| | #21 |

| PapaGriz Yo  Join Date: Apr 2004 Location: In the garage building the wife a crawler

Posts: 13,137

| Yup. The system can be made to multiply force through different size cylinders and such but all that aside...the harder you can push on the master cylinder the more force there will be at the wheels.

|

| |  |

| Sponsored Links | |

| | #22 |

| Quarry Creeper Join Date: Jan 2007 Location: Ontario, Canada

Posts: 341

|

I dont see any mechanical advantage happening here. The servo moves the same amount it always has and the trucks steers they same amount it always has. I realize that the master cylinders have a smaller diameter than the slave cylinder but they are also longer, when you go to rig the masters to your servo you are going to have to use a longer servo horn then you would have to use on the axle and lose the advantage right there. The only way to gain any performance here is to mod the servo for more rotation then it has now, it will make the steering slower then normal but you will have more torque. |

| |  |

| | #23 |

| Quarry Creeper Join Date: Jun 2007 Location: Torrance, CA.

Posts: 282

| I agree with what you are saying. If the throw is one to one there will be no gain or loss (theoretically) in torque. But for scale purposes I think it is a great idea. If he did want to multiply the torque of the servo the master cylinders would have to have a longer throw and move much less volume per an inch of throw than the slave on the axle. He could also uncomplicate things by making a master cylinder that is similar to the slave, doing away with the two masters. Last edited by _BEN_; 08-10-2007 at 12:15 PM. |

| |  |

| | #24 | |

| Rock Crawler Join Date: Feb 2007 Location: Ramstein Air Base Germany ...ya Ive been Ramshafted

Posts: 567

| Quote:

Ya I should have posted pics of the links also, I have that done as well but for some reason did the video without it conected | |

| |  |

| | #25 |

| Winner of the '07 RCC dumbass award! Join Date: Nov 2006 Location: Up on a Mountain, out in the Woods

Posts: 661

|

Does not look like much mechanical advantage.... Its cool, but HOW MUCH POWER??? |

| |  |

| | #26 |

| I wanna be Dave Join Date: Dec 2005 Location: between heaven and hell.

Posts: 3,367

|

Verry nice set up. how do/did you determine the lenght of each part to get the correct amout of pressure to give the adiquate amount of throw. Is there any mathmatical equations other that the amount of force that you posted. If I used a shorter, fatter tube for the Master you wouldn't need as much throw on the servo correct, but still be able to produce enough power for full steering. Now how do I do the math to figure out what size master cylindar I have to make to produce enough force with the amount of throw a servo has? Hope that made sense? |

| |  |

| | #27 |

| Rock Crawler Join Date: Jun 2007 Location: Flint/Mt. Morris

Posts: 570

|

I think he means the extra stroke of the master cyliners act as a preload or extra push at full lock. Anyways that is a great Idea. The set up he has there wouldnt cost that much but the engineering and the tuning might be tedious and I dont think there is much more gain from it. Also did someone delete a bunch of posts because it seems as if your talking to yourself lol.

|

| |  |

| | #28 |

| Rock Crawler Join Date: Jun 2007 Location: Flint/Mt. Morris

Posts: 570

|

I was wondering the same thing. I think the main thing would be how much fluid in them. Like Have atleast even amounts. But I think having the masters hold a bit more might give that mechanical advantage back.

|

| |  |

| | #29 |

| I wanna be Dave Join Date: Dec 2005 Location: between heaven and hell.

Posts: 3,367

| |

| |  |

| | #30 | |

| RCC Addict Join Date: May 2006 Location: In England, looking for the threadlock...

Posts: 1,150

| Quote:

I don't think CCFBERG was looking for a mechanical advantage from his Hydraulic steering, he did it for the same reason I got into crawling: To prove that he could. I for one, think it looks pretty damn trick! | |

| |  |

| | #31 |

| I wanna be Dave Join Date: Sep 2005 Location: USA

Posts: 11,196

|

Hook up four of those in place of Shocks... lol Looks hella Cool... How much power does that set up have? I really don't see the huge advantage really. You have to mount a servo, Cylinder, hose and what ever else. Depending on the Rig and the weight need to make it work. My guess the Bigger/Heavier the rig the more advantage it would have.. Keep this stuff coming.... I my 1/6th Scale Rig needs these Set up... I'll be talking with you about this very Soon. |

| |  |

| | #32 |

| Rock Crawler Join Date: Mar 2007 Location: Colorado

Posts: 635

|

Seriously amazing what you have achieved... any stats on the power compared to the servo? |

| |  |

| | #33 | |

| Quarry Creeper Join Date: May 2007 Location: melbourne, australia

Posts: 274

| Quote:

when are you going to start selling and how much because i would buy one right now | |

| |  |

| | #34 | |

| Rock Crawler Join Date: Feb 2007 Location: Ramstein Air Base Germany ...ya Ive been Ramshafted

Posts: 567

| Quote:

also yes you are right on master cyl would be more practical and is in work and will most likely be done tonight.  | |

| |  |

| | #35 |

| Rock Crawler Join Date: Feb 2007 Location: Ramstein Air Base Germany ...ya Ive been Ramshafted

Posts: 567

| |

| |  |

| | #36 |

| Rock Crawler Join Date: Feb 2007 Location: Ramstein Air Base Germany ...ya Ive been Ramshafted

Posts: 567

|

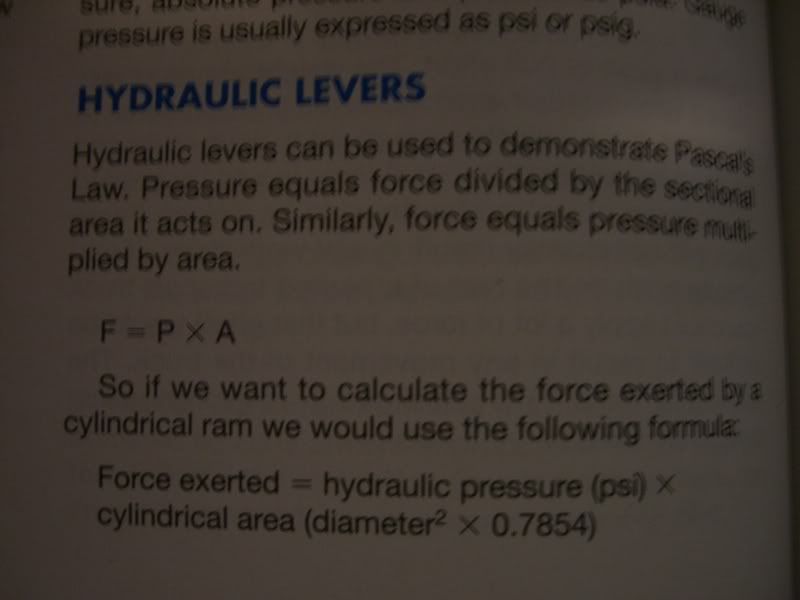

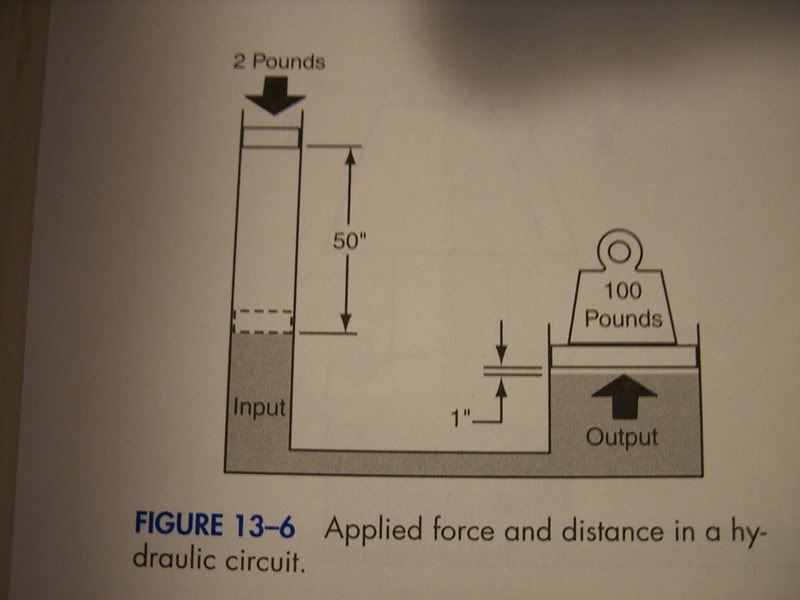

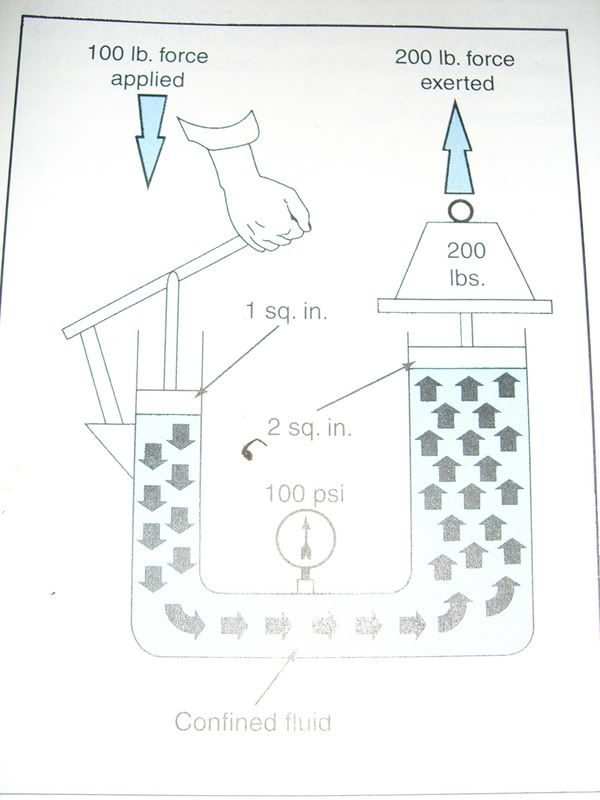

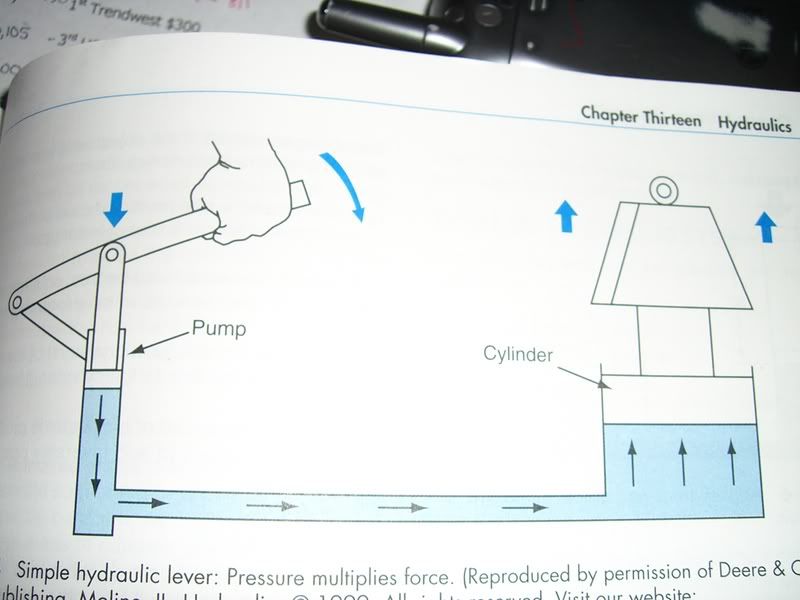

if we wanted to calculate the force exerted by a cylindrical ram (steering actuator) we would use the following formula: Force exerted (servo ) = hydraulic pressure (psi) x cylindrical area ( diameter squared x 0.7854) even simply put: 100 pounds of force on a 1 in piston produces 100 psi acting on a 2 in piston is 200 pounds of force applied to what you are trying to move ( like a steering knuckle) there for mechanical or hydraulic advantage! Also guys I did do this because I was told that it couldnt be done! At the same time I kept in mind the facts about the servo horn length and every other thing. I forget who it was that said it but someone said there would be much to gain from a better or properly set up system. ???? What isnt properly set up you saw the video right? It works correct! I posted this not for personal gain but to show all those people out there that it can be done and yes when the servo is set up correctly YOU WILL GAIN MECHANICAL ADVANTAGE! Its very simple read the equasion. Actualy hear is a pic strait from the hydraulics section of a book called Heavy Duty Truck Systems 4th Edition:     |

| |  |

| | #37 |

| Rock Crawler Join Date: Feb 2007 Location: Ramstein Air Base Germany ...ya Ive been Ramshafted

Posts: 567

|

So basicaly the servo I tested it with is rated at 148 inoz so just to keep it simple : 148 x 1 sq in piston (master cyl) = 148 x 2 sq in piston (slave) =296 inoz of linear motion. Whats a servo rated at 300 inoz cost now? about $250???? My way 20 bucks for the TLT shocks on ebay! or $40 if you include the fittings. You know both ways are correct and fine in my mind, I wont knock guys with servo's on thier axles and I wont say my way is the best way I just wanted to introduce something new that doesnt requir a pump or $800 (no disrespect Jason if you happen to read this)!!!! your **** is way cool and it inspired me to keep working on this months ago!!! But if you have the talent to do things other than type........tear it up in your shop and lets see it .......lets make this the coolest thing ever together.  |

| |  |

| | #38 | |

| RCC Addict Join Date: Jul 2006 Location: So Cal USA

Posts: 1,109

| Quote:

No need to explain man... I LIKE IT  Get it working, Id like to see how it turns out! ~John | |

| |  |

| | #39 |

| I wanna be Dave Join Date: Sep 2005 Location: USA

Posts: 11,196

|

A 300oz Plus servo costs about $115...For a Standard Size Servo.. A 1/4 Scale Servo with over 300oz is $30 bucks.....

|

| |  |

| | #40 | |

| I wanna be Dave Join Date: Dec 2005 Location: between heaven and hell.

Posts: 3,367

| Quote:

by the looks of the pics and with out doing any of the math. I'd need a smaller cylidar with a larger slave to create adiquate force. Lets say for space saving purposes, If I needed the master cylindar to be shorter, would it matter if it was "fatter"? It wouldn't work as correctly because the fatter the master the less amount of PSI it'd create?? becuase of the area.. OR could I simply adjust the hose or output of the master to creat the correct PSI?? I'm not trying to sound ignorant, just wanting to learn.  Thanks | |

| |  |

|

| |