| | #1 |

| RCC Addict Join Date: Oct 2008 Location: Alpine,CA

Posts: 1,258

|

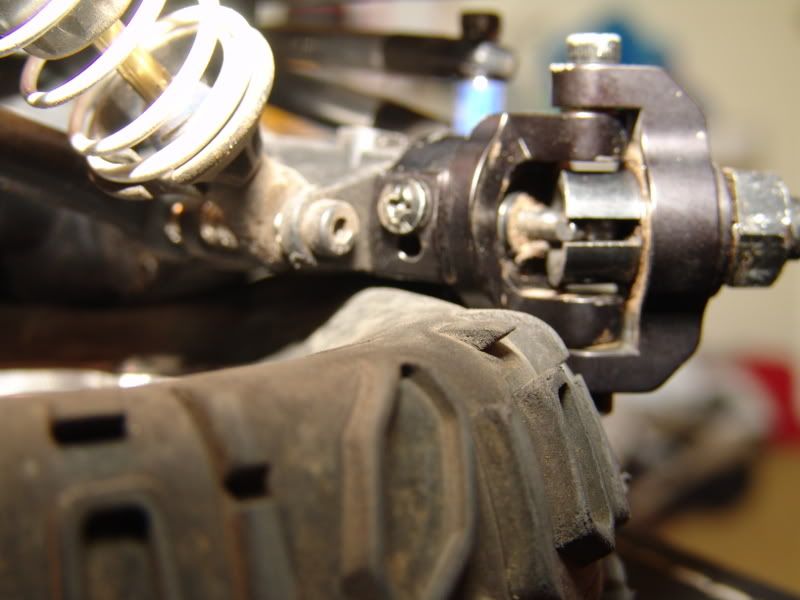

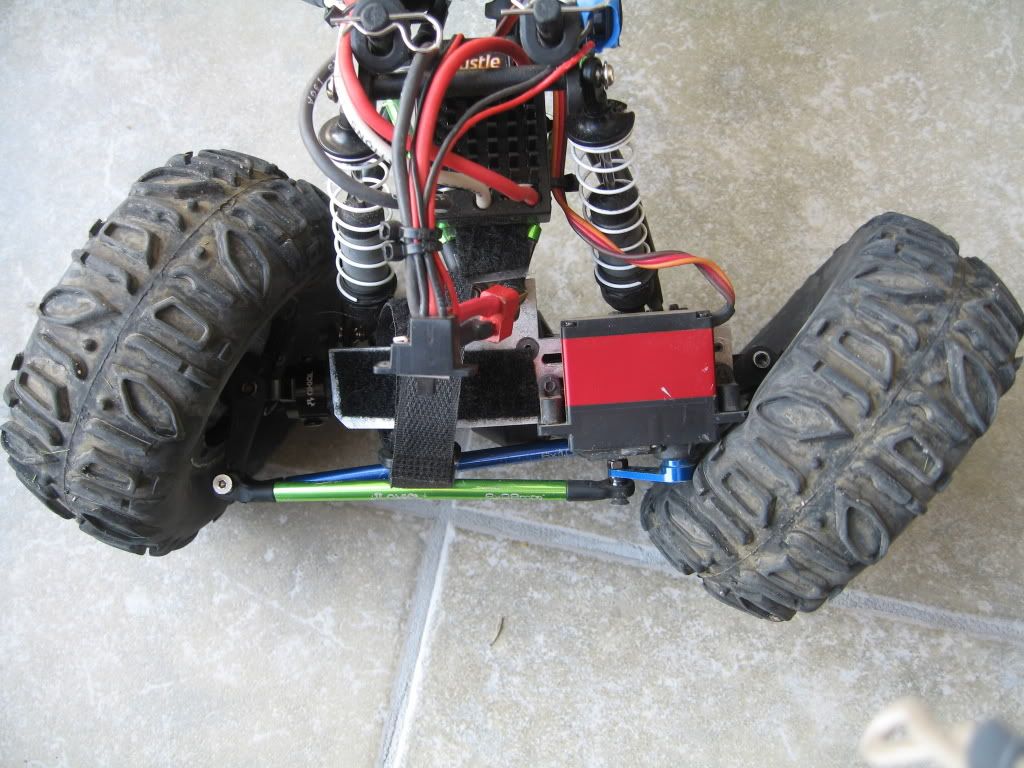

Well i dont know about you guys, But i break the pins in CVD's All the time. Well i came up with a fix after talking to "The Judge" Jason last night on RCC Live.. Heres a shot of what a 5T puller w/ 3s lipo and an aggressive torque curve till do in 2 minutes.  Ok. Now that we established that CVD pins Suck ass. Jason suggested grinding or machining the stock axial stubs.. Well i dont have immediate access to a lathe so i just used a 4 1/2" Grinder... Im sure a dremel can do about the same, just more time involved. I took the stock axial stub and removed apprx 1/8th of an inch off the backside... This will allow you to get full steering travel.  Jason suggested to me to take off as much as possible with leaving the "Exposed" pin about halfway engaged into the cup. Here is a picture of what mine look like fully turned.  Hopefully this helps the guys who have CVD Problems like me. And to be honest, these stub shafts fit in my bearings much nicer, less slop. We'll see how they hold up.. Thanks for the tip jason..... |

| |  |

| Sponsored Links | |

| | #2 |

| Quarry Creeper Join Date: Jan 2009 Location: El Cajon San Diego

Posts: 417

|

Neet fix. Is this a problem with MIP and Axial cvds? You're running mip's right?

|

| |  |

| | #3 |

| Pebble Pounder Join Date: Apr 2008 Location: nor/cal

Posts: 99

|

i gave up on the MIP and Axial CVD's a while back as well. if the pins were as large as those dog bones i doubt we would have any problems....... anyway, are you adjusting your endpoints on your radio to keep them from popping out? |

| |  |

| | #4 |

| RCC Addict Join Date: Oct 2008 Location: Alpine,CA

Posts: 1,258

|

No. Im adjusting them to get the most steering i can. You take the backside of the stub off so that you can gain as much steering as possible! Jason said he even lets the pin pop out the backside if necessary, Said it works for him. |

| |  |

| | #5 |

| Quarry Creeper Join Date: Apr 2008 Location: sanford

Posts: 228

|

cool thanks for the info  |

| |  |

| | #6 |

| Pebble Pounder Join Date: Jan 2009 Location: Vermont

Posts: 108

|

Should this be done when puting together a new kit? I was going to go with CVD's, used them in all my losi's, but if they do this......

|

| |  |

| | #7 |

| Pebble Pounder Join Date: Jan 2009 Location: Crestview

Posts: 166

|

ok guys, the measurement for it is 4.7mm. that is from where the bearing sits on the stub shaft to the edge of the cup. i used my dremel to cut it. took like 10 minutes. it's easy and cheap. the steering angle is good, at full left/right it wants to roll the tires off the rims. i vote for this to be put in the tips sticky... |

| |  |

| | #8 |

| Newbie Join Date: Dec 2008 Location: Sweden

Posts: 29

|

Nice tip, thanks.

|

| |  |

| | #9 |

| Pebble Pounder Join Date: Sep 2008 Location: Red Deer,Alberta

Posts: 174

|

Cool idea. I've actually just fabbed up a set of high clearance zero ackerman knuckle adaptors and this would be the perfect compliment to this upgrade. Can you turn more than 45 degrees? Thanks for the info |

| |  |

| | #10 |

| RCC Addict Join Date: Jan 2007 Location: San Jose

Posts: 1,697

|

that does work. use to do that when tlt's were popular couple years ago.  |

| |  |

| | #11 |

| Rock Crawler Join Date: Sep 2008 Location: Portland

Posts: 550

|

I'll keep this in mind  but I've never broken a pin in my mip cvds and I like throttle! And I run my wheel/tire combo at 1.25 lbs each front and dont let off when the tire is wedged! Guess Im lucky lol but I've never broken a pin in my mip cvds and I like throttle! And I run my wheel/tire combo at 1.25 lbs each front and dont let off when the tire is wedged! Guess Im lucky lol

|

| |  |

| | #12 |

| Quarry Creeper Join Date: Sep 2008 Location: Isle of Man

Posts: 469

| |

| |  |

| | #13 |

| Quarry Creeper Join Date: Dec 2008 Location: Ask Your Mom

Posts: 441

|

Sweet ,No more broken CVD's for me..:-P

|

| |  |

| | #14 |

| Rock Crawler Join Date: Nov 2004 Location: in a basement in Kalispell, MT

Posts: 857

|

You may also want to rechamfer the stub shaft, little more turning and doesn't chew up the inner axle behide the ball.

|

| |  |

| | #15 |

| Quarry Creeper Join Date: Dec 2008 Location: Paradise/Oroville/ in the hobby shop

Posts: 274

|

yeah thx for the info. we keep braking thoes pins.

|

| |  |

| | #16 |

| Quarry Creeper Join Date: Nov 2008 Location: N. California

Posts: 424

|

Good idea. Going to have to do that to my AX10. Thanks for the tip!  |

| |  |

| | #17 |

| Rock Stacker Join Date: Dec 2008 Location: c-wood

Posts: 90

|

thanks alot i just got my crawler back together after being apart for 4 days and now that i got it done you tell me this. i guess i will have to pull it back apart |

| |  |

| | #18 |

| Quarry Creeper Join Date: Aug 2007 Location: Morrison Crawlerado

Posts: 353

|

I got tired of replacing CVD pins so I decided to try this mod. Although it is a lot better than stock, I wasn't that happy with the result achieved from just cutting the shoulder. I really wanted it to have the turning radius as close to my CVD's as possible so I decided to do some additional modification. I used a Dremel and ground down the inside to create a deeper taper and more turning radius:   It's not quite as sharp as the CVD but it's close enough for me  : :   |

| |  |

| | #19 |

| Quarry Creeper Join Date: Feb 2009 Location: In my house

Posts: 243

|

I have been thinking of chucking up my stockers in the lathe and doing this to them. After tonight, I know what I am doing in the morning |

| |  |

| | #20 |

| Quarry Creeper Join Date: Feb 2009 Location: In my house

Posts: 243

|

OK, for those of you with a lathe: The cup measures .500" stock. I turned it down to .465", then use an 82* included angle counter sink in your tail stock and run it in until there is no more flat surface (from the cut you just made). They will look just like they did stock, same angle on the cup opening, just now shorter. Will post pics in a few. Last edited by durango#95; 04-30-2009 at 08:49 AM. |

| |  |

|

| Thread Tools | |

| Display Modes | |

| |