| | #1 |

| Newbie Join Date: Jan 2009 Location: Space Coast

Posts: 3

|

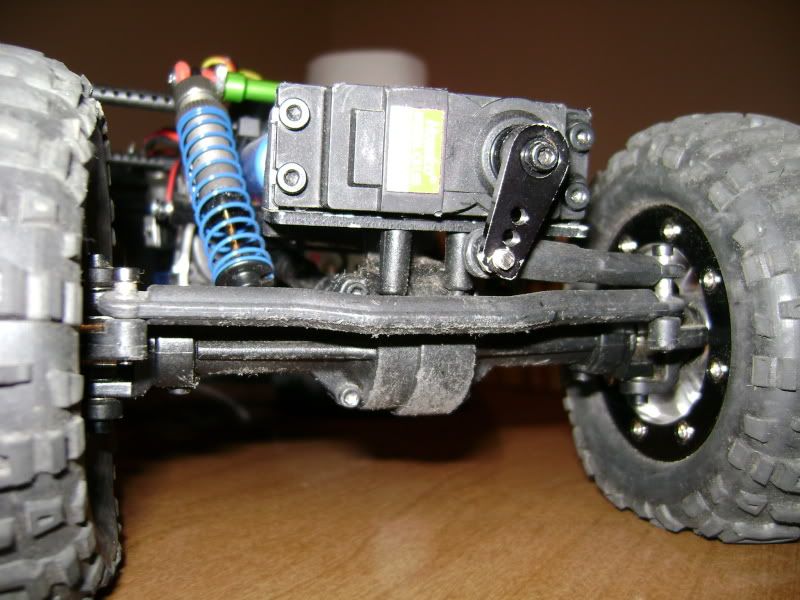

Can you guys explain how you attached the ball joint to the steering link on your 645 servo mods?

|

| |  |

| Sponsored Links | |

| | #2 |

| I wanna be Dave Join Date: Apr 2007 Location: We-Go, Chi-Town, Ill

Posts: 2,550

|

I just opened the hole furthest from center on the standard, single sided arm that the servo came with and it's worked fine for me.

|

| |  |

| | #3 |

| Newbie Join Date: Jan 2009 Location: Space Coast

Posts: 3

|

I was thinking of using the plastic arm that came witht the 645, but I was wondering if its best to put a nut on the ball joint, or just thread it into the arm. Anybody know the thread size for the ball joint?

|

| |  |

| | #4 |

| Rock Crawler Join Date: Mar 2009 Location: Cottontown

Posts: 880

|

I would nut it either way. Just my IMO. You can use the stock servo horns that came with it, and cut one of them down to make the right horn. Or you could just get an alum. one for like 3 bucks |

| |  |

| | #5 |

| Pebble Pounder Join Date: Jul 2008 Location: Texas

Posts: 108

|

i just threaded it in to the plastic one... i had a nut on it but it fell off so i just left it as is...

|

| |  |

| | #6 |

| Quarry Creeper Join Date: Oct 2008 Location: Crawlin' in NorCal!

Posts: 416

| You will strip the plastic horn out! I started with like you said putting the ball onto the horn, but your better off just ditching the whole thing and making a new steering rod.

|

| |  |

| | #7 |

| Quarry Creeper Join Date: Oct 2008 Location: Southwest VA

Posts: 361

|

I used an aluminum arm with the stock ball. Placed some loctite on the threads and put it in from the back.  |

| |  |

|

| |