| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Quarry Creeper  Join Date: Jul 2010 Location: My garage...

Posts: 366

|

Ok, so here goes nothing... my first build that I am doing a thread on! Be sure to give my suggestions and opinions on anything you see that could help me! build details: -SCX10 frame (Honcho) -Axial axles -Axial trans -probably a jeep body?? -Sidewinder ESC -Holmes Hobbies motor... which one?? -2.2 losi beadlocks with 2.2 Mud Slingers around them -120 mm internal spring air shocks from hot racing -4ws That should give a general idea of where I am going with this build. I got this truck in a trade for my T-Maxx. It was a bit beat and a rebuild was in store... So... Here goes! First I tore down everything, down to the frame rails. I washed all the pieces, then I sanded and re-painted the frame a metallic grey color.  now time for assembly of the frame.    Thats all the time I have for tonight! |

| |  |

| Sponsored Links | |

| | #2 |

| Rock Crawler  Join Date: Jan 2011 Location: bridgeport

Posts: 738

|

Great start and i like the color of the painted chassis...good luck bud.

|

| |  |

| | #3 |

| Quarry Creeper  Join Date: Jul 2010 Location: My garage...

Posts: 366

| |

| |  |

| | #4 |

| Quarry Creeper  Join Date: Jul 2010 Location: My garage...

Posts: 366

|

Time to de-anodize some links. Im using greased lightning, I let it soak for about half an hour then stirred it around and let it soak some more.  Ok, mounting the shocks, links and axles. The rear axle will be changed later on so that I can run 4ws on it.   Yes, I know the 3 link bar in the rear isnt de-anadized yet, Ill get to it. Also the bent links in the rear are having rubbing issues with that three link bar... any suggestions? I dont know if I like how high it sits, I may droop the shocks a little bit... Any suggestions on a body that would fit a 2.2 scaler decently? I figured some jeep body due to wheel wells looking good still if you cut them a lot. |

| |  |

| | #5 |

| RCC Addict Join Date: Dec 2009 Location: Rock Bouncin' with the Patented Technique

Posts: 1,374

|

Looking good. The HPI Jeep wrangler would probably look good. |

| |  |

| | #6 |

| Pebble Pounder Join Date: Jan 2011 Location: augusta

Posts: 133

|

Your probably going to have to do a full droop with those shocks to get decent drive shaft angles

|

| |  |

| | #7 |

| Quarry Creeper  Join Date: Jul 2010 Location: My garage...

Posts: 366

|

Any suggestions on links? I have a lot of rubbing when the shocks are compressed. Should I run the bent links or just get straight ones? Also, I may be getting a Novak Goat 3s with a 18.5t... whats everyones take on this system? I haven't seen to many bodies that look right with 2.2 tires on them to still look scale besides maybe some jeeps. any thoughts?? help! |

| |  |

| | #8 |

| Quarry Creeper Join Date: Mar 2009 Location: Colorado springs

Posts: 209

|

stright links will fix the rubbing. as for a body you dont have much of a choice with huge tires so yeap a jeep or a hummer. and you have to lower that down at least half droop if not full droop or your driveshaft will complain and be real tippy/ top heavy  oh and swezy  |

| |  |

| | #9 | |

| Quarry Creeper  Join Date: Jul 2010 Location: My garage...

Posts: 366

| Quote:

Thanks for all the advise double nut... I took most of it... oh and | |

| |  |

| | #10 |

| RCC Addict Join Date: May 2009 Location: Weston

Posts: 1,319

|

The HPI Bronco body looks real nice with 2.2's. I'll post up a pic of mine tomorrow for you.  |

| |  |

| | #11 |

| Quarry Creeper  Join Date: Jul 2010 Location: My garage...

Posts: 366

|

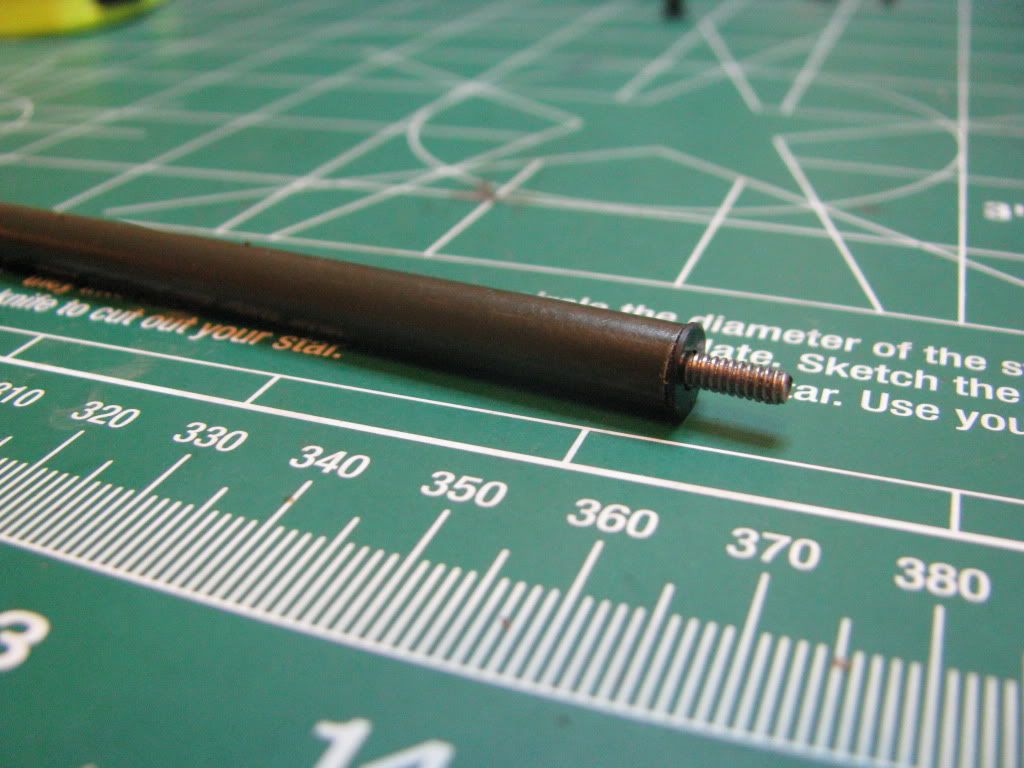

Ok... I got rid of the bent links and 3 link in the rear, decided to 4 link it and ditch the 4ws for now. Didnt have any extra links laying around so I make some custom ones out of 1/4 brakeline and these little spacers I found in my parts bin. quick lesson on how I made my own custom links. first I cut the brake line to size...   then press in the plastic spacer/gromet things I found to keep the all thread centered.    Heres the finished links  |

| |  |

| | #12 |

| Quarry Creeper  Join Date: Jul 2010 Location: My garage...

Posts: 366

|

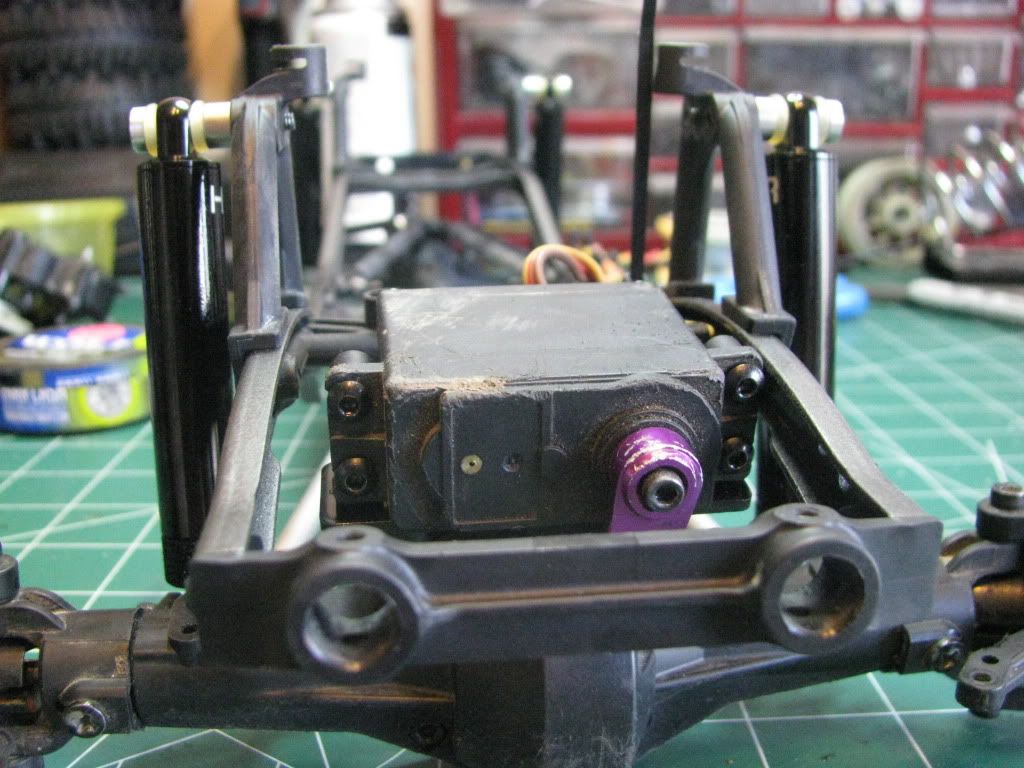

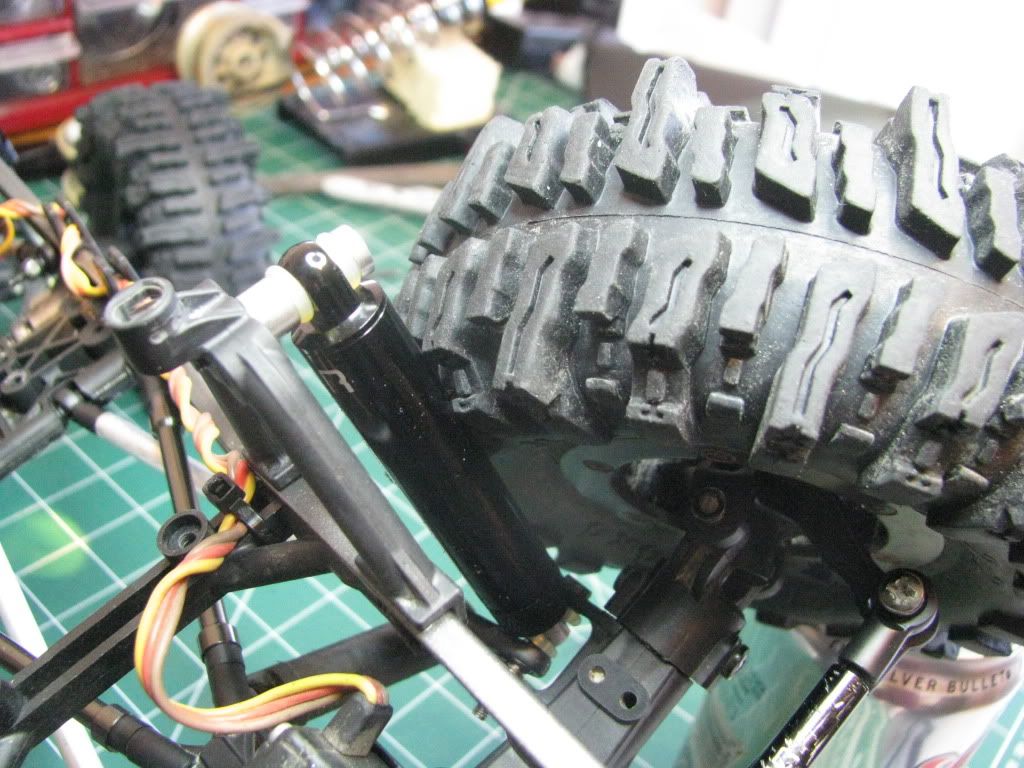

Dont know why that photo uploaded sideways Heres some pics of the 4 link in the rear, I also mounted the transmission and servo. The driveshafts are in and tires are on. I officially have a roller! I did a full droop on the suspension and removed the cross member above the servo so it wouldnt hit.   random cheapo 222oz servo   trans is in   Tires on, showing ride height and fully extended suspension   Flex shot  I do have some rubbing from the tire against the shock, so some sort of wheel spacer is needed.   well, thats all I have for you for now! next Im gonna make a mount for the electronics, and also I need to get a BODY!! I feel naked...  What do you guys think??? |

| |  |

| | #13 |

| Quarry Creeper  Join Date: Jul 2010 Location: My garage...

Posts: 366

|

Oh, and I know its the wrong spot to post this, but I want to show you where Im working on my rig. I'm very proud of it! I built it and stained it last week.  |

| |  |

| | #14 |

| Rock Crawler  Join Date: Jan 2011 Location: bridgeport

Posts: 738

|

Looks good,my only question i have is wont the plastic gromments just come out under presser?are they glued in?just dont think they will hold?..you ever think of solid aluminum rod?..here's what i did..i took solid 1/4 aluminum rod then i drilled down the center of the rod,then i taped the hole then cut the threated rod to fit inside and added the ends.     ..not tellin you what to do,just giving you some ideas.good luck man. ..not tellin you what to do,just giving you some ideas.good luck man.

|

| |  |

| | #15 |

| Quarry Creeper  Join Date: Jul 2010 Location: My garage...

Posts: 366

|

Hey thanks for the input! That's a good point, but I've been running the same links in my sportsman and they have held up for close to a year now, never pulled out. Your idea is great too, maybe if they do start messing up I will give your "genius links" a try lol. I don't have the tools really to tap the threads tho. Eh, well see how it goes!

|

| |  |

| | #16 | |

| Rock Crawler  Join Date: Jan 2011 Location: bridgeport

Posts: 738

| Quote:

...Keep up the good work man and hey,i just ordered those shocks myself,see how i like them ...Keep up the good work man and hey,i just ordered those shocks myself,see how i like them | |

| |  |

| | #17 | |

| I wanna be Dave Join Date: Jun 2005 Location: KENNEWICK, WA

Posts: 2,513

| Quote:

| |

| |  |

| | #18 | |

| Quarry Creeper  Join Date: Jul 2010 Location: My garage...

Posts: 366

| Quote:

thanks for the suggestion. I think the articulation right now is good, not too much, but we will see on the trails! How do you limit it if I do need to? | |

| |  |

| | #19 |

| Quarry Creeper  Join Date: Jul 2010 Location: My garage...

Posts: 366

|

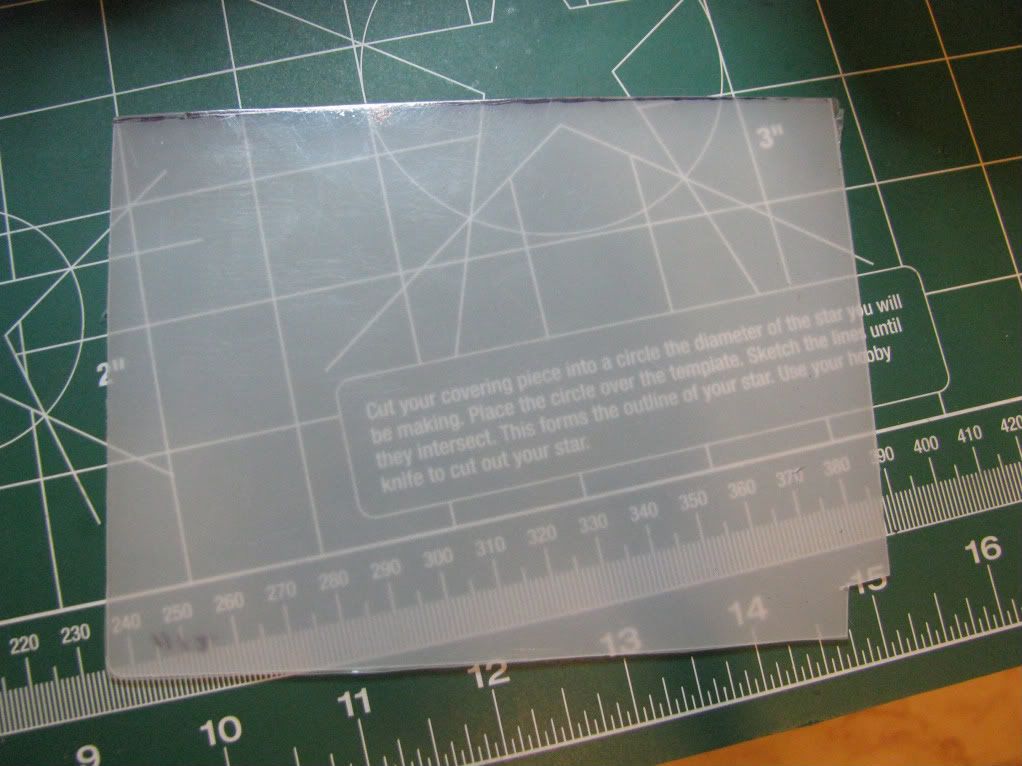

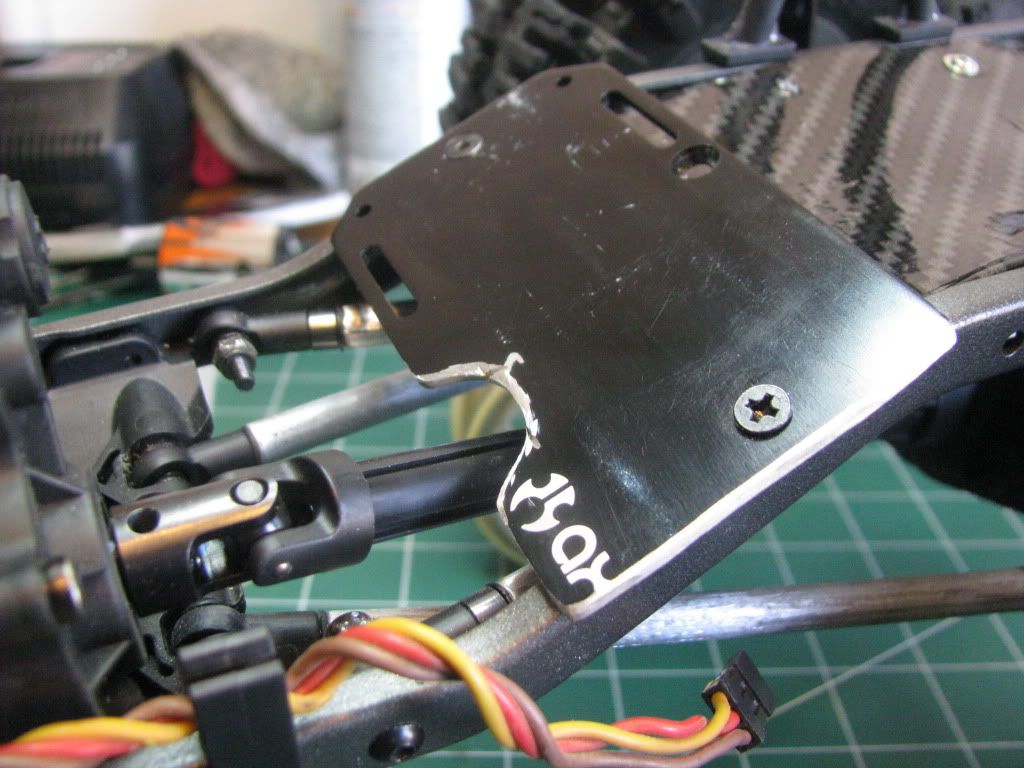

ok, I had a little time today to fab up an electronics tray. I work at a chemical plant, so I can get all the plastic you could ever want  I started with a piece of plastic sheet  Cut it to size and wrapped it with carbon fiber vinyl sticker sheet, drilled a couple holes and mounted it. thats where the battery will sit.  Then I took a stock Axial battery plate, marked out where to cut, and mounted it.   here it is all mounted. the esc and reciever will sit on the metal plate and the battery on the plastic/carbon fiber one.  |

| |  |

| | #20 |

| Quarry Creeper  Join Date: Jul 2010 Location: My garage...

Posts: 366

|

Also I am bidding on a body from ebay. Hopefully I get it! |

| |  |

|

| Thread Tools | |

| Display Modes | |

| |