| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Pebble Pounder Join Date: Nov 2008 Location: Near Saddleworth and Pennines, North West UK

Posts: 105

|

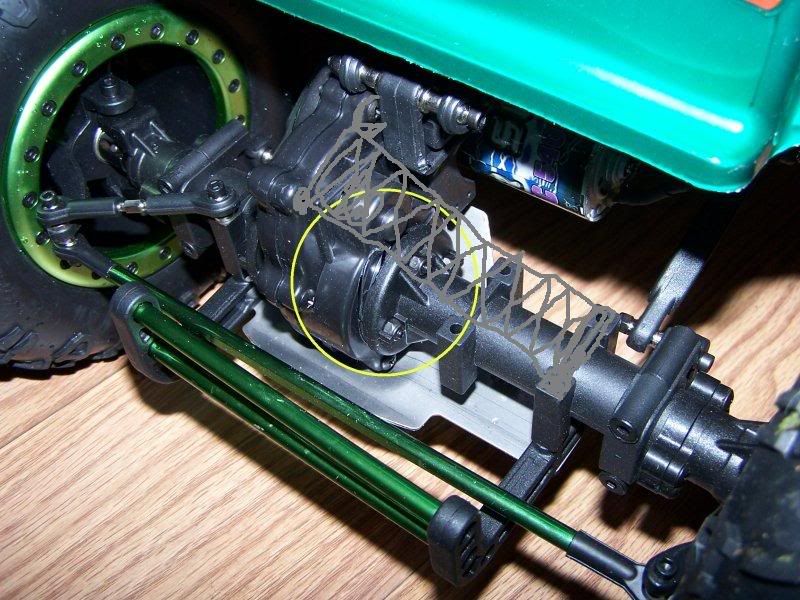

Hi, I am new to crawling and am loving it... I have bought a HSP 1/8th Jeep Crawler.  So far its been brilliant, could do with softening the tyres by star cutting the foam. While out making a short video in the garden, I got a little stuck and there was a cracking noise from the rear wheels. On close inspection have seen that where the axle fastens to the gearbox, the plastic has broke.  The more I try to use it, the worse it seems to be getting. Does anyone here have any ideas how I can fix this permanantly? Struggling to find spare for this model... Thanks in advance, Drew |

| |  |

| Sponsored Links | |

| | #2 |

| RCC Addict Join Date: Dec 2005 Location: Tucson

Posts: 1,190

|

Ouch that not going to be easy. Get rid of those axle and use Clod axle there cheap and have aftermarket support.

Last edited by Flyin Hawaiian; 12-02-2008 at 10:27 PM. |

| |  |

| | #3 |

| MODERHATER™  Join Date: Nov 2005 Location: Colorado

Posts: 10,939

|

Looks like when they copied the clod axles they forgot the most important thing, the axle braces. I'm sure if you contact the manufacture direct they will take care of you! |

| |  |

| | #4 |

| Rock Crawler Join Date: Jun 2007 Location: Great Britain

Posts: 935

|

I think it really needs a new case but you might be able to weld it bak together with a soldering iron.

|

| |  |

| | #5 |

| RCC Addict Join Date: Apr 2006 Location: Home of the ORIGINAL Terminator chassis

Posts: 1,252

|

You could try plasti-weld, but I really don't think it will work as that's a stressed area. If there's room, you may be able to put a washer inside the case drilled for the screws to run through. That would work as long as theres enough or the case left undamaged for it to fit. Your best set is a replacement gearcase half though. |

| |  |

| | #6 |

| I wanna be Dave Join Date: Dec 2006 Location: here

Posts: 3,042

|

Alright crappy pic make a brace like in pic out of alum. if you cant use top screw use the 2 front just an idea  once every thing (Crack) is back closed tight use silacone top keep dirt out. good luck. is this truck I seen on e-bay for like 240.00 once every thing (Crack) is back closed tight use silacone top keep dirt out. good luck. is this truck I seen on e-bay for like 240.00 |

| |  |

| | #7 | |||||

| Pebble Pounder Join Date: Nov 2008 Location: Near Saddleworth and Pennines, North West UK

Posts: 105

| Quote:

I have looked at the Clod axles and gearbox - not sure it would be wide enough. I have ordered the Clod gearbox B parts, to see if I can use them. Quote:

Quote:

Quote:

Quote:

Have thought about swapping the axles around, then put a brace on as you suggest. The front is fine, but does have the servo mount, which may add support. There is a piece of plastic missing now, its away from the screws, so will strip it down tomorrow. Thanks for the replies and ideas - you guys rock.  Will post some pictures of it stripped down. | |||||

| |  |

| | #8 |

| Pebble Pounder Join Date: Nov 2008 Location: Near Saddleworth and Pennines, North West UK

Posts: 105

|

Hi, Thanks for all the replies, I did try to respond to all at once, but the post does seem have been applied. Thanks for all the suggestions and ideas. I really like this crawler and want to get it sorted. I like the idea of the brace, but would have thought the diff protector would have done a job of stopping stress flex.  Will be sending an email to the manufacturer, if I can find the address... I may swap the axles around for now, as the front is still fine. Have ordered a Clod gearbox B kit, presume is the 2 halves. Do you think this would fit and allow the use of the rest of the axle to keep the width? Thanks again, excellent responses. Drew |

| |  |

| | #9 |

| RCC Addict Join Date: Apr 2006 Location: Home of the ORIGINAL Terminator chassis

Posts: 1,252

|

If the Clodbuster gearbox halves fit up and allows the internal gears to install correctly, go buy a lottery ticket right away. I can't see the Clodbuster gearbox design being identical to these.

|

| |  |

| | #10 | |

| Pebble Pounder Join Date: Nov 2008 Location: Near Saddleworth and Pennines, North West UK

Posts: 105

| Quote:

Whats the width of the clodbuster axles? Do you think this cracked because of flex? | |

| |  |

| | #11 |

| Pebble Pounder Join Date: Nov 2008 Location: Near Saddleworth and Pennines, North West UK

Posts: 105

|

Besides buying new axles from something else - the G-made Spider look really good... comments? And are the 1/8th scale. But are expensive, for a bit more, I could buy another Jeep, and use this one for spares. I will be looking in to adding a steel brace between the gearbox and axle as suggested above. Thanks Tapped-Out Cheers, Drew |

| |  |

| | #12 | |

| I wanna be Dave Join Date: Oct 2006 Location: Martinsburg WV

Posts: 2,781

|

Ouch!!! Blew the case wide open! That's from getting "a little stuck"?? Quote:

JB Weld the case back together, and make some braces, stock Clod style. Looks like there's lots of options for mounting them... Last edited by Big Mike; 12-01-2008 at 07:27 AM. | |

| |  |

| | #13 |

| Pebble Pounder Join Date: Nov 2008 Location: Near Saddleworth and Pennines, North West UK

Posts: 105

|

Just wanted to post that I have managed to effect a repair to this fab crawler.    I filled most of the empty space inside the cover with hot glue, so there are no dimples now, as can be seen in the first picture. Then ran some around the outside the re-enforce it, and to cover 2 cracks. The glue is fairly rubbery when dry, so should help to stop it cracking again. Had a test around my garden course - and it performed beautifully...  Also had a call from the supplier, they are going to send me the gearbox covers, but are waiting for them to arrive as the model is still fairly new... fantastic... Thanks for all the help here - love crawling... Cheers, Drew |

| |  |

| | #14 |

| RCC Addict Join Date: Apr 2006 Location: Home of the ORIGINAL Terminator chassis

Posts: 1,252

|

I'm glad the supplier got back to you. Many times you're out of luck with these. Looking at your last photo showing the inside of the gearcase, the anodized bracing they used around the motor mount is exactly what should have been used around the area that the axle tube mounts. That would have helped to prevent this damage from happening in lieu of using the external brace, which would be the best way to go. |

| |  |

| | #15 | |

| Pebble Pounder Join Date: Nov 2008 Location: Near Saddleworth and Pennines, North West UK

Posts: 105

| Quote:

The parts are on their way, had a call from the supplier... should be here in a couple of days. I agree, the internal brace for the motor is good and they should have put something similar where it broke. Will look at making something for the new cover, there is plenty of space for a washer type insert. Where should the external brace run from? the rear servo mount to the gearbox, or all the way across? I have looked at clod braces etc and they seem to have metal plates the length of the axle tube (each side), but dont appear to connect to the gearbox case. Its the same on the Gmade Spider.... Thanks for your help. Drew | |

| |  |

| | #16 | |

| RCC Addict Join Date: Dec 2005 Location: Tucson

Posts: 1,190

| Quote:

No i meant to buy complete clod axles. not just use the tubes. | |

| |  |

| | #17 | |

| Pebble Pounder Join Date: Nov 2008 Location: Near Saddleworth and Pennines, North West UK

Posts: 105

| Quote:

I have a replacement casing on the way now, so will look at re-enforcing between the axle tubes and gearbox casing. Probably going put something inside the gearbox, similar to the motor mount. Then add a support between gearbox and servo mount, as per an earlier reply. Thanks, Drew | |

| |  |

| | #18 |

| Newbie Join Date: Dec 2008 Location: England

Posts: 1

|

Hi All I got my truck last week and it came with a damaged diff case .Got back in touch with supplier and they are sending new part out to me. After a search found this http://www3.towerhobbies.com/cgi-bin...?&I=LXWHU5&P=7 then searched intergy website and found this http://www.integy.com/cgi-bin/webc.c...=4796&p_catid= . Ive sent a email to see if this can be used on the rtr When i get a reply i will let you all know |

| |  |

| | #19 | |

| Pebble Pounder Join Date: Nov 2008 Location: Near Saddleworth and Pennines, North West UK

Posts: 105

| Quote:

There will be at least 2 suppliers here in the UK, who will be carrying a stock of spares for this crawler. The standard gearbox is £17.49 (dont think it includes the gears), for comparison to the integy. Thanks, Drew | |

| |  |

| | #20 |

| Newbie Join Date: Oct 2008 Location: Scotland

Posts: 19

|

Following this thread with interest as mines is still in its box in fromt me and wont be available till xmas! Can you tell me who you got yours from as my supplier reckons he's not going to stock them? Heres the website for the manufacturer: http://www.hispeedmodel.com/index.asp They have some alloy upgrades that I want to get pretty soon. I think some proactive work will be done to mine in this are before it gets out of the house, the skid plats is quite thin, does yours show any signs of buckling there? I like the idea of a brace and as its built for 4WS, the servo mounting plate may as well carry on across and up on to the housing, perhaps with slightly heavier metal than just to mount the servo. Given that both front and rear are identical, it may be worth it to do both ends at the same time? Your pics also answered a question I had, as to whether the pinion could be changed easily enough? It looks like its pretty straight forward, so Im planning on switching the 27T motors for 35T. How did you find the performance of the lower 'bent' links? They sag a fair bit, I was thinking of fitting them with a broad delrin washer, or a spring arrangement before I tried making new metal ones with a flatter working surface at the ends, perhaps taking a bearing. Nice rig though buddy! |

| |  |

|

LinkBacks (?)

LinkBacks (?)

LinkBack to this Thread: http://www.rccrawler.com/forum/general-crawlers/146853-hsp-1-8th-scale-crawler-gearbox-cracked.html | ||||

| Posted By | For | Type | Date | |

| HSP CJ Jeep Rock Crawler | This thread | Refback | 10-04-2011 04:21 PM | |

| |