| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Rock Crawler Join Date: Dec 2005 Location: North Vancouver

Posts: 524

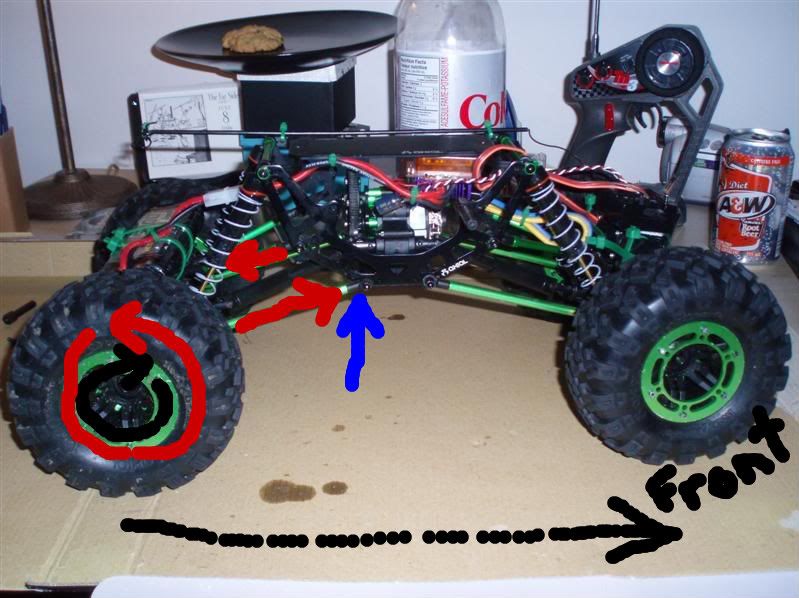

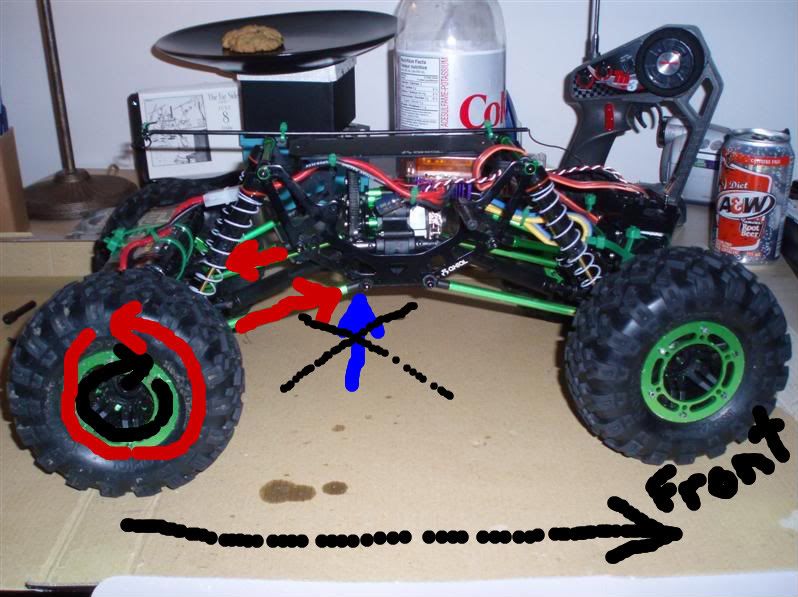

| I'm hoping that this post wont just fill up with people saying I tried this and that and it worked. Anyone that has owned a shafty has done the searches to dial in their rig and we know what the typical ways of minimizing it are. It's probably one of the most talked about issues with a shaft driven rig... yes I did sell out to MOA's lol. But before I did....I found something that helped and thought I'd pass it on. In fact I sold out because of COG advantages, not torque twist especially after running the v-link. I was also hoping a few people might be able to test this on their rigs with video before and after to see if it was just a fluke on my old comp rig. And a warning...I'm no physicist so I'm sure my terms aren't being used correctly so forgive me. ************************************************** ************** Newton's Third Law of Motion: Every action of a force produces an equal and opposite reaction. ************************************************** ************** PART ONE A spinning driveshaft creates an equal and opposite reaction that translates to torque twist (tt). The more resistance or force that it takes to turn the driveshaft the more you will see that equal and opposite reaction. That reaction twists the chassis in the opposite direction the driveshaft is spinning. (Please just let this idea fly and not start a debate on it.... the losi comp crawler driveshaft is very easy to turn because of the gearing in the axles so the opposing reaction is minimal too. That is why you don't see much torque twist. In an MOA there is no spinning shaft...so no twist) Black is the direction of the spinning driveshaft. Red is the opposite reaction that is noticed as torque twist. It is the opposing reaction to the spinning driveshaft. This also pushes down on the driver's rear spring.  What is common practice in the shafty world is to preload or increase the force needed to compress that driver's rear shock. That minimizes the twisting action of the chassis. The blue arrow is the transferred reaction of the spinning driveshaft to the shock. The straight red arrow on the shock is the spring's opposing force or opposite reaction. In theory if the spring's opposing force is equal to the downward force caused from the spinning driveshaft then we win and there is no torque twist. The problem is that the red arrow on the shock is constant while the blue arrow on the shock is variable and increases as there is more force being applied to the driveshaft. (And yes link geometry plays an important role but lets leave that out for now)  Driving on flat ground = less force to spin the driveshaft = less opposite reaction (tt) = less compressing force on the shock. Driving up an incline or binding the rear tires = more force to spin the driveshaft = more opposite reaction (tt) = more compressing force on the shock. The problem is that we need springs that are soft and compress so that the axles can articulate over uneven terrain. ************************************************** ************** PART TWO A turning tire will also create an equal and opposite reaction. Black is the direction of the turning tire, red is the equal and opposite reaction that is transferred back to the axle housing. That's why if you were to break your rear upper links your pinion would shoot skyward.  That means that your rear axle housing is going to be pushing your lower links into the chassis and pulling your upper links away from the chassis. That's where we get into antisquat stuff which is another topic. All things being equal both your lower links will split the reaction 50/50 to either side of the chassis and your upper links will split the reaction 50/50 to either side of the chassis. The blue arrow is showing that because of this leverage, your lower links are going to be creating a lifting force under the chassis upwards. Or they will be pushing the chassis upwards. This is really easy to see on a full droop rig with no internal springs sitting on the back tires near 90*. A little bit of throttle will tend to fully unload the rear shocks or lift the chassis.  ************************************************** ************** PART ONE + PART TWO = If we look at both of these combined they are actually working together to twist the chassis. They are compounding the torque twist. The round red arrow is the twist from the opposing force or opposite reaction of the driveshaft. That twist is counter clockwise which means that it's pushing the drivers side of the chassis down and lifting the passengers side of the chassis up (blue arrow). We ALSO have the passengers lower link pushing the chassis up (blue arrow) compounding that movement. The driver's lower link is also pushing up in an equal amount but forget about that for the moment.  Check out what is happening in the video. This was my old semi droop tuber. In a bind the rear driver's shock compresses and the passenger completely unloads. In an MOA with the same setup I would guess that both the rear shocks would unload evenly..maybe? http://www.youtube.com/watch?v=gYdnCacLVGk What if you could erase that compounding (blue arrow), move it...or even make it work against torque twist?  ************************************************** ************** The V-link Now before people say this isn't going to work...it does. On my old comp rig anyways. And I would love to have some other people give it a shot on their shafties. It's possible that this was just a fluke and I'd love to find out. It makes sense in my brain....but that doesn't mean much What if you could have all the pushing reaction from your lower links be equal to but opposite the reaction of twist on the chassis? The pushing/leveraging force from your lower links is an equal and opposite reaction to turning your wheels....which is also variable. The blue arrows are the forces or reactions canceling each other out. The compounding effect is eliminated and moved to work against tt (blue arrow with x). What's cool is that you should be able to play with antisquat to dial in how much leverage you have on the chassis to try and equal the downward force of torque twist on the driver's side. And the best part and main thing I was looking for is that it is variable. It is always canceling tt out.  This was the setup. I actually had the stock axial shocks with internal springs so it was sprung but mostly droop. When it worked I thought maybe the internal springs were just hard so I put my losi shocks in with white springs and NO preload. Same results. I had virtually no torque twist on the rocks. Even with a 7t puller 3s lipo on carpet launches I got a hint of it but to be honest I think it was just the torque from the motor.  This was something easy for me to try and it worked....the other option was to make a set of lower gears for the axles...like 5.29 or something. Not an afternoon project and out of my league lol. With the help of a friend we were going to give it a shot but went the cheaper route and got bully axles Can some of you guys give it a shot and see if it works? If you know how to make links it will literally take you 10 minutes. Last edited by miller; 11-19-2009 at 11:51 AM. |

| |  |

| Sponsored Links | |

| | #2 |

| I wanna be Dave Join Date: Jan 2005 Location: Hueytown, Alabama

Posts: 6,777

|

I dont see how this is much different than preloading a shock. You just putting all the force of the axle twist to one side, which keeps it from trying to squat the right rear. I could be wrong.....I drive a berg. Getting much axle swing? |

| |  |

| | #3 |

| I wanna be Dave Join Date: Feb 2005 Location: Cleveland, OH

Posts: 8,009

|

Holycaveman has a similar setup on his scaler. Seems to work well. I see you have the TCS boomerang plate. Why not just mount the left upper link under the plate? Works a treat |

| |  |

| | #4 |

| RCC Addict Join Date: Jul 2008 Location: Sin City

Posts: 1,332

|

Heres why i dont think this wont work as well as you hope. The force generated by the passenger side lower link is minimal because it is inline with the axis of the axle. The force you are talking about that lifts the chassis is comming from the axle housing trying to move around the axles with the axles having the resistance of the load. This will cause more force to transfer at the upper links than the lowers. In the end its caused by how much gear reduction is done at the axle and how must load is placed on the axle axis (traction vs inclination). You are moving in the right direction, proper 4link layouts and triangulation can control alot of torque twist. In theory once you can determine where your triangulation point is you could move that into the path of the rotational force (torque twist) to counter it (basically moving upper and lower links to the left). The problem with this will be that it will make your rig react differently from the right to the left and cause axle steer. Basically imagine this, if you put all your links on the left of the pumpkin of the axle you would force the twisting force into the path of the suspension cycle but you would have right biased articulation. This still wouldnt solve all of your twist either since the force is still being transfered back up to the chassis and the front wheels. Keep trying new things! I'm always afraid we will lose so much of the innovation that made me like crawling as it gets more and more mainstream every day. |

| |  |

| | #5 |

| I wanna be Dave Join Date: Jul 2005 Location: North Idaho

Posts: 3,648

|

One reason why the LCC suffers a lot less from TT has to do with where the torque is generated: On an Axial truck, all of the torque is generated in the tranny, which transmits all of that torque down the drive shafts, then to the diff, then to the wheels. In the LCC, the torque is generated at the diffs as a function of the worm gears, so you don't have all of that torque you are trying to generate to turn the wheels trying to turn the axels as well. |

| |  |

| | #6 |

| Oliver Custom Knives Join Date: Dec 2007 Location: Bloomfield NM , not something stupid

Posts: 1,047

|

Miller : BRAVO to you my friend  IDK if this would work or not , but that is a great display of what torque twist is and how and why it does what it does. I had an old WK comp crawler with double triangulated links and I mounted the uppers , one high and one low , and that solved my issues. |

| |  |

| | #7 |

| RCC Addict Join Date: Jul 2006 Location: Pasadena

Posts: 1,118

|

Down with the mainstream! |

| |  |

| | #8 |

| Quarry Creeper Join Date: Jul 2008 Location: Minot

Posts: 324

|

I'm going to give this a try.

|

| |  |

| | #9 |

| Quarry Creeper Join Date: Sep 2008 Location: Kuala Lumpur, Malaysia

Posts: 372

|

I appreciate the logic process you've applied, it makes some sense to me too. I also like the idea of balancing torque. Spring preload, when used, is there weather torque is there or not. Under light load, it can balance torque, under high torque it's not enough, under brakes it may be too much. Not ideal. But link geometry that reacts to varying torque sounds like the right approach. Basically, you're solution is providing offset anti-squat geometry, that is to say you now have anti-squat on the left and no reaction on the right. Squat does not need to be the same on each side, links don't need to be symetrical, and the other alternative mentioned by microgoat does a similar thing. By setting it up with squat for the right side links and with anti-squat for the left side links you would have geometry that pulls the right side of the chassis down and pushes the left side up, so it twists the chassis clockwise under load, and sits nuetral under light or no load. It reacts proportionaly to varying torque, and it opposes twist. And, by all reports, it works! This is not to say you're approach is not good, just that it's a different way of doing the same thing as vertical separation of the upper links at the axle. With your arrangement I would be a little concerned about asymetric axle steer when flexing though. Have you tried it with the upper links for comparison? Cheers. |

| |  |

| | #10 |

| I wanna be Dave Join Date: Jan 2009 Location: By a lake in Thornton

Posts: 2,218

|

i run my rear links asemtrical and it took out about 80% of my TT the rest was illimnated by running a thicker oil in the left rear shock |

| |  |

| | #11 | ||||

| Rock Crawler Join Date: Dec 2005 Location: North Vancouver

Posts: 524

| Quote:

Quote:

I knew this was going to come up that's why I referred to it. I'm not asking if it works. I'm saying it works. And I'd like a few people to try it out to see if it was just a fluke combination with my chassis. If someone had a stock ax-10 and just moved the link over to the other side I'd be interested to see if it does anything. But I do agree with everything you are saying, that's why I had to try it That is another discussion for another thread. Quote:

Thanks! Quote:

At the very least I'm hoping that the thread helps new folks visualize torque twist and understand how it works. It's already explained why offsetting the upper links one higher one lower works, same principal. As I already said and it's burried in my first post... it would be nice if the thread doesn't turn into.... this works and that works. We all know and there are tons of threads about it. Or the losi this and that...there are also long winded threads about that too. Also...hold back the "it's not going to work because...." If someone can post up some pictures...maybe some video saying "It didn't work...see here" That would be more helpful. If it doesn't it doesn't we still have a thread that lays out torque twist with some pictures for the simple folk like me Last edited by miller; 11-19-2009 at 12:08 PM. | ||||

| |  |

| | #12 |

| Rock Crawler Join Date: Dec 2005 Location: North Vancouver

Posts: 524

|

My apologies if some of my replies are short and come across stuck up. I just want to try to keep the thread on track and I'm also at work and only have a few minutes to read and respond.

|

| |  |

| | #13 |

| I wanna be Dave Join Date: Jan 2009 Location: By a lake in Thornton

Posts: 2,218

|

im not tryin to like, piss in your koolaide, but i think the asemtrical thing accomplished the same thing? youre doin good work, try asemtrical and compare and contrast? id like to see how they stack up to eachother |

| |  |

| | #14 | |

| Rock Crawler Join Date: Dec 2005 Location: North Vancouver

Posts: 524

| Quote:

I cannot compare and contrast because I sold out to MOA's. I was posting hoping some other folks might. God forbid we try something new eh | |

| |  |

| | #15 |

| I wanna be Dave Join Date: Jan 2009 Location: By a lake in Thornton

Posts: 2,218

|

lol why do you people call ham bacon?

|

| |  |

| | #16 |

| Quarry Creeper Join Date: Dec 2008 Location: B.C. Canada

Posts: 227

| |

| |  |

| | #17 |

| Suck it up!  Join Date: Mar 2008 Location: Arkansas

Posts: 11,652

|

Interesting. I would try it if I could fit two links on one side of my skid, but I can't. |

| |  |

| | #18 |

| Quarry Creeper Join Date: Sep 2008 Location: Kuala Lumpur, Malaysia

Posts: 372

|

Just looking at my rig and I think if I put the right lower link to the left of the skid it will clash with the drive shaft. It looks like it would need to be bent down a little in the middle. Looking at your pics it seems you run full droop? So maybe then it clears? I run fully sprung, need the clearance. And I'm still a bit shy about asymetrical flex because I notice the flex steer effect on my rig already. Still, I'd like to just try it for a while. Can always change back if it doesn't work or I don't like it. Cheers. |

| |  |

| | #19 |

| Rock Crawler Join Date: Dec 2005 Location: North Vancouver

Posts: 524

|

You'll have to make a new passenger link that's longer. And if you have driveshaft interference issues is your tranny flipped so the spur gear is facing forward? If you still have issues you can put some longer upper links in to push your pinion angle up. I'm building a rock racer with my old tube chassis and I'll take some pics to show if there is any axle steer. I'm also hoping to get some slow motion video of some full throttle launches when it's done to see if the setup works on the different chassis. |

| |  |

| | #20 |

| Rock Crawler Join Date: Oct 2009 Location: SO CAL

Posts: 598

|

how does upper link placement on the chassis come in to play? I have mine set at different heights from side to side and TT is much less noticable than before with the stock chassis and link placement as seen here on my LS2.0. This is my first setup on this chassis and haven't got to play with it much...  I know most people run the asymetrical setup with the left link on top, and i'll try this too to see how it changes things as well. |

| |  |

|

| |