| | #21 |

| I wanna be Dave Join Date: Mar 2008 Location: In the Dark Edges of your Mind

Posts: 6,386

|

So in this pic then, the outdrive you see with the hole in it is not the outdrive that you sand flat... correct. The one you sand flat engages the one you see in the pic somehow? Thanks...  |

| |  |

| Sponsored Links | |

| | #22 |

| Quarry Creeper Join Date: Nov 2007 Location: NH

Posts: 427

| correct, you file a flat on the output from the trans. On the opposite end of the one on the dig has a slot cut into it that will mate up with the trans output to lock it into 4wd

|

| |  |

| | #23 |

| Custom Carbon Fiber  Join Date: Oct 2007 Location: Connecticut :(

Posts: 4,501

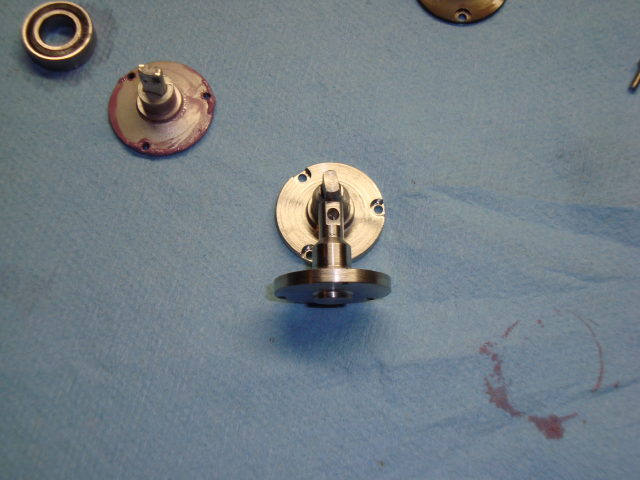

|  thats a set of CDW's done using a handfile left corner you can see the original aluminum one, definitely worn out Last edited by Robbob; 09-09-2008 at 07:53 AM. |

| |  |

| | #24 |

| I wanna be Dave Join Date: Mar 2008 Location: In the Dark Edges of your Mind

Posts: 6,386

|

One thing that I didn't really think about with this dig is that it mounts to the spur gear side, which I guess is opposite of the VF. If you get a chassis made for the VF (like the Black Widow from MFM) it's not going to work out just right. You should definitely get the undrilled skid, because the pre-drilled just doesn't work. Also... I got 3 brass bushings. One big one for the main shaft, one for the slider, and one that was the ID of the slider shaft, but it had a shoulder on the outside. The directions just say "Assemble the dig and put it on"... so what is that other bushing for? It works without it... |

| |  |

| | #25 | |

| Custom Carbon Fiber  Join Date: Oct 2007 Location: Connecticut :(

Posts: 4,501

| Quote:

| |

| |  |

| | #26 |

| I wanna be Dave Join Date: Mar 2008 Location: In the Dark Edges of your Mind

Posts: 6,386

|

Thanks!!  |

| |  |

| | #27 |

| I wanna be Dave Join Date: Mar 2008 Location: Pacific Ocean

Posts: 2,342

| I think that 3rd piece would com in handy of you wanted to mirror your tranny though as you would have to flip the plate. I think I saw someone do that.

|

| |  |

| | #28 |

| Custom Carbon Fiber  Join Date: Oct 2007 Location: Connecticut :(

Posts: 4,501

| |

| |  |

| | #29 |

| Pebble Pounder Join Date: Mar 2008 Location: yes

Posts: 182

|

Honestly, I had a terrible time installing my dig. The allen head screws included in the kit were too long and hit the tranny case with 1/8" left to go before they would actually tighten against the outermost plate. The screws included in the kit are the same length as my tranny case screws. The delrin spacers included in the kit were also too long and I couldn't attach the motor plate until I cut those down. Not to mention, only two screws were included in the kit itself and I had to supply one extra long screw for the dig mount tab farthest from the motor. Basically, the dig rocks but the hardware package is inadequate. Be prepared to supply your own screws and a dremel to pollish and cut some of the parts to make it work.

Last edited by tanmonster; 09-14-2008 at 08:23 PM. Reason: duh |

| |  |

| | #30 | |

| I wanna be Dave Join Date: Mar 2008 Location: In the Dark Edges of your Mind

Posts: 6,386

| Quote:

| |

| |  |

| | #31 |

| I wanna be Dave Join Date: Mar 2008 Location: Pacific Ocean

Posts: 2,342

| Nope, wasn't that one.  Did you have to drill the plate to accept the bushing? Did you have to drill the plate to accept the bushing?Edit: I guess you did as it looks like there's a little JB weld holding it in place. Last edited by dpdsurf; 09-15-2008 at 12:21 AM. |

| |  |

| | #32 | |

| RCC Addict Join Date: Jul 2008 Location: Sin City

Posts: 1,332

| Quote:

The binding everyone was talking about from over tighening the mount screws is cause from the slot in the main shaft not being perfectly centered so it gets tighter every 180 degrees. File the slot just a little bit and you can tighten the mount screws all the way. | |

| |  |

| | #33 | |

| Custom Carbon Fiber  Join Date: Oct 2007 Location: Connecticut :(

Posts: 4,501

| Quote:

yeah drilled it for the bushing but was a bit oversized, no side to side wobble but could pull it out easily. put a small hair line amount of jb on it and been working great since. | |

| |  |

|

| |