| | #21 |

| Quarry Creeper Join Date: Sep 2010 Location: where ever I layed my hat.

Posts: 225

| |

| |  |

| Sponsored Links | |

| | #22 | |

| Quarry Creeper Join Date: Sep 2010 Location: where ever I layed my hat.

Posts: 225

| Quote:

The VP housings are absolutely sexy, hope they hold up to the abuse of this heavy be-yotch. It will obviously be no speed demon, but we all know torque can be very damaging. | |

| |  |

| | #23 |

| I wanna be Dave Join Date: Oct 2006 Location: Martinsburg WV

Posts: 2,781

| |

| |  |

| | #24 |

| Quarry Creeper Join Date: Sep 2010 Location: where ever I layed my hat.

Posts: 225

|

So the wheels are done along with all 116 screws in place. It is not near a state to roll, but still had to sit the Willy's down on the axles with the newly mounted tires and wheels.   Not VP disc, but they were not available when I bought them.  Last edited by snydercj7; 04-10-2012 at 03:54 PM. |

| |  |

| | #25 |

| RCP CRAWLERS  Join Date: Nov 2007 Location: Upland CA

Posts: 1,541

|

thats gonna be nice!

|

| |  |

| | #26 |

| Quarry Creeper Join Date: Sep 2010 Location: where ever I layed my hat.

Posts: 225

|

Thanks Dave, again you started this... VP 1/4" Titanium control arms arrived today.  |

| |  |

| | #27 |

| Quarry Creeper Join Date: Sep 2010 Location: where ever I layed my hat.

Posts: 225

|

An order of 21' 3/16" tube from MSC direct and a visit to the local welding supply.  So input on my bender. Should this be adequate or do I need to invest the time and money in one of those custom fancy benders some of you guys have built? |

| |  |

| | #28 |

| I wanna be Dave Join Date: May 2008 Location: Baltimore

Posts: 4,442

| That's the same type of bender that I use, it works pretty well. I did find that I needed to mark a 10mm offset on the scale of the bender to the left ( or in front of, if that makes sense) of the '0' so that when I would layout a reference mark on the tubing where I wanted a bend to begin, the outside dimension of my bends would line up correctly.

Last edited by BigSki; 04-15-2012 at 07:36 PM. |

| |  |

| | #29 | |

| Pebble Pounder Join Date: Nov 2010 Location: Northern NJ

Posts: 157

| Quote:

| |

| |  |

| | #30 | |||

| I wanna be Dave Join Date: Oct 2006 Location: Martinsburg WV

Posts: 2,781

| Quote:

Quote:

Quote:

My advice to someone just starting to try scale tubework - DO NOT try to make multiple bends in the same tube. ESPECIALLY if you have to make another two pieces left and right to match. I taught myself this lesson the hard way, by wasting enough brakeline with inaccurate multiple bends to probably build 2 or 3 more rollcages. Any one piece of tubing with mulitple bends should be divided into a section per bend and then pinned together and brazed into a single piece once you've "adjusted" the length of tubing inside each bend for fitment. 3/16" brakeline fits inside 1/4", and 1/8" solid rod fits inside 3/16" brakeline. A perfect example is the grill guard that pretty much all of us have made to go around the headlights and across the hood in front. I made left and right side upper and lower sections seperately, then pinned them all together with 1/8" rod and brazed them into a "single" piece with 4 bends. Once the joints are ground over and painted you cannot tell it's not a single piece, and because each piece is made alone and the dimensions between each has been precisely adjusted, it is perfectly symetrical. A pair of rock sliders for the sides is another good example. It's very difficult to A) make two bends in one tube that are an exact distance apart from each other and then B) do it AGAIN in mirror-image to have two matching left and right sliders. Instead make each of them in two pieces. You can grind or cut the inside ends to make them the exact length they need to be, then pin them together, jig them flat on a piece of steel plate, and braze the joint. If you can imagine what I'm trying to describe and make it work for you, instead of trying to make marks on tubes and line them up in the bender (while at the same time keeping the previous bend(s) lined up on the right plane so your piece is either flat or follows the contour of where it is going to be) you will waste so much less material than I did while I was learning... Last edited by Big Mike; 04-16-2012 at 07:19 AM. | |||

| |  |

| | #31 |

| Quarry Creeper Join Date: Jul 2011 Location: olympia

Posts: 435

|

i scabbed together some cool bike frames with the same methods in highschool welding classes  |

| |  |

| | #32 |

| Quarry Creeper Join Date: Sep 2010 Location: where ever I layed my hat.

Posts: 225

|

Wow, lots of good info. I am totally picking up what you guys are throwing down. I ordered 3 sticks of material because I figured there would be some f-ups. I have a little experience with 1:1 bending. I will just have to practice and see what works. I would like to make a bender, we shall see how the main and front hoops go. Thanks again for the great info every one.

|

| |  |

| | #33 |

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

|

I've helped a lot of people power very similar rigs. Quite a few with the GI Joe body too. The one thing that you will really need is torque because of the heavy weight. Your final rig weight will be between 15 and 20 pounds I bet. You can get the torque from big geardown, or from a big motor. If you want to go super slow all the time a brushed setup would work well. FXR and 35t Handwound would give good pep on 3s without being too destructive. You won't have a lot of power, but torque will be usable at 35:1 geardown. If you plan to wheel the rig a lot, a sensored brushless setup will avoid frequent teardowns to access the motor. Something like a 17.5 or 13.5 Redline motor will have decent grunt if you can manage at least 35:1 total reduction, I would recommend closer to 50:1 because of the rig weight and small rotor diameter of the ROAR style inrunners. My next choice if you want more speed and power would be a Tekin 4 pole motor. The slowest they offer is 3300kv right now, so you will need lots of reduction for slow speeds. 50:1 would be a good starting point IMO, or else run on 2s lipo. My final recommendation for something high torque is a Revolver 540 or TorqueMonster motor. We don't have them fully in production yet, but you don't seem to be in a huge rush either. You won't need more than 35:1 geardown but the torque will be the highest of all choices. Plenty of ways to power it! I've had the same body for about 5 years now just waiting for some free time to build up a model around it. Love it! |

| |  |

| | #34 |

| Quarry Creeper Join Date: Sep 2010 Location: where ever I layed my hat.

Posts: 225

|

So better late then never? Maybe... Did not really pay attention to what my ratio's were in the drive train and just started going deep every where. We are talking gears here gents.. Really like to keep the disruptor transmission. So I see my gear is: * *Planetary transmission 16:1 *Disruptor transfer case 2.18:1 ***.75:1 ****.75:1 *Axles 43/13 3.31:1 **38/13 are 2.92:1 ***3.31:1 ****2.92:1 FINAL DRIVE RATIO 115.45:1 **101.84:1 ***39.72:1 ****35.04:1 I see this post is not keeping my variables seperated nicely. The amount of stars represent the column each should be in. Some thing I was using for the crawl ratio. californiajeeper.com John, that Revolver 540 is interesting me. Planning on running a FXR speed control. Last edited by snydercj7; 01-24-2013 at 06:40 PM. |

| |  |

| | #35 |

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

|

looks like the gear up transfer with either axle reduction would be a good choice. You would need a brushless speedo for the REvolver. |

| |  |

| | #36 |

| REST IN ALOHA CHIP  Join Date: Nov 2005 Location: *

Posts: 3,549

|

those lockers are nice. Who makes those? Keep going on the build..FYI I'm currently testing the revolver s in my Wreep, it weighs a good 12 pounds, so far the motor is doing great!!! keep it up!!!

|

| |  |

| | #37 | |

| I wanna be Dave Join Date: May 2008 Location: Baltimore

Posts: 4,442

| Quote:

Thanks for sharing that info JRH ! Can you tell us a bit more about this TorqueMonster motor? | |

| |  |

| | #38 | ||

| Quarry Creeper Join Date: Sep 2010 Location: where ever I layed my hat.

Posts: 225

| Quote:

Quote:

http://www.rccrawler.com/forum/axles...ls-locker.html Your Willy's is one of the ones that I constantly watch. I was thinking I might start practicing my tube bending this weekend. | ||

| |  |

| | #39 |

| Quarry Creeper Join Date: Sep 2010 Location: where ever I layed my hat.

Posts: 225

|

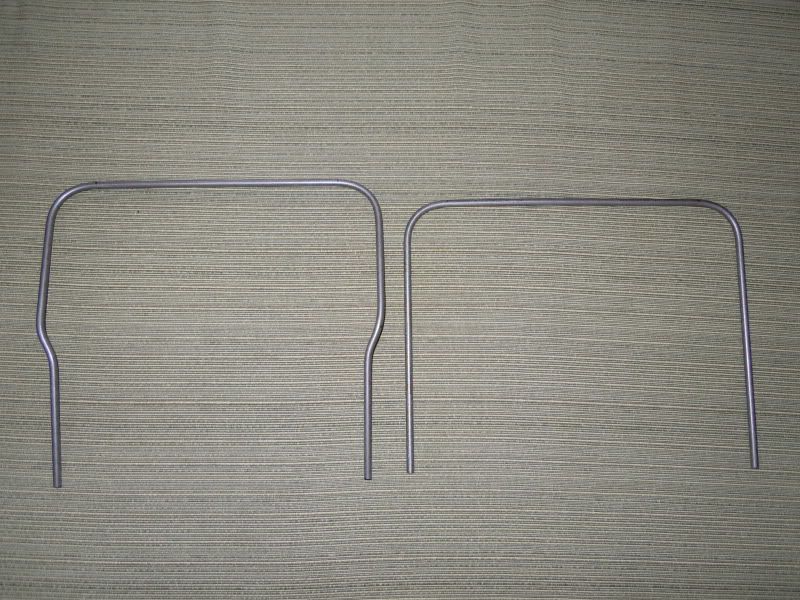

Well so far so good. I started off by bending a test 90 and 45 for a reference as to where to start my bends. Here are the front and main hoop. It took some time but they were both done on the first try. Just need to set the length on the main and clean up the ends. The front hoop was a bit nerve racking considering the bends tuck it into the tub, there is also about a 13 degree kick back for the windshield.  Thinking about building a jig to set this thing up to finish the rest of the tubes and start brazing. Last edited by snydercj7; 04-22-2012 at 01:34 PM. |

| |  |

| | #40 |

| Pebble Pounder Join Date: Feb 2009 Location: Augusta

Posts: 101

|

Excellent, man. Apparently, you've taken to bending quite easily. I did not and whizzed away about six feet of tubing before I got the hang of it. I'm very fond of the 1:6 scale builds and actually did it myself long before the days of scale solid axles. Mine was based on a Soldiers Of The World Willys and would haul ass, but wasn't much good for crawling. I actually had to make seat belts for the driver and passenger or they'd be slung out on a hard turn.  It was fun. Looking forward to seeing more of your build. |

| |  |

|

| |