| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #101 |

| I wanna be Dave Join Date: Oct 2006 Location: Milwaukie OR

Posts: 2,078

|

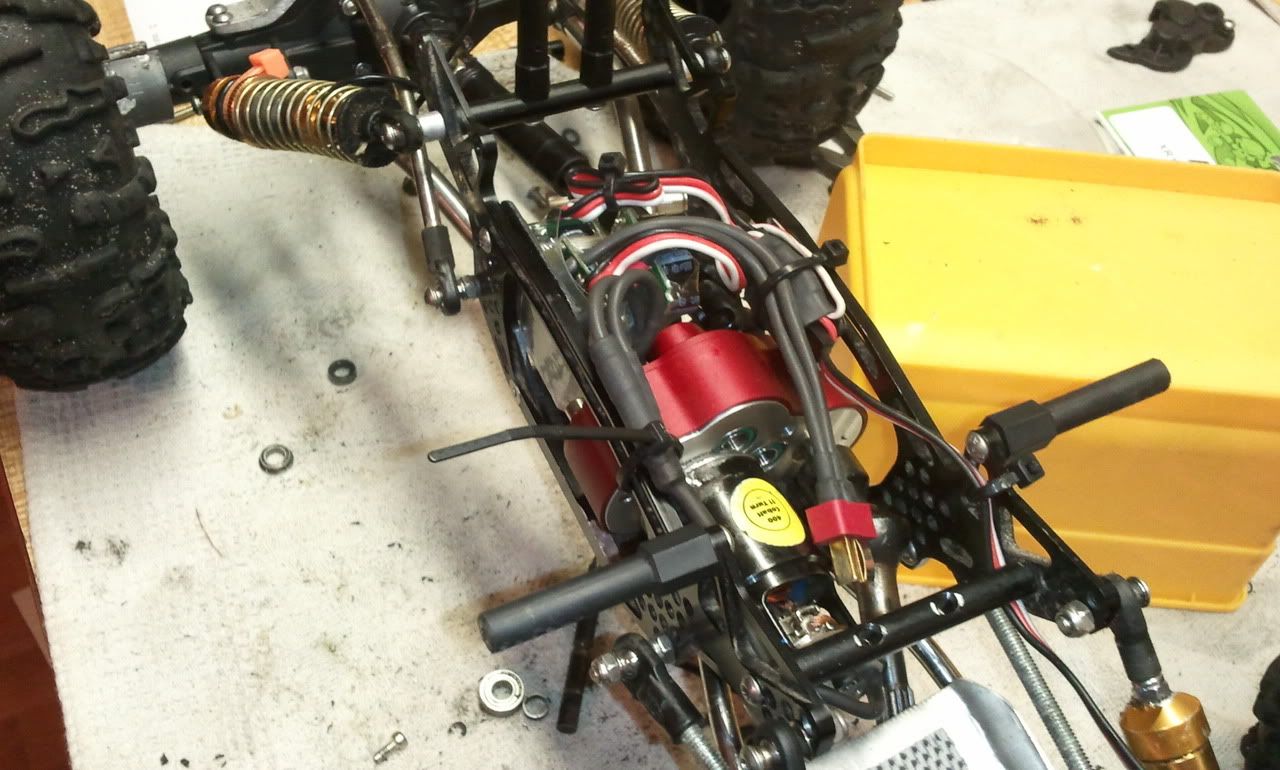

So I went to Tammies today and got a VP Case and motor plate to butcher up. Tired of nuking bearings, and I am past the proto stage. Concept works, now time to stop d!cking around.  I also needed to make a new shaft. Had these links that were a RCH too large. So they went in the drill press and some sand paper on high speed brought em down nice and tight  Then I drilled and punched in the pin. The pin needed to be punched in because the bit was the same diameter.  Grove cut on the shaft and flat spots grinded for the yolks     Motor plate cut. Forgot to grab pics of drilling the hole through the housing.   I chose red and I am glad. Looks like a heart.   Lastly, I took and bent some front links. Should help break overs a little  |

| |  |

| Sponsored Links | |

| | #102 |

| Rock Crawler Join Date: Oct 2007 Location: Grants Pass

Posts: 806

|

Dang, the vp case looks awesome as a tranny  . Nice job on the new install. I love seeing people use tools and actually make stuff in aBUILD thread. Im so tired of seeing all the "I spent more money than you and bolted on a huge pile of shit out of plastic bags" builds that seem to be the norm nowadays . Nice job on the new install. I love seeing people use tools and actually make stuff in aBUILD thread. Im so tired of seeing all the "I spent more money than you and bolted on a huge pile of shit out of plastic bags" builds that seem to be the norm nowadaysEDIT: whats the deal with the 2 bolts on the upper part of the tranny and the little plate they are holding? |

| |  |

| | #103 |

| Quarry Creeper Join Date: Mar 2007 Location: Sneads Ferry

Posts: 430

|

Did you put a bearing in the case side as well or are you just letting the shaft ride on the case? Do you have room to drill out large enough for a flanged bearing on the case side? I hope you don't mind me duplicating the FSJ and tweaking it a bit for my purposes. I intend on pushing the shafts out further and having holes for T-maxx outputs. Actually, I'm just using an output shaft from a T-maxx transmission...we'll see how it works. Great idea on the FSJ by the way, pure genius.

|

| |  |

| | #104 | ||

| I wanna be Dave Join Date: Oct 2006 Location: Milwaukie OR

Posts: 2,078

| Quote:

That bracket was the old cross brace in this pic. But now I don't need it, since the case is aluminum, and doesnt flex.  Quote:

I just drilled a hole big enough for the shaft to punch through, and kept the bearing in it's place. | ||

| |  |

| | #105 |

| Rock Crawler Join Date: Dec 2009 Location: Beaumont, Tx

Posts: 507

|

What locker are you using in the front?

|

| |  |

| | #106 |

| I wanna be Dave Join Date: Oct 2006 Location: Milwaukie OR

Posts: 2,078

|

Just an axial iron cross steel one. Using one in the rear also

|

| |  |

| | #107 |

| I wanna be Dave Join Date: Oct 2006 Location: Milwaukie OR

Posts: 2,078

|

Got a chance to sneak out and drive a couple packs before dark. This is the only pic I got of it. And yes it's that vertical, and yes, I made it Every time I drive her, she impresses me. I was sticking lines yesterday that I have always had to work hard at with an MOA and dig. Simply a blast to drive  |

| |  |

| | #108 |

| Quarry Creeper Join Date: Feb 2009 Location: French Guiana

Posts: 433

|

Hello, I have a AX10 with a very similar configuration, with the engine in front of tranny. But I use R2 (with dig). I put myself a question since one moment by reading your post very interesting. Which is the interest (or the advantages) to use elements of one XR-10 instead of R2? The weight? Volume? Sorry if the question with already posted Thanks Last edited by TotoRax; 05-21-2011 at 08:55 PM. |

| |  |

| | #109 |

| I wanna be Dave Join Date: Oct 2006 Location: Milwaukie OR

Posts: 2,078

|

I used it for 2 reasons. 1: I just wanted to do something unique and different. Plus axial parts are easy to get. 2: I don't trust rc4wd's quality. Those trannys are noise too!

|

| |  |

| | #110 |

| Ex Nor-CalRCRC slave  Join Date: Dec 2008 Location: San Mateo, CA.

Posts: 2,242

|

Did you make a plate for the open bottom of the gearbox like you did on the plastic case? It sure is nice to get rid of the big Axial spur gear.

|

| |  |

| | #111 |

| Quarry Creeper Join Date: Feb 2009 Location: French Guiana

Posts: 433

|

Hello, They is two excellent reasons  It is true that the R2 is very very noisy Thanks Last edited by TotoRax; 05-22-2011 at 05:32 AM. |

| |  |

| | #112 |

| I wanna be Dave Join Date: Oct 2006 Location: Milwaukie OR

Posts: 2,078

| |

| |  |

| | #113 |

| Rock Crawler Join Date: Oct 2009 Location: SO CAL

Posts: 598

|  this is probably the coolest thing I've ever seen. I want to do this to an axle so bad, but I want to keep the XR axle's width to get a wider overall end result. Do you think this would be do-able given your experiences with the XR parts? Also LOVEEE the frontside jones tranny too. Such a good idea! |

| |  |

| | #114 | |

| I wanna be Dave Join Date: Oct 2006 Location: Milwaukie OR

Posts: 2,078

| Quote:

Are you asking if it's possible to make an AX10 as wide as an XR? Probably, but you would need to either use a widener, or make some custom tubes to put it out where it should be. | |

| |  |

| | #115 | |

| Try to Bend it  Join Date: Aug 2009 Location: Perth Australia

Posts: 3,163

| Quote:

| |

| |  |

| | #116 |

| Quarry Creeper Join Date: Nov 2010 Location: Toronto Canada

Posts: 445

|

I am truly inspired by your build. I'm going to be starting an narrow OG Frogger build and thankfully got to see, due to your build that I can in fact use the XR10 stuff up front. I love the trans. just awesome, don't think I'll be building one but it's great to see another low CG option. To the OP talking about the R2, I just picked up a used rig with the R2d and it's noisy and slow as hell. I still got to try some different pinions, it's got a 10t and it doesn't even come close to the wheel speed of my GC3A with a 14t and crappy integy 55turn. On another note you can't knock people for building stuff from off the shelf parts, you've more than likely been at this for awhile and some folks just don't have the tinkering gene installed. Mind you at some time you have to start modding stuff off the shelf not only to be different but with so many options (pinion angle, castor clocking, ride hieght, link placement and so on) you really shouldn't just bolt stuff together. I started building my first crawler about 6-7 months ago and I'm already on the 4th rig which I will start a build thread on hopefully by the end of the week, I only hope it works as good as the "la licorne fatale"  |

| |  |

| | #117 |

| Quarry Creeper Join Date: Feb 2009 Location: French Guiana

Posts: 433

|

For R2, it is necessary to use +12t. Less than 12t, they is true snails  With 3S liPo, 40T motor and 14T pinions, It is a good compromise between speed and torque  Your steering angle is incredible  |

| |  |

| | #118 |

| Try to Bend it  Join Date: Aug 2009 Location: Perth Australia

Posts: 3,163

|

Chris how come you are using glued rims instead of bead locks?

|

| |  |

| | #119 | |

| I wanna be Dave Join Date: Oct 2006 Location: Milwaukie OR

Posts: 2,078

| Quote:

So I drove it some more tonight and found some changes that definitely need to be made. The shocks are uber lame. A buddy is running scx10 shocks with mini t springs and they're sooooooo nice. So I am going to put some of those on, and she should handle much mo betta. She might get some slw's and super softly foamed cut boss claws too. | |

| |  |

| | #120 |

| Try to Bend it  Join Date: Aug 2009 Location: Perth Australia

Posts: 3,163

|

Fair enough, function over form is always the best policy. That said though you killed the pig at the qualifier, so it does not matter. Its just a shame that function and form is so expensive. Have you considered big bores with mini T's. They are very, very smooth with a small canister diametre |

| |  |

|

LinkBacks (?)

LinkBacks (?)

LinkBack to this Thread: http://www.rccrawler.com/forum/axial-ax-10-scorpion/312337-project-la-licorne-fatale.html | ||||

| Posted By | For | Type | Date | |

| • Afficher le sujet - Du coté XR10 de la force... | This thread | Refback | 10-05-2011 03:02 PM | |

| www.rccrawler-france.com: Forum Dedié aux Crawler et Scales Radio-Commandé en France, Conseils, Astuces pour Créations Chassis Complet, News, Galeries Photos, Liens Utiles • Afficher le sujet - Du coté XR10 de la force... | This thread | Refback | 10-05-2011 02:35 AM | |

| Transmission out of an XR10 gearbox? - Oregon R/C Rock Crawlers | This thread | Refback | 10-05-2011 12:56 AM | |

| Thread Tools | |

| Display Modes | |

| |