| | #1 |

| Pebble Pounder Join Date: Dec 2005 Location: Knoxville

Posts: 169

|

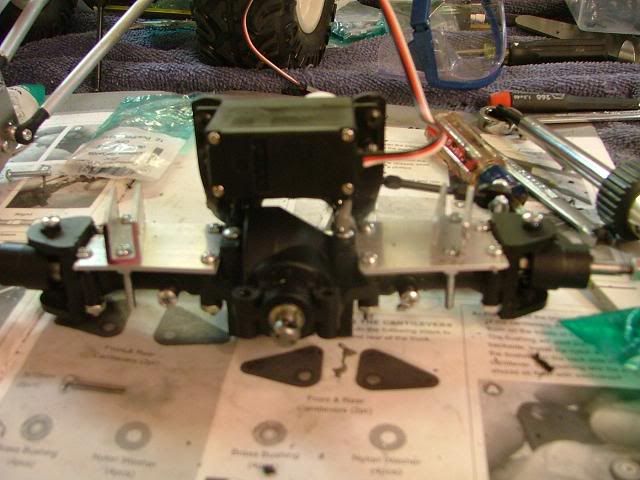

this is my goliath that i never gave a chance as stock it's lacking drive shafts, gear reduction unit, and speed control i have also yet to narrow the wheels as you can see in the pictures but this is what i have so far     |

| |  |

| Sponsored Links | |

| | #2 |

| Quarry Creeper Join Date: Nov 2005 Location: Western, NC

Posts: 490

|

Not bad man, what's the wheelbase on that thing? You probably want to keep it in the 11" to 12.5" range, anything longer on a 2.2 rig seems to kill the breakover angle. |

| |  |

| | #3 |

| Pebble Pounder Join Date: Dec 2005 Location: Knoxville

Posts: 169

|

lets not talk about how long it is cause its too long an i plan on shortening the front links about 2 inches....but thats my first rig i figure i did pretty well....and i want to say there are no after market parts for these goliaths

|

| |  |

| | #4 |

| Rock Stacker Join Date: May 2005 Location: castlerock

Posts: 97

|

I have also heard and that their axles arn't quite up to par for durability. Nylon or plastic gears, what ever they are. and the axle shafts arn't supported well in the housing. but that's just what I have heard and from the pics I have seen. I would be carfull with them.

|

| |  |

| | #5 |

| Rock Stacker Join Date: May 2005 Location: castlerock

Posts: 97

| |

| |  |

| | #6 |

| Pebble Pounder Join Date: Dec 2005 Location: Knoxville

Posts: 169

|

to late not this is what i have....and plus they look so cool

|

| |  |

| | #7 |

| Pebble Pounder Join Date: Dec 2005 Location: Knoxville

Posts: 169

|

ok the link mounts didn't survive....so i reworked it old link mounts  new link mounts    |

| |  |

| | #8 | |

| Rock Crawler Join Date: Apr 2005 Location: Upland

Posts: 546

| Quote:

As for the shafts, I wouldn't worry there either. They're steel and can handle quite a bit of torque. After all they're the same size as the ones used on Nitro cars and trucks. For rock crawling though, I would ditch the ball diffs and plastic outdrives. The out drives will break first before anything else. It's true, the shafts could have been sealed more like the TLT, but the PTI axle housings are pretty strong and are way thinner than the TLT axles. That means less of a chance to get held up on rocks. I'd like to see how this truck performs when completed. Good Job! | |

| |  |

| | #9 |

| Pebble Pounder Join Date: Dec 2005 Location: Knoxville

Posts: 169

|

thanks for the support....and i hope i get it finished! between classes and work i haven't had alot of time to put into it....but yea it seems like everytime you try something different and post it people have nothing but negative things to say about it...but if we all did tlt and clod trucks what fun would that be?

|

| |  |

| | #10 |

| Rock Crawler Join Date: Apr 2005 Location: Upland

Posts: 546

|

Exactly! You'll never know if something works or not with out trying. Good luck. |

| |  |

| | #11 |

| Pebble Pounder Join Date: Dec 2005 Location: Knoxville

Posts: 169

|

i finished the upgrade on the front axle all new lower link mounts and upper...i still have yet to upgrade the rear of the truck but i tought this was a good place to take pictures to show the progress....oh yea and im am going to shorten the rear links by 1/2 inch so it will fit a 1/10 scale body better.        |

| |  |

| | #12 |

| Quarry Creeper Join Date: Jan 2005 Location: Westchester

Posts: 370

|

Good progress, now if it can compete with the TLTs i guess time will tell. You made it about the best you can. Am I the only one who thinks those Goliath axles and a cleaner servo setup would look killer as a scale rig? |

| |  |

| | #13 |

| Pebble Pounder Join Date: Dec 2005 Location: Knoxville

Posts: 169

|

well it still has aways to bo befor it's able to compet with a tlt rig.....but the axles have a thinner profile compared to the tlt axles so they do have that one up....we'll see how it goes i still need to get this to completly lock the axles because i dont' know how well my locking method will hold up

|

| |  |

| | #14 |

| Pebble Pounder Join Date: Dec 2005 Location: Knoxville

Posts: 169

|

ok i've run into drive shaft pains....what i was gonna do is take the original drive shafts (that are a dog bone on one end and a cv on the other) and cut them in half then use brass sqare tubing to splice them back together.....well this sounded good in my head, but it's just no posible for the front end because the angle from the output drive to the axle is just too steep for the dog bone.....so i thought about using a drive shaft off of my xtm xfactor......well i did it but it doesn't really work because the motor hangs down and comes in contact with the overly larg drive cups on the end of the xfactor shafts....so now im right back where i started...and ideas or suggestions would be great (besides the; you should have got a tlt suggestion) oh and ill try to put some pictures up when i get home because it's easier to see in pictures thanks Ben |

| |  |

| | #15 |

| Pebble Pounder Join Date: Dec 2005 Location: Knoxville

Posts: 169

|

im done....except for a pinion gear and i don't have the front drive shaft on the truck for it is drying on to the pictures....oh and this is a temporary        this last picture is of the rear drive shaft....that i made by cuting the original drive shaft in half and graphing in square brass tube  |

| |  |

| | #16 |

| Quarry Creeper Join Date: Aug 2005 Location: crescent city

Posts: 304

|

my, what a wide post you have!!

|

| |  |

| | #17 |

| Pebble Pounder Join Date: Dec 2005 Location: Knoxville

Posts: 169

|

my what a 12 inch monitor you have

|

| |  |

| | #18 |

| Newbie Join Date: Dec 2005 Location: Nashville

Posts: 31

|

i love it man, i think it's great and thanks for the hi-res images. I like it when I can actually tell whats been done. Glad you didn't follow the norm and tried you're own thing too, thats what this hobby is all about! Keep up the good work!

|

| |  |

| | #19 |

| Pebble Pounder Join Date: Dec 2005 Location: Knoxville

Posts: 169

|

i think i've come up with a fix for the front drive shaft....the problem i was having is that the angle was to severe for the dog bone and out drive assembly i couldn't ever make it the right length it was either to short or too long....when ever i thought i had it the right length the dog bone would bottom out in the bottom of the out drive cup and would inhibit the degree of articulation the fix: i used a rustler half shaft two different sizes of square brass tubing... what i did was cut the universal joint off the end of the half shaft drill a hole for the larger square tube and inserted it to what was left of the half shaft...then i bored out the other end of the universal joint to accept 1/4 inch solid tube...i then cross drilled bothe ends where the square tube and the 1/4 solid was inserted i then pinned them...the i inserted the 1/4" tube into the out drive cup an cross drilled it to accept a screw to lock it into the out drive.... this seems to work it doesn't slip out and doen't inhibit articulation on to the pics    |

| |  |

| | #20 |

| Pebble Pounder Join Date: Nov 2005 Location: huntsville

Posts: 133

|

holy way-to-rig-a-driveshaft batman |

| |  |

|

| Thread Tools | |

| Display Modes | |

| |