| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Rock Crawler Join Date: Feb 2006 Location: Where the foams are always wet

Posts: 878

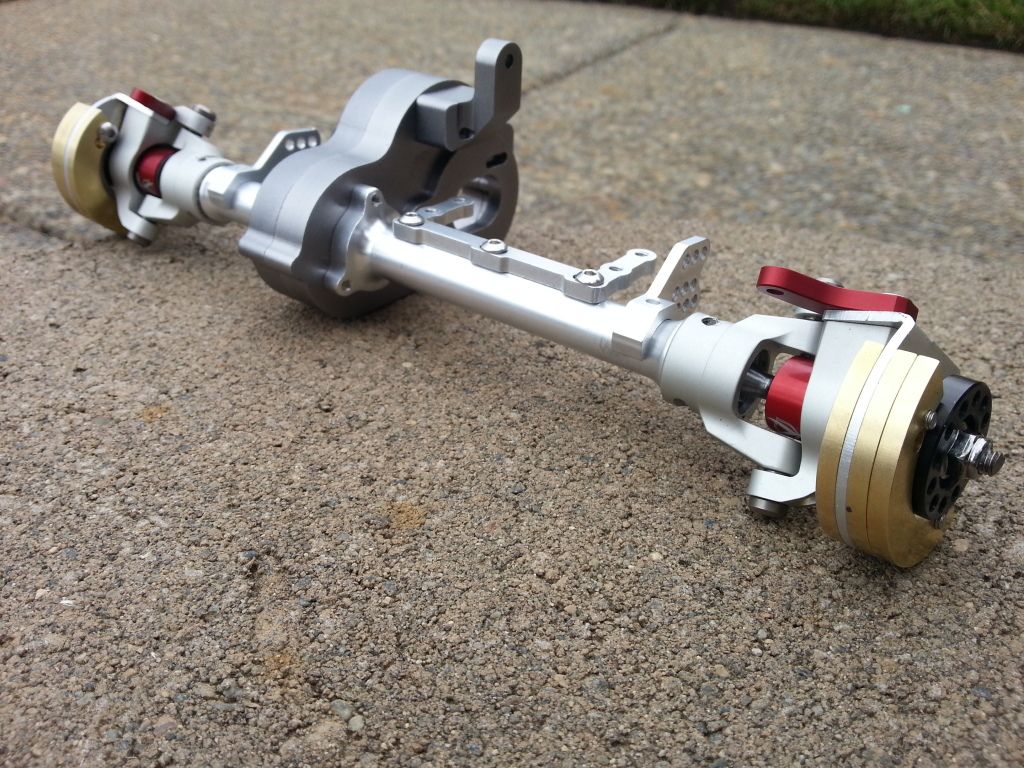

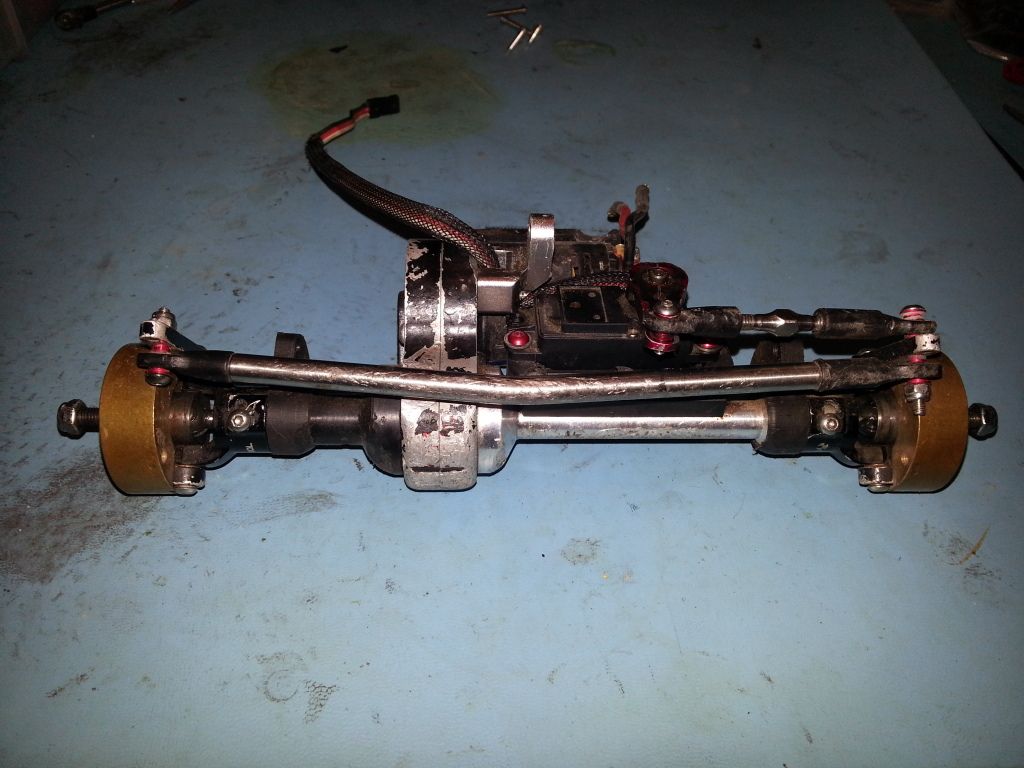

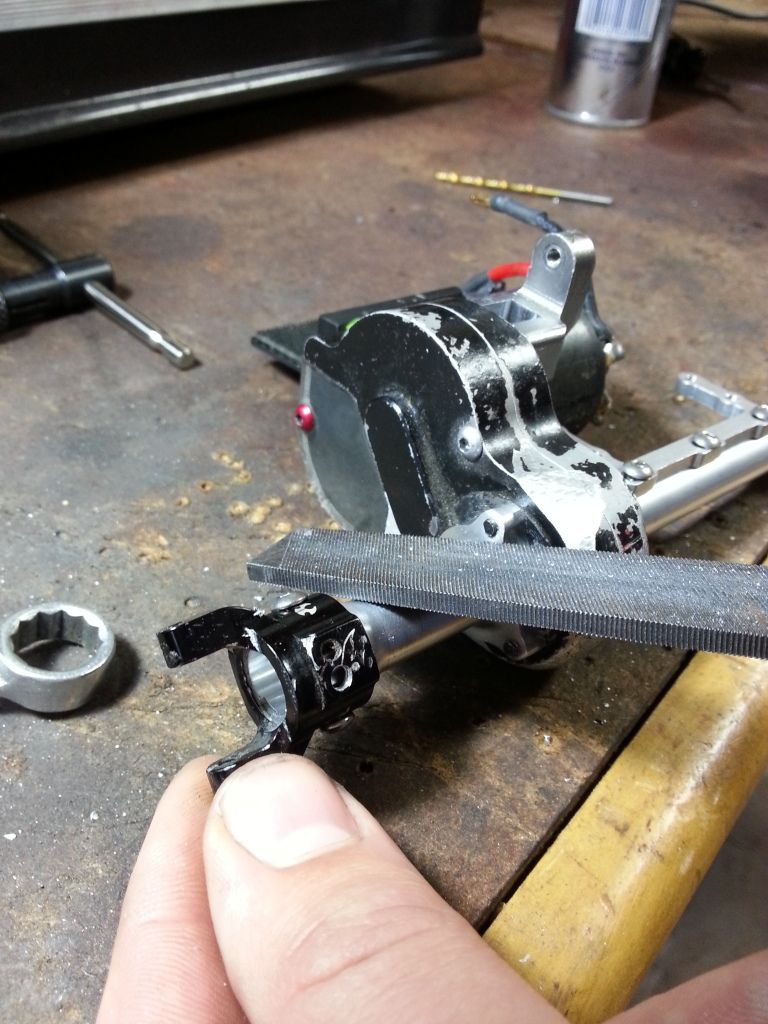

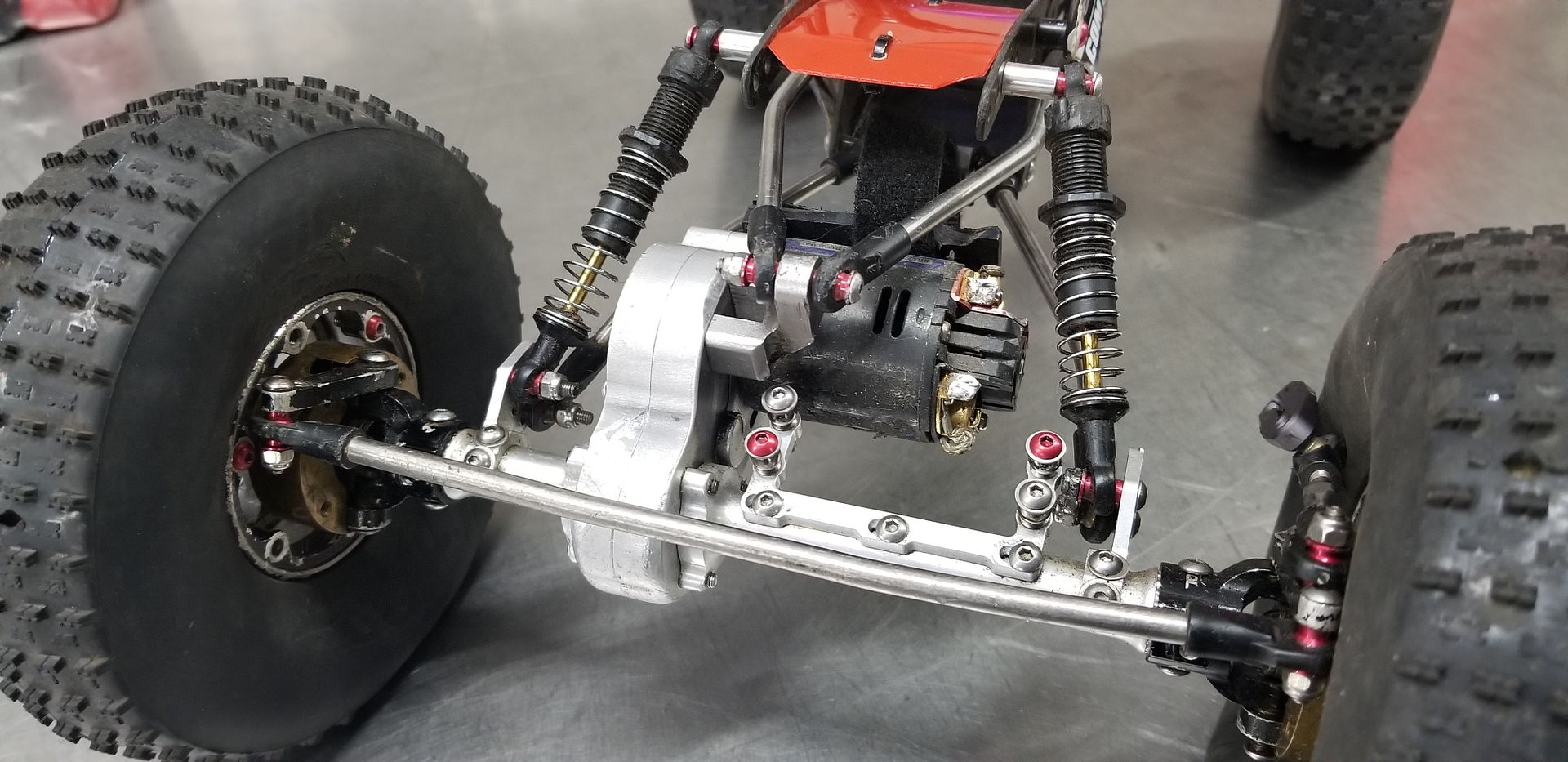

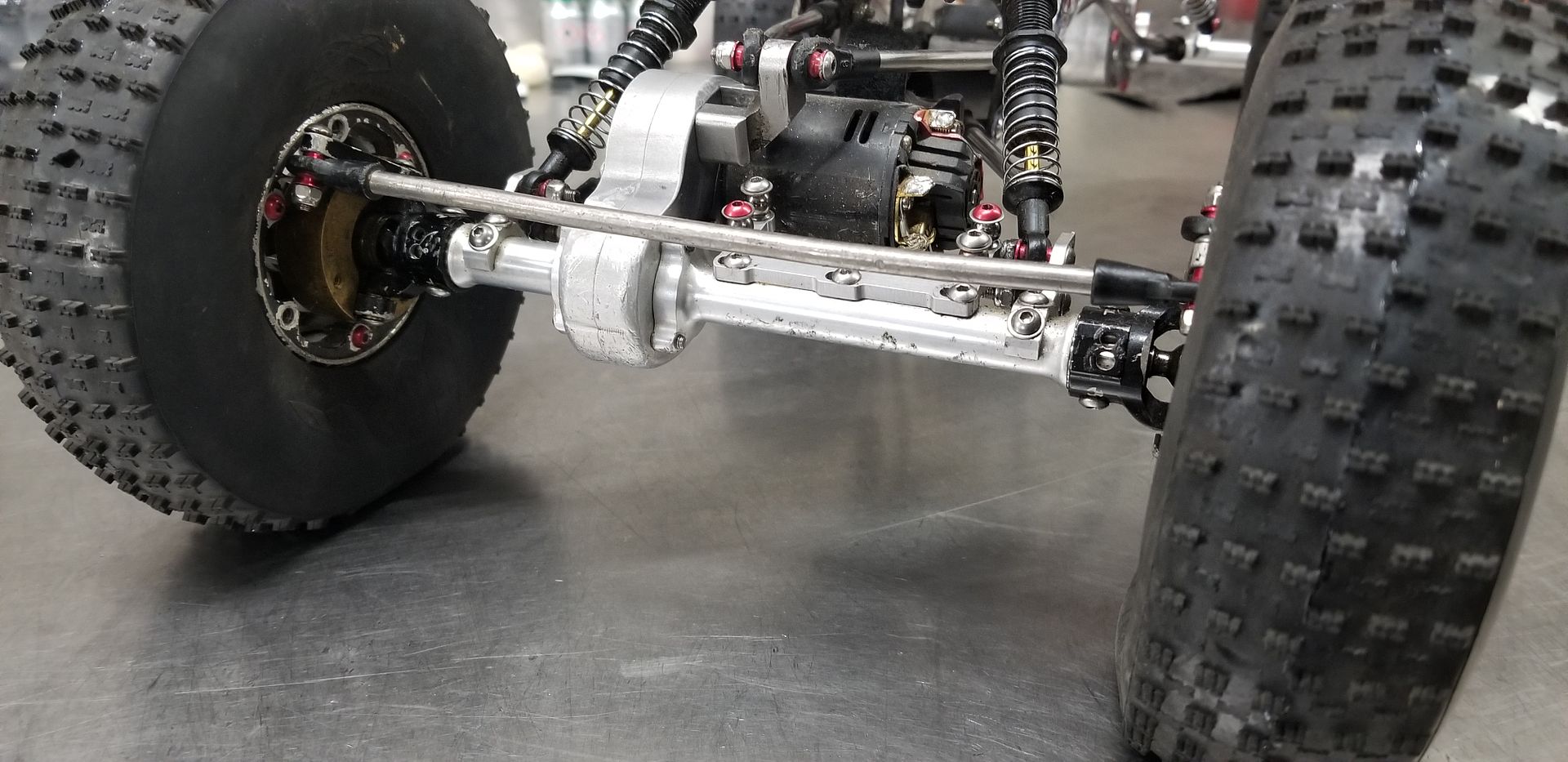

|  First off a huge thanks to Will at RcBro's for making these VERY WELL designed tubes! Our friend Jason needed to fix his front axle and Will came to the rescue on Sunday and got us these hot off the press. Here is a step by step on how we installed them... Step #1 Stay hydrated during these warm spring weekends  Step #2 Remove front axle and old worn out axle tubes   Step #3 Admire the pretty new light weight tubes! (notice the scribe marks for alignment)    Step #4 Mount tubes onto gear box with the notch on the end facing verticle  Step #5 (skip this step if using splined axle C's) dremel out C's to 0.550"   Step #6 Align C's to desired position   Step #7 Drill and tap C's onto tubes (I use a 3/32" drill bit and 3mmx0.5 tap with plenty of lube!)   Step #8 Throw food on the grill to keep from starving!  Step #9 Align link mounts to desired position. Notice the marks on the mounts are for 10 degree increments. We decided on a 20 degree clock for the gearbox.  Step #10 Drill 3/32" hole through top of mount into tube. Be very careful drilling this hole, and use a drill press if possible!  Step #11 Tap tube with 3x0.5 tap then file off the ridge the threads made on the tube. Again, use lots of lube!   Step #12 I forgot to take a picture of this step, but drill the link mount hole out to 1/8" so it get's clamped onto the tube when tightened down. Be sure to file off the ridge on the inner face of the mount after drilling the hole! Step #13 Drill another 3/32" hole in the front of the mount and tap both the mount and tube together. And of course, lots of lube!    Step #14 Admire your work so far, and flip the steaks!   Step #15 Install axles and knuckles. (we had to add a washer to the link mount screws to clear the OG super 300's)  Step #16 Install axle back onto truck and live happily not having to worry about C's coming loose!  Thanks for viewing! TOM & Jason |

| |  |

| Sponsored Links | |

| | #2 |

| RcBros Hobbies  Join Date: Nov 2005 Location: Oregon

Posts: 4,646

|

Nice work guys! Steak is making me hungy!

|

| |  |

| | #3 |

| Try to Bend it  Join Date: Aug 2009 Location: Perth Australia

Posts: 3,163

|

With bits like this and your gears I could just about be convinced to turned  Last edited by Highlucks; 05-14-2013 at 05:23 AM. |

| |  |

| | #4 |

| RCC Addict Join Date: Dec 2007 Location: Rochester Hills

Posts: 1,773

| |

| |  |

| | #5 |

| I wanna be Dave Join Date: Dec 2008 Location: ?

Posts: 5,055

| |

| |  |

| | #6 |

| Rock Crawler Join Date: Feb 2006 Location: Where the foams are always wet

Posts: 878

|

Almost forgot! 1,000 cool points for anyone who can name the brand of BBQ that isn't getting used in the picture! TOM |

| |  |

| | #7 |

| I wanna be Dave Join Date: Dec 2008 Location: ?

Posts: 5,055

| |

| |  |

| | #8 |

| RCC Addict Join Date: Nov 2004 Location: union

Posts: 1,657

| |

| |  |

| | #9 |

| Quarry Creeper Join Date: Jul 2009 Location: Woodburn, Oregon

Posts: 358

|

Great write up and now I have to get my hands on some tubes. Again thanks for the write up  |

| |  |

| | #10 |

| RcBros Hobbies  Join Date: Nov 2005 Location: Oregon

Posts: 4,646

|

So what kind of BBQ is it? Lol They are coming to a door near you!  |

| |  |

| | #11 |

| Rock Crawler Join Date: Feb 2006 Location: Where the foams are always wet

Posts: 878

| |

| |  |

| | #12 |

| Rock Stacker  Join Date: Dec 2011 Location: canada

Posts: 85

|

just wondering what knuckles u used ? the axial high steer?

|

| |  |

| | #13 |

| Rock Stacker Join Date: Mar 2012 Location: usa baby

Posts: 94

|

I was wondering how u got you servo to fit I'm using Holmes hobbies torque master and a hirec 7950 and the pinion will not mesh with servo mounted and this is with 11 tooth pinion

|

| |  |

| | #14 |

| I wanna be Dave Join Date: Jan 2008 Location: Arat Alabama

Posts: 2,678

| Is this with a stock(unmodded) gearbox? With the servo between the axle and motor the motor mount area has to be modded a bit to relocate the motor. There is several ways to do it.

|

| |  |

| | #15 |

| I wanna be Dave Join Date: Oct 2007 Location: Houston

Posts: 3,761

|

The grill looks sweet does it have a garage style door?

|

| |  |

| | #16 |

| Rock Stacker Join Date: Mar 2012 Location: usa baby

Posts: 94

|

Do u add another gear in the box or how u do it this is my first moa build and ain't a 100% sure on how to do it I've built a lot of other stuff tho

|

| |  |

| | #17 |

| I wanna be Dave Join Date: Jan 2008 Location: Arat Alabama

Posts: 2,678

|

Been hunting some pics! Here is your problem. The servo pushes the motor back. You'll need to do a little grinding and drilling to get the motor move upward to the gear. If you have the time and a few bucks a vendor like ErikDlux may do the mod for you and make it look good. Search for "86jeep" in the berg section. He pretty much was the first to do this servo location.  Here is what you would wind up with. It moves the motor back up to the gear.  |

| |  |

| | #18 | ||

| Rock Crawler Join Date: Feb 2006 Location: Where the foams are always wet

Posts: 878

| They are VP highsteer zero ack knuckles for axial axles. Quote:

Quote:

Yeah it's an aluminum garage style door, and the hopper for the pellets is behind the door. It's totally OG! | ||

| |  |

| | #19 |

| Rock Stacker Join Date: Mar 2012 Location: usa baby

Posts: 94

|

Hay I appreciate the help I got mine straightened out

|

| |  |

| | #20 |

| Rock Crawler Join Date: Feb 2006 Location: Where the foams are always wet

Posts: 878

|

Just wanted to take the opportunity to update these tubes that were installed during this write-up... They are still holding up great! Not a single stripped hole!!! Servo mount is just as tight as it was when new!   http://imgur.com/gallery/merj1cA http://imgur.com/gallery/WmObY3W Last edited by sourdojack; 10-17-2019 at 07:06 PM. |

| |  |

|

| Thread Tools | |

| Display Modes | |

| |