| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Rock Stacker Join Date: Apr 2008 Location: Bayonne

Posts: 85

|

Hi all, I've been buying most my chassis, but now I'm interested in making one. I'm at this point where I have an idea in my head, and have the ideas to execute it, but I'm probably buying of more than I can chew. I saw bully axles selling rather cheap so I figured why not. Then I looked at my current stuff and what I was building and I'm thinking I don't need to make another crawler-ish/buggy. This is where the whackadoodle that is my mind comes in. Bully's are moa - so that gives me more freedom in the body. So I figured I'd make pirate ship on wheels. Think a less pretty version of http://www.amazon.com/One-Piece-Thou.../dp/B005JABN8Y with a 4-link, and front and rear steering. Flotation not necessary Of course I wanted aluminum for strength, and got some 1/8 sheets and a 3 inch wide 'U' channel (also 1/ I spent 15 minutes hacking away with my grinder before calling it quits. I guess 1/8 is to much for me. I can do thinner but I don't want to compromise strength too much. How thick should I go? This caught me off guard too because I've cut 1/8 thick panels before though the aluminum then was rather soft by comparison (previously a computer case). The panels I am having difficulty with are 6061. Should I try a different grade of aluminum? |

| |  |

| Sponsored Links | |

| | #2 |

| Suck it up!  Join Date: Mar 2008 Location: Arkansas

Posts: 11,652

|

6061 is good stuff and used commonly around here for quality parts. Its harder and stronger than the gummy hardware store variety. It is also a bit brittle and will snap when you bend it. You also don't want to use a grinder on aluminum, it doesn't work very well and clogs up the disk. Use a saw. |

| |  |

| | #3 |

| I wanna be Dave Join Date: May 2007 Location: Fairfield ME

Posts: 3,886

|

What the hell kind of computer has an 1/8" thick case?

|

| |  |

| | #4 |

| Rock Stacker Join Date: Apr 2008 Location: Bayonne

Posts: 85

|

Thanks for the info. Is there an aluminum alloy that bends and won't break too easily? I'm probably exaggerating the thickness of the case, though the rolled edges were at least 1/8. This was back when I spent more money on custom computer builds. That said, the aluminum used there is soft in comparison to the stuff I got from McMaster. Sent from my LGMS500 using Tapatalk |

| |  |

| | #5 |

| I wanna be Dave Join Date: Oct 2004 Location: QC-AZ

Posts: 2,352

|

I've successfully bent 7075, 6061 and 5052 with less than ideal tooling. The higher alloys just require a larger radius to keep from cracking. Proper tooling is critical though once the bending tonnage starts adding up. This is a good place to learn about the forces involved... Bend Force Calculator For your first bent chassis I would think a good starting point would be .090" 5052-H32 |

| |  |

| | #6 |

| Web Wheeling  Join Date: Jan 2005 Location: Twin Cities

Posts: 3,004

|

You can do quite a bit of work on aluminum using a hacksaw, a good set of sharp hand files, and a drill.

|

| |  |

| | #7 | |

| Rock Crawler Join Date: Apr 2009 Location: NE Ohio

Posts: 794

| Quote:

I'll second the 5052 to start with, its prob one of the most forgiving aluminums you can work with while forming. It will be less pricey than 6061 or 7075 and is readily available from most metal retailers. Checkout onlinemetals if you can't source it locally they stock multiple sizes and I believe they have .090 if not then .080 for sure. --Dan | |

| |  |

| | #8 |

| Rock Stacker Join Date: Apr 2008 Location: Bayonne

Posts: 85

|

Rob, E type and Stick civic, thanks very much for the suggestions. I'll have to check that alloy out. I've cut the softer aluminum with my scroll saw, and was just testing it with half inch delrin for another project. Only "danger" is last time the aluminum caught on the blade, so my hands went up and down like a jackhammer, slamming my knuckles on the table repeatedly. Not really dangerous, but annoying Sent from my LGMS500 using Tapatalk |

| |  |

| | #9 |

| I wanna be Dave Join Date: Oct 2004 Location: QC-AZ

Posts: 2,352

|

Check into cutting fluids too. A-9 has worked well for me.

|

| |  |

| | #10 |

| I wanna be Dave Join Date: Sep 2011 Location: Douglassville, PA

Posts: 4,224

|

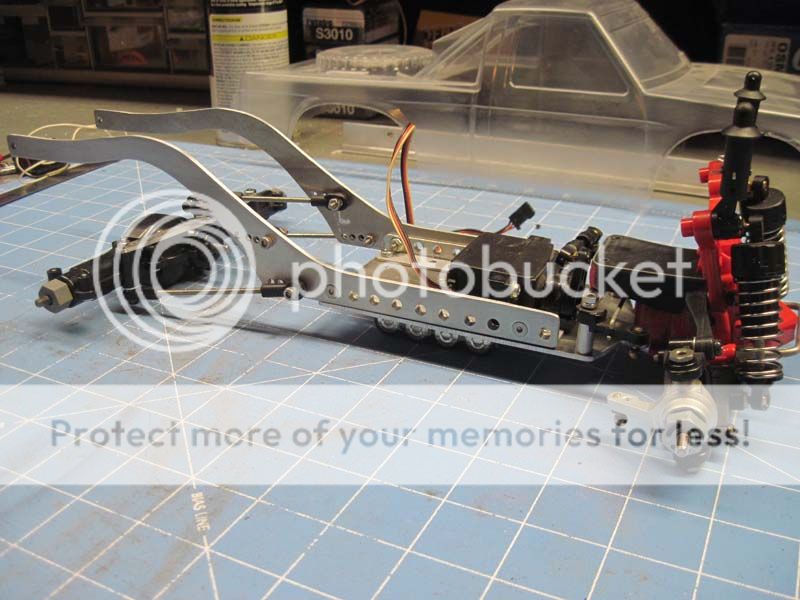

Do mine with a jigsaw and a set of files. Have made all kinds of chassis. 2 examples below. I generally use 2mm 6061 with very good results, though I've used 1.5 and 3mm as well depending on the application. Have found that 2mm thick is good for most builds as long as it is properly braced. It's very easy when you have a plan. Whipped one out start to finish in about 90 minutes last night. Couple of tips to help out: Draw up a plan...template it on cardboard to test if you like before cutting anything - much easier to change on paper than metal. I use graph paper to do an original design, then trace it with a second sheet to have 2 copies. For this one, I was laying out the components to make sure it all fit with no issues, as well as determine mount points.  I tape the 2 copies to my aluminum, and scribe the lines with an old exacto blade. I used to just draw them on but they would get smeared around when cutting. Scribed lines are much easier to see.  I then get busy with the jigsaw. Handheld saw, use plain old WD40 for lube, and a narrow blade as it makes it easier to get around corners and curves. Usually use a fine wood blade - cuts quick and is generally a thinner blade than standard metal ones. Clamp the sides together, and drill your holes. This is a must! Drill press or handheld drill - doesn't matter, but you want all your holes square and even to each other. What I do now is start with a clamp, drill 2 holes and then use a bolt and nut to keep them from moving around. Then drill the rest of the holes. Found sometimes the aluminum can shift under the clamps.  I use files to clean up the edges. Keep the chassis bolted together to keep it square. Belt sander works well here too.  Those are the basics... end result after a bit more work:   Few more examples:     Hope this helps!! Very easy once you get the hang of it. Last edited by OSRC; 06-25-2014 at 07:44 AM. |

| |  |

| | #11 |

| Rock Stacker Join Date: Apr 2008 Location: Bayonne

Posts: 85

|

Amazing work. thanks for the info Rob and OSRC. Wish I still had a drill press, but I had to chuck mine when I burnt out the motor boring wheel wells in a wooden toy. I may try working with delrin. The scroll saw cuts half inch pretty easy (had a little lying around). Would delrin handle impact better than .09" 5052 aluminum? |

| |  |

|

Aluminum thickness - strength vs durability - Similar Threads

Aluminum thickness - strength vs durability - Similar Threads | ||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| RC4WD T-Rex 60 Axle Durability and Strength | fallensk8man89 | 1.9 Scale Rigs | 5 | 05-16-2014 04:12 PM |

| Aluminum Hardware Durability | mrG | General Crawlers | 9 | 12-22-2012 04:39 PM |

| Help! Aluminum chassis thickness ? | juswin24 | General Crawlers | 3 | 01-20-2012 07:02 PM |

| |