| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Quarry Creeper Join Date: Mar 2005 Location: hudson (the big city)

Posts: 267

|

hello to all. i'm not sure if i'm in the right area for this but i've seen quite a few of wreckluse builds here in this thread. i just completed my wreckluse build and on to working out the bugs. one bug i found is in my steering. my servo is mounted up inside the chassis on a welded in plate. my drag link is running parallel with the tie rod (longer steering link). i noticed it causes quite a bit of side to side movement on my axle. i ended up popping a few rod ends off my front upper links and thinking that this could be caused by the stress added by my steering set up. i'd rather not have to cut out the plate to run my steering on the axle. does anyone have any solution to this? any similar set up recomendations? thank you in advance...

|

| |  |

| Sponsored Links | |

| | #2 |

| RCC Addict Join Date: Nov 2006 Location: southaven

Posts: 1,934

|

pics would help  |

| |  |

| | #3 |

| Quarry Creeper Join Date: Mar 2005 Location: hudson (the big city)

Posts: 267

|

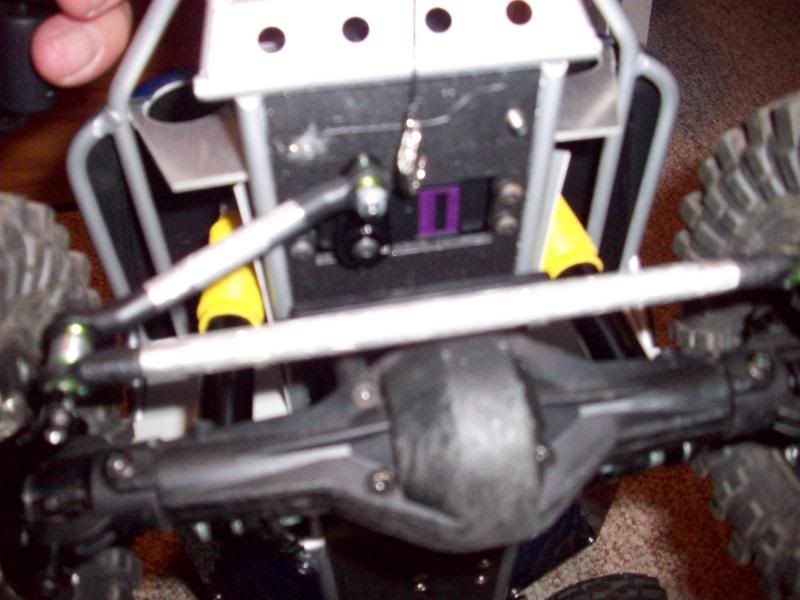

sorry for the poor quality photo.  |

| |  |

| | #4 |

| RCC Addict Join Date: Jan 2009 Location: Crawlifornia

Posts: 1,941

|

I would flip the servo around and use a longer draglink. As well as insert the servo from the bottom so that the mounting ears are visible from the bottom. I had the same issue with my SCX. The less angle on your draglink the better. Even a spacer between the tie rod and draglink would help a little.

|

| |  |

| | #5 | |

| I wanna be Dave Join Date: Jun 2007 Location: Arlington wa

Posts: 2,100

| Quote:

| |

| |  |

| | #6 |

| Quarry Creeper Join Date: Mar 2005 Location: hudson (the big city)

Posts: 267

|

thanks guys. i really appreciate the help. those were all the ideas i briefly though of. switch the servo around, mount it under the plate, etc... after swapping the servo so the horn is on the other side, should i still continue to run the drag link over to the same side i'm at now?

|

| |  |

| | #7 |

| Quarry Creeper Join Date: Nov 2007 Location: NH

Posts: 427

|

ryan you dont have to swap the servo around, you could run the link to the opposite side. You want to make your drag link as long as possible either way, by swapping the servo around or running the drag link to the other side on the axle will amount to the same thing. Also keeping the two links closer to parrell (when looking at it from the front) will help.

|

| |  |

| | #8 |

| RCC Addict Join Date: Jan 2009 Location: Crawlifornia

Posts: 1,941

|

Flippng and droping the servo down will look more scale. When have you ever seen a drag link coming from the passenger side unless over seas. |

| |  |

| | #9 |

| RCC Addict  Join Date: Apr 2008 Location: Singapore

Posts: 1,742

|

Here are some pictures to how I did the install.      I used a fabricated upper link mount. Shave-off the stock servo mount post on the axles for more clearance. Got the ride height lower to get the drag-link better aligned to the axle so it does not twist. |

| |  |

| | #10 |

| RCC Addict Join Date: Aug 2007 Location: Burbank

Posts: 1,189

|

Heres another way, Do a bell crank set up. Works bad ass, no bump steer

|

| |  |

| | #11 |

| I wanna be Dave Join Date: Jan 2006 Location: Henderson/Las Vegas, NV

Posts: 5,032

| |

| |  |

| | #12 |

| RCC Addict Join Date: Aug 2007 Location: Burbank

Posts: 1,189

|

Heres some better shots. The bell crank on the axle is off a 4tec car.      |

| |  |

|

| Thread Tools | |

| Display Modes | |

| |