| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| SCALE PERFORMANCE PARTS  Join Date: Oct 2007 Location: Cedar Park

Posts: 5,453

|

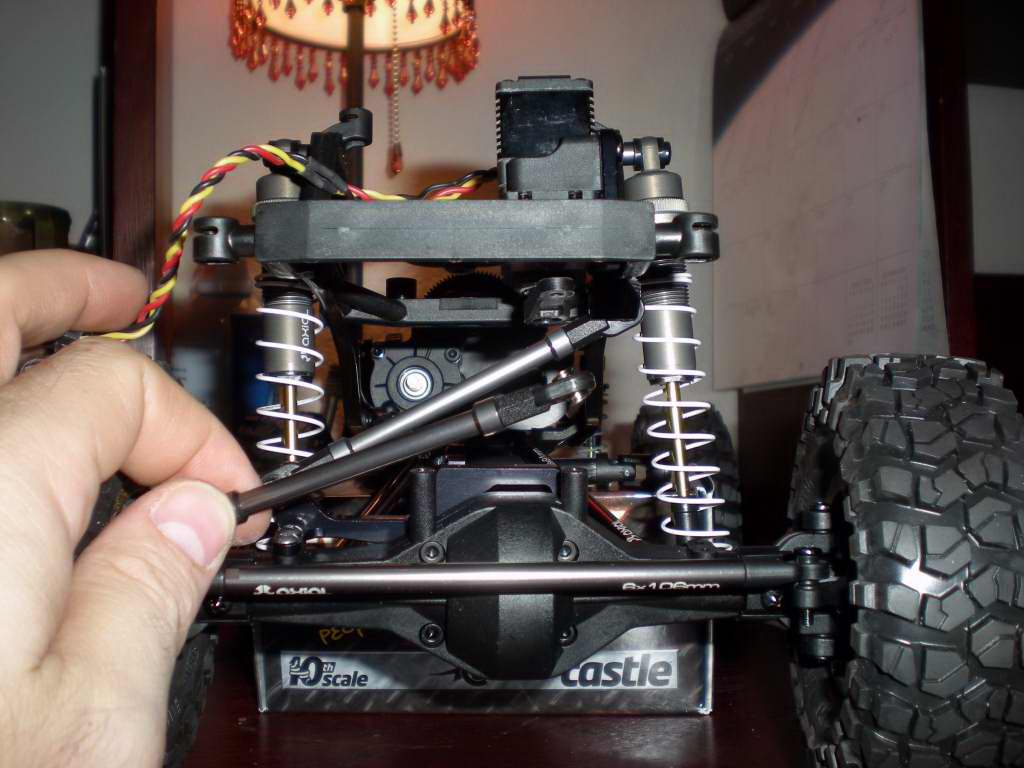

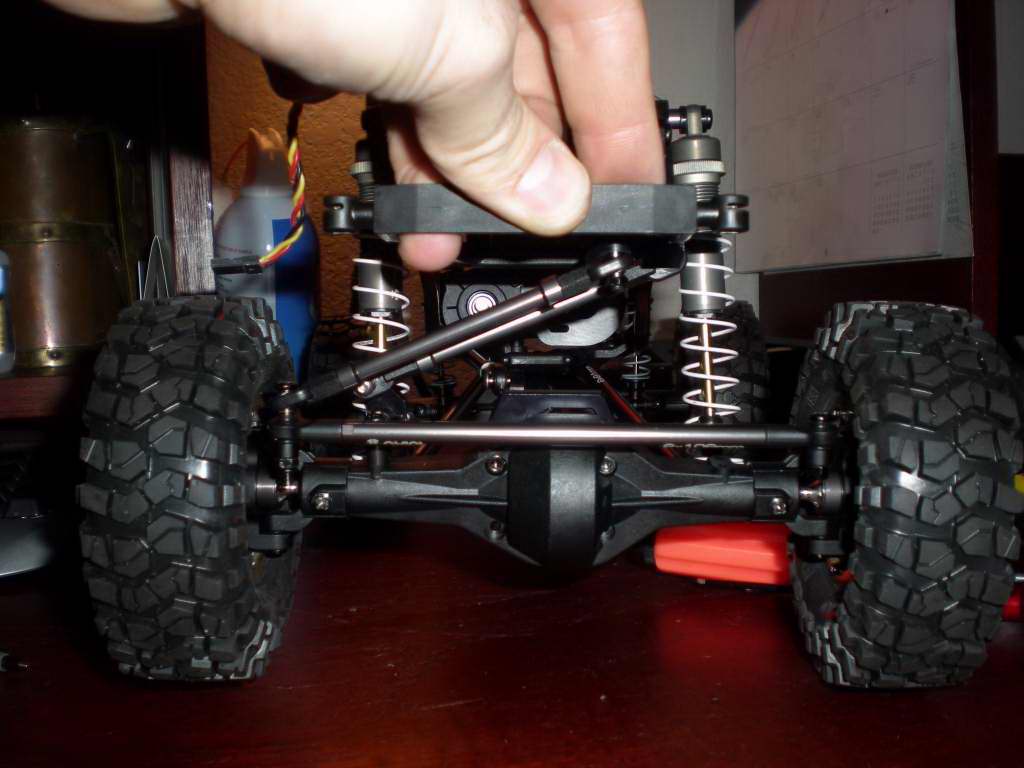

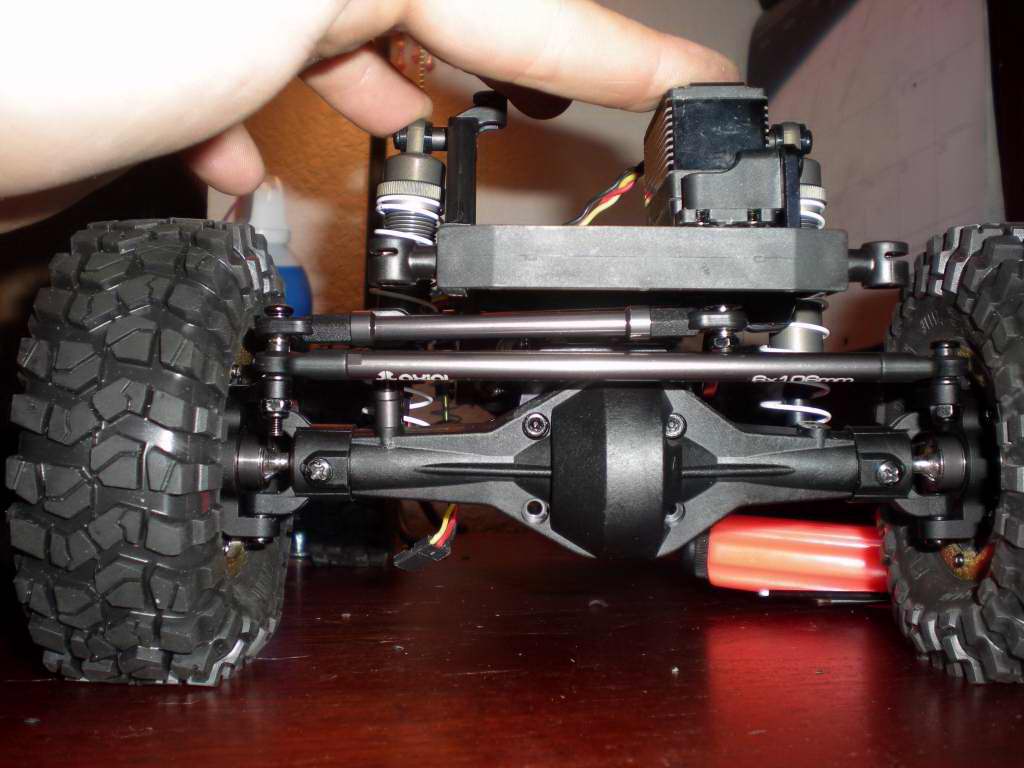

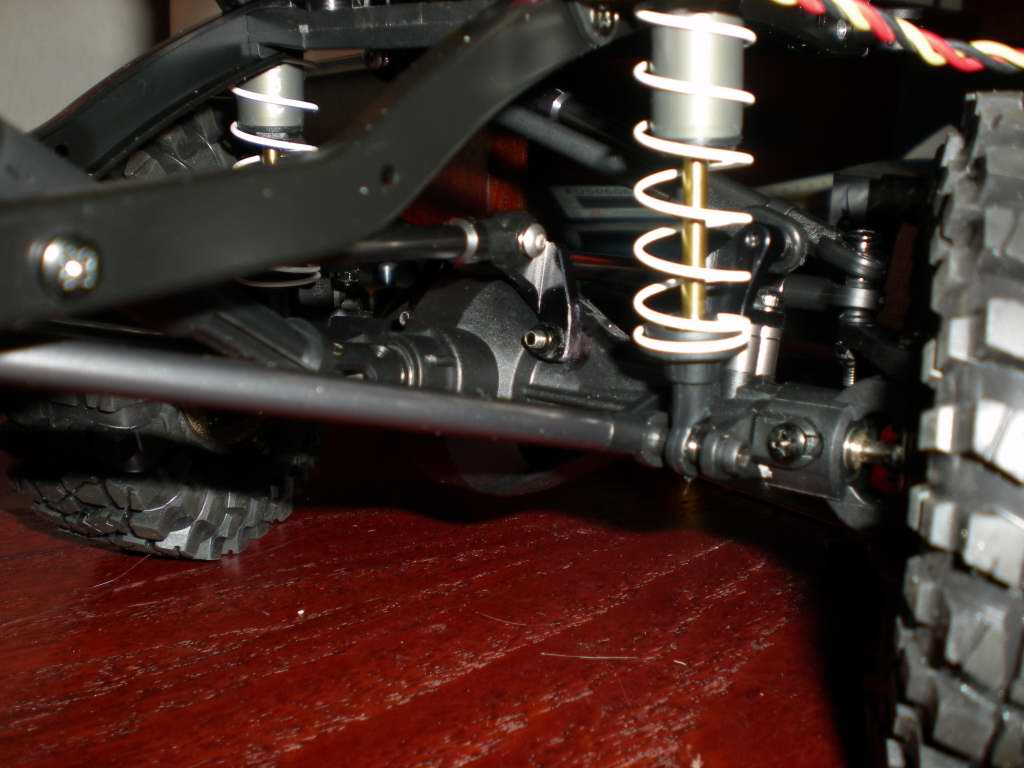

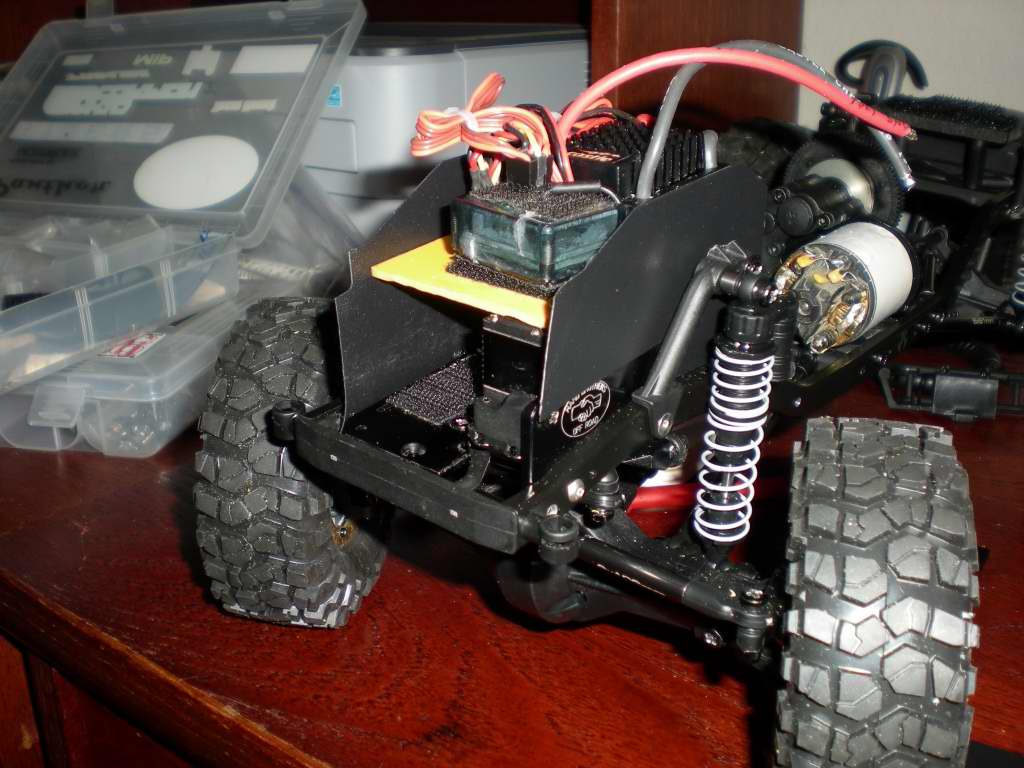

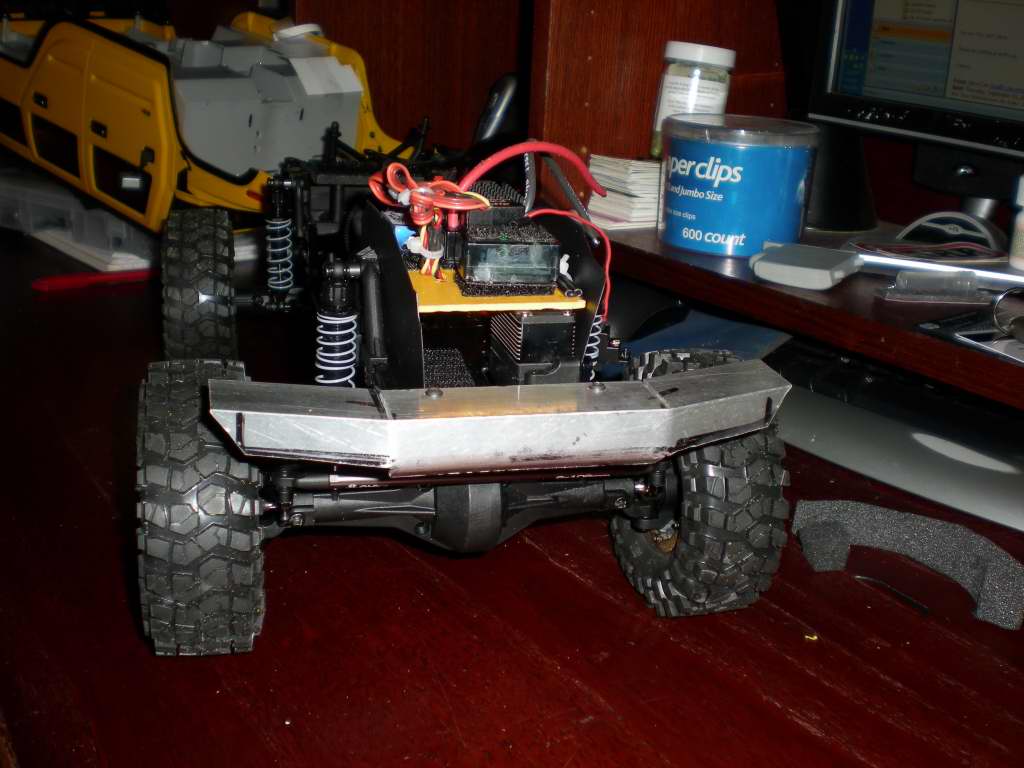

"Cliff's Notes" ... My most recent picture & specs:    Axial SCX10 frame & axle housings Front Axle: FI Spool, VP VVDs & Axial Overdrive Gears Rear Axle: FI Spool, LURC OT Shafts & Axial Underdrive Gears Bearings: Avid SCX10 Kit (rubber) Body: Locked Up RC H2 Wheels: Locked Up RC 2.2 AO8 Recluse with custom Agile rings. Tires: RC4WD 4.19" Baja Claws Hubs: Locked Up RC Ultra front & rear ESC: Tekin FXR Motor: Holmes custom hand wound 40t Spur: 87t 48P Pinion 18t 48P Steering Servo: HS-7954SH Winch: Locked Up RC RTR Upgraded winch line: 200lb Synthetic Fairlead: Aluminum 1/10 Tow Strap: Locked Up RC Standard Shackle: 1:10 D Ring Shackles Snatch Block: ARB Driver & Passengers:Locked Up RC Custom Bumpers Custom Sliders Custom Suspension --------------------------------------------- THE BUILD: --------------------------------------------- Here is my Axial SCX10 build. I'm using a hard shell H2 body and hope to make this as realistic as I can while still being pretty capable. I'll post up pictures, how to / DIY / Writeup stuff in here for you all to follow along with. So why an H2? I actually own a TJ and had a YJ and an XJ before that. So when it comes to 1:1 wheeling I'm not a fan of H2s, I'm a Jeep guy. However, there are already some really great Jeep builds out there, so I wanted to try something different. I looked around at the usual bodies for something that is hard shell, has lights and an interior. Then I scavenged the toy stores, goodwill, ebay and still didn't see anything very promising. Then I ran across this body and it had everything I wanted. I decided to purchase a few of them (so I'd have spare parts) and build it the way an H2 should have rolled off the lot. So that is what this build will be. A reasonably street legal but very capable off road SUV. It should be a pretty cool build when all is said and done. I hope you all enjoy it. Initial Build- Your Basic Put together of an SCX10: http://www.lockeduprc.net/misc/pictu...b/9-9-09b1.htm  Body Mounting- Nothing super special but I was pleased with the amount of option provided by the kit. http://www.lockeduprc.net/misc/pictu...9/9-10-091.htm  Gas Tank Mod & Playing with ring colors- I used a torch to burn off the green if anyone else is interested in getting the same goldish color. You'll note that some of them come out darker. The longer you torch them the darker they get. http://www.lockeduprc.net/misc/pictu...9/9-11-091.htm    Then I decided black wheels with Black rings: http://www.lockeduprc.net/misc/pictu...9/9-13-091.htm  Suspension: http://www.lockeduprc.net/misc/pictu...9/9-14-091.htm I got the hand brothers 3-link & chassis servo mount installed. It's a very well made unit and I was please as I installed it. However, because I am running the suspension "jacked up" there was a lot of bind in the steering at full droop. I could not even connect the drag link to the pitman, uh ...servo arm.  I also noticed that because I was running so high there was a lot of arc in the trackbar moving the axle to the driverside with droop and to the pass side under compression. Full droop:  So I had two problems with the geometry. While playing around with everything I also noticed that the trackbar & draglink didn't seem to be on the same plane. It seemed like the axle end of the draglink needed to come up a bit to get them even ... at least on my truck. So I decided to raise up the steering and lucky for me I carry spare everything from my comp rig, so a set of Vanquish high steer knuckles went in next. But then I knew I'd have bumpsteer, so I had to address the trackbar. I could not think of a good way to lower the frame end so I decided to raise the axle end. I'm sure there are a ton of ways to do this but this is what I decided on. I felt like the trackbar only needed to come up 8mm as opposed to the 14mm rise I'd get from the knuckles. But how to raise the trackbar mount? This required me to cut the Hand Bros. bracket in half. No pics yet but you'll get the idea. I cut the part that connects to the diff away from the part that connects to the outer housing/trackbar. The part that goes to the diff I used longer screws and locknuts to add strength when remounted. For the part that attaches to the trackbar and outer housing I did a little dremel work on the inside of the housing so I could fit a nut in there for extra strength. I tried using a grub screw (I was gonna just glue it all in there) but I don't have grub screws long enough to allow me to add the spacer I wanted. Here is the first attempt:  Unfortunately, the next pic sucks but you will see I used a cap head screw, 8mm worth of spacers all down into the housing (front half) and have a nut inside the housing. Use lock-tite liberally on that inner nut.  Here you can see the two axle halves together. I think with the nut inside it will be plenty strong. Since I had it apart anyway I slapped in some CVDs.  I ended up removing the little spacer between the steering linkage. Another option would have been to raise the trackbar another 2mm but I think this allows for more compression. Anyway, the result is perfect. Perfect alignment under compression and droop. I couldn't be happier... Droop:  Compressed:  Here is a shot so you can see how I cut the bracket:  Woohoo! I used the battery plate for ... my battery:  Then I cut up a Dewalt drill bit box and a length of Delrin stick to make a shelf:  Here it is coming together:  While doing the electronics shelf I decided to black out the wheel well ... or at least get started. Paper template:  I was walking around trying to think of where I could get some thin black plastic to make the wheel well liners and I remembered I had an old CD case lying around. This is the part that slips into the outer case:  Here is a shot with the engine lined and the top of the wheel well. Additional trimming still needed:  Finished shot of electronics and liners:  Never able to leave well enough alone ... I decided it was time to address my front bumper. I didn't like the fact that the bumper is attached to the body and not the chassis. So I started cutting stuff up. I cut all the lights brackets & pieces in half saving what I needed for the upper lights only. Then I chopped the bumper in half making sure ot leave the parts to mount the headlights:  The grill attached to the body alone now with just a small piece of the lower bumper for the headlights mounts on the back:  After considering reusing the stock bumper I decided to go with some angle instead:  Almost done. Still need to finish trim, clean and paint it .... then do the rear:  I also think it made it cleaner underneath:  More pics of it all in this gallery: http://www.lockeduprc.net/misc/pictu...9/9-15-091.htm Last edited by Locked Up; 04-26-2016 at 06:53 PM. |

| |  |

| Sponsored Links | |

| | #2 |

| SCALE PERFORMANCE PARTS  Join Date: Oct 2007 Location: Cedar Park

Posts: 5,453

|

More pics: http://www.lockeduprc.net/misc/pictu...9/9-16-091.htm I had decided to go ahead and mount the interior to the body and the body to the chassis .... separately. From the factory the interior mounted to the body in the front, but to the rear bumper in the back. The chassis was mounted to the body in the front but the interior in the back. Stupid setup. To mount the interior to the body in the rear, I put in some posts. After installing these I realized I should have done several and tied them together for a cage look. Maybe I'll do that next time. The screws on top are under the luggage rack and totally hidden.  While I had it out I decided to go ahead and address the back seat. I thought back to the different times I have wheeled an SUV and recalled that any time I had a long trip I laid the back seat down to fit more cargo and spare parts. With that in mind, I decided to lay down the back seat of the H2. No fancy hinge ...  It looks like one solid piece but it's not. I remembered my Blazer having a piece that folded forward with the seat to cover the exposed area left by the seat folding forward. I've never been in an H2 but it's GM so I took a stab at it. The styrene part poking out is the flap. Most of it is covered by Velcro. the pictures make it look more like one solid piece than it does in real life.  Another piece of styrene for strength and I'm all set to finish carpeting...  If you look carefully you can see the mounts for the posts sticking up.  I fabbed up some body mounts like the front with some posts that come down from the interior floor board. I know, this means the chassis mounts to the interior but it's got a piece of angle that should push the force right up into the body. With the interior mounted solidly to the body I took a step out of order and decided to address the rear wheel wells. I'll point out that having a spare body for parts, etc, is a great feeling of luxury. If I only had one body I would have just shortened the wheelbase. So to "stretch" the rear flares out I heated up a knife and did some melting:  The plan at this point was to use a heat gun and bend the flare back a little to give it a better angle. It worked too ... but I left the heat on it a bit to long and bubbled the blinker and a little bit of the body on one side. I can replace the blinker but may have to sane a little on the other side. We'll see what happens. This picture shows how much the flare got moved and how much I can re-angle the rear bumper to fit the tire.  I also went ahead an made up a rear bumper to match the front. I have no idea why I didn't mount it like the front to cover the screws (late night) ... may have to redo it.  Here you can see how the stretch came out .... and another melted blinker. Must remember to remove those next time.  Here is how it all mounts.  Last edited by Locked Up; 11-13-2013 at 07:48 PM. |

| |  |

| | #3 |

| SCALE PERFORMANCE PARTS  Join Date: Oct 2007 Location: Cedar Park

Posts: 5,453

| Last edited by Locked Up; 11-13-2013 at 07:49 PM. |

| |  |

| | #4 |

| SCALE PERFORMANCE PARTS  Join Date: Oct 2007 Location: Cedar Park

Posts: 5,453

|

I went ahead and finished out the wheel wells:  More Pics: http://www.lockeduprc.net/misc/pictu...9/9-19-091.htm AND I added some more realistic level floorboards:  More Pics: http://www.lockeduprc.net/misc/pictu...9/DSCN7572.htm Last edited by Locked Up; 11-13-2013 at 07:50 PM. |

| |  |

| | #5 |

| SCALE PERFORMANCE PARTS  Join Date: Oct 2007 Location: Cedar Park

Posts: 5,453

|

Wheeling shots from last weekend: And here are some action shots form last weekend:  More pics: http://www.lockeduprc.net/misc/pictu...9/9-20-091.htm Last edited by Locked Up; 11-13-2013 at 07:50 PM. |

| |  |

| | #6 |

| SCALE PERFORMANCE PARTS  Join Date: Oct 2007 Location: Cedar Park

Posts: 5,453

|

After the wheeling I have since bulked up the bumper and blacked out the grill. What do yall think:  I think I like this black bumper better ... it's a rear bumper modified to fit the front.  More pics: http://www.lockeduprc.net/misc/pictu...9/9-24-091.htm I'm kinda wasting time doing this as I really am hoping to get my hands on the Axial bumpers. But I figure I may as well toss on the black bumper till then. I liked the idea of the AL bumper but it just never looked right to me. I guess I could have filled it in and painted it but.... Last edited by Locked Up; 11-13-2013 at 07:50 PM. |

| |  |

| | #7 |

| SCALE PERFORMANCE PARTS  Join Date: Oct 2007 Location: Cedar Park

Posts: 5,453

|

I decided to "waste" more time with the front bumper. So I trimmed it up a little more then decided to see if I could get my winch to fit in there.  Things are tight in there but it'll work. It's laid down and I had to cut up the mounting plate. Hopefully the little roller can withstand the abuse.  I say I'm wasting time because I ordered a few Axial front bumpers. We'll see how they work out. I also made a small change to the rear bumper to help it slide off of things better.  And here are a few shots of the updated interior:   More pics: http://www.lockeduprc.net/misc/pictu.../9-24-0921.htm Last edited by Locked Up; 11-13-2013 at 07:50 PM. |

| |  |

| | #8 |

| RCC Addict Join Date: Jan 2009 Location: ?????

Posts: 1,059

|

man that thing looks awesome!!!  ima have to steal a few ides from you for sure!!! ima have to steal a few ides from you for sure!!!

|

| |  |

| | #9 |

| 20K Club  Join Date: Jul 2004 Location: Sending illegals home one Hayabusa at a time.

Posts: 22,981

|

Great build..........for a H2 Nice job hacking at the bumpers and steering kit  |

| |  |

| | #10 |

| Rock Crawler Join Date: Jul 2009 Location: talladega AL.

Posts: 787

|

I don't think I've ever seen a Hummer look this good. Good job  |

| |  |

| | #11 |

| Newbie Join Date: Apr 2009 Location: Crawlerado!

Posts: 35

|

That is awesome, nice job with the bumpers!

|

| |  |

| | #12 |

| SCALE PERFORMANCE PARTS  Join Date: Oct 2007 Location: Cedar Park

Posts: 5,453

|

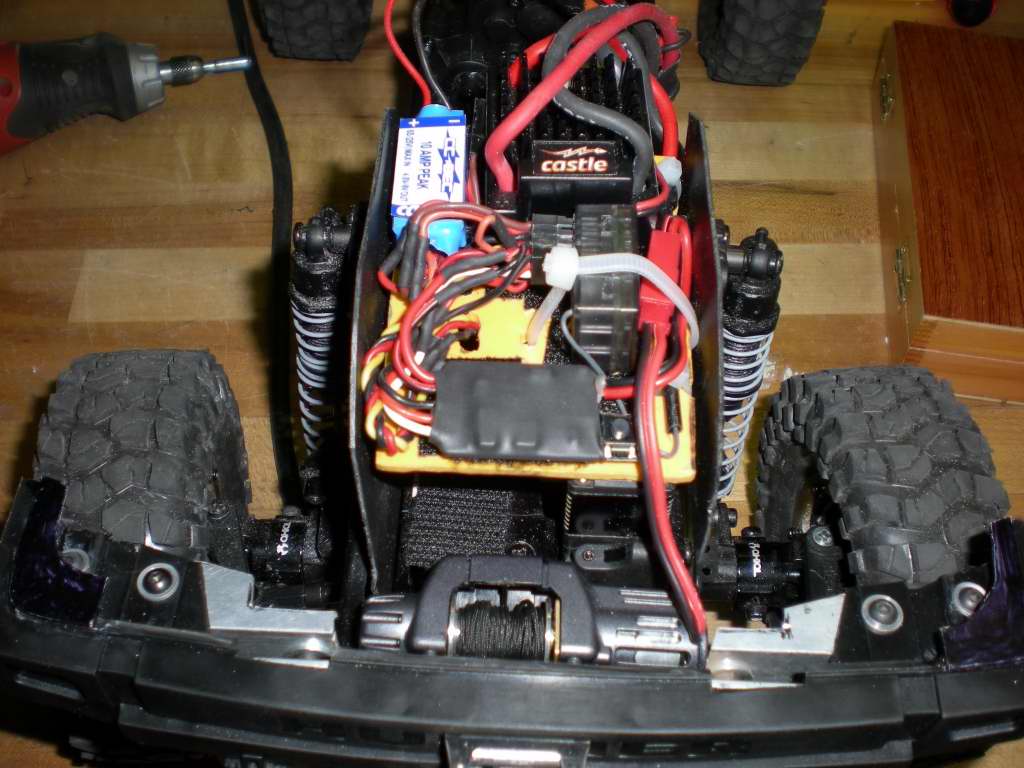

Thanks guys. Got the winch wired in and cleaned up the wiring:  I also had a test run (or two) of the winch.... It doesn't have the most balls in the world but it should prove useful. I'm only running it at 6.6v and they wanted it at 7.2. I may reprogram the BEC for a little more power... Last edited by Locked Up; 11-13-2013 at 07:51 PM. |

| |  |

| | #13 |

| SCALE PERFORMANCE PARTS  Join Date: Oct 2007 Location: Cedar Park

Posts: 5,453

|

As far as the winch controller & wiring ... I went my own way. Channel 1 is my steering servo, "B" is power to the RX from the BEC & channel 3 is the lead to the winch servo. Channel 2 is my ESC ... and power to the winch controller. Rather than run a second battery or a "Y" cable to the winch and second BEC I decided to use the slots available on my RX. And since the ESC really only needs signal from the RX I removed the +/- for the ESC going into the RX and plugged the +/- that the winch controller feeds the winch with. Last edited by Locked Up; 11-13-2013 at 07:51 PM. |

| |  |

| | #14 |

| Pebble Pounder Join Date: Feb 2009 Location: here

Posts: 134

|

nice rig may have to barow a fue ideas.

|

| |  |

| | #15 |

| SCALE PERFORMANCE PARTS  Join Date: Oct 2007 Location: Cedar Park

Posts: 5,453

|

Now it's really Trail Ready...   Ran out of screws but it's close enough for now ...  Waaaaaaaaaaaaay to much drilling for me today. Last edited by Locked Up; 11-13-2013 at 07:52 PM. |

| |  |

| | #16 |

| SCALE PERFORMANCE PARTS  Join Date: Oct 2007 Location: Cedar Park

Posts: 5,453

|

May have to get some flat black wheels to go with the rings .... we'll see.

|

| |  |

| | #17 |

| Pebble Pounder Join Date: Mar 2009 Location: Orange, CA

Posts: 184

|

I love your H2! I definitely need one of those bodies. Black out the wheels!  I am a member of H.O.A.B. (Hummer Owners Against Bling) |

| |  |

| | #18 |

| Rock Stacker Join Date: Mar 2008 Location: Mundelein

Posts: 99

|

wow man this is an amazing build. it deff. makes me want to build an h2 when i can get the funds for an scx10!!

|

| |  |

| | #19 |

| Pebble Pounder Join Date: Apr 2007 Location: Dupage County

Posts: 99

|

Looking really good so far, but I do have a suggestion: Look for some tires that appear more like ones that you would see on the road, maybe something with the BFG tread pattern, such as the RC4WD Mud Thrashers. Just a thought, take it or leave it. Looks great otherwise, keep up the good work  |

| |  |

| | #20 |

| Rock Stacker Join Date: Jul 2009 Location: casper

Posts: 70

|

that thing is pretty sweet looking and it looks like it performs well too!!! how much do those winchs generally pull and how are they put in and worked?

|

| |  |

|

| |