| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Quarry Creeper Join Date: Dec 2014 Location: Plainfield

Posts: 208

|

So I've been running a Tekin combo (RX8/T8 ) in my Yeti for a few months. I have used Corrosion X and Conformal Coating on 2 different ESCs. The Corrosion X ESC ran good for a while until it eventually cut out and died after some water/mud usage. The conformal coated ESC lasted for about 2 weeks, but took some severe mud and water punishment that led to its demise. I've since put the second ESC in some rice, with no effect letting it sit over night. So, i am planning on buying a new RX8 tonight. I Plan on applying 3 coats and then baking it on at the suggested hour @ 150 degrees. After that is set I am going to give it 2-3 coats of plastidip to try and ensure this one lasts me. I am going on Vacation on Saturday otherwise I would send one of the bad ones back to Tekin. HERE IS THE QUESTION: Is this going to be enough to keep me from blowing another ESC? I know guys have had very good luck with conformal coating, so I can't help but to feel like I am doing something wrong. Is there a certin wat to clean? Is there a certin way to apply it? How about drying maybe I didn't let it cure fully? I just want to be assured a little that I'm on the right track, because this will make over $750 in RX8's... |

| |  |

| Sponsored Links | |

| | #2 |

| Rock Crawler  Join Date: Nov 2010 Location: the 'burgh'

Posts: 976

|

That's a lot of coin my man! You may want to send HH an email and see what they may suggest, they do conformal coating alot. You might also want to think about one of their WP BLE ESC's. A lot of folks having real good success with that ESC. |

| |  |

| | #3 |

| Rock Crawler Join Date: Oct 2013 Location: Wiscasset, ME

Posts: 623

|

When I apply conformal coating I always spray down the board with plastic safe electric cleaner. This gives a clean surface for the coating to adhere to. The only other tip I've found useful is, less is more. Use thinner coats, making sure to get into every crevice. Also don't bother with plastidip. All that does, in my opinion, is create a pocket for water to sit in. It always leaks eventually, and since its thick and usually black, you can't tell what's happening underneath. Another waterproofing tool, is epoxy. Get some clear epoxy or I like using shoe goo or e6000 any of that type of adhesive. I can't remember the rx8 design, but if you can set the board into the bottom case half and fill it with epoxy and let it cure you'll have a totally water tight unit. Edit: BE PATIENT! It needs time to fully cure. They still conduct electricity while "wet". |

| |  |

| | #4 |

| Rock Crawler Join Date: Jan 2014 Location: Frog Lake AB, Canada

Posts: 696

|

I bought an RX8 from HH and they water proofed it for me, and I'm about to send another one ( a black RX8 ) to them for the same treatment. I think they told me it was Dow Corning conformal coating..... |

| |  |

| | #5 |

| Rock Crawler  Join Date: Nov 2010 Location: the 'burgh'

Posts: 976

|

RX8 is a little bit of a pain, only because it has two boards that need coated. I found more often than not that it's the sensor plugs that are the most vulnerable.

|

| |  |

| | #6 |

| Quarry Creeper Join Date: Nov 2013 Location: lethbridge,alberta, its mighty windy here!!

Posts: 234

|

use sillicon conformal coating, its flexible so less prone to eventually cracking over time, ive used it for countless rc electronics and its not let me down once. i bought a spray can of the mg chemicals sillicon stuff and coated lots of things and have barely made a noticeable difference to the cans contents, just a case of doing a few passes and letting sit for a little bit between and its good. worth every penny of the $23 it cost. tony |

| |  |

| | #7 |

| Quarry Creeper Join Date: Dec 2014 Location: Plainfield

Posts: 208

|

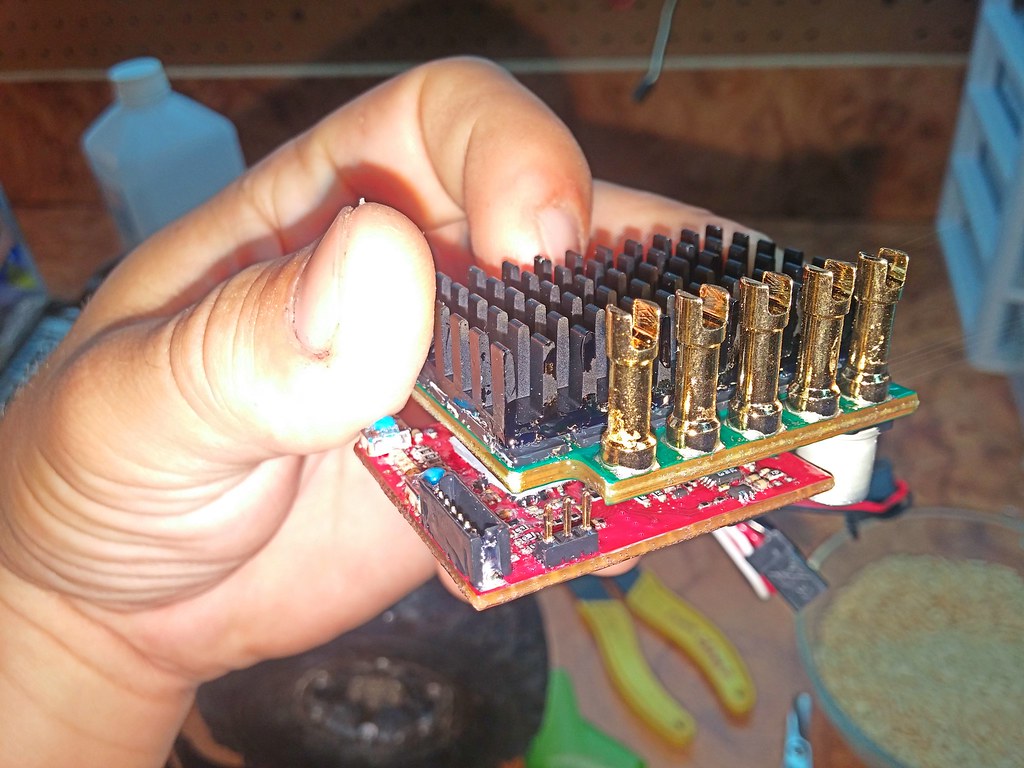

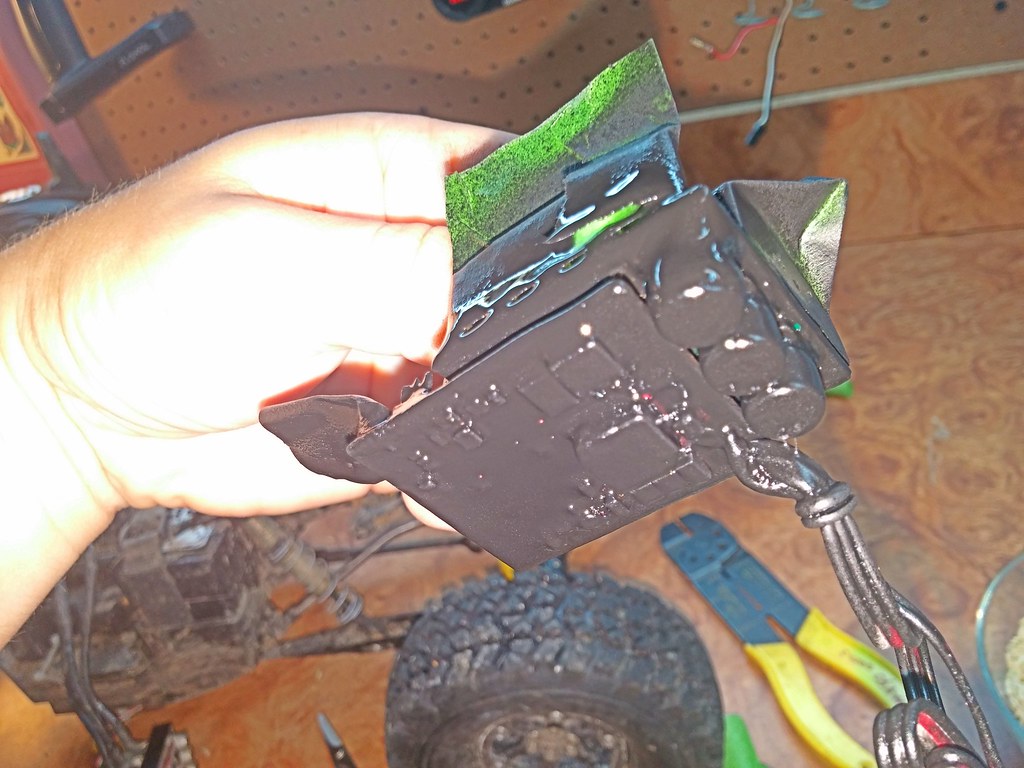

I got the conformal coating baked on last night and I got one coat of plastidip so far. Everything looks like it cured very well. Here's how it looked after getting 3 coats of MG Silicone Confomal Coating (422b).   On the first coat, I taped off the posts and the heat sink. Then thoroughly applied it one the seperated boards, once I had a nice coat built up I let it sit for a few minutes before removing the tape. Then I baked it in the oven at 170 degrees for 45 minutes. After that was cured, I applied my second caot and let that dry at room temp for about an hour and a half. Once that was dry to the touch I applied my third coat and baked again at 170 for 45 minutes. First thought is that the baking process definitely cured the coatings, as they hardened and stayed very clear. This morning I had a few minutes before getting ready for work so I (somewhat) hastily threw my first coat of plastidip on. i warmed the can for a finer spray, just by holding it under hot running water for a couple of minutes. Also I plan on 3 coats of the plastidip for the most protection possible. Here's out that first coat looked before curing (it shrinks a lot and I know there are a few spots I missed).   |

| |  |

| | #8 | ||||

| Quarry Creeper Join Date: Dec 2014 Location: Plainfield

Posts: 208

| Quote:

Quote:

Quote:

Quote:

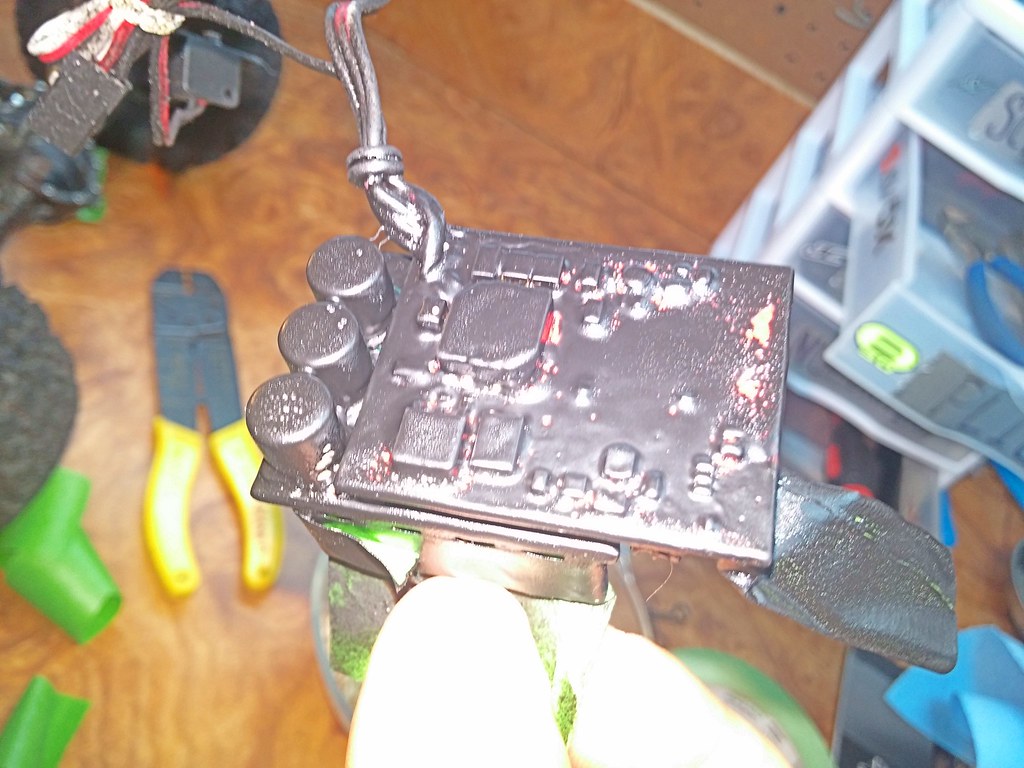

I applied another coat of plastidip this morning. The base coat looks alright, I am going for sheer coverage with the plastidip in hopes to keep even the conformal coating protected in all situations. Here's what the esc looks like after curing overnight.   | ||||

| |  |

| | #9 |

| Quarry Creeper Join Date: Nov 2013 Location: lethbridge,alberta, its mighty windy here!!

Posts: 234

|

im supprised that your having these issues with the coating, even more so as we are both using the same manufacturer/product. the only thing i do differently is i dont bake it to cure, just air dry between coats till its tack free then hit it with another, just several coats like that and so far ive not had issues with it. maybe worth trying the natural cure method when you next have to coat something, so far its not given me any problems. tony |

| |  |

| | #10 | |

| Quarry Creeper Join Date: Dec 2014 Location: Plainfield

Posts: 208

| Quote:

Good to know that you've had good luck with the same product, it just raises the question of why mine failed. I got the baking idea from MG Chemicals themselves on their site under usage instructions. It reads "Best results will be obtained by applying to thoroughly cleaned and dried parts or materials. It is essential that surfaces be free of any trace of grease or organic substances. At room temperature, the product will tack free in approximately 5-7 minutes, and full cure will be achieved in approximately 48 hours. Curing may be accelerated by applying moderate heat with either a convection oven or infrared lamps. We recommend curing in a convection oven at 65°C (149°F) for one hour, but other temperature and time combinations can work well. Heat curing will improve the physical strength of this coating." My oven only went down to 170 degrees so I figured it only needed 45 minutes. | |

| |  |

|

Trouble Waterproofing RX8 - Similar Threads

Trouble Waterproofing RX8 - Similar Threads | ||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Is waterproofing a must? | AMG4ME | Axial Yeti | 5 | 10-31-2015 01:25 PM |

| waterproofing | rgf27 | Newbie General | 13 | 04-10-2011 11:57 PM |

| waterproofing help | 4x4wheelier | General Crawlers | 1 | 12-24-2008 09:34 AM |

| Waterproofing!!! | suspekAE | Newbie General | 7 | 08-13-2007 10:05 PM |

| Waterproofing?? | Stallion1967 | Newbie General | 5 | 10-17-2006 09:45 PM |

| |