| | #21 |

| Quarry Creeper Join Date: Aug 2007 Location: NOR*CAL

Posts: 476

| |

| |  |

| Sponsored Links | |

| | #22 |

| Newbie Join Date: Apr 2006 Location: WJ

Posts: 9

|

I tore the hell out of my rear output shaft on the tranny. I know when i put the set screw it that it was plenty tight on in the middle of that flat spot on the shaft with adequate thread lock. I was up in bear lake this weekend and as the rear wheels got caught up it spun the set screw AROUND the metal shaft. The screw never came out so it was just a matter of pulling it out and reinstalling. But it is pretty gnarly to look at that and know that instead of it busting that plastic drive shaft it actually tore up that metal shaft.

|

| |  |

| | #23 | |

| Rock Crawler Join Date: Mar 2006 Location: Dogpatch

Posts: 811

| Quote:

Well it has'nt come out yet.They have been tested pretty good.I held an inner shaft up to the inner shaft mounted on the truck and there is PLENTY of shaft inside the outer shaft-did you get all that? Anyway-what im trying to say is there is plenty of shaft connection with the Traxxas Stampede shafts.Six pairs for $10 from Tower is worth the wait till Axial gets there replacement parts out!:-P | |

| |  |

| | #24 | |

| Debunking old stereotypes Join Date: Feb 2006 Location: 1st and Amistad

Posts: 2,260

| Quote:

For the guys popping shafts off, an easy fix is a small zip tie and a spot of CA to keep it from sliding off. | |

| |  |

| | #25 |

| Rock Crawler Join Date: Jul 2007 Location: central PA

Posts: 679

|

I too pop shafts off front and rear with ease. 27t P2k and have never stalled motor Curious to see how it will hold up to my 2/3a pack in the works and 55t lathe. |

| |  |

| | #26 |

| Rock Crawler Join Date: Mar 2007 Location: Colorado

Posts: 635

| |

| |  |

| | #27 |

| Pebble Pounder Join Date: Jan 2005 Location: Idaho

Posts: 97

|

Can anyone get replacement Axial parts yet? I need drive shafts or aftermarket ones... would like metal but can't figure out what traxas metal ends I need?

|

| |  |

| | #28 |

| Newbie Join Date: Aug 2007 Location: Richmond

Posts: 46

|

To date, I have broke the front and rear driveshafts and two wheel hubs. I have a brushless with a R2 w/disconnect. I put the rear traxxus with metal yokes in the rear and a tmaxx up front. I'm trying to fix my wheel hubs before the comp. next week. I'm also running the 11.1v li po. I have a habit of standing on the throttle!

|

| |  |

| | #29 |

| Quarry Creeper Join Date: Apr 2005 Location: LexVegas

Posts: 295

|

Just popped my first one

|

| |  |

| | #30 |

| Pebble Pounder Join Date: Jan 2007 Location: H D

Posts: 197

|

i moved the upper links into the front hole and the straightend the drive shaft and no more popping off its great

|

| |  |

| | #31 |

| Pebble Pounder Join Date: Jul 2007 Location: A-pop-kuh, FL outside Orlando

Posts: 136

|

I just went to my LHS and ordered 2 sets of Axial stock replacements and also learned that Integy is making steel replacements in measured metric lengths, so, I've got some of those coming as well.  Also didn't Axial supply all the kits with metal yokes? My friends and I all have metal yokes on ours. |

| |  |

| | #32 |

| I wanna be Dave Join Date: Jan 2004 Location: Detroit

Posts: 3,583

| |

| |  |

| | #33 |

| Rock Crawler Join Date: Jul 2007 Location: central PA

Posts: 679

|

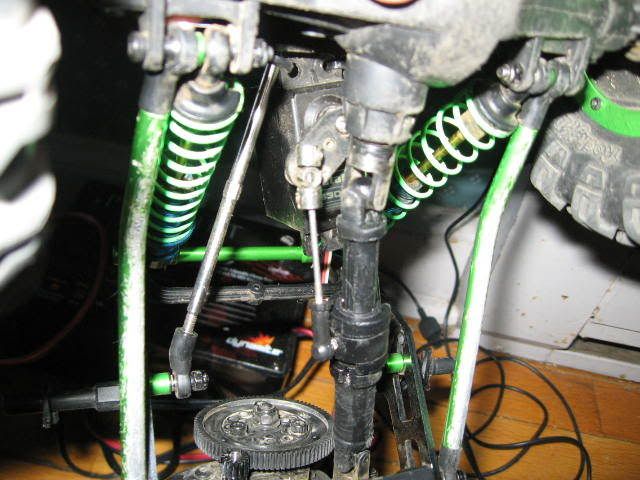

A free and temporary fix to a repeatedly popping driveshaft is to replace it with the opposite end. (front, rear) You just switch them out and replace them in the same manner as before. I did this and it has not popped on me since. I figure the plastic was worn from mainly forward torque. Now I am applying torque opposite and the plastic is not yet rounded on other side so to speak. Also, I made a rear disconnect using all stock parts and a little piece of allthread. 2 thin shock spacers, 1 thick, some linkage and a servo ziptied securly to my 4 linked rear.    |

| |  |

| | #34 |

| Quarry Creeper Join Date: Aug 2007 Location: tx

Posts: 254

|

[quote=sharpe351;845816]I just went to my LHS and ordered 2 sets of Axial stock replacements and also learned that Integy is making steel replacements in measured metric lengths, so, I've got some of those coming as well.  quote] quote]have you got the integy replacments yet? I have been trying to get a set of T-MAXX shafts on for about an hour and so far no luck. The yolk does not clear the spur gear its a little bit to big. |

| |  |

| | #35 |

| Newbie Join Date: Jun 2006 Location: B_town, CO

Posts: 45

|

I have been running a set of pede/rustler sliders for quite some time with no issues. My ax10 has been lowered a little so they may not work if you are trying it at full height.

|

| |  |

| | #36 |

| I wanna be Dave Join Date: Jun 2004 Location: Whales

Posts: 2,939

|

It's too bad that this is happening to such a great kit. I think they just selected the wrong plastic or thickness for the part. I just popped a drive line as well, but I should have known that with as easy as they where to install that they where going to come apart easy. For now I'll use the traxxas drive lines like I did on my TLT and hope that they address this weakness. |

| |  |

| | #37 |

| I wanna be Dave Join Date: Dec 2006 Location: In Cali.

Posts: 4,109

|

We have been running a cable tie on our for a little while with no issue, but now that I said something...you know what's going to happen! |

| |  |

| | #38 |

| Quarry Creeper Join Date: Aug 2005 Location: San Juan Bautista

Posts: 268

|

will these two work together on my ax-10? http://www2.towerhobbies.com/cgi-bin...?&I=LXJH85&P=7 http://www2.towerhobbies.com/cgi-bin...?&I=LXJG59&P=M |

| |  |

| | #39 |

| Quarry Creeper Join Date: Apr 2007 Location: Kapahulu Safeway

Posts: 281

|

I contacted axial about the issue of the driveshafts popping off the metal yokes. They are fully aware that the pins on the u joint are a little too short. They actually suggested that I try the traxxas yokes. I was also told that they're not planning on changing the design. The driveshafts are not a good weak link. Put a slipper clutch on the transmission. To say the least, I was not happy with the response from the company. They make a mistake in the engineering of the product and then screw the customer:-(. I hope axial comes to their senses, redesigns the yokes and offers replacements to the customers who have already purchased the kit.

|

| |  |

| | #40 |

| Quarry Creeper Join Date: Jul 2007 Location: south jersey

Posts: 393

|

i used e savage driveshafts a little trimming and they fit great, also i drilled through the output shaftsand used set pins

|

| |  |

|

| |