| | #321 | |

| Rock Crawler Join Date: Oct 2010 Location: Reno

Posts: 646

| Quote:

| |

| |  |

| Sponsored Links | |

| | #322 |

| I wanna be Dave Join Date: May 2010 Location: The east coast

Posts: 2,599

|

i wasn't expecting a new forum but it was worth asking. i know it isn't a high volume rig like many of the other crawlers out there. like most i didn't get an exceed product expecting a comp worthy bulletproof crawler. you get what you pay for and i think the exceed has done well for the investment. seeing my son smash his around and it survives tells me it was worth it. if others create new exceed threads out there i hope they post links in this thread so the rest of us can visit and share information. i don't have many updates myself yet for my son's maxstone. i'm waiting for the snow to melt so we can run it in the yard on the rocks. i'll be sure to get some pics when that happens. |

| |  |

| | #323 |

| Newbie Join Date: Mar 2010 Location: llano

Posts: 47

|

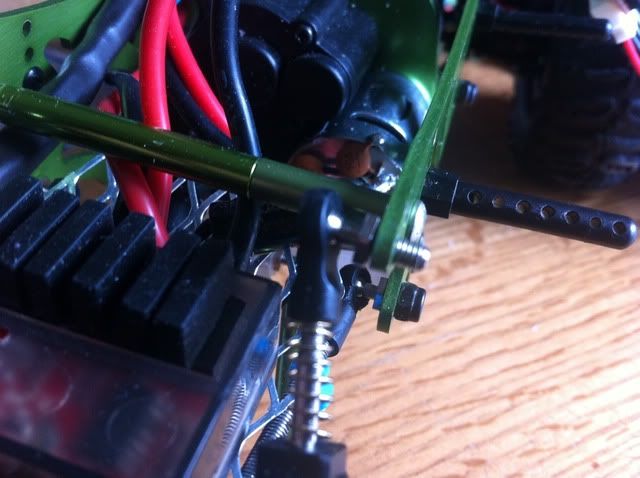

okay heres the pics of the modified cvd ends dont have pic of unmodified but this is really simple and self explanatory when all the parts are sitting in front of you.

|

| |  |

| | #324 | |

| RCC Addict Join Date: May 2010 Location: Los Altos, California

Posts: 1,509

| Quote:

a anyways, i think too little people own a Exceed to actually become a topic compared to Axial, losi, enroute, etc... | |

| |  |

| | #325 |

| Rock Crawler Join Date: Oct 2010 Location: Reno

Posts: 646

|

About how far do they go into the EMS plastic spool? I wouldnt want to strip it out. There is no metal diff option.

|

| |  |

| | #326 |

| Newbie Join Date: Mar 2010 Location: llano

Posts: 47

| they slip in there entirely the little tit on the end of each axle actually touches. thats why i hit them a little lick with the file. but your getting very nearly the same if no the same contact area but also thats why i filed them down a little fatter to ensure a good uber tight fit. also i think if i remember right nitrorcx offers an aluminum spool but i think they were pretty proud of it. i am expecting my other crawler with gc3 chassis etc any day now then ill be testing the losi tranny gears for swapping into this too. actually since ill have a full losi to side by side compare this to i will be trying a few things. one is if this bottom gear for the exceed tranny will fit in the losi. if so youd have the best of both worlds the bigger stronger outputs and the slipper clutch. then also i want to look at the overall axle widths between the two. if they are the same i think i will run the losi in the rear with lockouts and the exceed in the front as the exceed is geared slightly faster so sort of an overdrive int he front and under drive in the rear. but then that brings up drive shaft issues ofcourse so we will see when i get them in. i am going to be running a 2300 kv motor on 3 cell and so will le toyu know about durability. i know losi axles hold up once they hav e metal lockers as i used to run a 9300kv on 3 cell motor in my old losi and never tore up axles or tranny gears just kept twisting drive shafts. anyway enough rambling for now will update asap.

|

| |  |

| | #327 |

| Rock Crawler Join Date: Oct 2010 Location: Reno

Posts: 646

|

Jereosbou, thank you. Your rambling is fine. You have some good info to share. If you look back in this thread you will find that i have attempted to swap MRC parts into the EMS axles and trannys and EMS into MRC. I don't know if your find it helpful.

|

| |  |

| | #328 | |

| Rock Stacker Join Date: Nov 2010 Location: Ned

Posts: 75

| Quote:

| |

| |  |

| | #329 |

| RCC Addict Join Date: May 2010 Location: Los Altos, California

Posts: 1,509

| |

| |  |

| | #330 | |

| Newbie Join Date: Mar 2010 Location: llano

Posts: 47

| Quote:

will update when i find out though | |

| |  |

| | #331 |

| Rock Crawler Join Date: Oct 2010 Location: Reno

Posts: 646

|

Jereosbou, I took apart my axle again to check out your mod to the Losi CVDs. I totally understand the mod at the diff end of the axle. What are you doing at the c-hub/knuckle area? That where it appeared to be to much effort. The only reason I could see trying to keep the EMS axle housing and diff is because of the 5mm pinion. And I don't know I that is worth it. But fill me in. Maybe I'm missing something simple.

|

| |  |

| | #332 |

| Newbie Join Date: Mar 2011 Location: antioch

Posts: 5

| |

| |  |

| | #333 |

| Rock Crawler Join Date: Oct 2010 Location: Reno

Posts: 646

|

Dwinn, to make that 4 link I used all the factory parts and some extra servo links and it works excellent. It was very easy to make. I can give you a more specific run down on how it was made if you'd like. ( with part numbers) The picture you have quoted is actually the first attempt i made if a 4 link. I have actually attempted to make my own 4 link with threaded rod to make it even better and just yesterday I went back to the original design because it worked the best.

|

| |  |

| | #334 |

| Newbie Join Date: Mar 2011 Location: antioch

Posts: 5

|

a run down would be appreciated! just added 2oz to each wheel and took out the foam which helped alot with traction, now i need to lower the COG.

|

| |  |

| | #335 | |

| Newbie Join Date: Mar 2010 Location: llano

Posts: 47

| Quote:

hope this helped. on a side note my other package wound up being sent from colorodo to philadelphia instead of to sanantonio lol but i got hold of the seller and its in dallas as of yesterday so hopefully ill have all my goodies in monday and be able to further test fit things. | |

| |  |

| | #336 | |

| Rock Crawler Join Date: Oct 2010 Location: Reno

Posts: 646

| Quote:

To attach the new upper links to the axle you need to 2 ball stands and servo mount per axle. (http://www.nitrorcx.com/51c00-68029.html and http://www.nitrorcx.com/51c00-68007.html) You will need to drill and tap holes in the servo mount. Refer to picture.  I have since replaced the stock servo mount/upper link balls with the Losi Pro servo mount with built in upper link mounts (http://www.tlracing.com/Products/Def...rodID=LOSB1705) because I needed a bigger servo. Funny enough I built my upper link mounts before I knew about the Losi pro mount and the happen to be almost identical in placement. You will need to flip the original ball stand and nut that was the upper 3 link chassis mount so the ball is on the inside of the chassis instead of on the out side. When you make these mods to the upper links to make the 4 link you will need to change the lower links and shocks. You need to move the lower links in at the chassis side because if you don't the suspension has to much side to side movement. To do this I custom made a new skid plate out of a $3 1/4" cutting board from Walmart. If you look back in this thread Jebster also did the same think with a little different design but same result. Shocks need to be spaced out at the axle end other wise the will hit the new upper links all the time. To space them out at the bottom you just need a longer mounting screw and another ball stand to fill the gap and use as a spacer (http://www.nitrorcx.com/51c00-68028.html and http://www.nitrorcx.com/51c00-68043.html). Refer to the picture.  You have options with how you mount the upper portion of the shocks depending on what you have done with the battery tray. Here is a picture of how mine is currently mounted. Chassis to upper shocks.  I hope you find this helpful. If you have more questions just asked. | |

| |  |

| | #337 | |

| Rock Crawler Join Date: Oct 2010 Location: Reno

Posts: 646

| Quote:

If this doesn't make sense to you we can drop this subject. I know how to fix it my way I just was not understanding what you have done. I appreciate you trying to explain it to me. And your picture of the diff end of the axle that you have filed down was very helpful. Thanks. | |

| |  |

| | #338 |

| Newbie Join Date: Mar 2010 Location: llano

Posts: 47

|

oh this is something i adressed in the first post but maybe didnt make too clear. when all is said and done im getting a small patch of contact between the bearing and the bearing mount surface. maybe it will turn out not to be enough but i think time will have to be the teller of that. im sitting right at a 32nd of an inch contact between the two i also gave some thought too adding a washer between the knuckle and cvd to plce more contact between the axle housing bearing. |

| |  |

| | #339 |

| Newbie Join Date: Mar 2011 Location: antioch

Posts: 5

|

Thanks alot Toyota! totaly makes sence, you helped me alot! ill show ya the finished product lol.

|

| |  |

| | #340 | |

| Rock Crawler Join Date: Oct 2010 Location: Reno

Posts: 646

| Quote:

| |

| |  |

|

| |