| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Powered by Awesome  Join Date: Sep 2004 Location: Parker, Colorado

Posts: 3,622

|

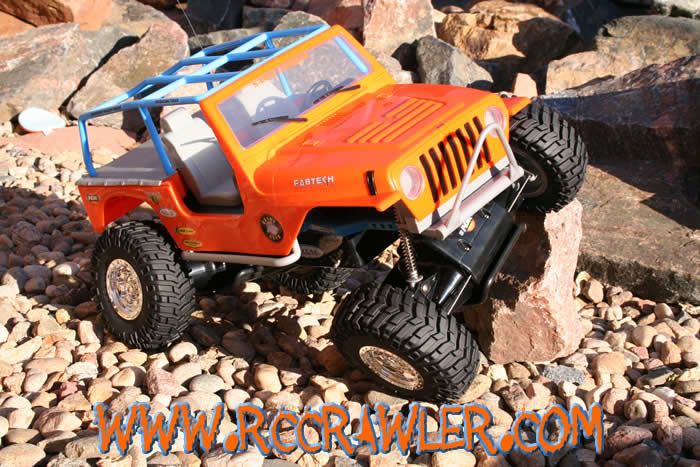

This article is being written to bring into view the capability of your Nylint Rock Crawler. The 1/6th Nylint Crawlers are a great entry level 4x4 rig to help newcomers get involved in the sport of Radio Controlled Rock Crawling. At the existing price ranging from $50.00 to $99.00, local Wal-Mart’s are making it easy for people to get their hands dirty in Radio Controlled Rock Crawling. Nylint offers a 90 day warranty on parts as long as no modifications have been made to the chassis (i.e. the drive train). Nylint Customer Service can be reached at either consumerservice@funrise.com or 1-800-882-3808 for any questions or concerns you may have. There are only 2 people fielding all of the calls and emails, so please be patient. Either Don or Steve will handle your request. This next point has been stressed in every forum across the board. These items are plastic and just like any other toy will break at some point in time. While wheeling, you may encounter obstacles where the rig becomes “bound up”. When this happens some people want to try to power out of it by hitting the throttle or trying to back out of it. Doing this can cause various problems to your crawlers chassis. The most common are a stripped outer hub, broken steering, and broken axles (plastic insides). Nylint has made chassis upgrades to help prevent breakage (i.e. Bump stops on the hubs, looser belts to prevent breaking axles, and steel parts in axle for strength). Rather then trying to power out of it, try picking up the crawler and either reposition it or bypassing that obstacle all together. Doing so will help preserve the life of your crawler. Since the debut of the first Nylint crawler, the company has taken information from this website and other customers that have called in to try to make the chassis better via various chassis upgrades. These chassis changes are referred to all over the forum as Generations 1 through 4. The latest generation (to date) is being labeled as the 4th generation chassis. This chassis has many changes from the first. Please see this lnk for all generation information on what changes have been made. There a lot of posts on how to modify your rig here on RCCrawler.com to help it perform better. These include but are not limited to: locking the axles in low, re-mounting rear motor, replacing belts with tighter O-rings, and Tummy Tucks. Any of these modifications voids manufacturer warranty leaving you to fix it if it breaks. So please take caution when choosing to modify your Nylint Rock Crawler. No one here is in anyway responsible for the changes that you make to your chassis. Due to the fact that this is not a hobby grade crawler, parts are not readily available locally. All parts must be sourced directly from the manufacturer. The term “Hobby Grade” refers to Radio Controlled vehicles that are purchased from local hobby shops. Local hobby shops tend to carry replacement parts for vehicles that they sell. This fact seems to lead to certain frustrations when trying to get replacement parts for your Nylint Crawler. Currently, Nylint is working on a Replacements Parts Website which is still in the works with no available estimated time to be up and running. Please keep and eye on the board to see when it comes online. So for now please be patient and Funrise (Nylint) will take care of your request. Last but not least, the sport of four wheeling has its ups and its downs. Climbing over obstacles is really fun but it can also cause extreme stress on vital components of your rig. When this happens, things tend to break. No matter if it is a hobby grade or store bought crawler, you will at some point break something. RCCrawler.com has tons of useful information on how to fix these breaks and our members will do their best to help you. If this happens to you, please start out with a search or the stickies located at the top of every forum, if you can’t find the information you seek, please post up your problem and we will do our best to help you.  Thanks for reading... The Mods |

| |  |

| Sponsored Links | |

| | #2 |

| Newbie Join Date: Apr 2006 Location: NOR CAL

Posts: 6

|

"There a lot of posts on how to modify your rig here on RCCrawler.com to help it perform better. These include but are not limited to: locking the axles in low, re-mounting rear motor, replacing belts with tighter O-rings, and Tummy Tucks. Any of these modifications voids manufacturer warranty leaving you to fix it if it breaks. So please take caution when choosing to modify your Nylint Rock Crawler. No one here is in anyway responsible for the changes that you make to your chassis." Well stated. As an FYI, if you decide to do the tummy tuck, be very careful with the circuit boards, if they touch metal or touch eachother they will likely be toast, as was my case. This ofcourse voids the warranty and you will have to search around to buy a ckt board set privately. Just my 2 cents on making your Nylint last longer. Justin |

| |  |

| | #3 |

| Quarry Creeper Join Date: Apr 2006 Location: winchester

Posts: 423

|

hey man USE IT AND ABUSE IT

|

| |  |

| | #4 |

| I wanna be Dave Join Date: Sep 2005 Location: USA

Posts: 11,196

|

The main thing that I think helps these things last longer is to drop as much weight as you can. Less weight less breakage. Start cuttin them help and enjoy.

|

| |  |

| | #5 | |

| Rock Crawler Join Date: May 2005 Location: Minnesota

Posts: 588

| Quote:

Luke | |

| |  |

| | #6 |

| Newbie Join Date: May 2006 Location: North Texas

Posts: 8

|

Anyone with the 1st-3rd gen units can install a small screw in the steering knuckle to act as a steering stop. it works the same as the molded in style and is real easy to do. This will save your outer cups from breaking and help save the knuckles.I can post pics if ya like.

|

| |  |

| | #7 | |

| Newbie Join Date: Jun 2006 Location: Central

Posts: 10

| Quote:

| |

| |  |

| | #8 |

| Rock Stacker Join Date: Jun 2006 Location: Balto.

Posts: 51

|

I second that emotion!

|

| |  |

| | #9 |

| Pebble Pounder Join Date: Jan 2006 Location: Chattanooga

Posts: 139

|

3rd that!

|

| |  |

| | #10 |

| Rock Crawler Join Date: Mar 2006 Location: Dayton

Posts: 712

|

I think it goes something like this (quick photoshop)  -Dalton |

| |  |

| | #11 |

| Quarry Creeper Join Date: Sep 2006 Location: Ithaca, NY

Posts: 208

|

A common problem with the plastic drive pulleys is that they are two pieces that simply have a peened via heat way of joining the two halves together. After a time they start to seperate which lends itself to making for not only an unstable component, but as they seperate from the play in the three points where they are joined together the pulley actually becomes a "smaller" diameter and leads to the belt(s) slipping here is a fix with pix................. !. Drill out the plastic attachment points one at a time with a 1/8th inch drill. 2. After drilling out just ONE.........insert a 1/8th inch X 1/4 inch long aluminum rivet with a backing washer. Then move on to the next one and repeat........... 3. What ever excess of the rivet that is remaining grind off so it will no impede the pulley from spinning unobstructed. 4. Done.................. PIX are below and another 2 pix show the final results in the next post. Hope this is helpful to others...............Kerry Last edited by kerrywittig; 11-30-2006 at 09:02 PM. |

| |  |

| | #12 |

| Quarry Creeper Join Date: Sep 2006 Location: Ithaca, NY

Posts: 208

|

Final results of the pulley modification...........

|

| |  |

| | #13 | |

| Rock Stacker Join Date: Jan 2007 Location: st. louis, MO

Posts: 74

| Quote:

so are these the only mods that void it because i want to make sure that i dont void it so i can get a new 1 wen it breaks am i right on this aspect and does cutting the flex tab limiters void it i hope not! AJ | |

| |  |

| | #14 |

| Newbie Join Date: Sep 2007 Location: UK

Posts: 1

|

Hi, Last year I bought a 1:6th Nylint Rock Crawler. It ran perfectly for a long time before developing a fault. In high gear it would only run down hill, came to a stop on the flat and wouldn't run up hill at all. In low gear it covered all terrain. So I sent for a new chassis. All was okay again. Now it has developed the same fault. Can it be repaired? Could it just be drive belts slipping? I can hear the motors running when it stops and I try to drive it still. Any help much apreciated as I use this model as a promo vehicle for our club when we attend shows. Best wishes TonyVee |

| |  |

| | #15 |

| Rock Stacker Join Date: Jul 2007 Location: colorado

Posts: 68

|

sounds like belts to me You can go to your local auto parts store and get some o-rings that are a little bit smaller then the stock belts.

|

| |  |

| | #16 |

| Quarry Creeper Join Date: Jul 2009 Location: Bel Air, MD

Posts: 224

|

The issue I am having on mine is there is a plastic couple inside the gearboxes, between teh axle and the stub shafts, mine are shattered(junk plastic)...anyone have replacements or an idea of what to make them out of?

|

| |  |

| | #17 |

| Newbie Join Date: Mar 2022 Location: GAINESVILLE

Posts: 1

|

hi do any of you guys know what size the drive belts are or where to get want to change belts while doing above pully repair thanks in advance db |

| |  |

|

| |