| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Rock Crawler  Join Date: Feb 2014 Location: ?

Posts: 747

|

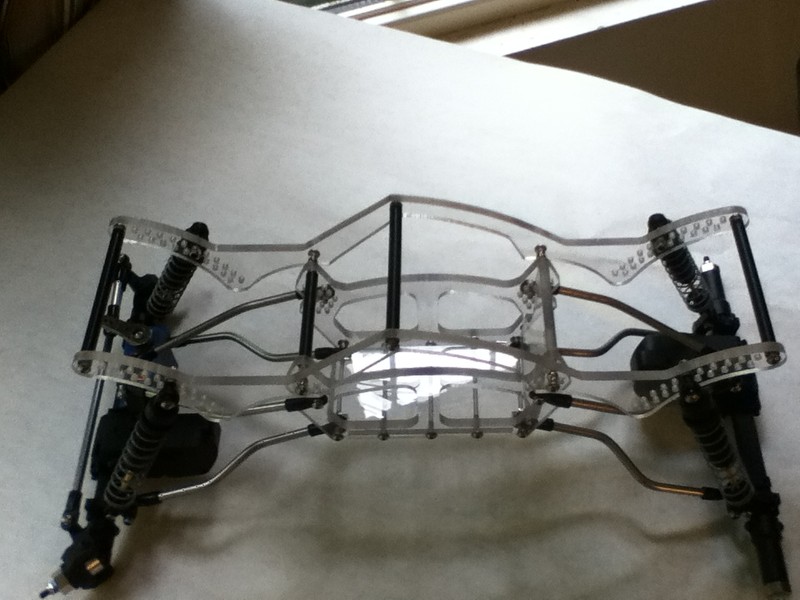

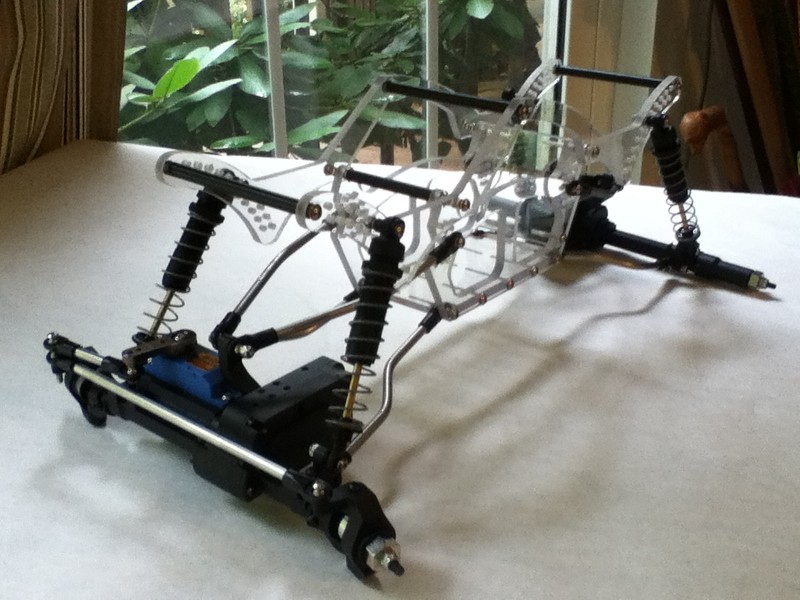

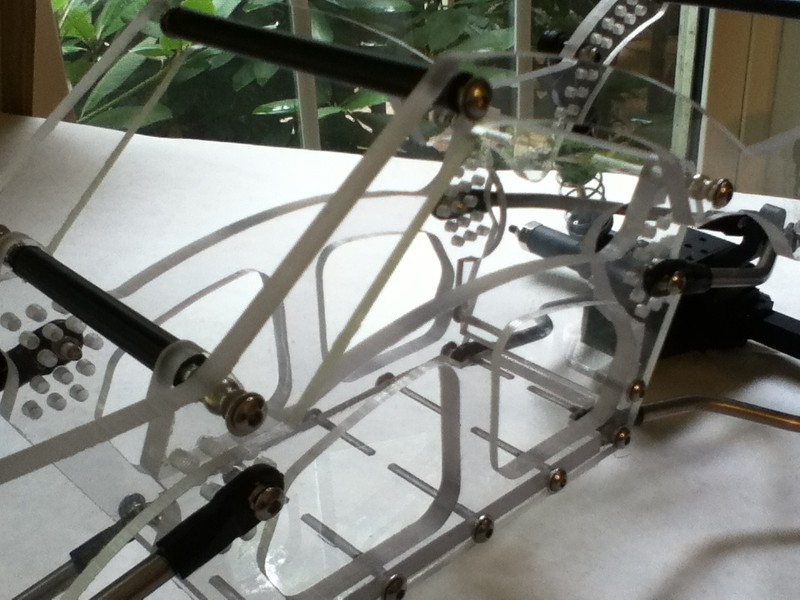

Here's a client commissioned chassis I designed and built. The client specified Bully2 Axles, 4s 4500mah LiFe Battery 145mm x 53mm x 36mm, a location to mount a 44mm x 42mm x 46mm smash, 5-1/2" tires, 14-1/2" wheelbase, body-less chassis type, and a 75-25 degree range of adjustment to shock angle. Working from those constrictions I designed the chassis around 105mm shocks using polycarbonate (Lexan) panels, acetal (Delrin) crossbraces, Stainless Steel links with Revo ends and M3 hardware. Access to the battery necessitated putting the smash plate behind the battery. To shift weight forward the battery overhangs the 100mm skid plate by 45mm. This limits potential upward travel of the links, which is the trade off for having such a large battery. The client was realistic in his expectations and knew from the beginning this will not be a super capable crawler or a scale trailing vehicle. It's out on the fringe of crawling: a general purpose MOA for playing around in the woods. That aside the design features are applicable to any MOA axles and the dimensions could easily be adjusted. Expect to see a "regulation" comp crawler variant of this in the near future with less range of shock adjustment, less overall height and length, and of course, less weight. Thanks again to Infodragon for commissioning this build.            |

| |  |

| Sponsored Links | |

| | #2 |

| Quarry Creeper Join Date: Feb 2014 Location: Chapel Hill, NC, USA

Posts: 191

|

Hey WOW that is really cool looking. I love the materials you chose to use. I don't see many optically clear materials used very often. kind of an odd design with the giant battery and upright shocks mounts but I am sure the buyer has his reasons. Regardless the craftsmanship looks top notch. You must have been tempted to keep them axles though right? |

| |  |

| | #3 |

| Rock Crawler  Join Date: Feb 2014 Location: ?

Posts: 747

| |

| |  |

| | #4 | ||

| Pebble Pounder  Join Date: Jun 2014 Location: White Plains

Posts: 98

| Quote:

Quote:

Again I couldn't agree more, I feel I'm getting a lot more than I anticipated! | ||

| |  |

| | #5 |

| Rock Crawler  Join Date: Feb 2014 Location: ?

Posts: 747

|

Packed and Labeled. Let me know how it works for you.

|

| |  |

| | #6 |

| Pebble Pounder  Join Date: Jun 2014 Location: White Plains

Posts: 98

|

I got a few minutes of lovin' with the new rig. Got it mocked up enough to do a maiden run and even with cheap terrible wheels it was incredible. I got terrible steering angle (about 1/2) due to the ripsaws "deep" hub but even so it handled incredibly well in the basement. I'm buying some very inexpensive wheels/tires from the classifieds and will get much better steering angle. (I threw on my T1E CF wheels with rock claws and the steering angle and performance were much improved) I just don't want to use them on a non-comp crawler rig. I tried to move the shocks to the inside of the axle mounts to give a bit more clearance for the tires but on the servo side it was about 1.5mm too narrow Speaking of which, there are too many holes! Both on the chassis and on the axles. RC4WD did an incredible job making excellent axles that are flexible AND this chassis is excellent with an incredible amount of flexibility. Too many holes = nearly infinite options! I LOVE IT! I didn't anticipate you would send so much Lexan 0.04" paneling. Thank you! What is the best way to cut and bend/mold it? I have a heat gun, what is the temp I should use (if that's the route) Thanks again! |

| |  |

| | #7 | |

| Rock Crawler  Join Date: Feb 2014 Location: ?

Posts: 747

| Quote:

Couple those with Lattice Innovations "Shifts" Presenting Shifts, Lightweight n' Flexible Offset Hubs to get the offset you need. You can order them from BC-Brian here on the forum. Awesome alternative to the pricey SLW hubs and best engagement. Check to make sure those work with the Bully2 sized pins. Or you can make the shock horns even wider by putting some wider spacers in there to spread them out. If you have tender girly hands I would suggest running some fine sandpaper over all the 90 degree edges of the lexan to avoid christening your chassis with human blood. The panel material was a gift to me so I passed (some of it) it along to you. You can cut it with scissors and it can be bent like thick paper if you want to crease it. Lexan is tricky to heat because it gets soft all of a sudden then bubbles when it gets over heated; and it cools rapidly so working time is short. I would suggest having a look at my friend Spiitz's Hammond build Spiitz' Bully 2 build a.k.a. "Hammond" to see some expert tricks on how to make some sexy looking panels and attach them neatly using cable ties. No heat involved. Enjoy! Last edited by MountainStorm; 08-29-2014 at 05:18 AM. | |

| |  |

| | #8 |

| Rock Crawler  Join Date: May 2007 Location: Salt Lake City

Posts: 977

|

Skid looks super cool and strong! If I ran it I would want the skid screws countersunk in the chassis side so they don't get hung though.  Last edited by tuner; 08-29-2014 at 10:57 AM. |

| |  |

| | #9 | ||

| Pebble Pounder  Join Date: Jun 2014 Location: White Plains

Posts: 98

| Quote:

Quote:

Hammond looks awesome! As soon as I can re-up on my car budget I'm going to be building a comp Bully 2 crawler. Thanks again for an incredible chassis! | ||

| |  |

| | #10 |

| Rock Crawler  Join Date: Feb 2014 Location: ?

Posts: 747

|

Any time!

|

| |  |

|

Custom Chassis Design & Fabrication by Mountain Storm - Similar Threads

Custom Chassis Design & Fabrication by Mountain Storm - Similar Threads | ||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Calderwood Design & Fabrication XR10 upper link mount | Jslick | Axial XR10 | 1 | 01-16-2014 08:06 PM |

| Thread Tools | |

| Display Modes | |

| |