| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Newbie Join Date: Jul 2005 Location: Madison

Posts: 14

|

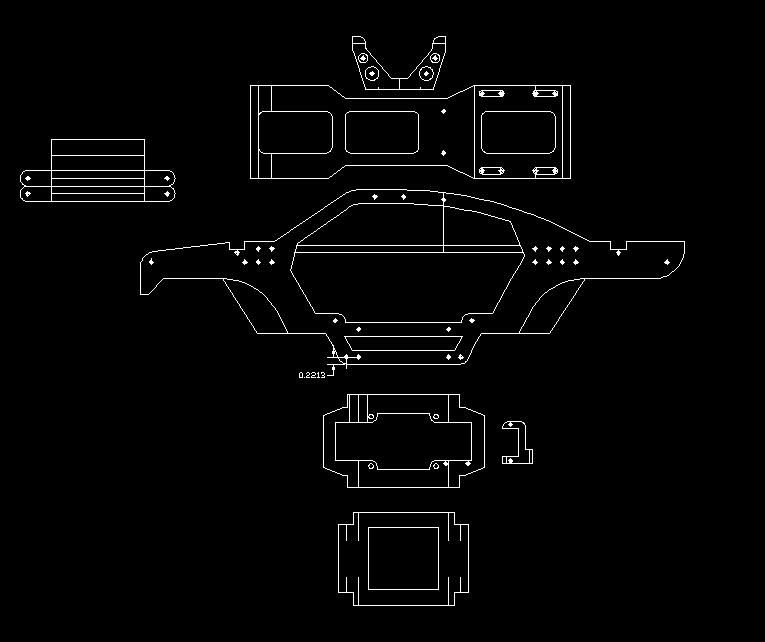

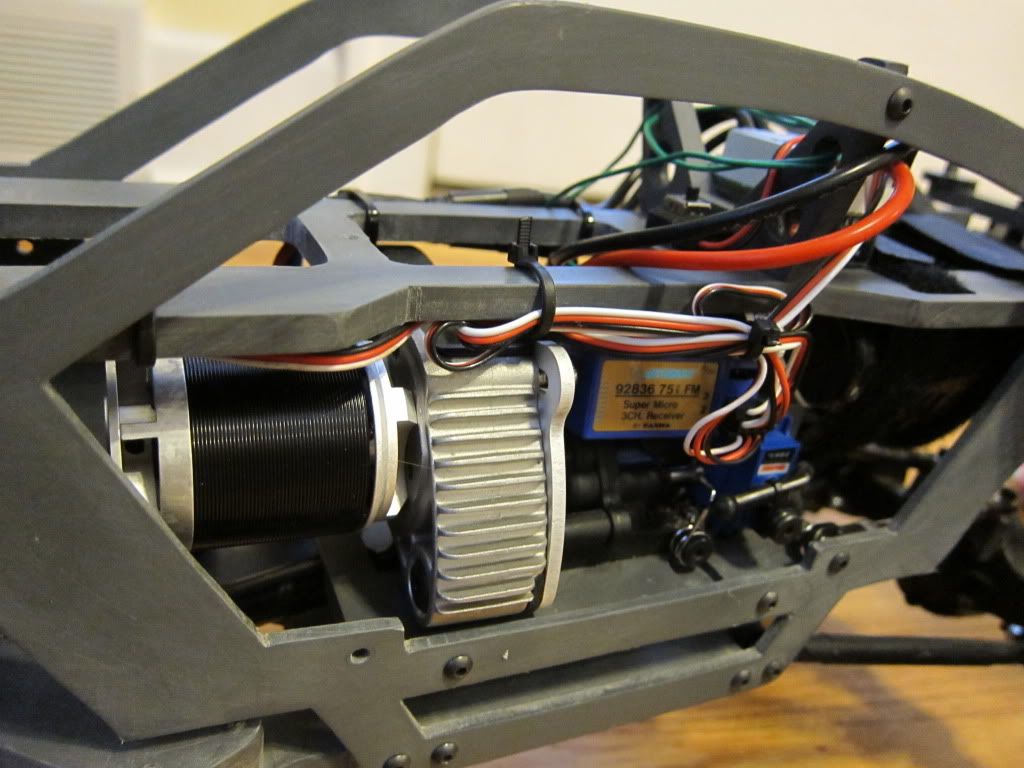

I thought I would put up a few pictures of a project I am working on. It is meant to be scale, cheapish, and fun. I wanted to use a Summit trans and fabricate a cheap tough chassis from sheet PVC. I wanted a crawler that could bash. I also am working on a interchangeable IFS front end from Slash 4x4 parts. I have made CAD templates to cut the parts out from. Everything is cut from either 1/8 or 1/4 PVC. I'll try to get some better pics up as I make progress on it. I am currently working on getting better driveshafts and shocks. Oh yea and it has Wheely King axles and Slash electronics. Enjoy    Here is why the chassis is shaped the way it is:  A little bling:  |

| |  |

| Sponsored Links | |

| | #2 |

| Rock Stacker Join Date: Feb 2010 Location: ashland

Posts: 56

|

sweet looking build! i built one similar using straight frame like the axial but didnt turn out too well CG sucked o well lol

|

| |  |

| | #3 |

| Newbie Join Date: Jan 2009 Location: Baltimore

Posts: 37

|

Man, that is awesome!

|

| |  |

| | #4 |

| Rock Stacker Join Date: Sep 2010 Location: Earth

Posts: 62

|

i like your idea for the chassis. did you cut out the pieces by hand or use a cnc mill?

|

| |  |

| | #5 |

| RCC Addict Join Date: Nov 2009 Location: Tulsa

Posts: 1,667

|

That's real cool I never thought of PVC how durable is it

|

| |  |

| | #6 |

| Rock Crawler Join Date: Feb 2010 Location: costa rica

Posts: 705

|

Well It looks nice, have you tested it to see how it performs? I have a similar project but I plan in using an older emaxx 2 speed transmission.

|

| |  |

| | #7 |

| Newbie Join Date: Jul 2005 Location: Madison

Posts: 14

|

I have ran it this past weekend for the first time. First bent the crawler king links, then spun a traxxas hex, then split the crawler king rear driveshaft (the long way). And that was in just two packs and yes I was beating it! The good news is that the PVC held up great! It took several direct hits, landing upside down. Oh yea I just printed the template 1:1 and glued it to the PVC then cut it on a scroll saw, and drilled the holes with a drill press. The PVC is really easy to work with. I would be willing to share the template if anyone is interested in the .DWG. |

| |  |

| | #8 |

| Rock Stacker Join Date: Sep 2010 Location: Earth

Posts: 62

|

from where did you acquire the pvc sheet? i checked the lowes up the street from me, briefly, and did not see any pvc sheet material. also, how does the pvc hold threads? did any of the holes strip out when you were screwing it together?

|

| |  |

| | #9 |

| RCC Addict Join Date: Nov 2009 Location: Tulsa

Posts: 1,667

|

That's awsome where do u get sheet PVC

|

| |  |

| | #10 |

| Newbie Join Date: Jul 2005 Location: Madison

Posts: 14

|

This is where I found the PVC also you might have a local plastics company that might sell it. www.mcmaster.com also a good place to get hardware. I Used M3 hardware and drilled the holes slightly smaller than the screw in order to get a tight fit. I have not tried actually tapping the PVC yet. The screws have worked well I am not worried about stripping. PVC Material Chemical-Resistant PVC (Type I) Plain Back Finish Smooth Shape Sheets, Bars, Strips, and Cubes Thickness 1/4" (or 1/ Opaque Gray Lowest Temperature +0° to +60° F Highest Temperature +100° to +200° F Last edited by jibberjabbs; 09-10-2010 at 05:02 AM. |

| |  |

| | #11 |

| I wanna be Dave Join Date: Sep 2005 Location: USA

Posts: 11,196

|

Now that looks like it's going to be fun to drive... |

| |  |

| | #12 | |

| RCC Addict Join Date: Nov 2009 Location: Tulsa

Posts: 1,667

| Quote:

Thanks a lot | |

| |  |

| | #13 |

| Newbie Join Date: Jul 2005 Location: Madison

Posts: 14

|   Here is a little progress on the IFS front end! |

| |  |

| | #14 |

| Quarry Creeper Join Date: Feb 2010 Location: melbourne

Posts: 215

|

If batman had an off-road truck this would be it........sick ride  |

| |  |

| | #15 |

| Newbie Join Date: Jul 2005 Location: Madison

Posts: 14

|

Here are a few updates, but its not done!      |

| |  |

| | #16 |

| Rock Crawler Join Date: Aug 2007 Location: Dela-where?

Posts: 501

| |

| |  |

| | #17 |

| RCC Addict Join Date: Oct 2009 Location: west coast..

Posts: 1,522

|

Very cool build man any action shots?

|

| |  |

| | #18 |

| Quarry Creeper Join Date: Feb 2010 Location: Knee deep in a creek with a fish on the line

Posts: 456

|

Very nice build. Would you mind posting some detailed picks of the IFS front end specifically the steering, and frame mounts?

|

| |  |

| | #19 |

| Quarry Creeper Join Date: Aug 2008 Location: Warwick

Posts: 302

|

Sweet build  It looks like you did your homework! That body compliments the chassis very well. It looks like you did your homework! That body compliments the chassis very well.

|

| |  |

| | #20 |

| 0 0  Join Date: Jul 2006 Location: FT. Thomas

Posts: 1,830

| |

| |  |

|

| |