| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Rock Crawler Join Date: Feb 2011 Location: Courtenay

Posts: 716

|

This thread will cover in great detail my experience installing 540's on my RS10xt. I will take my time to cover every step and every obstacle met throuout the process. *Other members please feel free to post your 2-cents, and your solutions to problems you encountered. BUT, Please wait untill I have reached that step in the process. Thanks. I will be using ZNO-RC's "Big Boy 540 kit". I believe mine are from the second production run of these kits. I will be using "RC4wd 45t crawler" motors. An inexpensive sealled can 540 motor, Also available from ZNO-RC. A likely choice for many economy-minded crawlers considering this kit. My order, the day it arrived;  |

| |  |

| Sponsored Links | |

| | #2 |

| Rock Crawler Join Date: Feb 2011 Location: Courtenay

Posts: 716

|

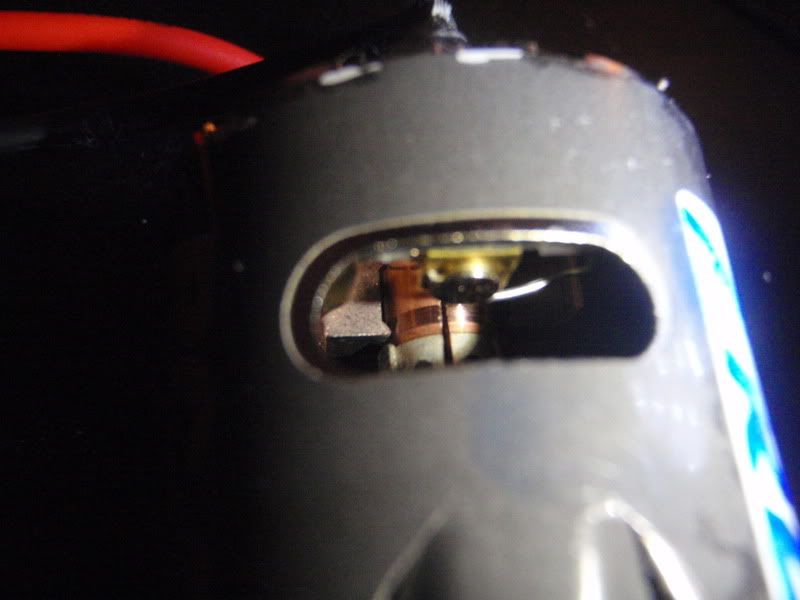

The very first thing that I want to do is look at the motors I'll be using. They came allready equipped with wires and bullet connectors just like the stock 390's on my crawler.  No soldering there. No soldering there.At first glance though, I don't see any visible capacitors installed on these. However, I later noticed something inside the cans that look just like capacitors, blue ones, one on either side. ** If anyone knows for sure, please chime in.  I Looked inside the cans at the brushes, and noticed that they are actually "C" shaped, or I guess " [ " shaped. They come to a point at the top and bottom of the brush, therefore contact the comm at the 2 points instead of the whole face. The Stock 390 motors also come with these style brushes. When I first got my RS10, I water-dipped my motors and ran them until the entire face of the brush was on the comm (breaking in)  |

| |  |

| | #3 |

| Rock Crawler Join Date: Feb 2011 Location: Courtenay

Posts: 716

|

A Lot of ppl say you don't need to Break-In motors on a crawler. I talked to a motor builder, EddieO of Teambrood,com, and he says it's always a good Idea. I thought it worked GREAT on my stock motors, so I'll keep doing it. EddieO says he's never seen brushes shaped like this before, but he suggested running them at about 2volts for a while and rounding them down to the comm. He also recamended against water dipping! I hooked mine up to a D cell energizer, and its been running for an hour and a half, and the middle of the brush is just STARTING to contact the comm. This is going to take awhile |

| |  |

| | #4 |

| Rock Crawler Join Date: Feb 2011 Location: Courtenay

Posts: 716

|

I need to put a pinion gear on each of my new motors. The stock motors have a 5/64" shaft diameter, and the 540's have a 1/8" shaft diameter. I'll need to drill the pinions out to fit. When I bought my crawler, I ordered the "steel gear kit" from http://www.crawfordperformanceengineering.com/ . The Kits came with a hardened steel 10 tooth pinion. I left the stock 8 tooth pinions on my 390 motors, So I figured I'd drill out the 10t's for the 540's. ............I've snapped 2 drill bits so far, |

| |  |

| | #5 |

| Quarry Creeper  Join Date: Mar 2011 Location: Houston

Posts: 227

|

I ordered the steel gear kit from zno, I assume it's the same kit...I tried and tried to drill out those hardened steel 10 tooth pinions. I tried many bits, broke a couple. Even went and picked up some cobalt bits (for drilling metal), which were still no good. What worked best for me were some bits in my dremel stuff. They were hard enough and sharp enough. I finally got 80% through one and the pinion broke, prob had something to do with me putting it in a vise. So after a couple hours of all this I decide that these gears can't be drilled and I drill out my stock 8 toothers which was so easy. If I had to do it over or if I decide I want faster pinions I would just buy some diff 10 tooth pinions that have 1/8 hole already. |

| |  |

| | #6 |

| Rock Crawler Join Date: Feb 2011 Location: Courtenay

Posts: 716

|

I had the pinions mounted on a drill press, pouring cutting oil constantly, using high-speed bits, slow-speed bits, and cobalt stainless bits. These are tough little F-ers! I called around, and no-one on Vancouver Island has the proper pinions on hand (only 12t and up). I'll wait untill I need to order more stuff before ordering these over border from the U.S. Thanks for the write up CrawlHTX. Thats where I'm at now; I'll be Drilling out the stock 8t's for the new motors until proper pinions are available. |

| |  |

| | #7 |

| Rock Stacker Join Date: Dec 2010 Location: San Anselmo, Ca

Posts: 96

|

Glad I came across this. I'm doing this swap as well but I'm using the integy pro lathe motors. I'm just waiting my 540 diy kit from ZNO. |

| |  |

| | #8 |

| Quarry Creeper Join Date: Oct 2010 Location: denver

Posts: 301

|

thats the kit i just ordered let me know how it runs

|

| |  |

| | #9 |

| Rock Crawler Join Date: Feb 2011 Location: Courtenay

Posts: 716

| Motor Break-in Finally got these motors broken in. If you plan to buy these (RC4wd sealled can 540 $9.99) You COULD just drive em, But I highly recamend a water break-in for at least half an hour at 3volts. otherwise, your only using about 15% of your brush contact area! I'm pretty sure these motors and our stock 380's/390's are by the SAME manufacturer with different labels. These motors brushes NEED to be worn down for best performance. Pinions If you are lucky enough to have 8 or 10 tooth pinions available at your LHS with the 1/8th shaft diameter, GET THEM! The steel pinions from the steel gear sets are harder than chinese algebra and won't drill out! My 8t stockers won't come off my motors. I heated them up and the set-screw just strips out the hex part but doesn't turn. I got fed up and ground down the shaft on the 540's to fit the 10t pinion. That worked like a charm. I just hooked it up to my break-in power supply, and held the file to the shaft like a lathe. |

| |  |

| | #10 |

| Rock Crawler Join Date: Feb 2011 Location: Courtenay

Posts: 716

|

Now I want to take a close look at the BIG BOY gear housing from ZNO-RC. It's fuctional, but it sure isn't pretty. It looks like a rough cut plate, glued to a piece of plastic........................Cuz thats exactly what it is  . Don't get me wrong, ZNO made a good product, (And props to them for offering it, Cuz no-one else has!!!) I'm just saying I hope it gets better in time, and this version is just 'windows 2.0'. . Don't get me wrong, ZNO made a good product, (And props to them for offering it, Cuz no-one else has!!!) I'm just saying I hope it gets better in time, and this version is just 'windows 2.0'.Edit; If you are using the Do-It-Yourself kit, see this thread for the install of the diy plates http://www.rccrawler.com/forum/redca...-overload.html Last edited by The Jackalope; 02-20-2012 at 10:16 AM. |

| |  |

| | #11 |

| Rock Crawler Join Date: Feb 2011 Location: Courtenay

Posts: 716

|   |

| |  |

| | #12 |

| Pebble Pounder  Join Date: Jan 2010 Location: Emmett, ID

Posts: 148

|

Sure based on these pictures it not going to win a beauty contest. Get her all dressed up and see how she looks. The goal here was great function and trying to keep the price in the RS10 catagory. Can't wait to see it finished and how you get your links around the motors. Also when drilling the pinions start on the side away from the set screw hole. It will help keep you in the center.  |

| |  |

| | #13 |

| Pebble Pounder Join Date: May 2011 Location: Vacaville

Posts: 179

|

Thanks for the write up Justin |

| |  |

| | #14 |

| Quarry Creeper Join Date: Oct 2010 Location: denver

Posts: 301

|

what type of glue are you uesing to conect that plate?

|

| |  |

| | #15 |

| Pebble Pounder  Join Date: Jan 2010 Location: Emmett, ID

Posts: 148

|

We are using a two part epoxy. Proves to be very strong.

|

| |  |

| | #16 |

| Rock Crawler Join Date: Feb 2011 Location: Courtenay

Posts: 716

|

Hey team ZNO, Glad your looking in. Just want to mention, I'm not trying to poke holes in your product. I'm Real greatfull you guys are making them! The point of this thread is to give an unbias impression, and to work through the issues for future builders. And to pioneer new product developement too. Thanks |

| |  |

| | #17 |

| Rock Crawler Join Date: Feb 2011 Location: Courtenay

Posts: 716

|

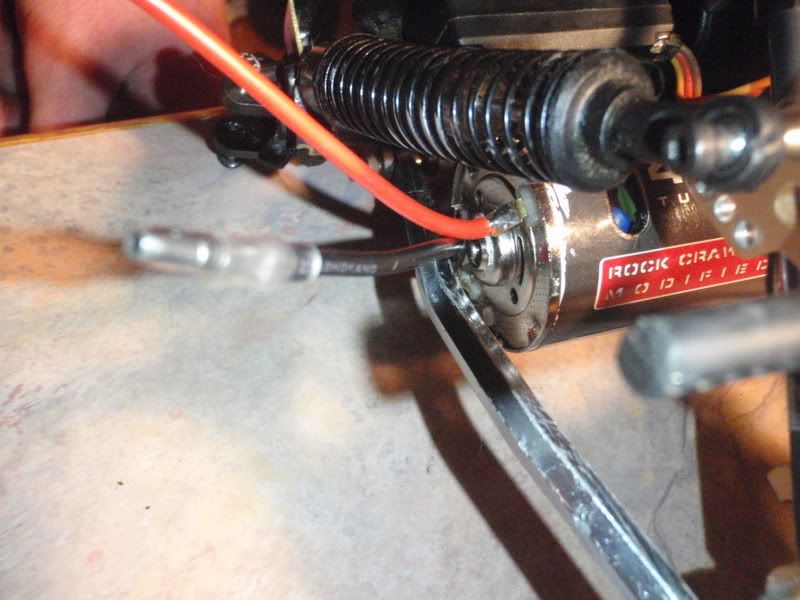

So I don't think there will be any issues with strength. These gear housings are plenty strong. The second gear pin is actually held in place by the aluminum now too.  My beef with them is the thickness of the plate. It stands the motors out an additional 4mm off the original housing. That, in conjunction with the RC4wd motors I'm using, Adds a wopping 10mm to the motor length from stock. This will need some serious thought and design to the suspension layout to keep from binding. Gear housing + stock motor total width = 65mm BB Gear Housing + 540 motor total width = 75mm +/- (not measuring wire leads) My current setup will Defenitly not work. the motor is allready pushing on the lower link on flat ground.   |

| |  |

| | #18 |

| Pebble Pounder  Join Date: Jan 2010 Location: Emmett, ID

Posts: 148

|

Hey no worries. That's why Im here. We want to see the issues as they come up. We stand behind our products and want to help when needed. Keep up the good work on the build.

|

| |  |

| | #19 |

| Rock Crawler Join Date: Feb 2011 Location: Courtenay

Posts: 716

|

One thing I would like to see, is if the aluminium plate could be mounted to the inside of the housing, and "sandwhich" the plastic, while keeping stock length. OR, and offset gear housing would be oh-so-sweet! Heres where these motors sit on the lower link right now. Articulation is not currently possible. Once I solve this link issue, I'll have the shock to contend with.  |

| |  |

| | #20 |

| Newbie Join Date: May 2011 Location: Albuquerque

Posts: 36

|

I've heard that the motor protrudes out a bit more with this set up and a link modification needs to be done. Overall, it sounds like a big build. Thanks man for really posting all this and saving others a lot of time and effort. I'm really hoping that ZNO-RC will soon develop an even better kit that fixes your problem, includes a 1/8" pinion gear and all new metal gears as well. Something that can be assembled and put on. The actual build isn't the problem it's all the little things that arise during the build. Good luck and also thanks to the ZNO guys, hopefully an improved version will come out when I'm ready to upgrade, in a couple of months.

|

| |  |

|

| Thread Tools | |

| Display Modes | |

| |