| | #21 |

| Rock Crawler Join Date: Jan 2008 Location: Essex, UK

Posts: 654

|

Looking great! Think it'll be a little lighter than 25/30lbs, as your wheels/tyres are quite light. I have a similar build going and it's using heavy alloy 40 series wheels and the same body (diff colour). The wheels are like 3lbs each when mounted lol What lipo's are you going to use? I'm going to be using 2 separate 2 cells together and I think it came out at about 24lbs with everything piled on the scale. Looking forward to seeing it done |

| |  |

| Sponsored Links | |

| | #22 |

| Rock Stacker Join Date: Aug 2010 Location: nanoose bay, bc, canada

Posts: 94

|

Looking very nice, those twins in the engine bay really look killer. Those tires and wheels look really sweet too, the rims look like about a 16-17" scale rim size, and the tires look to tuck perfectly like a real super duty with 35" meats. I am seriously going to start looking for one of these shells/rc's. What was the name/make of the starting truck? Thanks and keep up the good work ;)

|

| |  |

| | #23 | ||

| Quarry Creeper Join Date: Jan 2011 Location: Lyons, MI

Posts: 329

| Quote:

as it sits right now without the batteries my crappy bathroom scale sais a little over 21 lbs. And I have a pair of turnigy 4s 5000mah's I planed on mounting in the back to level the weight out, the majority of the weight is in the front with those twin pullers Quote:

the body is made by fast lane rc and from my research they made several different models each one kick a$$...but there nearly imposible to find and even harder to find in good shape, I lucked out when my brother dug this one out of his garage still in the box and said work your magic..lol I've tried finding another just to have as a back up but not having any luck Last edited by Diesel-tech; 01-05-2013 at 05:10 PM. | ||

| |  |

| | #24 |

| Quarry Creeper Join Date: Jan 2011 Location: Lyons, MI

Posts: 329

|

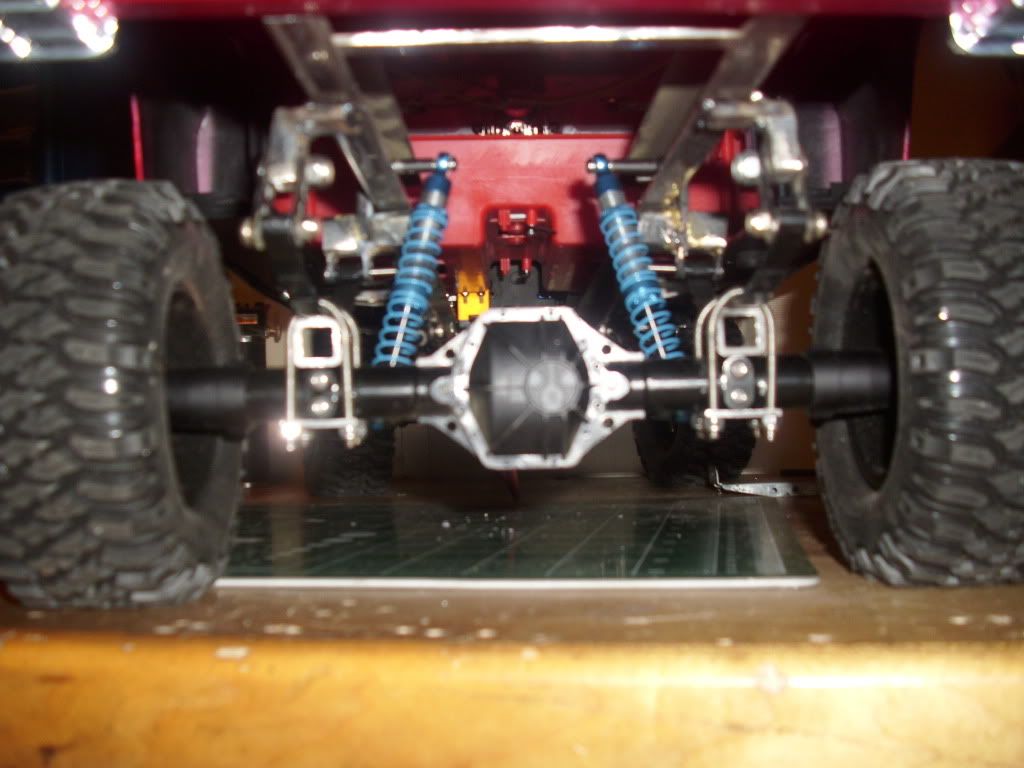

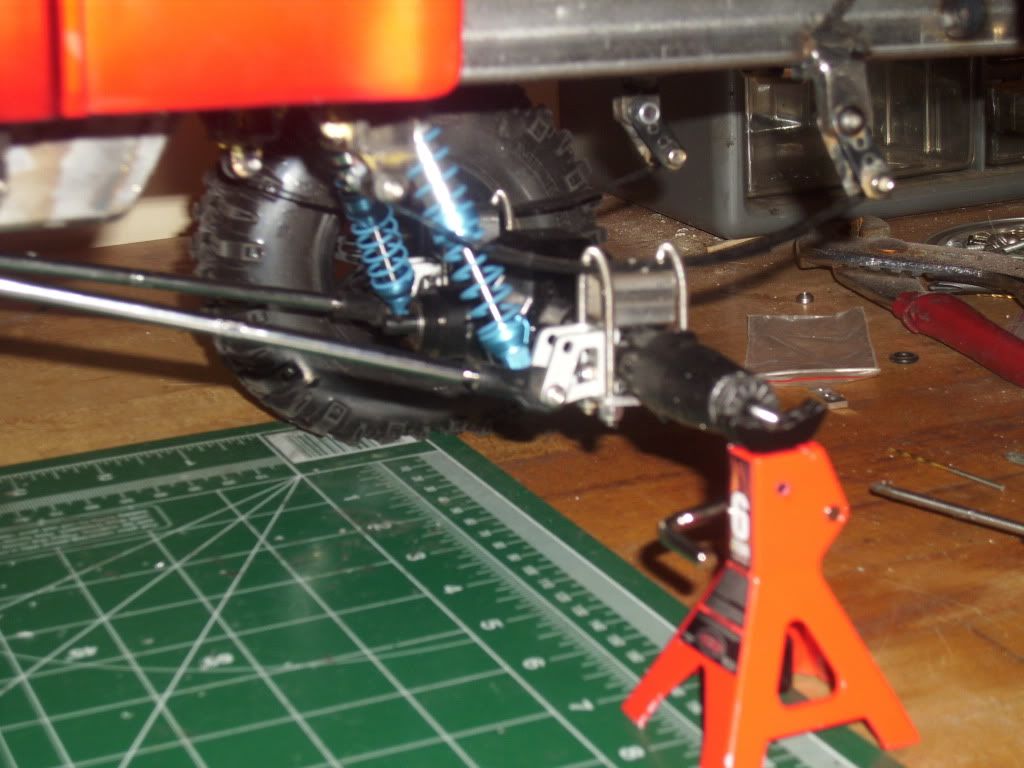

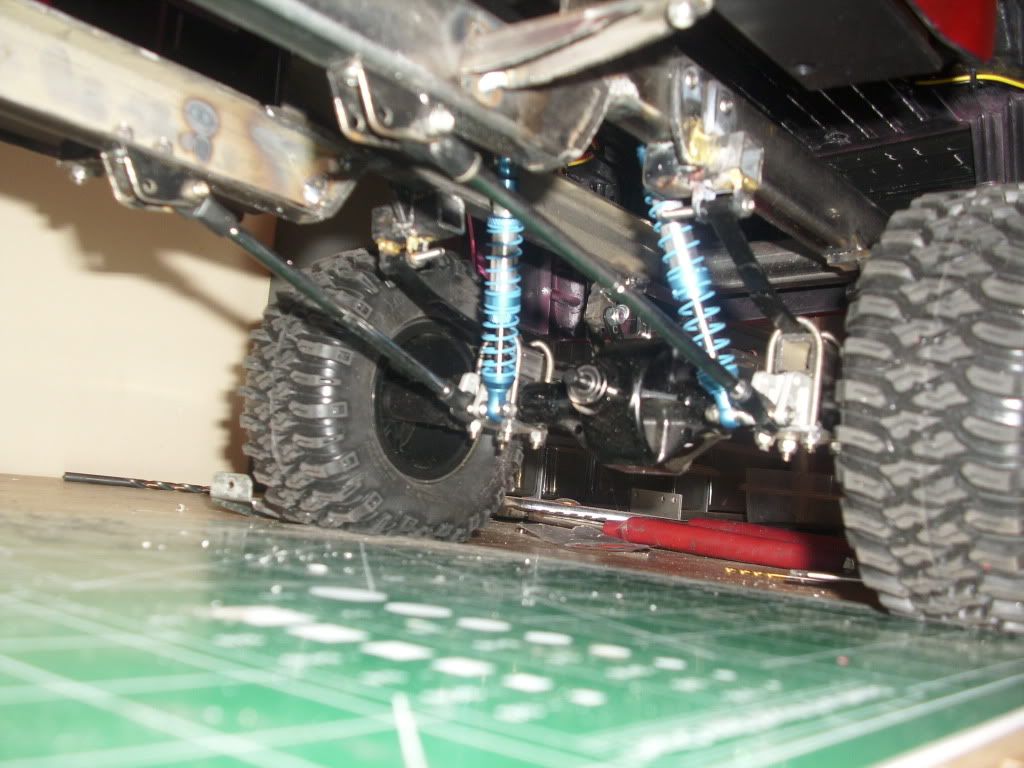

Played around with it a bit today. modded the rear axle u-bolt plates and flipped the u-bolts. one they looked way too big to be scale seeing as the plate was three times the size of the leaf spring and two i've lifted many trucks and I dont ever remember a ford with the u-bolts facing up..thats a chevy thing. Also got the rear shocks mocked up. I wanted to mount them behind the axle but that would interfear with the future battery location and it would have involved some goofy extra mounts on the back of the axle. I already planned on using a VP factory link mounts for a ladder bar mount so they also double as a shock mount. the shocks are rc4wd 100mm dualsprings as far as an actual shock absorber they are deffinatly not but they look killer and also help support the ass end of this pig...it desperatly needed it.    other than that started planning some wiring options and electronics mounting locations.. all for now back to the sunday beer. Last edited by Diesel-tech; 01-06-2013 at 02:16 PM. |

| |  |

| | #25 |

| Rock Stacker Join Date: Aug 2010 Location: nanoose bay, bc, canada

Posts: 94

|

Nice work man, keep it up

|

| |  |

| | #26 |

| I wanna be Dave  Join Date: Dec 2009 Location: Outside DC

Posts: 2,997

|

Really nice work on this truck! I love all the engineering you're doing. I'd love to see bigger tires, but understand about not cutting the body. If it were me, I'd go a little larger and cut the body just a little, either take an 1/8th off the whole wheel arch, or try to scale the amount of suspension travel. If it were a 1:1, you'd only have so much travel. In the scale world we look at flex shots like they're normal. From what you posted, your flex is well within reason. On a real truck that is stock, you're only going to see a little flex, so great job there. If you decide on bigger tires, keep that in mind, it will only help. Subscribed to see where this goes.  |

| |  |

| | #27 | |

| Quarry Creeper Join Date: Jan 2011 Location: Lyons, MI

Posts: 329

| Quote:

I'm really starting to see the need for bigger tires but I'm holding out on buying bigger tires one because I love the MTZ'S I run them on my 1:1 I'm on my second set there awesome tires. and two I'm waiting for my wheels to come back in stock and then I plan on modding them to accept air. Given the size and weight of this pig I think it needs it and I think it will help alot with steering plus airing up the tires will deffinately make them expand. In the end I'm going for something like this..  | |

| |  |

| | #28 |

| I wanna be Dave Join Date: Jun 2006 Location: Here

Posts: 2,319

|

Looks awesome so far, I have the same body and plan on copying a few ideas of yours. I will use jugg2 axles though with the 4:1 reduction gears installed in them

|

| |  |

| | #29 | |

| Quarry Creeper Join Date: Jan 2011 Location: Lyons, MI

Posts: 329

| Quote:

If you happen to have a spare body like this or ever come accross another one LET ME KNOW... lol I'm not even finished with this one and want to start another two is always better than one | |

| |  |

| | #30 |

| Rock Crawler Join Date: Jan 2008 Location: Essex, UK

Posts: 654

| |

| |  |

| | #31 |

| Quarry Creeper Join Date: Jan 2011 Location: Lyons, MI

Posts: 329

| |

| |  |

| | #32 | |

| I wanna be Dave Join Date: Jun 2006 Location: Here

Posts: 2,319

| Quote:

| |

| |  |

| | #33 |

| I wanna be Dave Join Date: Jun 2006 Location: Here

Posts: 2,319

|

Right now I'm working on a Ranger truggy, then finish the F250. H2 and Cherokee after that

|

| |  |

| | #34 |

| RCC Addict  Join Date: Apr 2012 Location: Land of 10,000 Lakes

Posts: 1,460

|

Woah. |

| |  |

| | #35 |

| Quarry Creeper Join Date: Jan 2013 Location: Benicia/Vallejo

Posts: 490

|

Nice truck! Your U bolts are upside down though.  |

| |  |

| | #36 |

| Rock Stacker Join Date: May 2010 Location: tx

Posts: 73

|

The axles look perfect on there.

|

| |  |

| | #37 |

| Quarry Creeper Join Date: Jan 2011 Location: Lyons, MI

Posts: 329

|

Got to dink around with it a little bit today been crazy busy paraticly living in my work truck all week. Finished my custom selectable transfer case. with a little engineering and re-engineering this is a combination of parts from a couple different RC4WD R2 transmissions. I used the center case and gears from a R2 1:1 ratio and the disconect section from an R2 disco trans. With a Robinson Racing 28t 48 pitch 5mm pinion gear to complete the series. also used the lower brass bearing cups from the disco donor trans. The process wasnt very dificult as long a you follow the golden rule ..measure twice cut once I only had to make about 3 sets of plates to finaly get the gear mesh perfect Now that its all put together i could have just bought a disco trans replacement gearset and a 1:1 trans but didnt know what all I was going to use at the time better to have the parts in front of you than looking at a picture wondering I re-engineered both outside covers to accept a through shaft instead of a motor and to also accept the disconect section.        Now that it's all assembled and working properly I can tear it back down and paint, then waterproof and seal off the case. I havn't made up my mind on weather to use a heavy weight oil pooled in the lower section of the case maybe some lucas 75w140 or just thread in a grease zirk. I'm leaning towards a self lubricating gears might be quieter and more efficient. |

| |  |

| | #38 |

| Quarry Creeper Join Date: Jan 2011 Location: Lyons, MI

Posts: 329

|

Also got the t-case mounted in the frame now back to the drawing board for driveshafts as it will all probably have to be custom. Had to notch out a section of the frame didnt want to but it was necesary to get the driveshaft angles right. if theres one thing I cant stand it's d-shafts off center.   All for now got some more research to do on parts. Does anyone know if somebody makes a driveshaft coupler/ reducer? I heed a reducer from 6mm shaft on the E-maxx trans to the 5mm for everything else. I like the revo shafts but there a bit wobbley on the 5mm shafts. |

| |  |

| | #39 |

| I wanna be Dave Join Date: Aug 2004 Location: Tri-cities, WA

Posts: 4,831

|

That's a sweet t case you've come up with. For the drivelines it'd be easy to swap ends for 5mm or 6mm as needed. If you want to go that route I'm sure I have a 6mm yoke for mips that will hook right up to axial type mip shafts.

|

| |  |

| | #40 | |

| Quarry Creeper Join Date: Jan 2011 Location: Lyons, MI

Posts: 329

| Quote:

Nice, only problem is getting them long enough. I need two shafts in roughly the 7-9" mark The revo shafts have the right size for the scale of the rig but I just cant have the sloppy connections | |

| |  |

|

Real Steel 1/6th F250 Project working class reborn - Similar Threads

Real Steel 1/6th F250 Project working class reborn - Similar Threads | ||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Gavin's Class 2 SORRCA Toyota Truggy reborn - the 3rd & 4th time now | Nova's Ark | 1.9 Scale Rigs | 96 | 08-14-2019 01:05 PM |

| Project "working class superduty" true scale | Diesel-tech | 1.9 Scale Rigs | 10 | 05-21-2011 09:36 PM |

| reborn tlt project | tltcrawlerxtrem | Tamiya TLT Crawlers | 20 | 02-17-2007 01:52 PM |

| New 1/6th Nylint Not Working | mulchman | General Crawlers | 2 | 04-11-2006 08:07 PM |

| |