| | #1 |

| Wanna get? Gotta want.  Join Date: Apr 2010 Location: SLC, UT

Posts: 7,052

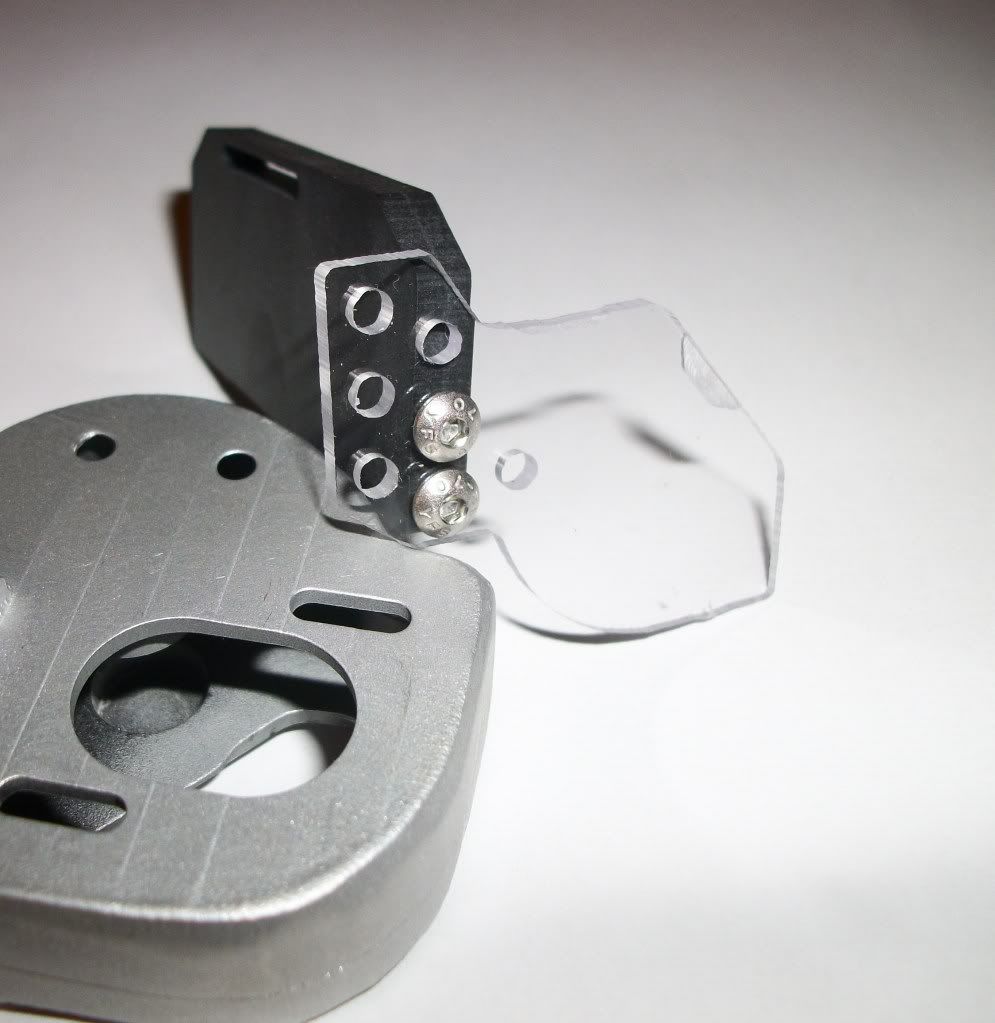

| All of my Berg parts are in post #1. Info/instructions post #2 Berg services post #3 Berg/Bully services post #4 I decided to keep all the Berg parts that I am building here in one single thread so I dont cluster up the vendor section. From start to finish, every item on this page is made with pride in the U.S.A. Most is even now made in house! Gear case battery mount $14 DLUX FAB | Products  No slop kingpin bushings Axial:$9 Berg:$9 DLUX FAB | Products  Knuckle weights $83 DLUX FAB | Products  Delrin link sliders $12 DLUX FAB | Products  Clear gear box covers $5 DLUX FAB | Products  Servo mounts $13 DLUX FAB | Products  Rear link mount $15 DLUX FAB | Products  TI links for the T1E rockshow SS - Berg version only Full set (aluminum uppers) $85 Rear only $29 Front only $29 DLUX FAB | Products  TI drag link and tie rod - Used with Vanquish zero ackerman version only Not on site, I need drag link lengths. PM me to order. $25 -  Axle tubes and shock/link mounts please read here BEFORE purchase DLUX Berg axle parts - RCCrawler.com Bulletin Board $150 DLUX FAB | Products  Rear weight holders $7.50 DLUX FAB | Products  Dlux Rear 7075 shafts $90 DLUX FAB | Products INFO on the shafts: Jam these in your rear end! You will LOVE it!  Last edited by Erik D_lux; 01-28-2013 at 10:44 AM. |

| |  |

| Sponsored Links | |

| | #2 |

| Wanna get? Gotta want.  Join Date: Apr 2010 Location: SLC, UT

Posts: 7,052

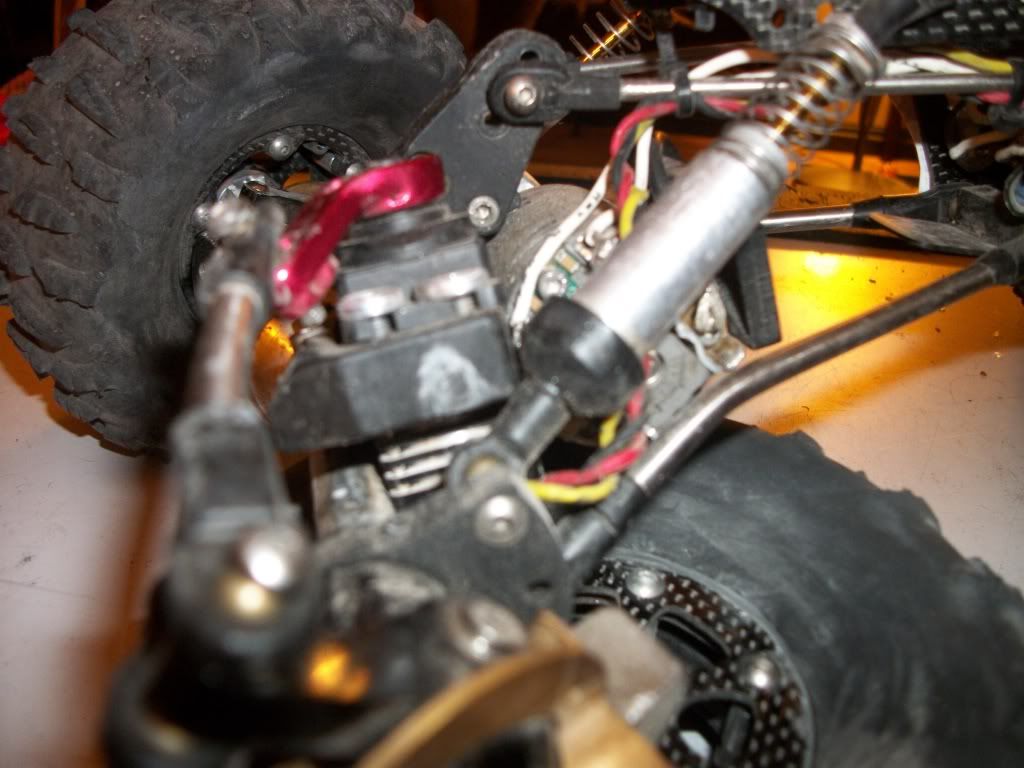

| Why you want to buy DLUX Delrin axles: Lightest axle tubes on the market. Approx .75oz lighter per axle than any other tube on the market, much lighter than stock. Infinitely adjustable shock/link mounts and caster adjustments. No more clocking the axles. You get to put everything where you want it. 86Jeep style steering with no axle tube mods. No more cutting and hacking your tubes. Rear lock out design gets rid of all the bulk and slop from aftermarket lockouts. The only axles on the market for any brand of car that gives a rear knuckle weight design that puts the weight right where you want it. Down low and all the way out to the face of the wheel. Delrin gives a nice slick surface for dragging across the rocks. Much better than stock aluminum housings. Smaller diameter tubes give more clearance. Make no mistake. These tubes are tough! ZERO failures to date. For the axle tubes, here is a touch of information that may help. Front axles do no use the inner bearing. They are designed for use with Super 300s. You will need to drill and tap holes for the set screws on all the parts. Everything will need 2 set screws 180* apart from each other except the rear weight holders, they are fine with 1 screw since they see no loads. On all the delrin I drilled it out smaller than suggested for a better bite. I used a #42 bit, a #40 is suggested normally. All screw sizes are 3mm x .05 pitch, 6mm long. Set screws are provided. You will need a fresh good tap and drill bit. Delrin is not the strongest material and can strip easily when there is not much to grab onto (like the thin lockouts). There should be virtually no torque applied as you are just setting the screw into the plastic (and not tightening against something). Since every screw should be set in the part AND the tubes, it will hold. If you use the set screws I provided, inserting the screw until its flush with the top of the delrin is just fine. I did not put any locktite on any of the set screws and everything has held great. The only exceptions to that are the servo mount and the C's. For the servo screws, I would do red loctite and never touch those again. Taking the screws in and out of the servo mount after putting locktite on them could damage them. Since there is not a lot there, make sure your threads are in like new shape if you ever take them out or put new ones in. For the C's, I put red locktite on those. I did have those come loose a couple of times. The servo mount is designed for a forward facing servo horn. If you have a rear facing servo horn, extra bracing on the servo mount is suggested. For the shock mounts, drill and tap where it starts to get thick, right where it ramps up and goes from the ring to the shock/link mounts. This gives a good spot for more material and is also a great spot because it is out of the link/shocks way and can easily be adjusted once installed. For the rear lockouts, you can simply push the lockout on until its tight against the bearing and then drill through the lockout and into the axle housing. Its ok to go all the way through, you just dont want to put the set screw into the housing so far that it causes problems and rubs the axle shaft. 12mm bearings are included for the lockouts. Right now the tubes are expected to use a one piece axle shaft. I am using stock dog bones in mine now. If you want to run dog bones in the rear you will need to contact me before purchase. For the servo mount, the axle shaft has to be out of the housing. Install the servo in the mount and then you can hold the servo against the housing, choose 1 out of the 3 holes to drill and then tap it. Then put the screw in and snug it down. Again, there is not a lot of material in the aluminum so dont get crazy. These will strip easily if you act like a gorilla. After you get the first screw in, drill and tap the next one. Do this one screw at a time. This will ensure that you can get all 3 screws in. If you were to drill all 3 and then tap all 3, you could be off a bit and it will really ruin your day. Once you have the screws in look down the axle tube. You should see that the 3 screws just barely poke through the aluminum. You want the entire screw to be threaded in the aluminum, not a thread short. You need to double check that the screws do not come through so far that the axle shaft will contact them. You can do this by gently putting the shaft in and turning it. If they are too long you may have to grind the screw down. If you do, make sure you chase the threads with a tap. Only use Aluminum screws. If your screws are not long enough you can source some longer ones or contact me for more. In order to fit the servo between the axle tube and motor you will need to move the motor up and back on the gear box. This is standard for all 86jeep style steering. I put one of the motor bolts right below the screw that holds the gear box cover on then I can see where I need to place the next one. On the C's, you can snug them up until you find where you want to be. Then, I take a small drill bit and just drill enough so it shows where you need to drill. I then take the C off and finish drilling with the appropriate bit. (You can try and drill with the C on but when I did this I caught some of the threads in my C and ruined them). I didnt tap these and I am not sure how it would turn out since you would be going from a thread to a thread. They would have to match up perfectly. I think you could get away with it on the delrin side, AL might be risky. Having just a divot for the screw to sit in has worked great for me on the AL side. Make sure the divot is smaller then the screw size. If it is bigger, it can walk around. I have been drilling and tapping an additional hole on the top and bottom of the C on the delrin side so its captured on all four sides of the C. My super had problems from the start and this fixed it so I have now been doing it on all the 2.2's also. Sorry, no refunds or replacements for errors made on install. You will need some fab skills or you will need to have somebody that does have fab skills do this for you. Out of all my testers, none had a problem. When I very first built this car I ran a stock upper link mount on the front. I noticed right away that my steering was taking a serious beating. I managed to put the then rear link mount on the front. I noticed right away that this link mount was saving my steering from being beat with every roll over. I have tried to spread the word about this all over the place but I am guessing that most think I am going for the up sell or that it just does not matter that much. Added info: I recently changed my front upper links to a shorter link. The adjust-ability of my upper link mount allowed me to do this without changing anything else (caster, motor clocking etc,.). The problem is that now with my mount clocked all the way back, it was no longer protecting my servo horn. Again, I noticed right away that every single roll was beating down my servo horn. Obviously the servo mount was never intended to take this kind of force or shock loads. I took a really hard backwards roll off a climb on Thursday and landed straight on my servo horn. This mutilated my servo horn and it also broke off the screws that hold the servo mount to the tube. If you do have this problem you can tell if your threads were done correctly whether or not the screws broke or the tube stripped. If your screws stripped, hopefully you read the directions in my vendors thread and you used the appropriate size bit, RED loctite, Aluminum screws cut to the right length and never touched them after initial install. To prevent all of this from happening, you will need to have something like my upper link mount to protect the servo horn. I am going to have to revise the mount for my car but I am sure 99% are not using as short of links as I am in the front. In addition to protecting the servo horn, I also realized that I could simply use my mount that I have intended to use with the supers. This mount gives 5 screw holes instead of 3. If you are running my standard servo mount with 3 holes you could even switch to the 5 hole as they share 3 holes and then the super just simply adds 2 more. Just in case anybody else runs into this problem, there is also a chance that if you do strip 3 holes out you can push your servo mount all the way to the flange and move the mounting holes over. If youre already to the flange, you can grind the servo mount a bit to get it closer to the flange and should be able to start 3 new holes that way also. I always grind the servo mount anyway as I like more clearance between the shock mount and servo mount. Hopefully this info will help somebody along the way. Broken mount with sweet servo horn.  New super servo mount with 5 screws. I am keeping my new custom bent servo horn as it helps protect it. If you look close you can also see how I did some grinding on the servo mount to get it closer to the flange.  Adding more info on installing the servo and moving the motor back.... When moving the motor back, here are some pics of what I consider the best way to do it. I use a 7980 servo with a 13t pinion so a 7950 should be an easy fit.   Last edited by Erik D_lux; 01-08-2013 at 02:27 PM. |

| |  |

| | #3 |

| Wanna get? Gotta want.  Join Date: Apr 2010 Location: SLC, UT

Posts: 7,052

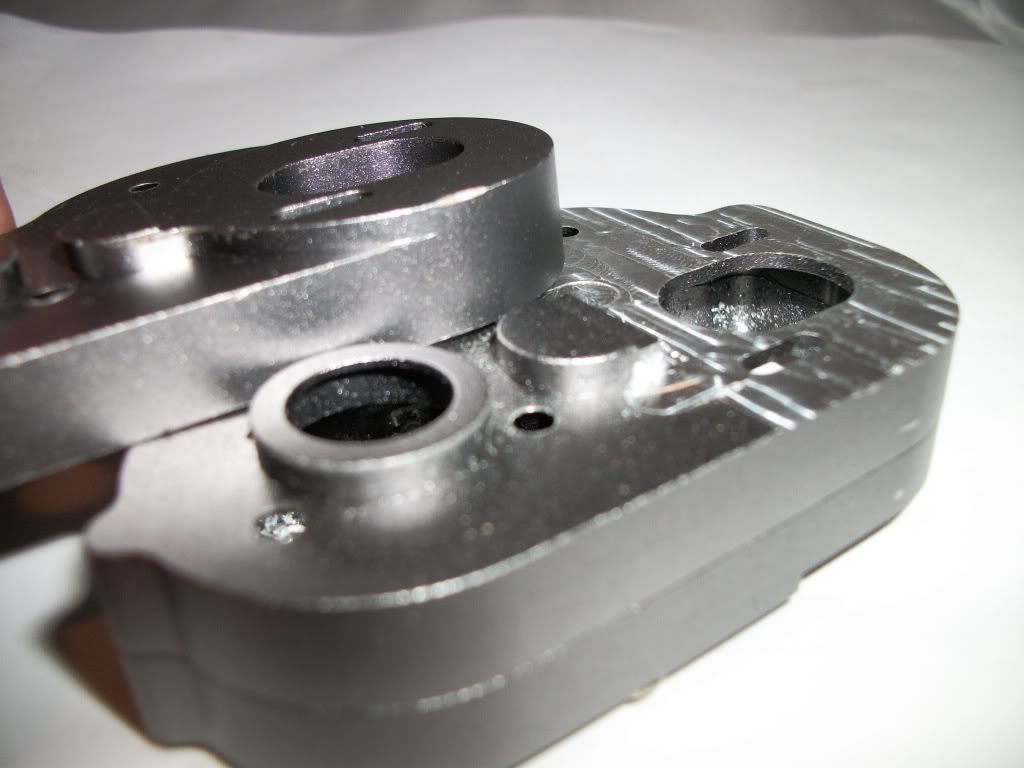

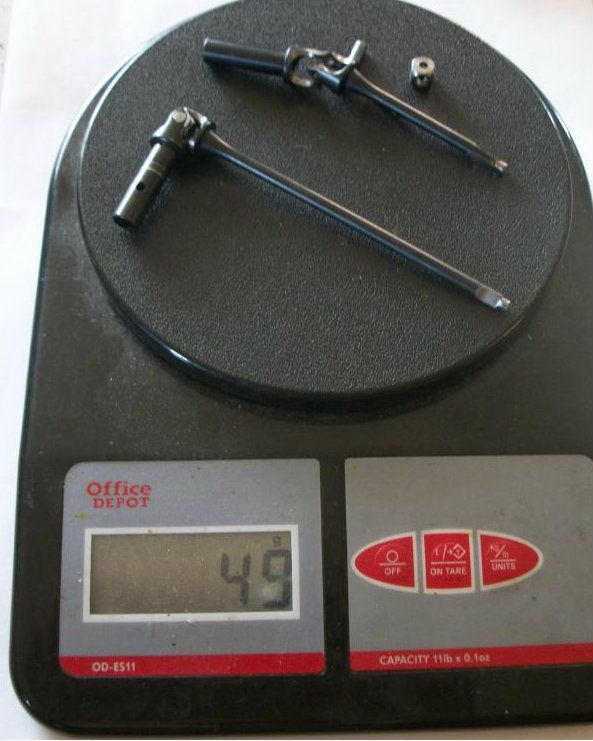

|

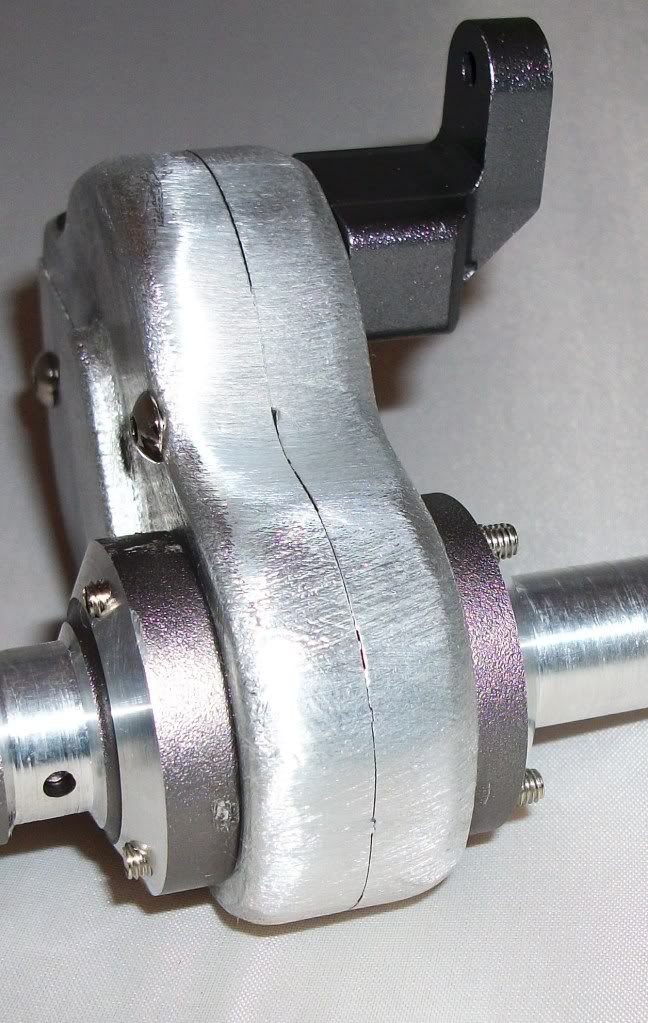

Here are some of the services I can do for the Berg axles.... I can lathe down the stock axles. This gives a smaller diameter tube and weight loss.  I can lathe the tubes and take off the C but leave the shock mounts. You can use the AX10 C this way and have adjustable caster.  I can lathe the entire stock tube down so you can use my delrin shock mounts and AX10 C's.   I can also lathe the rear to accept my lockouts   I can do a shave job on your cases. This will bring weight down and help with clearance issues.  Mill the motor mount face. This saves weight and moves the motor in which gives better link/shock clearance and also gives the pinion a better surface to mount on.   Mill the gears for weight reduction (23g weight loss for both cases)  Mill the slot and drill the gear for bigger pins. This mod would include the pins. Stock 1.5mm pin on the right, new, bigger 3/32 pin on the left.   Pricing: $25 for lathe work on a long and short tube or $50 for a whole cars worth if you send me the housings alone. $20 to do a shave job on your gear case. $20 to do just the lathe work to fit Axial C's for an entire front axle. $40 for a super. $20 for a servo cut to do the 86Jeep steering mod. $20 per gear box to mill the motor mounting surface. $15 added to the above if the axles come bolted to the gear case, knuckles attached etc,. Just send the tubes themselves to avoid this charge. $25 for 4 delrin shock mounts. $25 for 2 rear lock outs $60 to mill the slot and drill the hole in the gears for bigger pins. If you have problems with just one gear (probably the 3rd gear in the front axle) I can do that single gear for $20 $60 to mill out the gears for weight reduction. This is for all 6 gears. Last edited by Erik D_lux; 08-13-2012 at 03:05 PM. |

| |  |

| | #4 |

| Wanna get? Gotta want.  Join Date: Apr 2010 Location: SLC, UT

Posts: 7,052

|

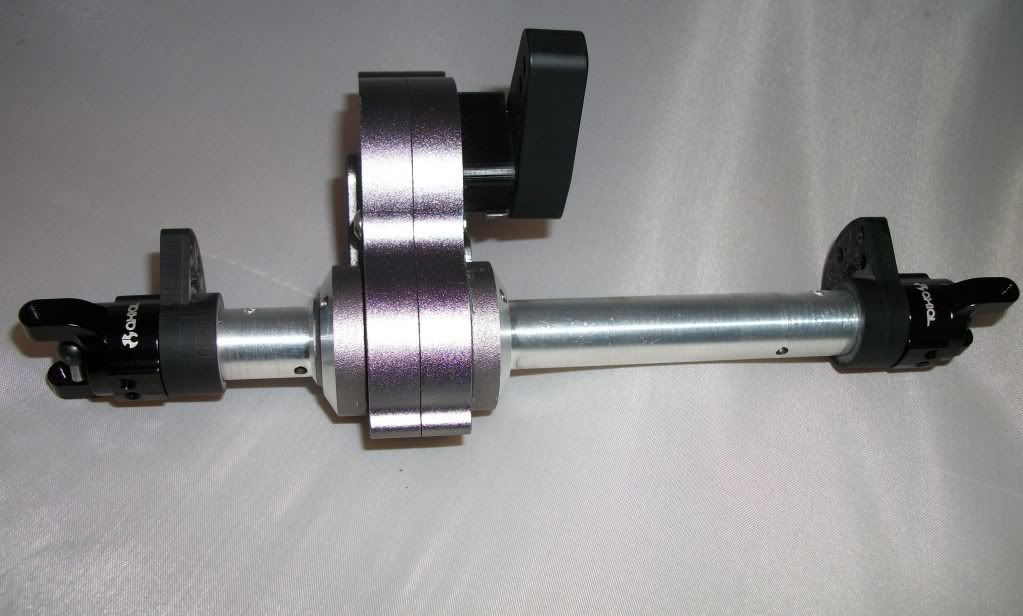

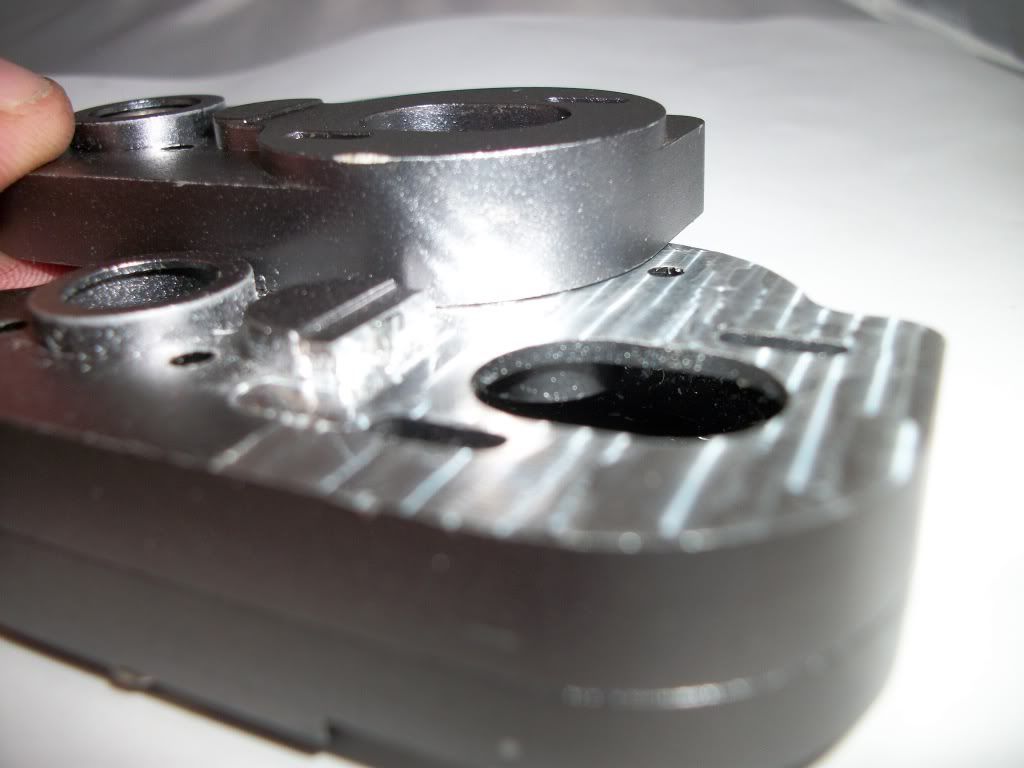

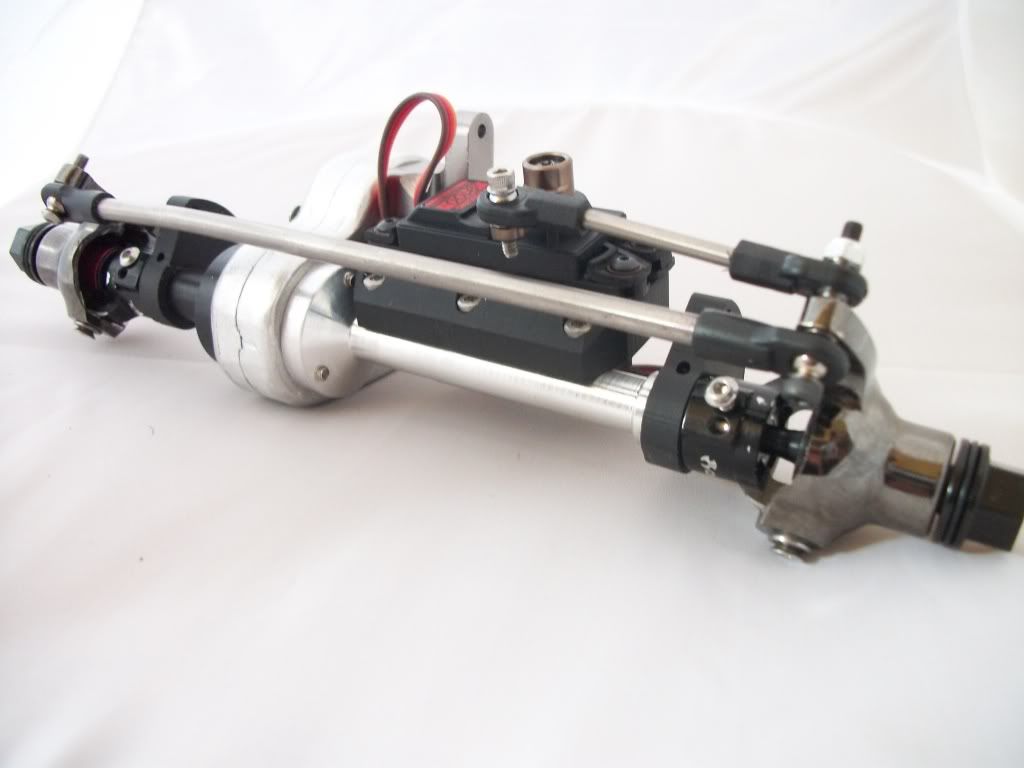

Now offering parts for the Bully/Berg conversion.  This conversion keeps everything stock from the chubs inward. If you are waiting on super 300's and need a fix or if you want to change to a different setup this is the ticket. If you ever want to change back, just put your old parts on and youre good to go. You will want to run a face type wheel such as the DLUX wheels since this does increase your width over 1/2" per side. I used to run Dlux wheels with an 850 hub for 11" and super 300's. Now I run a 225 hub on Dlux wheels for the same width. Parts needed: Bully knuckles including 2- 8 x 12 bearings per knuckle Bully hexes Axle shafts New tie rod New drag link Possibly Bully knuckle weights if you want to switch those over too. All my rings for my knuckle weights fit all the styles of knuckle weights, so, if you already have rings, you just need the main Bully knuckle weight. All of the modifications can be done with a dremel however, if you want a better fit and finish or just to make your life easier I am offering the following services to complete the modification. Cut down axle shafts: I am now moving away from the Bully shafts and on to the Universal style shafts... $90 for a pair of shafts that allow 70* of steering  When installing the new universal style shafts, you will need to do some mild grinding on the Axial hub and a slight taper to the delrin tube so that the shaft fits all the way in.   Milled out knuckles: $55 for machined style knuckles, $45 for cast. This includes 4 - 8 x 12 axle bearings and 4- 3 x 6mm kingpin bearings for no slop. I do I have the measurement for the tie rod and I can do the drag link also if you give me a measurement. $29 for both TI. Bully style knuckle weights: $60 for the main weight.  Since the demand is not huge for the Bully stuff it is common for me to not have stock and for there to be a small wait for me to make the parts. Last edited by Erik D_lux; 03-18-2013 at 11:12 AM. |

| |  |

| | #5 |

| Wanna get? Gotta want.  Join Date: Apr 2010 Location: SLC, UT

Posts: 7,052

|

Last one. I hope its enough.

|

| |  |

| | #6 |

| I wanna be Dave Join Date: Oct 2008 Location: Sumter

Posts: 6,141

|

Ordered the link mount and two of the gear case covers! I can't wait to see the other parts available  Keep up the good work Erik...it's great to see a vendor taking on some new additions to the product lines and delivering as promised. Thank you. Keep up the good work Erik...it's great to see a vendor taking on some new additions to the product lines and delivering as promised. Thank you.

|

| |  |

| | #7 |

| Rock Crawler Join Date: Mar 2010 Location: England & SoFlo

Posts: 744

|

Great news Erik, keep up the good work  Once the tubes are available will be ordering up the parts I'm looking for - international shipping costs just too high to split the order as parts come out Once the tubes are available will be ordering up the parts I'm looking for - international shipping costs just too high to split the order as parts come out Cheers, Darren |

| |  |

| | #8 |

| I wanna be Dave Join Date: Sep 2005 Location: Houston, TX

Posts: 16,952

|

Ordered up a few pieces. Thanks again for making some great parts Erik!

|

| |  |

| | #9 | |

| Wanna get? Gotta want.  Join Date: Apr 2010 Location: SLC, UT

Posts: 7,052

| Quote:

Thank you Jeremy! I will have it out in a bit. | |

| |  |

| | #10 |

| "HOLLYWOOD"  Join Date: Dec 2008 Location: Miami

Posts: 3,119

|

Eric do the lower links for the T1E come with the sliders as shown in the pic.?

|

| |  |

| | #11 |

| Wanna get? Gotta want.  Join Date: Apr 2010 Location: SLC, UT

Posts: 7,052

| |

| |  |

| | #12 |

| Rock Crawler Join Date: Mar 2010 Location: England & SoFlo

Posts: 744

|

[QUOTE=Erik D_lux;3176978]I totally understand however, if you do ever see something that I make that is small that you like, let me know. Something like the gear box covers I could ship out first class mail. That would only cost you about $3 for shipping. I have been doing this with pretty good success with shock ends and such. Sometimes I think its even faster getting there because I dont think it has to deal with customs. QUOTE] Cheers Erik, i'm looking at the servo mount, rear mount, gearbox covers, axle tube set, rear weight mounts. so pretty much everything Appreciate the offer though man  |

| |  |

| | #13 |

| "HOLLYWOOD"  Join Date: Dec 2008 Location: Miami

Posts: 3,119

| |

| |  |

| | #14 |

| Wanna get? Gotta want.  Join Date: Apr 2010 Location: SLC, UT

Posts: 7,052

| |

| |  |

| | #15 |

| Wanna get? Gotta want.  Join Date: Apr 2010 Location: SLC, UT

Posts: 7,052

|

Special thanks to the BYBRCC for testing the servo mount on other types of axles. Looks like it should be a good solid, universal mount for other axle housings with mild modifications.  |

| |  |

| | #16 |

| I wanna be Dave Join Date: Dec 2009 Location: Lady Lake, Fl

Posts: 2,128

|

Is it possible to order just the REAR T1e ti links? Thanks

|

| |  |

| | #17 |

| Wanna get? Gotta want.  Join Date: Apr 2010 Location: SLC, UT

Posts: 7,052

| |

| |  |

| | #18 |

| I wanna be Dave Join Date: Nov 2009 Location: Chico now

Posts: 2,384

|

Just installed the No Slop Bushings, love em! They were a couple thousandths short, just shaved the top and bottom of the knuckles, works perfect.  Awesome product, thanks Erik  |

| |  |

| | #19 |

| I wanna be Dave Join Date: Dec 2009 Location: Lady Lake, Fl

Posts: 2,128

| |

| |  |

| | #20 |

| Rock Crawler Join Date: Mar 2010 Location: England & SoFlo

Posts: 744

|

Hey Erik hope you're good man? just back from travelling for work and catching up on things, any thoughts on when the axle tubes might be available? I know you mentioned you were doing these yourself with no CNC machine and wanted to build up some stock ready for a run, not chasing just figured i'd touch base  Cheers, Darren |

| |  |

|

| |