| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| RCC Addict Join Date: Jan 2010 Location: Dallas

Posts: 1,848

|

I did some searching on this and wondered what you all think. I am using a small diameter althread (the same size as standard nylon ball ends). I have sleaved it with stainless steel tubing and I am going to use the nylon ends. This is going to replace a solid aluminum link that is catching on rocks ALOT. Any reason why I should not use this build? I am worried that my setup will be week. Thanks. RickM |

| |  |

| Sponsored Links | |

| | #2 |

| Newbie Join Date: Mar 2009 Location: Kalispell

Posts: 33

|

I understand your thinking of using SS rather than aluminum due to less drag while grinding against something but I'm not sure you will have desireable results. They SS tube over the all-thread will help strengthen it but I have a feeling it would still be the weak link. Also, it's still going to get caught on just as many obsticles.

|

| |  |

| | #3 |

| RCC Addict Join Date: Jan 2010 Location: Dallas

Posts: 1,848

|

I here you and I like the ss version of this but now I have one solid aluminum piece and by replacing it with a ss section and nylon ends I am worried I am now making a week link to it.

|

| |  |

| | #4 |

| I wanna be Dave Join Date: Sep 2005 Location: Houston, TX

Posts: 16,952

|

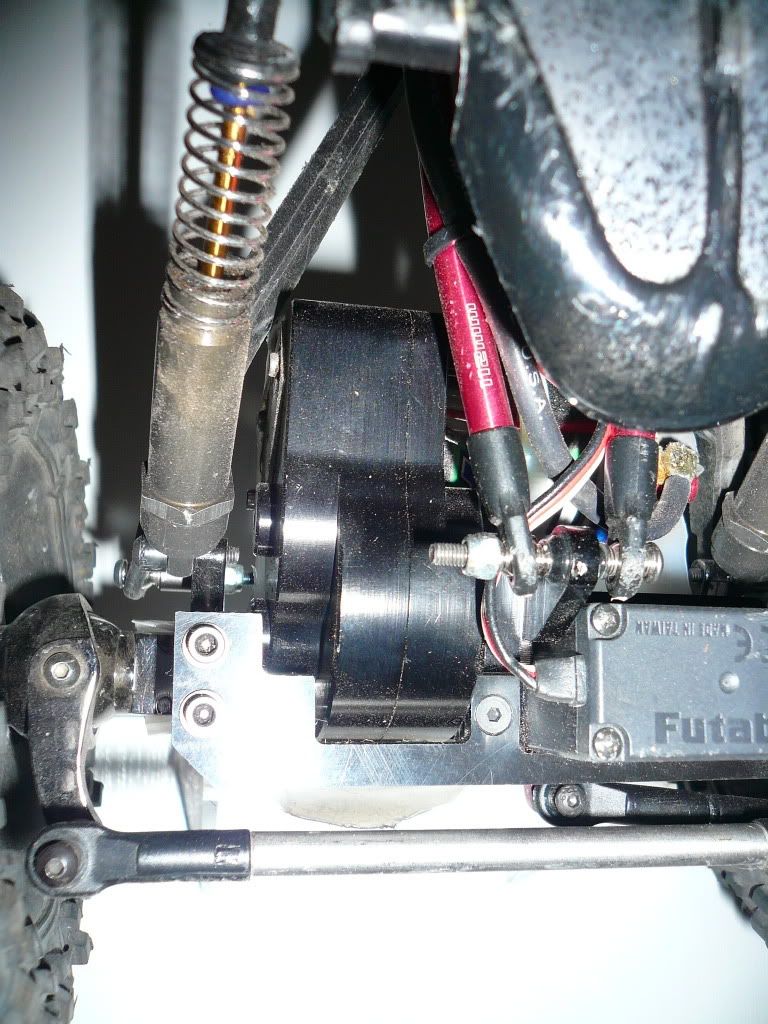

I have been running stainless sleeved links on many of my crawlers for quite some time with excellent results. I use 8/32" threaded rod with 0.25" OD, 0.035" wall seamless tubing and either jato long or revo rod ends. I have never had a failure. Here is the result:  |

| |  |

| | #5 | |

| Quarry Creeper Join Date: Sep 2009 Location: Concord

Posts: 215

| Quote:

| |

| |  |

| | #6 |

| Rock Stacker Join Date: Aug 2004 Location: Under a Rock

Posts: 95

|

Use the ball point pen trick over your stock link.... turns it into a roller sleave...  Last edited by orange-appeal; 03-16-2010 at 09:52 AM. |

| |  |

| | #7 |

| I wanna be Dave Join Date: Sep 2005 Location: Houston, TX

Posts: 16,952

|

Must be the angle of the picture....it cycles perfectly.

|

| |  |

| | #8 |

| RCC Addict Join Date: Jan 2010 Location: Dallas

Posts: 1,848

|

Well I just finished up my ss links with althread and a little nylon ends and sure enough while I was trying to run things to check it out I stripped out my servo arm. I donta gotta one of those so I am done for the night! I really like what I am seeing so far and If it breaks I can always slap back on my crappy alu ones.

|

| |  |

|

| |