| | #1 |

| RCC Addict Join Date: Aug 2005 Location: Akron

Posts: 1,784

|

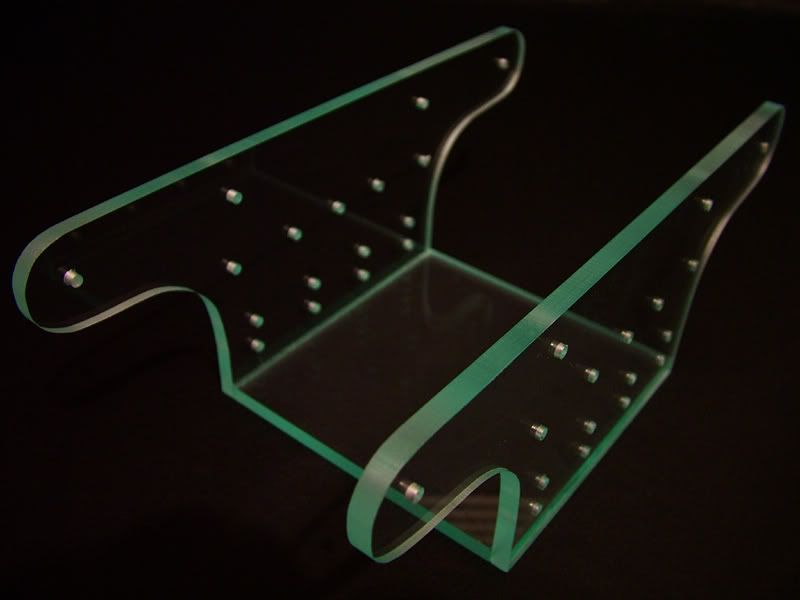

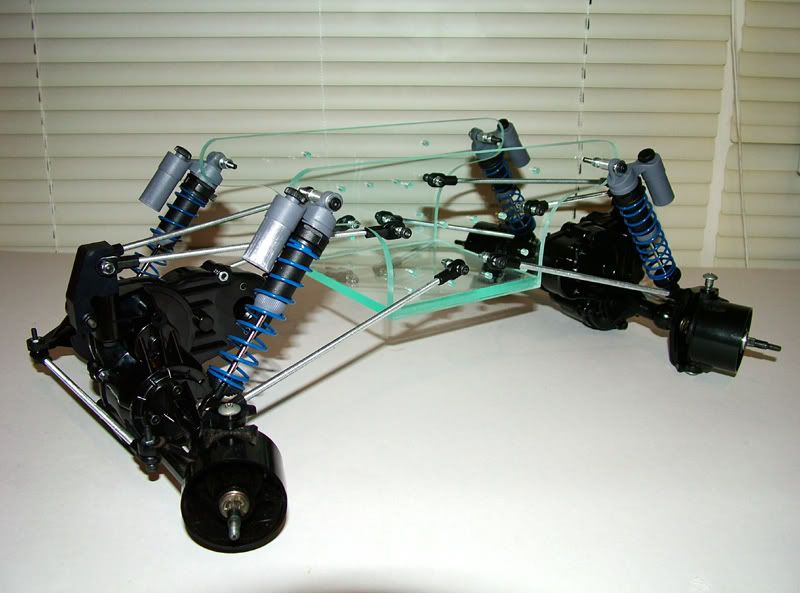

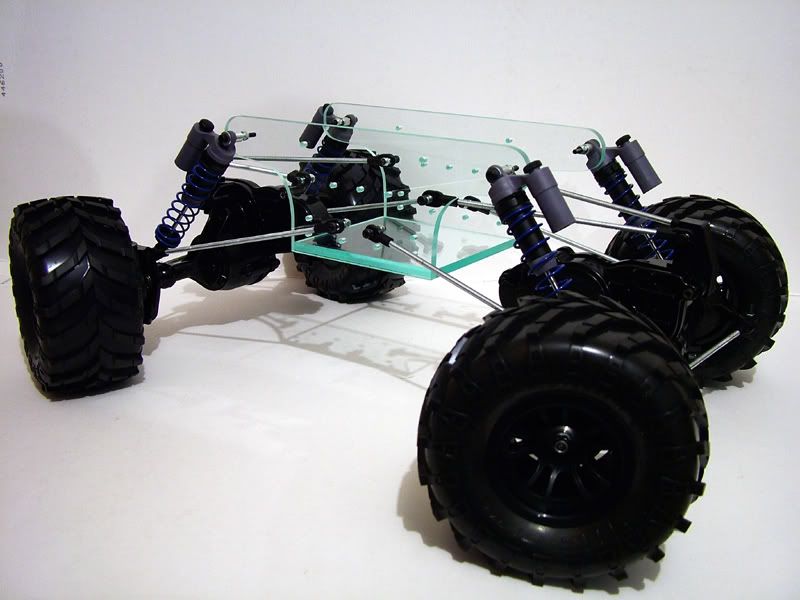

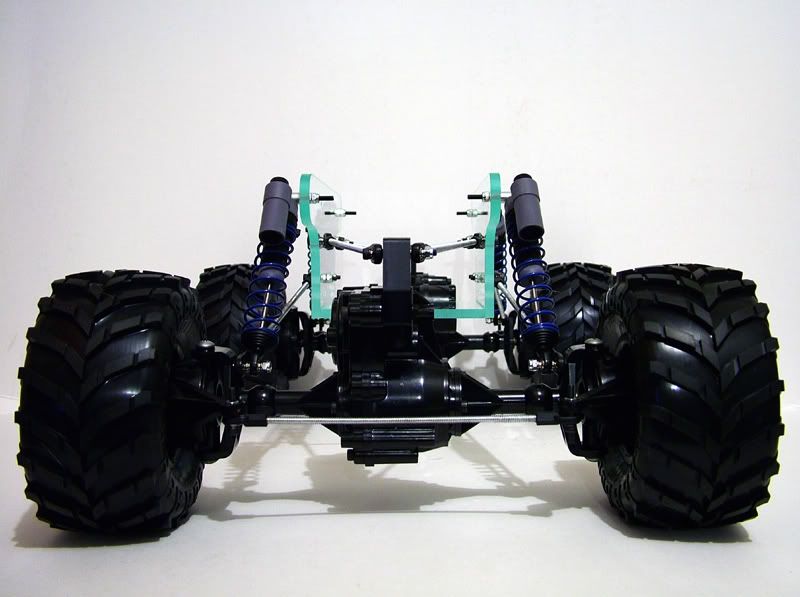

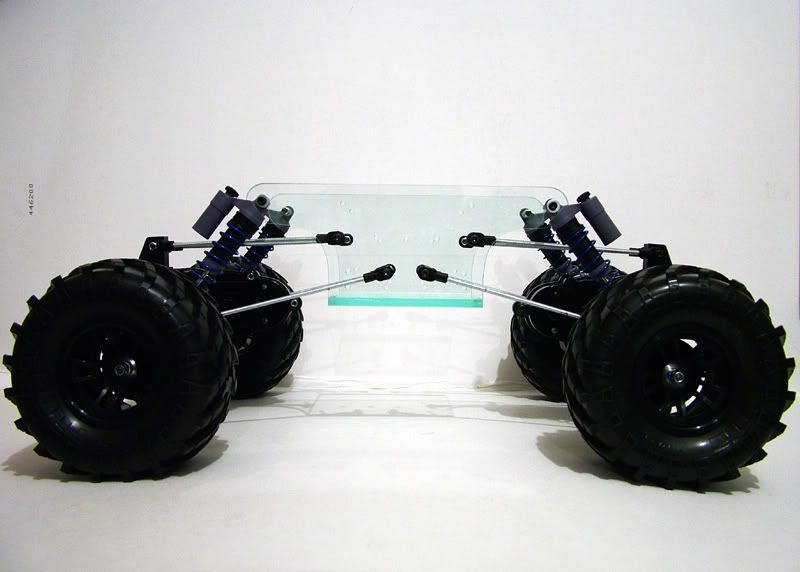

So I randomly picked up a Nylint 1:6 without knowing RC rock crawling even existed. Through searching for information about the Nylint I came across this site finding people who had the same rc interest as myself. It didn't take long to realize I wanted something more customizeable than the Nylint (I'm not knocking the Nylint however) but I wanted something closer to the lines of hobby grade RC like I had a few years ago. With the help of my "search button" (who was immediately introduced to me by mods on this site) Wheelbase = 13" Track Width = 12.25" Belly clearence = 3.5" Articulation = 7.25" RTI score = 1115 Electronics to be installed after suspensions kinks worked out: 65t Lathe motors with 9t pinions (I want creeper slow) Teken Rebel 2 ESC Traxxas 2055 servos (couldn't pass the price I found, I'll get 645's if needed) Traxxas TRQ3 radio with rear steer mod. The chassis - 1/4" Clear acrylic. I made one that was heat bent instead of cut and glued. The glue is just as strong and was easier to make. After everything gets worked out I'll redo the chassis in black acrylic thats heat bent. There will also be 1/4" aluminum cross braces between upper shock mounts and a couple other places between the side walls of the chassis. I don't have them made for this mockup since I'll do those when I make the suspension links.  Since I've never made a crawler before I decided to mock up some suspension links. I didn't want to make aluminum ones then find out they were the wrong length. I just used some 6-32 threaded rod and cut them to the length I had calculated in CAD. Worked out well.  Here are a few pics of the mashers mounted to hpi split 5 wheels.    The suspension seems to work pretty well. The MGT shocks are WAY to stiff and have really slow rebound. What weight oil would be good and are stock maxx springs good? I see most people using them, I'm thinking 30wt oil? Last for now, I rough cut the F-100 body and set it on there. After seeing this I realized it looks exactly like CSR's.... CSR, you have the chevy body right? I hope so!  Any and all comments are appreciated. Thank you for this archive of info. |

| |  |

| Sponsored Links | |

| | #2 |

| Im Brandon  Join Date: Feb 2005 Location: Colfax, CA

Posts: 8,156

|

Looks awesome man! Good work with the CAD, and following through with the design! I think CSR has the ford courier body. Regarding the shocks, get some maxx springs like you said, i think they are very close to not fitting due to the large diameter of the shock bodies on the MGT's but try it because I think thats what I used before. In my tlt I had 25wt oil in them, but this is a different truck so test it out, its mostly trial and error with shocks |

| |  |

| | #3 |

| Rock Crawler Join Date: Jul 2004 Location: Salt Lake

Posts: 684

|

Looks great! but you may need some bracing to stop any possible flexing. Other than that its a great start!

|

| |  |

| | #4 | |

| RCC Addict Join Date: Aug 2005 Location: Akron

Posts: 1,784

| Quote:

" | |

| |  |

| | #5 |

| RCC Addict Join Date: Mar 2005 Location: Saginaw

Posts: 1,721

|

Looks like crunching the numbers beforehand worked out well. Just be sure to route your wiring neatly - that clear chassis will lend itself well to showing off all the electronics. Nice work.

|

| |  |

| | #6 |

| Rock Crawler Join Date: Dec 2004 Location: Land of the Free, because of the Brave

Posts: 891

| Looks great to me! If it were mine, I would further carve up the chassis, dropping some of the unnecessary weight in the process. (in the final design, of course) Something like carving "windows" in the sides of the chassis, and cutting off what's not needed on that top rail. Also, is 1/4" necessary? I don't have any black here, but I've got plenty of 1/8" (maybe 3/16") clear acrylic scraps if 'ya need it. -WRM FYI...I'm on page 73 in AutoCAD 2006 for Dummies, but I'm workin' on it... |

| |  |

| | #7 |

| Rock Stacker Join Date: Mar 2005 Location: natick mass

Posts: 81

|

thats totally sick, you do nice work my experience with acrylic is that if it gets hit hard enough it shatters or cracks, but u know more than me.... -matt |

| |  |

| | #8 |

| Pebble Pounder Join Date: Nov 2005 Location: Back in MICHIGAN

Posts: 196

|

looks good. i just say switch out and use maxx springs like you said, i got hotbodies t/e maxx springs for my clod with 20 weight oil and they seem perfect.

|

| |  |

| | #9 |

| RCC Addict Join Date: Aug 2005 Location: Akron

Posts: 1,784

|

Thanks for all the input! I work at a point of purchase display company so we have a lot of scrap acrylic laying around. The 1/4" stuff is strong. It'll take a heck of an impact to crack this stuff. Now if it were 1/8" i'd imagine it could crack pretty easily. I like it because it doesn't gouge easily and should slide smoothly. As for selling them. Not to sure about that idea. For one, not sure how well it works yet and for two. Mine's unique |

| |  |

| | #10 |

| RCC Addict Join Date: Aug 2005 Location: Akron

Posts: 1,784

|

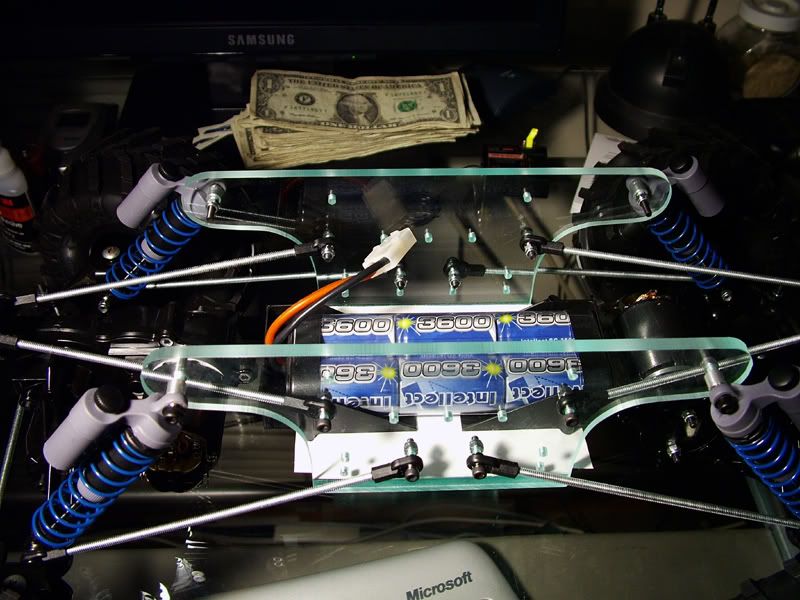

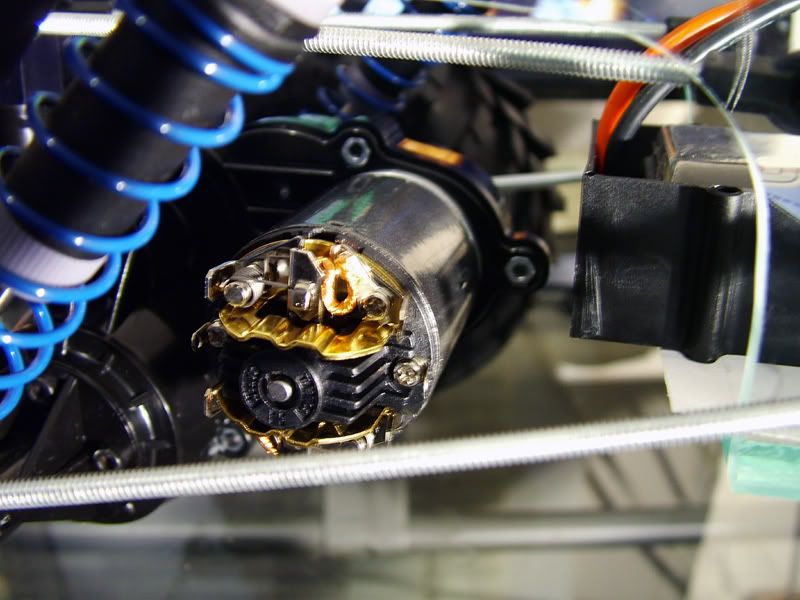

Little more progress. Got the 65T lathes in and the SMC battery. Mocked up the battery mount and mounted up the motors to the axle to check for clearence. Looking good so far.   |

| |  |

| | #11 |

| Newbie Join Date: Dec 2005 Location: mountains

Posts: 6

|

theres just something about the cool green color. my mock up was in plexi to get everything right. it just didnt look that nice or i might have kept it. the maxx springs i have sitting here are .610" id.

|

| |  |

| | #12 | |

| RCC Addict Join Date: Aug 2005 Location: Akron

Posts: 1,784

| Quote:

I ended up buying some maxx springs. Haven't tried them yet. The more weight the truck gains the better the suspension is. Recoil is still slow but oil/plunger holes will fix that. The blue springs might be ok. | |

| |  |

| | #13 |

| Newbie Join Date: Jun 2005 Location: Anchorage, Alaska

Posts: 17

|

Project "Sarge" huh? Are you building it for me?! Unfortunately, the pics aren't showing up for me here at work, but it sounds cool. I'll have to check out the thread from home, so I can see the pics. |

| |  |

| | #14 |

| RCC Addict Join Date: Aug 2005 Location: Akron

Posts: 1,784

|

haha I'm sure we could work something out to get it to your house but you wouldn't like the greenback equivelant Got the steering together today. Here's a teaser flex pic on a mason jar. Still has a good amount of articulation left. How much flex are you 2.2 guys getting with around a 13" wb? I don't want to over do it.  |

| |  |

| | #15 |

| Rock Crawler Join Date: Dec 2004 Location: Land of the Free, because of the Brave

Posts: 891

| Looks good! -WRM |

| |  |

| | #16 |

| RCC Addict Join Date: Aug 2005 Location: Akron

Posts: 1,784

|

haha it's just thick card stock we have at work. One side is black and the other is white. I just folded it in half I believe it's the only white item I own. It's almost time for the trash already. |

| |  |

| | #17 |

| I wanna be Dave Join Date: Dec 2005 Location: Orlando

Posts: 7,420

| I like everything about that setup, you know what you're doing! Keep up the good work, NNNNNNice! |

| |  |

| | #18 | |

| RCC Addict Join Date: Aug 2005 Location: Akron

Posts: 1,784

| Quote:

Tonight I'm cutting the rest of the aluminum to length. (5) cross members for the chassis, (4) lower links, (4) upper links and (4) body posts. I'm hoping to get the body posts drilled and tapped so I can mount the body and get it completely trimmed. I'm working overtime today though so who knows what will get finished. | |

| |  |

| | #19 | |

| RCC Addict Join Date: Aug 2005 Location: Akron

Posts: 1,784

| Quote:

| |

| |  |

| | #20 |

| Rock Crawler Join Date: Jan 2005 Location: Nanakuli

Posts: 638

|

very clean i like it !!

|

| |  |

|

| |