| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Quarry Creeper Join Date: Nov 2008 Location: London UK

Posts: 273

|

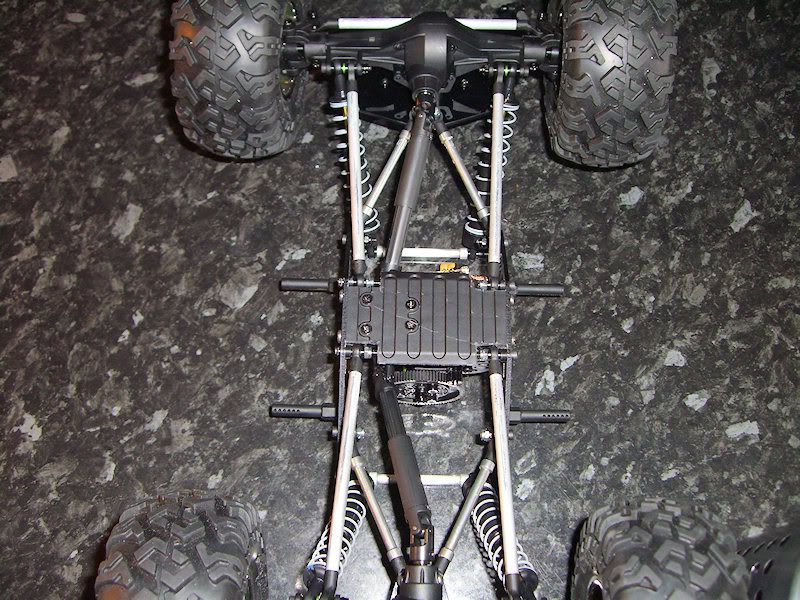

It's amazing how much you can learn from experienced people on here, thanks for a great forum. This is my first rc car in 20 years, it hasn't seen action yet but I couldn't resist doing some mods before I start. Can someone tell me is it's going to be a problem having the ends of the drive shafts a bit lower then the links? (where they meet the axles) Clearance is 2.75". The plan is to mount some batteries next to and over the servo, I'm having to split apart a stick pack for this.. Enough waffle, here's some pics.       |

| |  |

| Sponsored Links | |

| | #2 |

| RCC Addict Join Date: Oct 2008 Location: Alpine,CA

Posts: 1,258

|

Save yourself the headache, Turn that trans and skidplate 180 degrees!!!! heres the best picture i have of a mirrored Transmission, Helps so much on torque twist...  Last edited by DiEzel; 01-02-2009 at 11:46 AM. |

| |  |

| | #3 |

| Quarry Creeper Join Date: Oct 2008 Location: Jamestown

Posts: 357

|

the front driveshaft angle should be fine ya dont want to clock that axle because you end up loosing steering that way also ya wont see as much hitting on it due to its not leading into the rocks like the rear is (unless your going in reverse) the rear you might want to consider clocking up some this can be done fairly easily by adding spacer to the rear upper links to lengthen them. I used the spacers that came with the kit to space the 3 link off the chassis (the little 6mm ones) I just added those on and it clocks the rear axle nicely. This was with the STRC 4 link plates so you might need a bigger or smaller sized spacer. experiment with it so you can get a decent clock on the axle and not get any binding in the driveline also. you might want to think about also getting 30 degree bent lower links in the rear at least and this along with clocking the axle will really help ya out. Also driveshaft rings are an absolute must if you are useing the stock axial axles. They WILL without a doubt pop off as soon as any sort of heavy load is put on them (like if a tire gets stuck or something) Last edited by swisherteets; 01-02-2009 at 11:52 AM. |

| |  |

| | #4 |

| I wanna be Dave Join Date: Jan 2006 Location: Henderson/Las Vegas, NV

Posts: 5,032

|

i can't tell from your pics but how are the top of the shocks mounted? if they're bolted in solid than you'll get some binding. if they're not on some kinda ball end up there try mounting them on some nitro fuel tubing. and your drive lines shouldn't be a problem. |

| |  |

| | #5 |

| Quarry Creeper Join Date: Nov 2008 Location: London UK

Posts: 273

|

Hey appreciate the tips fellas. I shall mirror the transmission and sort out the links. Dieselfuel, the tops of the shocks have spacers next to them, protecting them from rubbing against the chassis. They still swivel on the ball ends. I'll get some more pics up when she's ready to go... Thanks again... |

| |  |

| | #6 |

| Newbie Join Date: Jun 2008 Location: Winnemucca

Posts: 46

|

nice start on your crawler can't wait to see it finished   |

| |  |

| | #7 |

| Quarry Creeper Join Date: Sep 2008 Location: !! MOAB !!

Posts: 373

|

as far as the driveshafts, use a clockable c block and extend the upper links a little. I have my pinions pointing straight at the tranny and the C,s turned to the front hole to help with caster and steering.

|

| |  |

| | #8 | |

| Quarry Creeper Join Date: Nov 2008 Location: London UK

Posts: 273

| Quote:

Apart from extending the upper links that made no sense to me at all. Sorry to be stupid... | |

| |  |

| | #9 |

| Pebble Pounder Join Date: Mar 2008 Location: yes

Posts: 182

|

He said that you should get aluminum clockable c's from rcpcrawlers.com...then run them with your axle clocked up as high as possible to prevent the driveshaft from hitting the rocks. Don't feel stupid, if you're new crawling just remember that you're not alone.

Last edited by tanmonster; 01-02-2009 at 01:07 PM. Reason: addendum |

| |  |

|

| Thread Tools | |

| Display Modes | |

| |