| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Pebble Pounder Join Date: Feb 2007 Location: Sawyer

Posts: 183

|

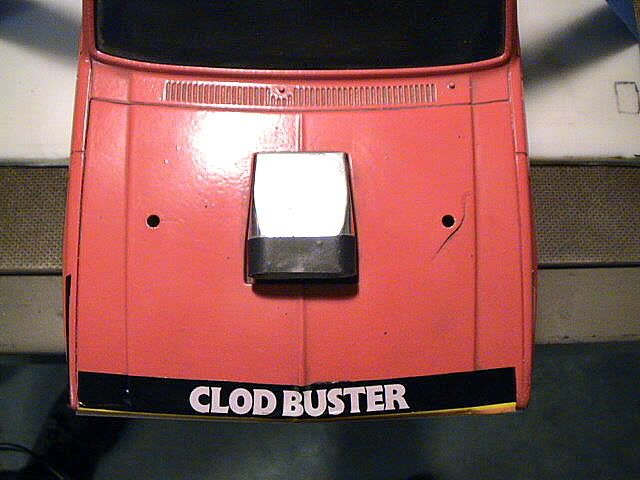

For those of you that don't already know how to do this, I'm going to try to show you the basics of Cutting with thread. For making fine line cuts in plastic, using sewing thread has always been my favorite method, Here's what your going to need to get started. 1 spool of thread. 1 sewing needle. 1 roll of masking tape. 1 nice clean flat board. 2 hands (Yes you have to use your hand's, If you are afraid of working with you hands please leave now!) And last but not lest, What ever it is you decided you want to cut apart. Hear I will be cutting the hood out of a Clod body using,You guest it, Thread!  First you want to position the body over the board so that you have access to the back of where your making your cut.  Next grab that roll of masking tape and tape that sucker down to the board so that it can't move around on you.  Now position the board so that the piece to be cut is overhanging your, workbench\ dinning room table. Some times it helps to clamp the board down,Or put something heavy on it. Here I got lucky and was able to fish the thread above the grill for my starting point. (It's easier to have the spool on the top side of the cut)  If not so lucky and you don't have a leading edge to start on, Grab that needle up in a pair of vice grips and heat it up with a heat gun, Or a lighter, It does not have to be red hot. " WARNING" DO NOT POKE YOUR SELF WITH THE NEEDLE! FOR IT IS HOT AND HURTS ALLOT MORE THAN A POKE WITH ONE THAT IS NOT HOT!!  Now just make a hole in line with what your going to cut.  And put your thread through the hole you just made  Next Grab the spool in one hand,  And grab the piece coming out the bottom with the other, Give your self about a foot of cutting thread between your hands.  To start your cut, apply light pressure in the direction you want to cut, At the same time move your hands up and down making the thread like a scroll saw blade. As your doing your cutting, Every dozen strokes or so feed off a bit of thread from the spool and take up the slack on the bottom, It's like putting a new blade in all the time your cutting. So if your doing it right it you should be about here by now, If your not, Than Your staring at a pile of thread on the floor,and your wondering why your truck is taped to board siting on your bench. Well, Keep trying.  All right! Your 2/3 the way done! So how many times did the thread snap on you? I told you, just keep feeding in new, You'll get the hang of it. The plus side for all you young builders, If you lose control of the thread, It's not going to take a chunk out of your finger or worse..The fender!!  So there you have it, You just cut up a perfectly good Hard body!   As you can see it leaves a nice clean edge.  Now that a straight factory hood line!  I'm not knocking using a X-Acto to do this job, But besides the fact that the hood now opens you can't tell i did anything, No nick's in the paint (That it did not already have) Or OOP's I slipped and cut to far back and now the hood opens all the way to the windshield. And i still have my finger tip's!!!  So now that your a Pro at Cutting with sewing thread, Don't stop now! go ahead and make those doors open like you have always imagined, See what you can come up with, after all, It's just plastic  Ryan. Last edited by BECKWORKS; 05-31-2008 at 07:23 PM. |

| |  |

| Sponsored Links | |

| | #2 |

| RCC Addict Join Date: Nov 2007 Location: BV

Posts: 1,170

|

That's awesome! Thanks for the write-up.

|

| |  |

| | #3 |

| Quarry Creeper Join Date: Jun 2004 Location: aurora, CO

Posts: 472

|

i had no idea you cut one of these bodys with sewing thread! great tip i cant wait to give it a shot on my own

|

| |  |

| | #4 |

| RCC Addict Join Date: Jun 2004 Location: ORegon

Posts: 1,002

|

nice. I would have never thought of that. I never thought thread could do that to plastic. Also I'd be afraid of using an xacto because it is easy for it to slip and cut in a not so straight line or cut a finger. cool how-to  |

| |  |

| | #5 |

| Newbie Join Date: Aug 2007 Location: BC

Posts: 45

| |

| |  |

| | #6 |

| Rock Crawler Join Date: Dec 2007 Location: Shreveport, La

Posts: 544

|

are you serious?! THREAD!??? |

| |  |

| | #7 |

| Pebble Pounder Join Date: Feb 2007 Location: Sawyer

Posts: 183

|

Trust me, it works! I have more important things to do than write my first "how to" article about a technique that doesn't work I picked this handy tip up back in the day when I was building model cars  Ryan |

| |  |

| | #8 |

| RCC Addict Join Date: Dec 2007 Location: Calgary

Posts: 1,575

|

thats cool. Thanks for the info. I'm going to try it.

|

| |  |

| | #9 | ||

| RCC Addict Join Date: Oct 2006 Location: crawlifornia

Posts: 1,612

| Quote:

I was so intrigued that I didn't even look at who started the thread, I just kept reading. When I got to the bottom and read this Quote:

Last edited by rockhugger; 05-29-2008 at 11:14 PM. | ||

| |  |

| | #10 |

| RCC Addict  Join Date: Sep 2007 Location: Western ND, Bakken central

Posts: 1,653

|

thats pretty cool, now I just gotta find a body to cut up that K9-01 shit is hilarious  |

| |  |

| | #11 |

| I wanna be Dave Join Date: Sep 2005 Location: USA

Posts: 11,196

|

Inmates have been using this method for making shanks and cutting bars for Years....... So the real question is. Where did you learn it? LOL Nice tip for sure. Can't believe I've never seen it on here before.. Glad you posted it up... |

| |  |

| | #12 |

| RCC Addict Join Date: Jun 2006 Location: Sin City

Posts: 1,852

|

This is an old plumber's trick to cut PVC pipe.

|

| |  |

| | #13 |

| Oppan Gangnam Style  Join Date: Jun 2005 Location: Shingle Springs

Posts: 5,164

|

The secret's out! Nice write up. |

| |  |

| | #14 |

| RCC Addict Join Date: Jun 2004 Location: ORegon

Posts: 1,002

|

does it work on lexan too?

|

| |  |

| | #15 |

| Newbie Join Date: May 2008 Location: Rock Hill, SC

Posts: 9

|

a thread about thread..... thanks for sharing that, learned something new! |

| |  |

| | #16 |

| I wanna be Dave Join Date: May 2007 Location: Taylors Falls just hanging with the MNRCRC crew.

Posts: 7,843

|

Nice trick hard to imagine that thread could cut plastic that cleanly. Love the Avitar.

|

| |  |

| | #17 |

| Pebble Pounder Join Date: Feb 2007 Location: Sawyer

Posts: 183

|  Last edited by BECKWORKS; 05-31-2008 at 07:21 PM. |

| |  |

| | #18 |

| I wanna be Dave Join Date: Jan 2008 Location: Arat Alabama

Posts: 2,678

|

I do Electrical work for a living and many time I've cut schedule 80 3" and 4" pvc conduit with small nylon string. Like when in tight quarters or having to cut it of flush with something where power tools could not be used. The same principle applies here. Excellent write-up Beckworks.

|

| |  |

| | #19 |

| Quarry Creeper Join Date: Oct 2006 Location: where fear and common sense don't get in the way

Posts: 451

|

Great write up  , never would have thought of that. However, if the wife ever caught me working with thread she'd expect me to start hemming things or making curtians :-(. , never would have thought of that. However, if the wife ever caught me working with thread she'd expect me to start hemming things or making curtians :-(.

|

| |  |

| | #20 |

| RCC Addict Join Date: Mar 2005 Location: Saginaw

Posts: 1,721

|

Great post  I especially like how it removes very minimal material. What type of thread do you suggest? Cotton or synthetic? |

| |  |

|

| |