| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| RCC Addict  Join Date: Jan 2010 Location: Lafayette

Posts: 1,077

|

I am working on the power plug for a dual esc setup with a CC BEC. Trying to avoid using a Y. I need to solder two red esc wires plus 1 red BEC wire to the positve terminal, same but opposite for the neg. terminal. Everytime I try to add a wire to the terminal, one of the previously soldered wires pops off. I have tried to solder all 3 together then solder it as a mass to the terminal, same thing happens. As soon as the solder liquifies, the wires pop apart. I've thought about trying to use a ziptie around them, right next to the tinned ends. I'm using a helping hand thing with the alligator clips already, it still happens. I'm going to try the microwave next. |

| |  |

| Sponsored Links | |

| | #2 |

| RCC Addict  Join Date: Jan 2010 Location: Lafayette

Posts: 1,077

|

Would this fit better in the tools section?

|

| |  |

| | #3 |

| RCC Addict Join Date: May 2008 Location: Chicago/Bloomington

Posts: 1,505

|

The simple answer is to only solder one wire to the terminal. Solder the other wires to a spot about 1 or 2 cm on the wire from the terminal. In other words take two of the red wires and solder them to the third red wire in an area away from the Deans, then solder the one red wire that the other two are attached to onto the Deans. Done. (it really doesn't matter where on the main wire you attach the other two.)

|

| |  |

| | #4 |

| RCC Addict  Join Date: Jan 2010 Location: Lafayette

Posts: 1,077

|

So, have the wires inline with each other, but stacked sequentially behind the one that is soldered to the term? Then I guess I just need to make sure I have a big enough diameter on the heatshrink to cover that section. OK, thanks. I think I can make that look clean. I'll post up a pic when I'm done. |

| |  |

| | #5 |

| Rock Crawler Join Date: Oct 2006 Location: Fernley

Posts: 870

|

Depending on what esc you are using, I've seen people solder the bec to the battery posts on the esc. Might save some headache. Or I have also done the inline soldering, but it's hard to get the shrink tube on there. The liquid electrical tape is good for this though.

|

| |  |

| | #6 |

| I wanna be Dave Join Date: May 2007 Location: Vancouver, BC

Posts: 2,379

|

If it is not too late, my suggestion would be to take a thin strand of maybe 22 gauge or 24 gauge and wrap around the stripped portion of the wires you want to solder to the Deans. This will help hold it together, then tin the bundle. The Deans should be tinned too. Then go for it. Good luck

|

| |  |

| | #7 |

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

|

A set of small hemostats could help. You need a good mechanical bond to the joint anyway, solder is a poor conductor.

|

| |  |

| | #8 |

| Rock Crawler Join Date: Dec 2009 Location: Jersey Strong!

Posts: 564

| |

| |  |

| | #9 |

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

| |

| |  |

| | #10 |

| RCC Addict  Join Date: Jan 2010 Location: Lafayette

Posts: 1,077

|

Mamba Micro Pros, so no exposed battery posts. What temp do you guys recommend for 16 gage wire? I'm using 300*C and it seems to be pretty good, do I have room to come down some more? |

| |  |

| | #11 | ||

| RCC Addict  Join Date: Jan 2010 Location: Lafayette

Posts: 1,077

| Quote:

Quote:

Obviously not a hi-getter in his younger days. | ||

| |  |

| | #13 |

| Rock Crawler Join Date: May 2010 Location: Calgary, Alberta, Canada

Posts: 771

|

when i do dual escs i put the bec wires on one of the posts on one of the escs, it's easier and allows you to shorten the bec wires because you'll probably put the bec right next to the esc anyways, also it allows the little bec wires avoid the abuse caused by connecting and disconnecting the battery all the time.

|

| |  |

| | #14 |

| RCC Addict  Join Date: Jan 2010 Location: Lafayette

Posts: 1,077

|

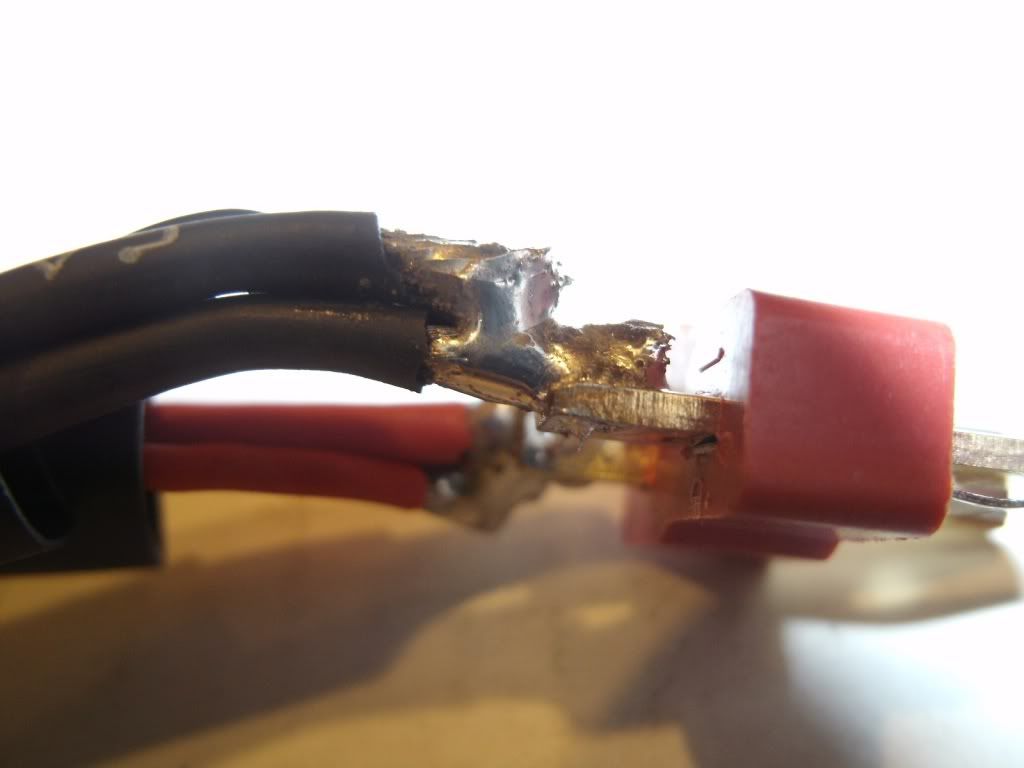

Got it done. Staggering them slightly made all the difference in the world. This closeup makes it look pretty nasty but it's not that bad I think. I didn't have to add any solder, just used what was tinned on the wires. Thanks for all the help!  |

| |  |

| | #15 | |

| Rock Crawler Join Date: Dec 2009 Location: Jersey Strong!

Posts: 564

| Quote: I'd give ya one of these EDIT: Damn Im slow, Looks good  | |

| |  |

| | #16 |

| RCC Addict  Join Date: Jan 2010 Location: Lafayette

Posts: 1,077

|

Thanks man.  Now John's got me rethinking everything due to his mechanical connection comment. I may need to rethink my method for the builds after this. |

| |  |

| | #17 |

| I wanna be Dave Join Date: Mar 2008 Location: Wayne county. PA

Posts: 2,507

|

my method of doing what you need done is this....take any wire core bread wrapper and strip off the paper/plastic coating to give yourself a fine wire wrap....get your wires as you would like them soldered together but leave one 1/4" longer....that one will be soldered to the deans tab and twist the bread wrapper tightly around them to hold them in place and solder away  .......bob .......bob.... |

| |  |

| | #18 |

| I wanna be Dave Join Date: Sep 2005 Location: Houston, TX

Posts: 16,952

|

Damn Shell.....is that 12G wire? Use 16 or 18!  |

| |  |

| | #19 |

| RCC Addict Join Date: Jul 2009 Location: Shreveport, LA

Posts: 1,005

| |

| |  |

| | #20 |

| RCC Addict  Join Date: Jan 2010 Location: Lafayette

Posts: 1,077

|

It's 16 gage, that's what comes stock on the Micro Pros. Yeah TC, servo wire is easy too.  |

| |  |

|

| |