| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #21 | |

| RCC Addict Join Date: Jun 2007 Location: MESA

Posts: 1,389

| Quote:

The shaft is 2mm. I used the smallest gear from a trany gear kit. Wait a day and i may have worked out an install on the largest of the pinion gears that you get with the rig. I just need to shave some material from the case to make it all work with a 56 tooth aluminum gear. Wish me luck cause this could be the ticket!!! | |

| |  |

| Sponsored Links | |

| | #22 |

| Rock Crawler  Join Date: Dec 2010 Location: Madison Co.,Ms.

Posts: 711

|

Good luck!  I appreciate you taking the time to answer my questions. My rig has been built a while now and I'm getting the itch to tinker with it again. |

| |  |

| | #23 |

| RCC Addict Join Date: Jun 2007 Location: MESA

Posts: 1,389

| You know what really suck??? I have 3 micro's and not one is running. All 3 are under some sort of mod. One is in peices and another had a DP chassis but I still need to install a motor and I really need a new body.

|

| |  |

| | #24 | |

| Rock Crawler  Join Date: Dec 2010 Location: Madison Co.,Ms.

Posts: 711

| Quote:

Soooo......more dumb questions ...... Is that tranny gear correctly splined to the shaft, or friction /press fit? Also, the footprint of the mounting holes looks a bit bigger than stock. I'm thinking a stock motor plate would not accommodate mounting that beast. A new motor is about all I really would need to finish mine. | |

| |  |

| | #25 | |

| RCC Addict Join Date: Jun 2007 Location: MESA

Posts: 1,389

| Quote:

| |

| |  |

| | #26 |

| RCC Addict Join Date: Jun 2007 Location: MESA

Posts: 1,389

|

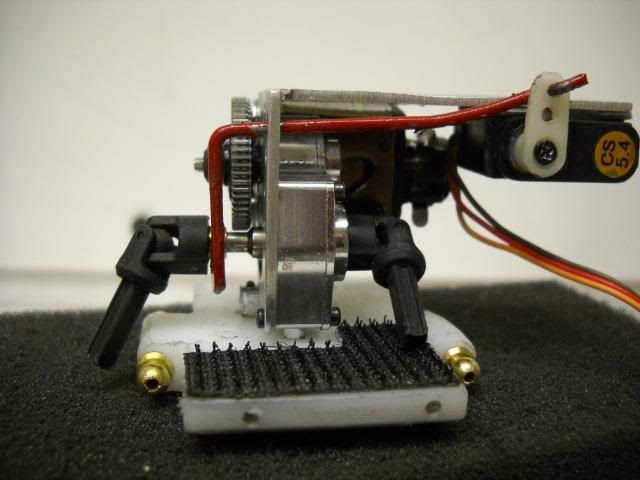

Just updating some pics... Here is a breakdown of the driveline mod. Drill out the driveline and insert a peice of tube.  Drill out the tube through old hole.  Use a factory driveline screw and it's done.  If you can see it...the screw acts as the locking mechanism on the cut end of the driveshaft.  A pic of the new trany plate for the BIG BLOCK  Compared to the factory trany plate.  Here is what the trany plate started out as...2" wide x 1/16" thick aluminum angle from Home depot  Notice I had to grind down the trany case next to the motor...it made the next part possible.  BIG NEWS!!! I got the largest pinion and the 56t aluminum spur gear to fit. I had to shave the trany case down so that the motor would fit closer for gear mesh.  I had to cut down the brass driveline tube on the dig so it clears the spur gear. It still hold on to the trany output shaft without falling off during dig. REALLY TIGHT TOLLERANCES. This pic is in drive mode...  In dig mode...  I have the frame done! I think it came out great. I am painting it now and will be assembling the rig tomorrow. I ordered the neo magnets and bearing case for the motor. Anyone know of a good driveline swap??? I may be blowing up the stock ones soon..I guess we will see |

| |  |

| | #27 |

| I wanna be Dave Join Date: Jan 2009 Location: By a lake in Thornton

Posts: 2,218

|

Now that is a freggin keen idea right there sir!!! how much did you grind off the output shafts to make it open like that so it can engage the screw in the drive shaft? and what prevents the drive shaft from popping off/ stay in 4wd? is the brass tube tacked to the dig arm? |

| |  |

| | #28 |

| I wanna be Dave Join Date: May 2007 Location: Taylors Falls just hanging with the MNRCRC crew.

Posts: 7,843

|

Bob it looks like the worm locks the dig when the servo disengages the dig collar and the pressure from the spring holds it in place for 4 wheel drive. Man that's some great Micro engineering.  |

| |  |

| | #29 |

| RCC Addict Join Date: Jun 2007 Location: MESA

Posts: 1,389

| I think you are correct. The brass tube slides smoothly over the output shaft and the pressure from the spring holds it in contact. It stays put well but can wobble a bit under heavy acceleration. I will do a video soon.

|

| |  |

| | #30 |

| I wanna be Dave Join Date: Jan 2009 Location: By a lake in Thornton

Posts: 2,218

|

So your spring, is wedged between the female piece of DS in the aluminum tube and the male piece. So your dig collar and spring keep it in place.  hmmmmmmmm i may suddenly have a use for these 1.5gram micro servos i have left over from a micro plane...... thank you guys, Im kinda like an old truck. I may need a few kicks, patience, and a little choke. But the brain will fire eventually. |

| |  |

| | #31 |

| RCC Addict Join Date: Jun 2007 Location: MESA

Posts: 1,389

| |

| |  |

| | #32 |

| RCC Addict Join Date: Jun 2007 Location: MESA

Posts: 1,389

|

Here it is! I had to modify the dig twice to make it stay together. Cutting the brass sleeve on the driveline to clear the spur gear was a bad idea. The driveline came apart a few times. As for the big BIG BLOCK: what a power monster...and with great control. I still havent even put in the ball bearing can or Neo magnets yet. I can't wait!!! I have to say it's the perfect motor for the bigger rigs that weigh over a pound or have QLO's. Mine weighs in at 18oz including the 450mah battery. I got about 25 minutes of hard running on a charge and thats running 2 servo's and a big motor. I also made 2 400mah split packs for the rig that fit way better. I used my TQ4 4 channel 2.4ghz radio gear this time too. Way better than the old TQ3 am unit! On to the pics.  You may notice the front end bars are bent a bit...I had to tweek them a bunch for the ESC to fit. Thats what I get for painting it before eveything was proven to fit.       And a few quick video's. I took one of the dig system but it didn't come out. It was too close for my camera to focus on. http://www.youtube.com/watch?v=NzrPlZBRsx0 http://www.youtube.com/watch?v=5ptTJR-_QTY http://www.youtube.com/watch?v=HCPW88yGO8k More pics and videos to come OH...and possibly 4ws to go on it too...should I? |

| |  |

| | #33 |

| Rock Crawler  Join Date: Dec 2010 Location: Madison Co.,Ms.

Posts: 711

|

4WS! You cannot go wrong with more capability and maneuverability. It's gotta be strange to build a chassis asymmetrical when naturally the eye prefers it being symmetric. Nice work. |

| |  |

| | #34 |

| Quarry Creeper Join Date: Mar 2010 Location: Massachusetts

Posts: 394

|

Oh my god, that thing is amazing. I think 4ws would officially make that rig one of the coolest things I've ever seen. Keep up the great work!

|

| |  |

| | #35 |

| Rock Crawler Join Date: Dec 2005 Location: houston

Posts: 650

|

Looks great! Now I have some more inspiration to get my dig working.  |

| |  |

| | #36 |

| Pebble Pounder Join Date: Feb 2010 Location: Canada

Posts: 195

|

Worlds biggest micro crawler? ahah Im with bryco13,put some 4WS on that man! |

| |  |

| | #37 | |||

| RCC Addict Join Date: Jun 2007 Location: MESA

Posts: 1,389

| Quote:

Quote:

Quote:

The 90t motor you made for me worked great in this rig. Since I went big block I am re-using the 90t in my next project. I will never get rid of it as long as I have a micro. Great motor dude  | |||

| |  |

| | #38 | |

| RCC Addict Join Date: Jun 2007 Location: MESA

Posts: 1,389

| Quote:

(I can't beleive I just said that) but I think some others have me...I heard one guy say he had 2 pounds and I hear of 5.5" wheel bases. This sits just barely over 5" wheel base and 18oz loaded. I will take some pics to compare it to stock micro's just for reference. (I can't beleive I just said that) but I think some others have me...I heard one guy say he had 2 pounds and I hear of 5.5" wheel bases. This sits just barely over 5" wheel base and 18oz loaded. I will take some pics to compare it to stock micro's just for reference. I have to say one thing for sure...these are way more of a challenge than most people give credit to. Whats that saying??? like trying to fit 10 pounds of crap in a 5 pound sack? | |

| |  |

| | #39 |

| Rock Crawler Join Date: Feb 2009 Location: Milwaukee

Posts: 609

|

Awesome work Danally. I will be making a dig for future build, Yours looks like a winner.   nice looking "rig" also. |

| |  |

| | #40 |

| Pebble Pounder Join Date: Jan 2011 Location: USA

Posts: 122

|

Simply amazing!! *DANALLY do you think you could start a thread with detailed information and images of how to do a dig best for the LMRC. I'm sure a whole bunch of us would like to try our own but just are not completely sure where to start, I think a detailed thread with parts, recommended esc, images and instructions would make many here Smile from ear to ear! Last edited by atracys; 03-21-2011 at 02:15 PM. |

| |  |

|

| Thread Tools | |

| Display Modes | |

| |