connecticut :(

Posts: 4,501

| Quote:

The drive to do good comes from seeing builds like yours and many others around here.   Quote:

Couldnt have said it better. No heat since its only hollow brake line, just patience and enough pressure to hold the tube. Couldnt have said it better. No heat since its only hollow brake line, just patience and enough pressure to hold the tube.Thank you, I appreciate that alot. | ||

| |  |

| | #68 |

| no talent hack  Join Date: Feb 2007 Location: Redwood City

Posts: 2,479

|

did i mention that i hate you? i get depressed everytime i look at this thread. if you EVER decide to sell it let me know |

| |  |

| | #69 |

| Sinking with the ship    Join Date: Mar 2005 Location: El Capitan...sole survivor and sinking fast

Posts: 8,864

|

amazing attention to detail  One of the best scale tubers on RCC, cant wait to see more One of the best scale tubers on RCC, cant wait to see more |

| |  |

| | #70 |

| Newbie Join Date: Jun 2005 Location: Liberty

Posts: 32

|

thats gonna be awesome...I would like something like that myself..  |

| |  |

| | #71 |

| Adilynsdad too!    Join Date: May 2004 Location: G ville

Posts: 8,844

|

I just soiled myself, in a good way... Gosh danged cool freakin build! |

| |  |

| | #72 | ||||

| Custom Carbon Fiber  Join Date: Oct 2007 Location: Connecticut :(

Posts: 4,501

| Quote:

Will do. I know alot of people including myself will hate me if i sell it before I run it ..... im very well known for doing exactly that lol. Quote:

Quote:

Quote:

Glad you like it. | ||||

| |  |

| | #73 |

| Custom Carbon Fiber  Join Date: Oct 2007 Location: Connecticut :(

Posts: 4,501

|

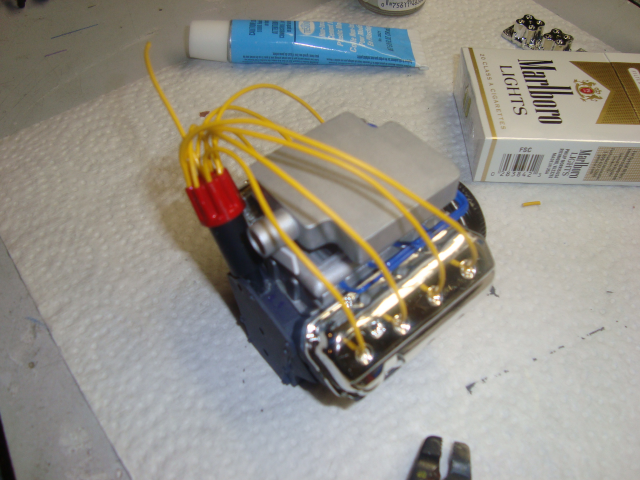

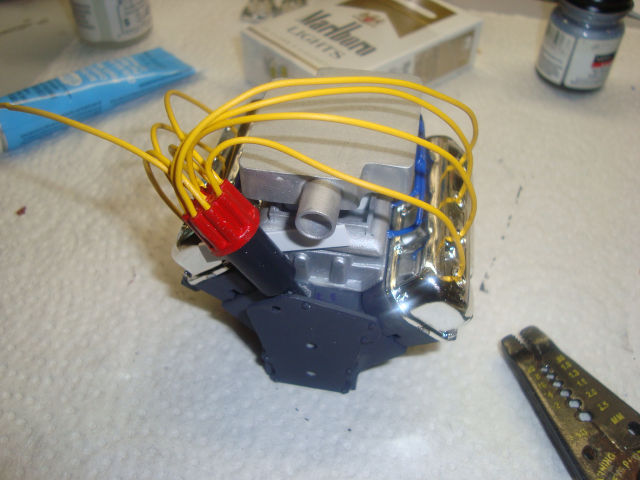

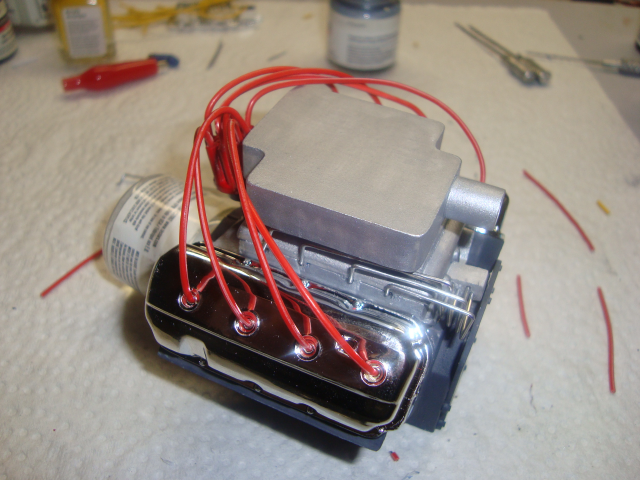

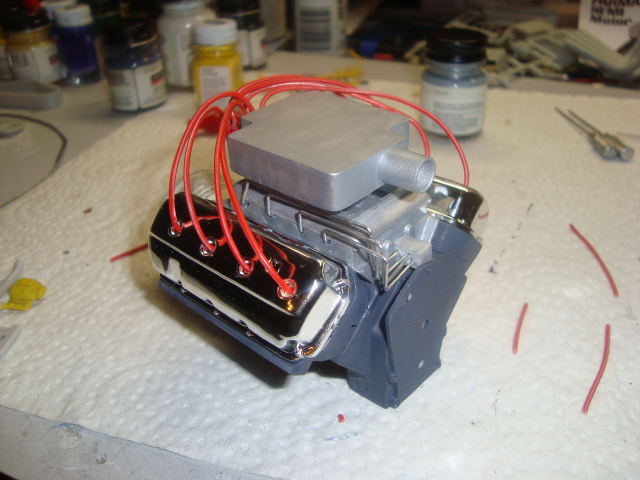

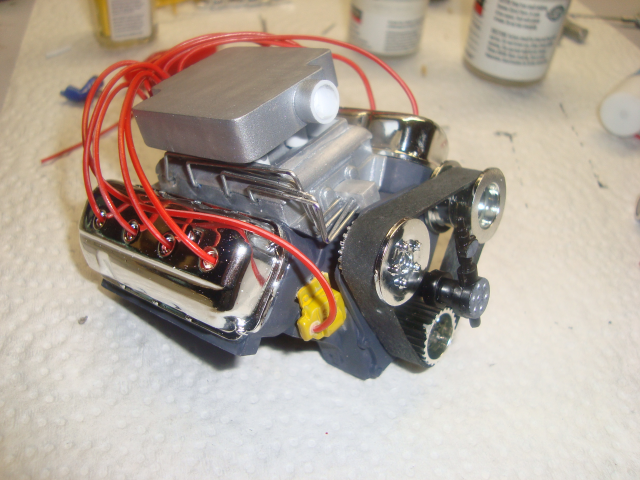

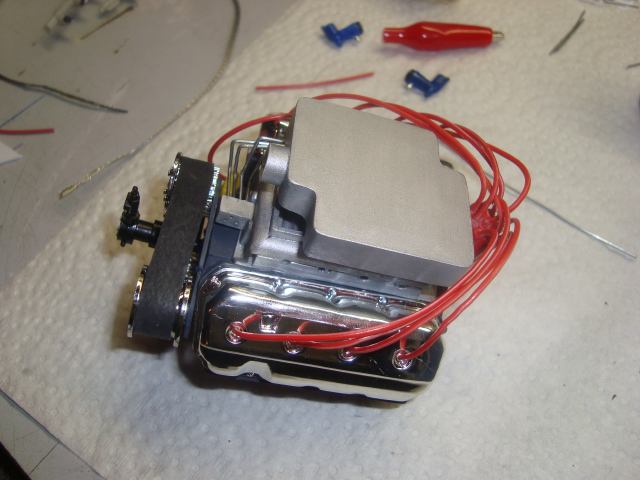

well i got the motor almost done. i started building it the Hemi way but just wasnt happy with it, even built a matching manifold to the original.    the dist up front wasnt doing it for me when trying to match the original so i pulled it out and went the GM way.   still got a bit of work to do on the pulleys and the fuel injection/fuel pump   |

| |  |

| | #74 |

| Rock Crawler  Join Date: Nov 2006 Location: Spanish Springs, Nv

Posts: 697

|

Wow, you must not have many distractions. That is freaking awesome. PATIENCE. How much time do you have in it so far?

|

| |  |

| | #75 |

| Custom Carbon Fiber  Join Date: Oct 2007 Location: Connecticut :(

Posts: 4,501

| |

| |  |

| | #76 |

| I wanna be Dave Join Date: Apr 2007 Location: clarksburg

Posts: 2,009

|

Killer fab work!!!! You are making it look easy,, and we all know it isnt... What are you using for heat and if you already stated Im sorry ,but I cant seem to read any of this dialog with all these bad ass pics!!! Thanks for sharing your talent..... |

| |  |

| | #77 |

| Rock Stacker Join Date: Aug 2005 Location: Hiding in a Cornfield

Posts: 65

|

This is one of the best builds I've seen all year. Oh and what kind of motor is that. Is it one of the model motors you can buy from a model car kit?

|

| |  |

| | #78 |

| Rock Stacker Join Date: Nov 2008 Location: B-Town Crawlarado

Posts: 77

|

Very nice work..  What do you have planned for panels?? |

| |  |

| | #79 | ||

| Custom Carbon Fiber  Join Date: Oct 2007 Location: Connecticut :(

Posts: 4,501

| Quote:

Quote:

Thank you. I dont want to cover up to much of the tube work but still keep it like the original, figured some lexan for a hood to show the motor off and some on the sides painted silver to look like aluminum. | ||

| |  |

| | #80 |

| Custom Carbon Fiber  Join Date: Oct 2007 Location: Connecticut :(

Posts: 4,501

|

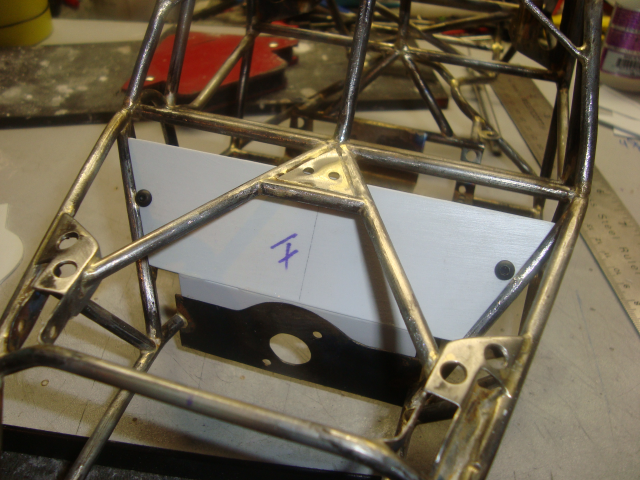

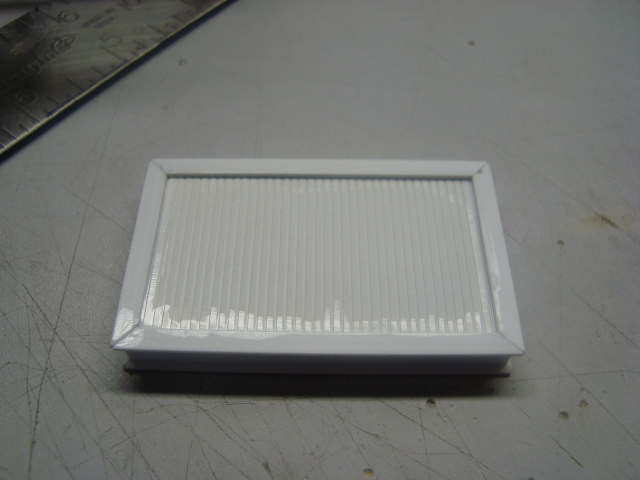

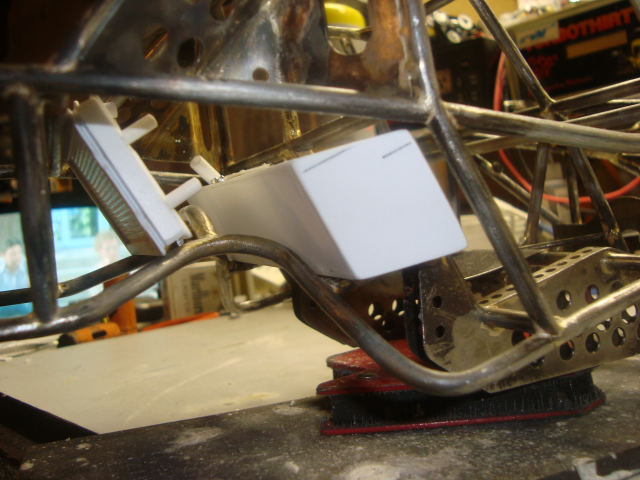

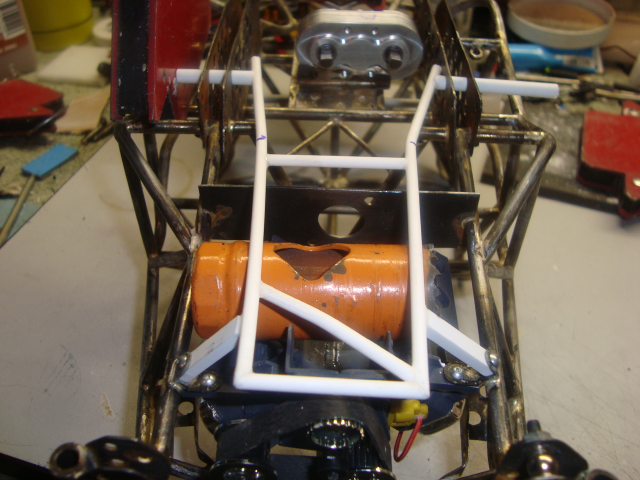

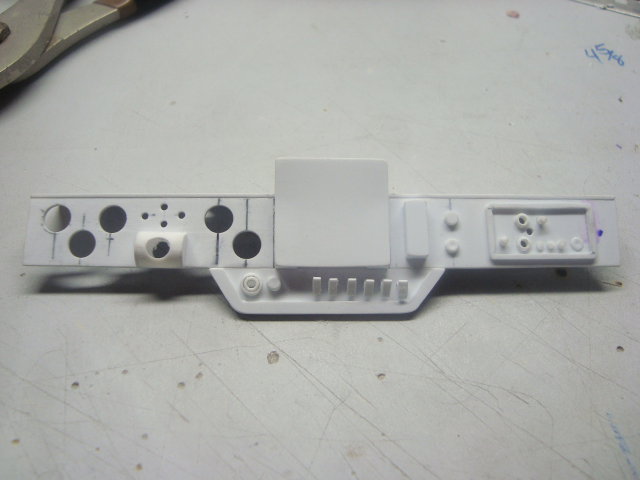

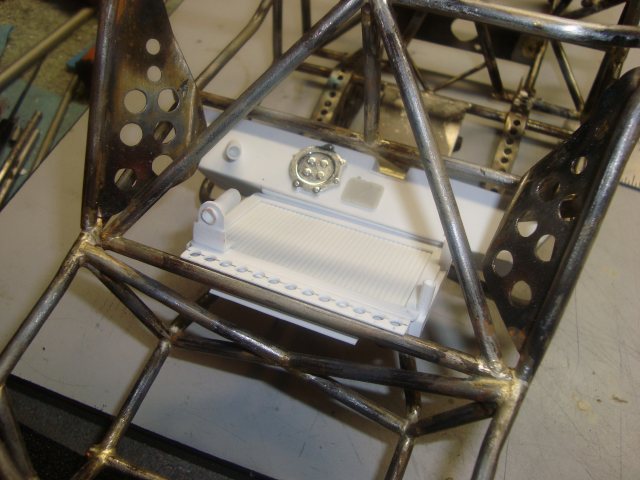

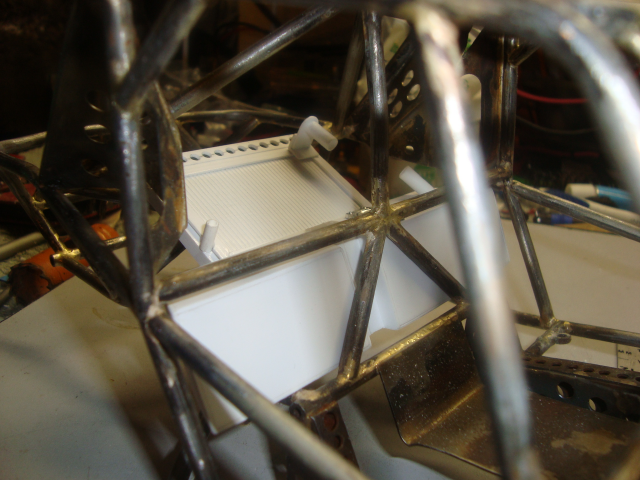

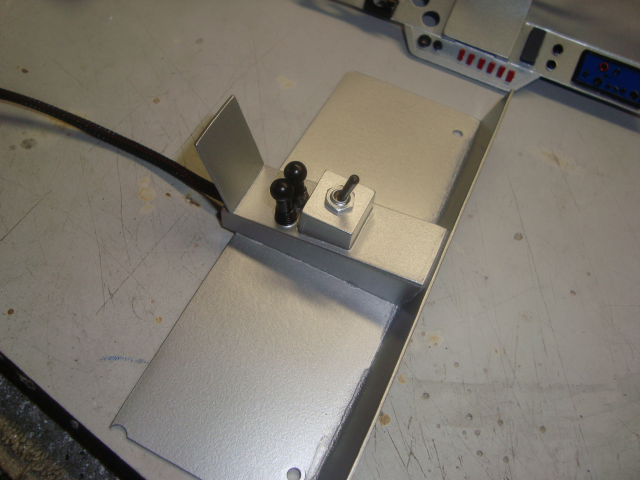

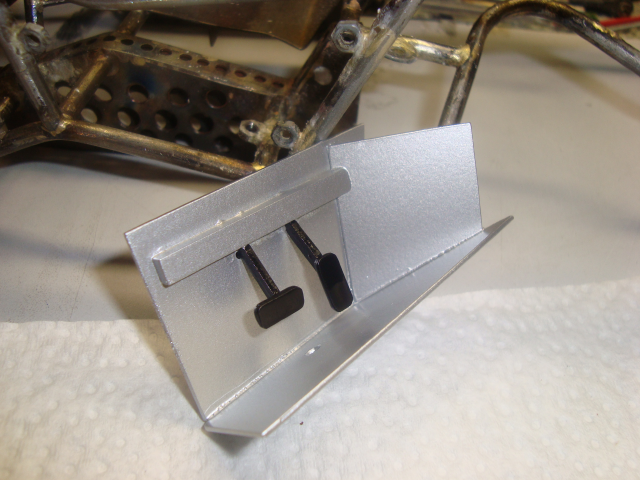

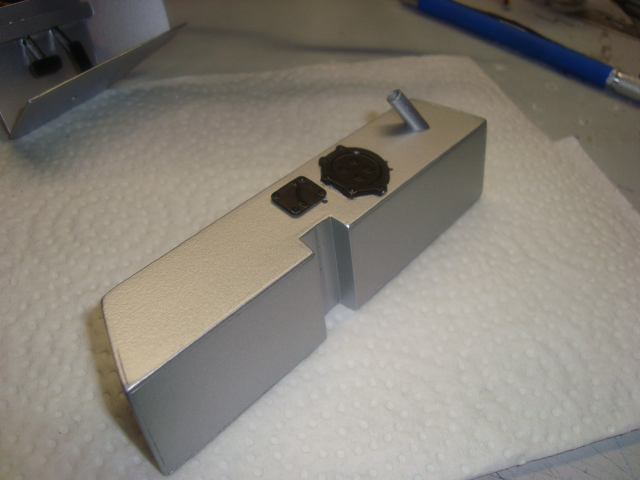

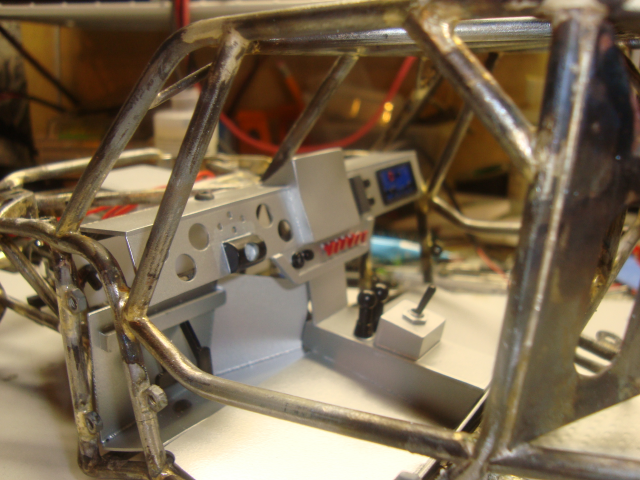

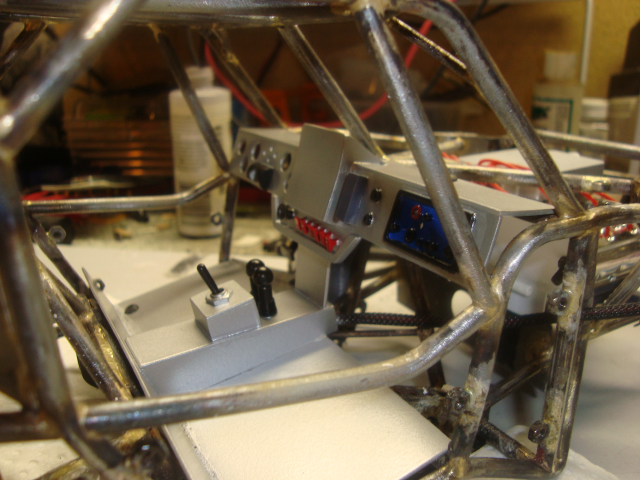

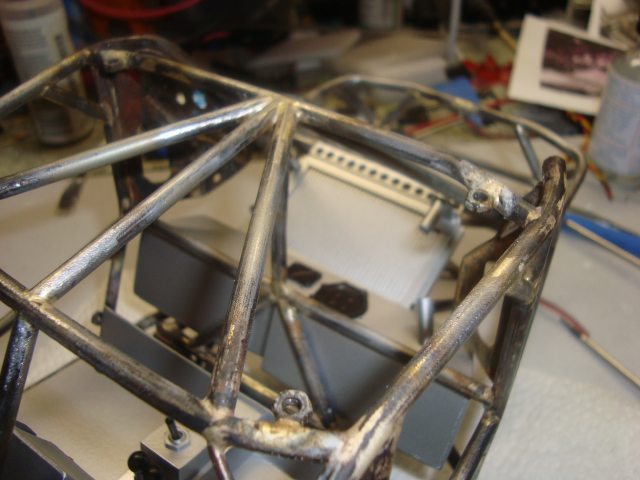

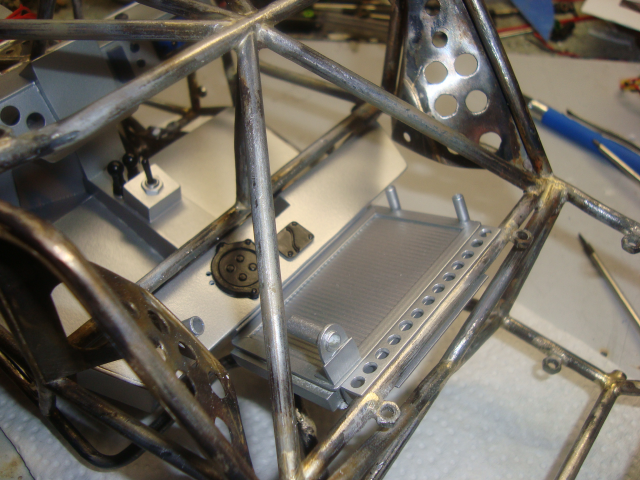

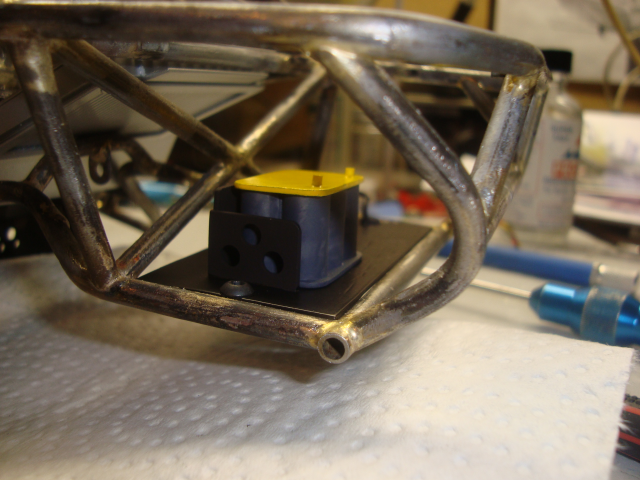

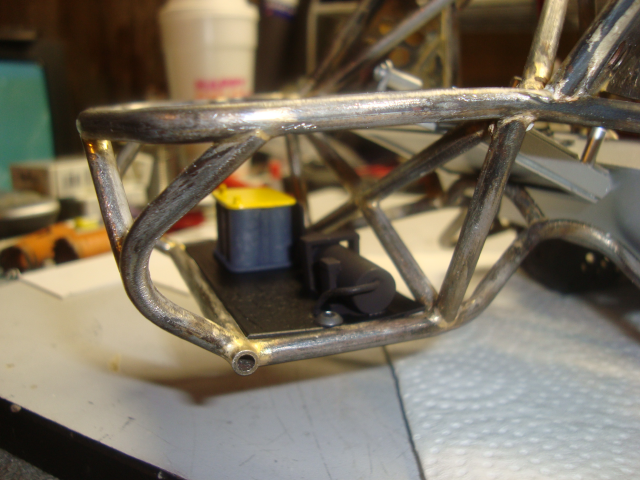

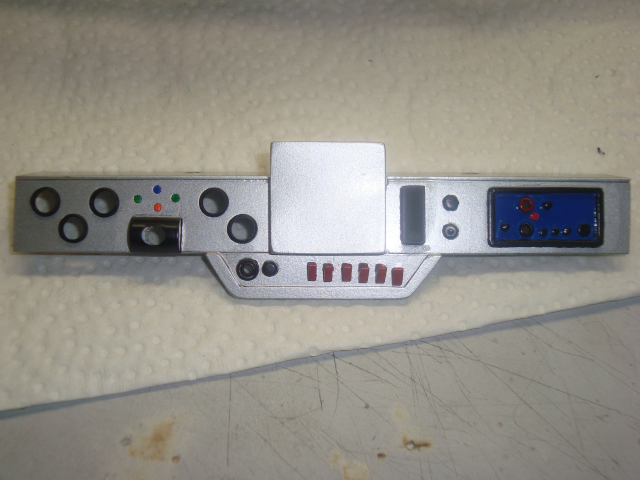

got some styrene work done over the past week. firewall is in  got the radiator  fuel tank and radiator built  worked on my engine belly pan  little dash work  tank and radiator mocked up    interior floor with shifter/switch in  pedals done  radiator and fuel tank painted up   and some mock ups of it all together     cant forget the juice .... little Optima should do it   dash done with gauge pots in ..... just waiting on the gauge faces to show up  more planned this week after the rest of my suspension and shock stuff comes in. got some minor things for the frame left to do plus rear bump stops then off to the sandblaster ........  |

| |  |

|

| |