| | #1 |

| Pebble Pounder Join Date: Mar 2015 Location: Fairland

Posts: 103

|

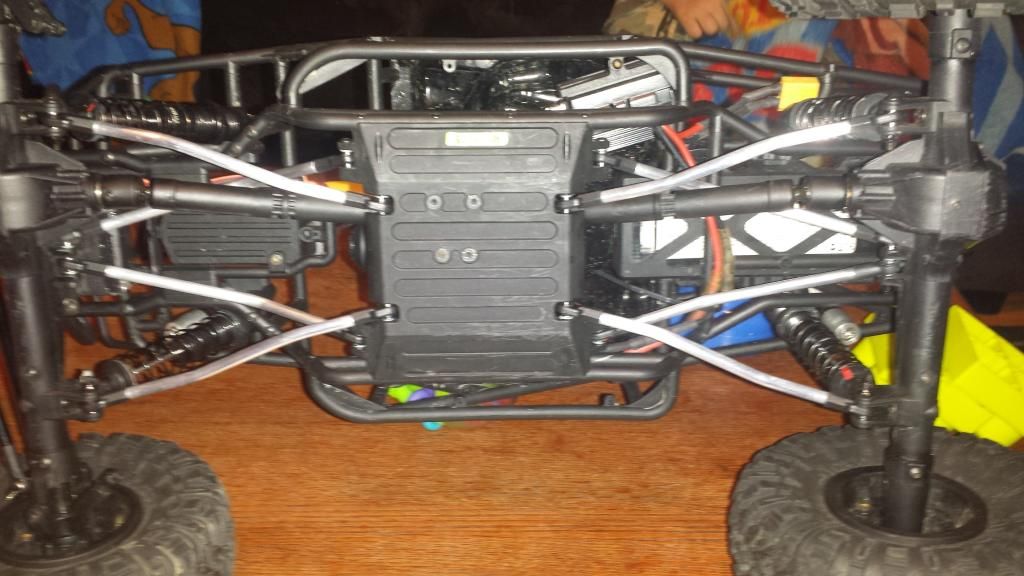

So I figured I would Show you guys these just in cast anyone else is playing around with the idea of making their own links. Aluminum is Aircraft 6061. Traxxas ball links.    |

| |  |

| Sponsored Links | |

| | #2 |

| Rock Stacker Join Date: Jan 2015 Location: Alabama

Posts: 60

|

Very nice looking. Did you just run a die over the end?

|

| |  |

| | #3 |

| Pebble Pounder Join Date: Mar 2015 Location: Fairland

Posts: 103

|

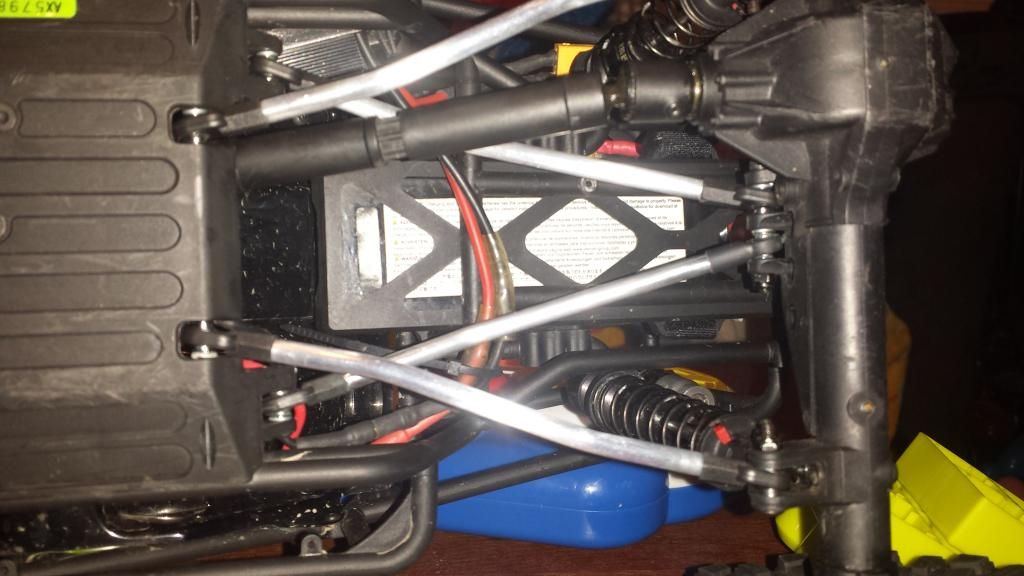

Thought about doing that but instead I just drilled and tapped a hole around an inch deep and used some all thread. I wanted a stronger joint because I plan on going to all metal ball links eventually. Might be overkilll but better to have the strength and not need it than.......yeah you know how the rest goes.

|

| |  |

| | #4 |

| Pebble Pounder Join Date: Mar 2015 Location: Fairland

Posts: 103

|

Well good idea horrible end result. Was out running around with a buddy today since it was such a nice day here in Indiana and jumped a small dirt mount truck kinda landed on front bumper. And wouldn't you know it one of these things bent. And not just a little bend it was an all out bend in half almost kinda bend. Needless to say I was pissed but I got over it. I am not going to try it again and figured I would just go ahead and order the Titanium links from Vanquish. I do not think these tubes were 6061 aluminum btw. The guy at hobbytown must not know what he is talking about, that or I just got my hopes to high for using aluminum. My steering link from RC4WD didn't bend though. Anyway Any ideas on what I did wrong here?

|

| |  |

| | #5 |

| Quarry Creeper Join Date: Feb 2006 Location: Muskegon

Posts: 223

|

Where did they bend? And how did you bend them in the first place? I have a few ideas actually. First, 6061, isn't all that strong, 7075 is... Second, a solid rod doesn't have the resistance to bending a tube would. |

| |  |

| | #6 |

| Pebble Pounder Join Date: Nov 2014 Location: in the woods

Posts: 123

|

As soon as I saw 6061, it threw up a flag. 6061 is a very soft aluminum. use 7075 as mentioned above and you should be good to go! you could also use 1/4 x .049 316 stainless tubing and thread each end with a 6x32 tap and then insert your all thread, made a few sets like this and it works PERFECT !! Here is a link to the tubing and aluminum, hope this helps 7075 Alum McMaster-Carr 316 Stainless McMaster-Carr |

| |  |

| | #7 |

| Pebble Pounder Join Date: Mar 2015 Location: Fairland

Posts: 103

|

Alrighty I was under the impression that 6061 was strong. So you guys think I should give it another try and just use 7075 or stainless instead of spending $80 on the Ti links? I am more than willing to try again I just do not want the same disappointing result that I got this time. The ones a made are sleeves. I used two tubes one larger than the other slid the larger tube over the smaller alum tube then inserted a piece of 4-40 all thread into that and then did the bends.

|

| |  |

| | #8 |

| Pebble Pounder Join Date: Nov 2014 Location: in the woods

Posts: 123

|

I know for a fact the Stainless will hold up> iv made a few set of links using this method with no fails. the 7075 aluminum should hold up with out any problems at all. if you read in the links I posted Mcmaster carr has the yield strength ratings on all there products listed. 6061-35,000 psi 7075-72,000 psi |

| |  |

| | #9 |

| Pebble Pounder Join Date: Nov 2014 Location: in the woods

Posts: 123

|

here is a link to the solid stainless rod if you'd rather use it and run a die over the ends McMaster-Carr |

| |  |

| | #10 |

| Pebble Pounder Join Date: Nov 2014 Location: in the woods

Posts: 123

| |

| |  |

| | #11 |

| Pebble Pounder Join Date: Mar 2015 Location: Fairland

Posts: 103

|

Which would be better...a 7075 aluminum rod. Or the 15-5 stainless. And can you thread stainless fairly easy. Do you have to have special dies to thread stainless. Everything I read about stainless is people griping about how hard it is to work with.

|

| |  |

| | #12 |

| I wanna be Dave Join Date: Oct 2007 Location: Castle Rock, WA

Posts: 8,785

|

See this post about buying McMaster standoffs, and set screws, using revo rod ends. Stand offs are solid AL and tapped on ends. Get the 8/32" stand offs with threaded ends, 8/32" set screws and use Revo rod ends. The standoffs come in lengths of 0.5" and using different rod ends and a pipe cutter, you can shorten or extend the links. Jato rod ends are handy too. How To: Make your own links My post showing how I cut small pieces off other links to extend. How To: Make your own links Edit, you can get Stainless standoffs too but my AL links are holding up fine. ... Last edited by Szczerba; 03-09-2015 at 08:38 AM. |

| |  |

| | #13 |

| Pebble Pounder Join Date: Nov 2014 Location: in the woods

Posts: 123

|

I don't have a problem working with stainless. people have problems with it because its such a hard metal witch makes for great links. you will defiantly need a bench vice to hold the rod while trying to thread it but next to Titanium id say for $23 it may be worth the extra effort. that's my .2 though. I feel the aluminum would work without fail but aluminum is a lot softer metal then stainless 7075-72,000psi 15-5-145,000psi |

| |  |

| | #14 |

| Quarry Creeper Join Date: Feb 2006 Location: Muskegon

Posts: 223

|

It's a toss up as far as effort/benefit goes. For 100 bucks you can get some links that will work, won't bend, and you already know fit. Bolt them on and go. Personally, I like to fabricate and make stuff. That's why I dink around building my own esc plates and cages. If I just wanted to run, I'd call BMG and be done with it lol. Sometimes, my screwups and learning curve, mean I spend more than I would have to just buy a bolt on part. 6061 is a lie lol. People see aircraft grade, and buy it. 6061 is suitable for like, light fixtures and stuff, not stressed components. Stainless isn't difficult to work with, use antiseize, take your time. |

| |  |

| | #15 |

| Newbie Join Date: Feb 2015 Location: Portland

Posts: 31

|

I made some links useing allthread I don't have brushless so no crazy speed or anything holding up quite well.

|

| |  |

| | #16 | ||

| I joined the Band! Join Date: Dec 2014 Location: Earth

Posts: 1,188

| Quote: Also check the tensile strength and hardness of the metal you're thinking of using, and compare that to the specs of known grades of aluminum links available and the specs on the aluminum you just used. 15-5 stainless Yield Strength: 145,000 psi Hardness: Hard (Rockwell C35, Brinell 327) 7075 aluminum Yield Strength: 62,000 psi Hardness: Medium (Rockwell B80, Brinell 150) You need alloy dies to cut threads in most stainless, and use cutting fluid. Quote:

The correct phasing is: "a hollow tube can be stronger than a solid bar/rod of the same mass" not size/diameter and it depends greatly on the application and wall thickness. The tube would need to be physically larger to equal the same mass as a solid rod and as such could then be stiffer. It's strength to mass ratio, not strength to size ratio and it's specific to the load being applied. Some of the details (mass vs. size, and stiff mistaken strong) that get lost in the "close enough" and/or "you know what I meant" society we live in today. Another factor with aluminum is anodizing, it's not just for the appearance and corrosion resistance, it also adds surface strength and wear resistance. Another reason we anodize aluminum is to prevent galling in thread components (e.g. shock collars & shock bodies), but that is directly related to surface strength and wear resistance. Last edited by Eric0424; 03-09-2015 at 09:40 AM. | ||

| |  |

| | #17 |

| Quarry Creeper Join Date: Feb 2006 Location: Muskegon

Posts: 223

|

You are correct, hollow rubes of less mass can be more rigid, and look more scale as an aside. I just was feeling lazy and didn't want to go into that much detail lol

|

| |  |

|

My Custom Made Links - Similar Threads

My Custom Made Links - Similar Threads | ||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Steering/Suspension Aluminum, Titanium, Delrin links. Custom made | Erik D_lux | Chassis and Suspension | 72 | 07-31-2020 05:28 PM |

| Need custom links made | dirtyjed | Newbie General | 9 | 02-18-2015 10:57 PM |

| custom made links,the long & short of it. | big dude | Newbie General | 2 | 02-23-2009 08:32 AM |

| |