| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #21 |

| Moderator  Join Date: Sep 2008 Location: PA

Posts: 13,935

|

In something new, such as RC rock crawling, people don't know what works so everybody tries something different. After a little experimentation and comparison/competition the best ideas and designs rise to the top. Then everybody seems to change to that design until something better comes along. I applaud you for trying to create something new and improved. All great things are born from the people willing to experiment. |

| |  |

| Sponsored Links | |

| | #22 |

| Custom Carbon Fiber  Join Date: Oct 2007 Location: Connecticut :(

Posts: 4,501

|

any video?

|

| |  |

| | #23 |

| Pebble Pounder Join Date: Mar 2006 Location: igloo, Alaska

Posts: 193

|

Everytime i look at this, i think 1 link with traction bars. I think it is anwesome idea and with refinements, may be the ticket... Props man  |

| |  |

| | #24 |

| Rock Crawler  Join Date: Feb 2008 Location: Copperopolis

Posts: 973

|

Decent idea, looks like it will function...but it may not have the performance of a traditional 3 or 4 link and it might not hold up to the stress of crawling having all 4 of the links going to one plate attached to the servo plate mounts of a TLT axle....way to much stress..My steering servo, hitec 645mg, not the strongest of servos managed to crack and break those servo plate mounts off of 2 TLT axles...those mounts were not even designed or meant to support the stresses from even the most common mod of the upper links attached to the servo plate which was only meant to support a servo and the stress applied.... If you are having axle steer issues it can be one or a combo of these things: vertical separations are off between the chassis and axle mounts chassis is to wide or thin for the original mounting points on the axles....the original TLT chassis was something like 2.5" wide... so your link mounts placement on the axle were designed around a 2.5" wide chassis. Links are to short or uneven in length... Also the 30 degree bent links will make axle steer even more noticable when the things stated above are off more than straight links only because bent links tend to allow more axle roll depending on set up which also can cause axle steer in full flex situations...There is reasons for the industry standard of 30 degrees and axle steer is one of them. Last edited by DORK VADER; 02-12-2009 at 09:44 AM. |

| |  |

| | #25 | |

| Quarry Creeper Join Date: Jan 2007 Location: Italy

Posts: 297

|

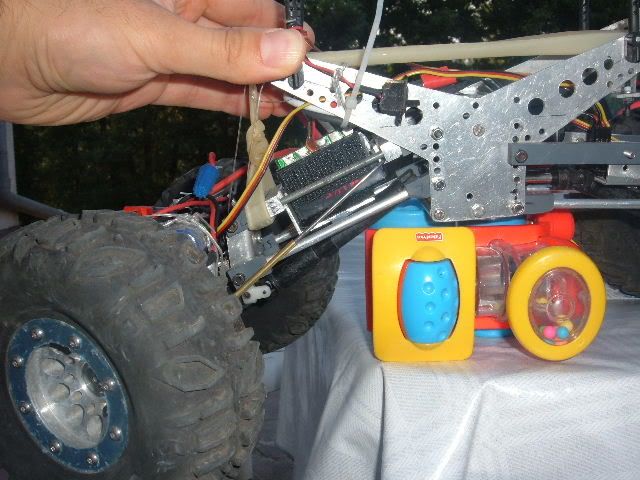

It's time for a short update. I didn't check this thread for a long time and I'm proud other people appreciated my work: in my Country the only suggestion I got is that my TLT is ugly! Unfortunately I don't have Moab style rocks near home, the best ones I can find not too far from where I live are these ones: Cliff in Marina di Massa Quote:

Recently I tryed a way to remove the shocks. I used a 'torsion bar' between the axle and the links. When the axle twists it exercise a force in the opposite direction of the movement.  I had to limit the vertical movement of the axle: normally it is fixed by the shocks stroke, while I had to put a thin rope to limit the axle moving down and a mechanical stop with a screw for the up movement. I think the suspension stroke can be limited in other ways but I didn't find a simpler way. The force to keep close axle and chassis is given by a tourniquet   The droop on fron axle can be impressive.  The reasons I removed the shocks are the following: - I hate tires scrubbing in the shocks - Shocks limit the drop. - In a drop setup an internal spring is put in the shocks: it further reduces the shock stroke. Besides the force of that spring is very low when the axle is close to the chassis, so the chassis moves easily in a steep climb, while it reaches its maximum when the belly is high centered and the axle drops. In that circumstance that force reduces the grip of the axle because it is pulled up by the chassis. Using a long tourniquet instead of a shock with internal spring I can fix better the initial force which prevents the chassis moving away from the axle during a climb. Due to the fact that the tourniquet is quite long it can extend very much (impressive drop can be obtained) with minor differences in the force exercised: less weight is subcracted to the axle by the closing force when the crawler si high centered. Any suggestion and feedback is welcome. Feel free to correct my poor English or ask what is not clear. Bye Filippo Last edited by setecastronomy; 08-18-2009 at 03:38 AM. | |

| |  |

|

| |