| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Newbie Join Date: Mar 2013 Location: Melbourne

Posts: 6

|

Hello fellow Rc addicts. I've recently been attempting to rebuild my brushed Tekin 45t Heavy duty motors. I've watched/read pretty much every video and thread about rebuilding motors and some where I'm mucking up and It just eats up the brushes when running in the motor. The comms have been lathed. The edges of the comm have had the sharp edges bent down with a tooth pick. The hood has been aligned with the right tools and the shims are all in their correct places. I'm completely stumped. has anyone had this happen to them? any ideas what I could be doing wrong? |

| |  |

| Sponsored Links | |

| | #2 |

| Rock Stacker  Join Date: Mar 2013 Location: UK

Posts: 77

|

Not too clued up on them myself, but a picture or 2 may assist, 1 on the comm and another of the spring/brush area. It wouldn't be the first time I've missed something sat right in front of me |

| |  |

| | #3 |

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

|

What rig, gearing, voltage, and timing? On a typical 45t installation running 3s you should see brush life between 15 and 30 hours, assuming you stay out of water/ mud/ heavy dust.

|

| |  |

| | #4 | |

| I wanna be Dave Join Date: Nov 2010 Location: 07456 N. NJ USofA

Posts: 8,314

| Quote:

Do NOT do a "water break-in!" | |

| |  |

| | #5 |

| MODERATOR™  Join Date: Jul 2004 Location: Ohio

Posts: 18,928

|

I still have no problems with water break in, but there are more steps to do. And leave the sharp edges on the comm slots, faster on/off of the segments. |

| |  |

| | #6 |

| Newbie Join Date: Mar 2013 Location: Melbourne

Posts: 6

|

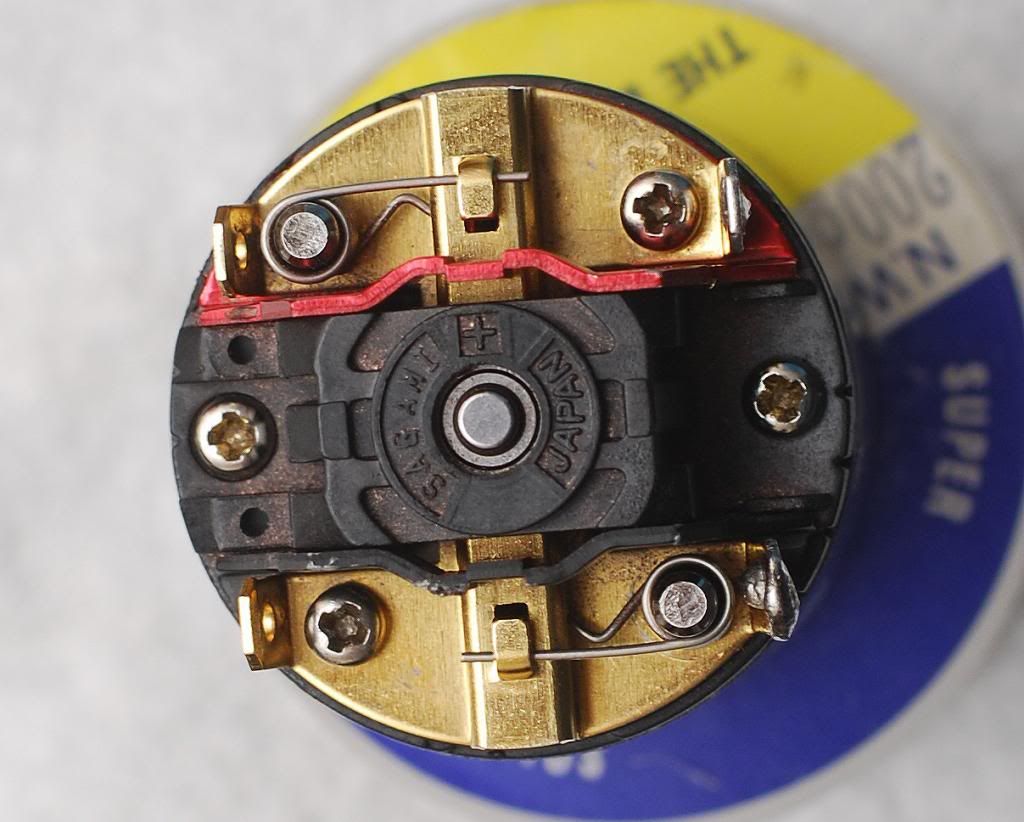

Ok so more info as requested. Im running the Tekin 45t Heavy duty motor and last time I was out crawling the bearing in the can started making noises so I decided it was time for a rebuild. I purchased new bearings and installed them. While I was at it I decided to lathe the comm and put new brushes. I watched the following youtube vid as info for the lathe and rebuild process. RC Culture - Restoring Brushed Motors - YouTube I watched this vid for info on breaking in the motor. RC Brushed Motor Break In Methods-Both Wet & Dry Break In - YouTube I actually tried the dry method first. A lot of the brush material ended up between the gaps in the comm. So I then cleaned the comm out. installed new brushes and did the wet method. after about an hour at slow running I pulled it out, cleaned it up and span it up to about 3/4 throttle and the brushes went in 2 seconds. allot of heat was being produced. Have I got the timing completely wrong? Hood:  Hood 2:  Comm:  comm 2:  Brushes:  |

| |  |

| | #7 |

| Newbie Join Date: Mar 2013 Location: Melbourne

Posts: 6

| gearing isn't an issue. This is before the motor is even installed. voltage is usually 7.4v on super slow speed when running in. Timing im sure is set to 0deg but I cannot confirm. All my other tekin motors, which i havn't rebuilt have lasted longer then 15-30 hours even in wet, dusty conditions

|

| |  |

| | #8 |

| I wanna be Dave Join Date: Apr 2007 Location: Arlington, Washington

Posts: 2,303

|

You broke a motor in at 7.4 volts? The water method is crap, why people keep trying it is beyond me. I break in 100+ motors a month....and never use it. From your pics timing looks advanced a few degrees. Comm looks like it took a brutally deep cut. Whats it measure at? Gearing does matter, you may of smoked the motor prior....the shorted armature is just gonna keep eating brushes. Later EddieO |

| |  |

| | #9 |

| MODERATOR™  Join Date: Jul 2004 Location: Ohio

Posts: 18,928

| Agreed. And there isn't much left looks like to me.

Last edited by EeePee; 07-28-2013 at 01:04 AM. |

| |  |

| | #10 |

| Rock Stacker Join Date: Feb 2012 Location: Kelso,wa

Posts: 69

|

EddieO spoke the truth. So from what I read, you broke it in dry (once) decided that because there was break in dust between the comm bars, you would try water break in. So it doesn't " keep " eating brushes, it ate the brushes once? 7.4volts is screaming for break in. I'm surprised that it even made it an hour under water @ 7.4! Clean the comm, new brushes and break it in dry at 3 volts or so, (just the way I've done it motor builders may be different here) until the comm is contacting the brushes completely or almost. Tear it down, clean it out oil the bearings and you should be back in business.

|

| |  |

| | #11 |

| Newbie Join Date: Mar 2013 Location: Melbourne

Posts: 6

| |

| |  |

| | #12 |

| Newbie Join Date: Mar 2013 Location: Melbourne

Posts: 6

|

So from what I gather Ill trash this armature and try again with new brushes, new armature and go the dry run in method using 3-5volts for 20min. clean it up and it should be fine. If it is still eating brushes after all of this what could it be? Bearing not seated right? Does team brood stock 45t armatures? |

| |  |

| | #13 |

| I wanna be Dave Join Date: Nov 2010 Location: 07456 N. NJ USofA

Posts: 8,314

|

I never break-in @ 7VDC, I usually use 3-5. Can't say I've ever heard of a 1 hour water break-in, maybe a few minutes. I used to use water break-in ~20 years ago for high load racing motors and very hard brushes, but that was a few minutes. You can try new brushes, run "no load" for ~5 minutes @ 3-5 volts. Blow out, lube bearings & install in rig. Make sure the brushes move freely in the brush hoods before installing. Maybe read the stickies in this section regarding taking care of motors, much better info than other places. |

| |  |

| | #14 |

| I wanna be Dave Join Date: Apr 2007 Location: Arlington, Washington

Posts: 2,303

|

Yes we stock armatures....handwound and machine wound. Later EddieO |

| |  |

|

Brushed motor rebuild problems. Help! - Similar Threads

Brushed motor rebuild problems. Help! - Similar Threads | ||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| 3s Goat system running brushed brake problems. | justScale'n | Electronics | 2 | 02-16-2011 11:47 PM |

| how long b4 rebuild on brushed motor? | tj on 37s | Electronics | 2 | 11-26-2009 11:02 AM |

| sidewinder+ brushed problems help | Tklan Crawler | Electronics | 4 | 10-01-2009 09:21 PM |

| Brushed Motor rebuild/replacement parts | JohnRobHolmes | Holmes Hobbies | 3 | 11-11-2008 06:43 AM |

| Thread Tools | |

| Display Modes | |

| |