| | #1241 |

| I wanna be Dave Join Date: Apr 2007 Location: Arlington, Washington

Posts: 2,303

|

Well, the brushes are broke in the other way....sounds strange, but it does make a difference. More than likely too, you aligned the hoods to the opposite way also. How long are you waiting between pulls? Motors can heat up pretty quick with the dyno pulls. You should be waiting till the motor cools down for another run. A temp gun helps, but make sure to take readings on the endbell and the can. I even point it at the comm if I can. On these slower RPM motors, as you continue up the spring tension, you are GOING to lose power in most cases. The only reason we used such stiff springs in racing was because of the voltage we had with the batteries towards the end of the brushed/nimh days. To give you an example, in 2002 we were racing with GP3300, which a great pack would usually be 1.15 volts at 30 amps on the matchers....by 2006, we were running IB4200 which had 1.25 volts at 35 amps (which translated really into about 1.30 at 30 amps). Motors were burning up like mad, from brush bounce and the excessive voltage. Fade was a big issue in the spec classes......stiff springs were the answer, even if they cost us a couple of watts on the dyno. Just like in racing though, you should REALLY use the lightest spring you can that still gives you the drag brake you want. (fade prevention in racing)...I typically think purples do a good mix of both, though I've used reds on motors that were running castle based speedos with crazy drag brake. Increased voltage (ie 4s or 5s) really will dictate spring tension too...gotta have enough or those brushes will bounce, even at low RPM. Later EddieO |

| |  |

| Sponsored Links | |

| | #1242 |

| Nobody  Join Date: Sep 2008 Location: Maine

Posts: 966

|

That's a good point. Before I realized the motor direction changed in relation to the installed position of the endbell, I had it on and off several times. Odds are that after I aligned the brushes and skim cut the com, I put the end bell on opposite of how the brushes were aligned. I know, I'm a dumbass. But I am trying. Some pulls are back to back. Most are a minute or two apart. The motor usually feels cool. I have a temp gun so I'll monitor it. Purple are the lightest springs I have for now. When I get some lighter ones I'll test with them. Even if the drag brake is good with red springs, are they strong enough to prevent brush bounce with 3s? I mostly run 3s. |

| |  |

| | #1243 |

| I wanna be Dave Join Date: Apr 2007 Location: Arlington, Washington

Posts: 2,303

|

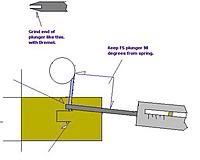

You are too hard on yourself....the only dumb question is the one not asked. You can bend your springs to be different tensions....you can typically go down about one grade by bending (purple to a red, but not purple to green). Here is how to do it. Red is fine for 3s....I've used them on 4s before, just makes maintenance more important..... Later EddieO |

| |  |

| | #1244 |

| Nobody  Join Date: Sep 2008 Location: Maine

Posts: 966

|

thanks for the spring bending tip. I wasn't doing it that way... I realigned the brushes on this Integy with it spinning the right direction, re-serrated the brushes, seated them, skimmed the comm and cleaned it up. Power pretty much came back as it was before rotating the other way. |

| |  |

| | #1245 |

| I wanna be Dave Join Date: Apr 2007 Location: Arlington, Washington

Posts: 2,303

|

Kinda shows how important correct break in is, along with alignment. Also shows how the reversed motor needs different attention to break in for an MOA.....makes the matched pairs make a little more sense now doesn't it? Later EddieO |

| |  |

| | #1246 |

| I wanna be Dave Join Date: Nov 2010 Location: 07456 N. NJ USofA

Posts: 8,314

|

Cordwood.....sorry for the late reply, traveling home from a business trip yesterday, then dealing with a work laptop issue today...... As Eddie0 stated, you want to run the lightest spring you can, taking into consideration: Brush bounce (more spring tension, less bounce) Drag brake (more tension, more drag brake) Keep in mind, more tension also adds to mechanical drag, thus dyno numbers tend to drop when running the same input voltage. Sorta like climbing angle, you can get great angles, but have no ground clearance.... "You fix one thing, you FUBAR another..." |

| |  |

| | #1247 |

| Nobody  Join Date: Sep 2008 Location: Maine

Posts: 966

|

I'm definitely seeing the power differences of different springs. I'm thinking that I'll set crawler motors up with purple springs as EddieO recommended. Once I get some drive time in and a feel for drag brake I'll spring up or down from there, depending on the crawler and esc setup. I'll Likely spring down for scaler motors. On that note, here's a pic on using a fiddlesticks EddieO pointed me to.  |

| |  |

| | #1248 |

| Nobody  Join Date: Sep 2008 Location: Maine

Posts: 966

|

Here's what that 55t Integy makes with some lighter springs. They're the original Integy springs double tweaked stiffer and come in around 6 FU's --------- rpm-------power--------torque-------eff Max P---4384-------57.2---------124.5-------50 Max eff-7785-------32.4---------30.7---------86.9 Avg------------------36.7-----------------------47.5 Avg 18-35-----------31.2----------------------20 Torque 237 9055 rpm Seems like descent gains over the pre rebuild numbers to me. |

| |  |

| | #1249 |

| Nobody  Join Date: Sep 2008 Location: Maine

Posts: 966

|

Next under the scalpel.....unknown turn Integy V11  I had to tweak the positive spring stiffer just to get it to run. -----------rpm--------power---------torque--------eff Max P-----7029--------79-------------107---------41 Max eff---11675-------39--------------32---------71 Avg---------------------51--------------------------37 Avg 18-35-------------76.7------------------------43 Torque 190 13457 rpm I'll guess a 35 turn? Here's a 6 turn P-94 at 8 volts, just for fun. 265 Watts and 52698 rpm. I thought it was going to take off... http://i583.photobucket.com/albums/s...s/f73437ef.mp4 |

| |  |

| | #1250 |

| MODERATOR™  Join Date: Jul 2004 Location: Ohio

Posts: 18,928

|

Guess what I got?  TEDROCKZ! |

| |  |

| | #1251 |

| Nobody  Join Date: Sep 2008 Location: Maine

Posts: 966

|

Bad ass. Is that the 45? I'm looking forward to comparing the turbodyno to the robi.

|

| |  |

| | #1252 |

| MODERATOR™  Join Date: Jul 2004 Location: Ohio

Posts: 18,928

|

Yep, 45.  A power supply might be my issue. |

| |  |

| | #1253 |

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

|

What PS voltage you need? I have some pretty beefy ones, and could point you to some reputable vendors as well.

|

| |  |

| | #1254 |

| I wanna be Dave Join Date: Jan 2008 Location: Arat Alabama

Posts: 2,678

|

I had it on a 45 amp 12volt Aston. It was a pretty consistent 12.5 volt.

|

| |  |

| | #1255 |

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

|

Pick up two of these in parallel, you can adjust the output voltage to what you need. 12V 30A DC Universal Regulated Switching Power Supply | eBay |

| |  |

| | #1256 |

| I wanna be Dave Join Date: Jan 2008 Location: Arat Alabama

Posts: 2,678

|

Just found the instruction sheet for it. Recommends 12-13.8v and 30 amp! So just one like JRH suggested may suffice. Plus that is a good price.

|

| |  |

| | #1257 |

| Nobody  Join Date: Sep 2008 Location: Maine

Posts: 966

|

How electrical savvy do you have to be to wire those up? I'm a + is positive, - is negative type of guy. I'm not sure if my TD45 is coming with a power supply but I'd assume not if it's a 70 dollar setup.

|

| |  |

| | #1258 |

| I wanna be Dave Join Date: Jan 2008 Location: Arat Alabama

Posts: 2,678

|

Its simple. Two motor leads and two battery/power supply wires.

|

| |  |

| | #1259 |

| Nobody  Join Date: Sep 2008 Location: Maine

Posts: 966

|

Here's some fun data. This V11 Integy was pretty beat. I had to stiffen the positive spring to get it to run. The comm was hammered and the brushes spent. I tore it apart, cut the comm and soldered on the only stand up brushes I had.....those old school race prep "P" brushes I had. I aligned the hoods and broke them in. I was surprised to find a very small increase in power. I did notice an odd noise and upon inspection, found the pinion bearing was junk. I don't have any spare bearings yet, so I went to pop some out of an Orion revolution, and decided to just use the Orion can and end bell with the Integy arm. Here are the results Stock, 0 deg timing, 8 volts -----------rpm--------power---------torque--------eff Max P-----7029--------79-------------107---------41 Max eff---11675-------39--------------32---------71 Avg---------------------51--------------------------37 Avg 18-35-------------76.7------------------------43 Torque 190 13457 rpm Orion revolution can/end bell swap, 0 deg timing, 8 volts -----------rpm--------power---------torque--------eff Max P-----7193--------88.5---------117.5---------44.9 Max eff---11813-------40.5----------32.7----------71.6 Avg---------------------59.1-------------------------40.1 Avg 18-35-------------85.4-------------------------48.1 Torque 247 13544 rpm 7 degrees timing, 8 volts -----------rpm--------power---------torque--------eff Max P-----7247--------97.1---------128-----------49.7 Max eff---11692-------49.7----------40.6---------77.9 Avg---------------------63.2-------------------------42.5 Avg 18-35--------------94.1-------------------------51.7 Torque 254.8 13800 rpm Serrated brushes, broke them in, skim cut comm. 7 deg and 8 volts I put the pre rebuild/tune numbers in () ---------------rpm-----------power------------torque------------eff Max P------(7029)7434---(79)103.3------(107)132.8-------(41)55.2 Max eff--(11675)11340---(39)59----------(32)49.7---------(71)79.5 Avg-------------------------(51)65.9---------------------------(37)45 Avg 18-35------------------(76.7)100.4-----------------------(43)56 Torque (190)253 (13457)13891 rpm  I don't know much but that looks like a descent gain from my house. Eric |

| |  |

| | #1260 |

| I wanna be Dave Join Date: Nov 2010 Location: 07456 N. NJ USofA

Posts: 8,314

|

Some nice gains there. Sorta makes me want to drag out my "dyno" and go over some of my motors. Time is my main issue. I do motor maintenance, just not the dyno runs. |

| |  |

|

LinkBacks (?)

LinkBacks (?)

LinkBack to this Thread: http://www.rccrawler.com/forum/electronics/223989-cutting-motor-commutator-motor-tweaks.html | ||||

| Posted By | For | Type | Date | |

| Hiilimoottorin kunnostaminen | This thread | Refback | 10-04-2011 03:19 PM | |

| |