| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Newbie Join Date: Aug 2008 Location: nc

Posts: 36

|

Total noob question here but, I see where motors are listed like "55 turn", "75 turn", "17 turn", etc. What does that mean precisely? Is it how many revolutions per minute? If so, I guess a 17 turn would give more torque and less speed then a 55 turn...right?

|

| |  |

| Sponsored Links | |

| | #2 |

| RCC Addict Join Date: Feb 2006 Location: ccxc

Posts: 1,176

|

no...opposite. 17 turn less torque more speed than a 55. Its the number of turns of wire around the armature.

|

| |  |

| | #3 |

| Newbie Join Date: Aug 2008 Location: nc

Posts: 36

| Cool. What is a "good" turn for a crawler and should the motor for each axle have the same turn number? Any specific advantage or disadvantage to having different turn numbers?

|

| |  |

| | #4 |

| RCC Addict Join Date: Jun 2008 Location: Mudville

Posts: 1,592

|

the Turns of a motor (ie 7t, 45t, 65T) ect refer to the windings the motor has in it. the lower the amount of turns, typically the faster the motor will spin. the more the turns, typically the more torque you ll have. while this is the Normal case, its not always like this. there are alot of things theat make a differance in the way a motor operate. this also refers to Brushed motors. hth T |

| |  |

| | #5 | |

| I wanna be Dave Join Date: Sep 2005 Location: Houston, TX

Posts: 16,952

| Quote:

Also, no they dont have to be the same turn front and rear. I run my 2.2 with a 60 turn motor on the front axle and 55 turn in the rear. It gives a bit more wheelspeed for the front and helps with ledges. | |

| |  |

| | #6 |

| RCC Addict Join Date: Jul 2008 Location: San Diego

Posts: 1,144

|

If I where to start over I would run a 8 cell saddle pack. 4 on each side of the axle of the front axle. I would run 45t or 55t motor. Do you and a ax10? ax10artr or the ax10rtr. I have a ax10rtr Matt |

| |  |

| | #7 |

| RCC Addict Join Date: Jun 2004 Location: ORegon

Posts: 1,002

| well he said motors for front and rear so i'm assuming its a clod style truck. and jeremy, do you have that backwards? 60t in the front is less wheelspeed...

|

| |  |

| | #8 |

| I wanna be Dave Join Date: Sep 2005 Location: Houston, TX

Posts: 16,952

| |

| |  |

| | #9 | |

| Newbie Join Date: Aug 2008 Location: nc

Posts: 36

| Quote:

I am still in the process of researching and I have not bought anything of hobby grade yet. I am looking at few things though....CR-01 for one. | |

| |  |

| | #10 |

| I wanna be Dave Join Date: Sep 2005 Location: Houston, TX

Posts: 16,952

|

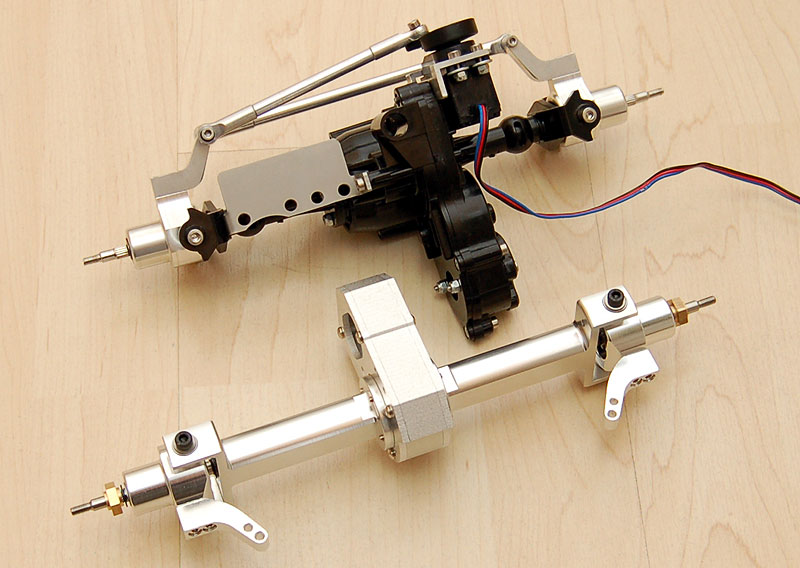

AR, well, that really depends on the crawler that you want. There are crawlers that use motors that are DIRECTLY mounted to the axles, like those seen here: (Tamiya Clodbuster Axle)  (OCM Newage Berg Axle that doesnt have any motors mounted)  (Raptor axle made by RC4WD is show here on the bottom and pictured with a Clod axle)  None of these axles require anything like a transmission or driveshafts...just direct drive from the motor to the gears in the axle. You can see the hole in the axle where the motor would be mounted. There is also a style of axle that only requires a single motor to drive both axles. These are referred to on this site as "shafties" because they require driveshafts to spin the gears in the axle. These types of vehicles will have a single motor somewhere in the middle of the truck and it will be mounted to a transmission which will spin both the front and rear driveshaft and will turn both axles, making the truck 4wd. Here are pictures of some different "shaftie" axles: (Axial AX-10...you can see the driveshaft pointing up)  (Ax-10 truck...you can see the motor/transmission in the middle and the driveshafts leading to each axle)  (HPI Wheelie King)  (Tamyia TXT-1/Jugg...the truck is upside down, but you get the idea)  (Tamyia TLT)  (Tamyia CR-01)  Again, there are other axles out there with similar designs, but you get the idea. |

| |  |

| | #11 |

| Newbie Join Date: Aug 2008 Location: nc

Posts: 36

|

What a great education! You should be elected for a forum promotion! LOL. I guess mainly it will come down to what my wallet can afford. Do you know what type of setup the Tamiya Lunchbox uses?

|

| |  |

| | #12 |

| I wanna be Dave Join Date: Sep 2005 Location: Houston, TX

Posts: 16,952

|

Not exactly, but I believe that the Lunchbox has rear axle similar to the Clodbuster (motor mounted directly to the axle) and an independent front suspension (with no motor) which means that the stock Lunchbox is only 2wd. Here is a link to the user manual (with Large pictures) of the Lunchbox: http://www.tamiyausa.com/pdf/manuals/58347ml.pdf |

| |  |

| | #13 |

| Newbie Join Date: Aug 2008 Location: crawlarado

Posts: 14

|

Ok so I haven't been into electric RC's in years. went in to gas cars for a while. Can some one refresh my memory. I have a old Modified motor. it says its a 19turn triple. What exactly does that mean? I have a few left over from my old RC10T. and I have a 12turn triple. Last edited by SwanSong; 08-18-2008 at 09:19 PM. Reason: correction number of turns |

| |  |

| | #14 |

| Rock Crawler  Join Date: Jul 2008 Location: E. City

Posts: 883

|

Electric motors have turns and winds. Turns, as explained above, refers to the wire on the armature. If you have a 19 turn that means the wire is wrapped around the armature 19 times. The lower number of turns the faster it will be. Winds refers to how many wires are wrapped around 19 times. So a 19 Triple will have 3 wires wrapped 19 times around the armature. Winds affect torque as well. The more winds, the more torque. Turns range from 3 up to 70 or above. Higher turns also means more torque. Winds come in single, double, triple and quad.

Last edited by dont slow down; 08-18-2008 at 11:50 PM. |

| |  |

| | #15 |

| Newbie Join Date: Aug 2008 Location: crawlarado

Posts: 14

|

so the 19turn triple would be a highspeed high torque motor?

|

| |  |

| | #16 |

| I wanna be Dave Join Date: Sep 2005 Location: Houston, TX

Posts: 16,952

|

Nope, a 19T is a high speed, lower torque motor. A 70T would be a low speed, high torque motor. |

| |  |

| | #17 |

| Newbie Join Date: Aug 2008 Location: crawlarado

Posts: 14

|

But according to the post above mine a 19turn triple wind motor will have greater torque than a 19turn motor Since it has 3 winds on the armature over 1 wind.

|

| |  |

| | #18 |

| I wanna be Dave Join Date: Sep 2005 Location: Houston, TX

Posts: 16,952

|

Ahhh....sorry, I didnt know you were comparing two 19T motors with different numbers of wires. I missed that.

|

| |  |

| | #19 |

| Rock Crawler  Join Date: Jul 2008 Location: E. City

Posts: 883

|

The amount of torque that different winds make is not very noticeable. You would notice more torque from more turns than winds. A 19 turn motor is a very mild modified motor. A stock motor has 27 turns. These high turn motors that you hear about (50, 70 etc) are either crawler specific motors or motors that are built for something other than an r/c car. When deciding what turn and wind for your car consider these. For example: a touring car is fairly light therfore not requiring a lot of torque to get it moving. A touring car would benefit from a single or double wind motor. A buggy is a bit heavier and might need a little more "oomph" to get it going so a double or triple would do nicely. A stadium truck is much heavier than a touring car so it would benefit from a triple or quad wind motor. The whole idea is how much wire is energized when power is applied. For example in a stadium truck and good motor would be, say a 17 turn triple. By having three wires wrapped 17 times there is more wire on the armature creating an opposite magnetic field, resulting in more power or torque. Rock crawlers require lots and lots of torque but not much speed. So instead of wrapping 3 or 4 wires on the armature, they wrap one 50 times, again putting lots of wire on the armature to create that negative magnetic field. There are other ways to make more torque from a lower wind as well such as gear reduction units (GRU) or simply by changing the gearing. Many times the motor choice is completely based off what car its going in. I hope you understand the idea and if I made a mistake on anything feel free to correct me.  |

| |  |

| | #20 |

| RCC Addict Join Date: Mar 2007 Location: St. Louis (High Ridge)

Posts: 1,279

|

Not to jack this thread, but understanding traditional brushed wind counts, How do brushless wind counts compare? I've seen 18.5 or 3.5, how the heck do you get half a wind? |

| |  |

|

| |