| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #21 |

| Rock Stacker Join Date: Jan 2006 Location: Citrus Heights

Posts: 70

|

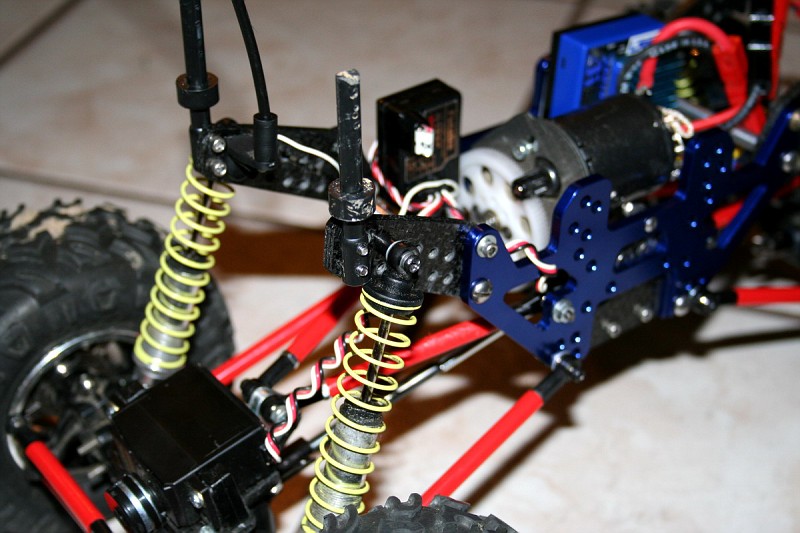

Just bought 2 more, 15.27 with shipping. The setup in the pics had a little too much articulation. It would twist too much on tough inclines and raise one of the front tires off the rock, (can you say torque twist |

| |  |

| Sponsored Links | |

| | #22 |

| Quarry Creeper Join Date: Jan 2006 Location: Winston-Salem

Posts: 200

|

Thanks for the update. I just ordered a set of these towers to convert my stock chassis'd TLT. I think I'm going to go pretty wide with the chassis plates, to try and lay the Stealth down as low as I can without needing a spur cutout (not much you can cut out on these shock towers!). We'll see. Also, following your lead, I think I'm going to fabricate a few strips of carbon fiber to extend the chassis out at the top with a half dozen shock mounting points and body post mounts. Post pics when you can! |

| |  |

| | #23 |

| Rock Stacker Join Date: Jan 2006 Location: Citrus Heights

Posts: 70

| |

| |  |

| | #24 |

| Pebble Pounder Join Date: Apr 2006 Location: griswold

Posts: 130

|

First I said that looks so cool!...until that ugly body went on..naked that thing looks bad a$$!

|

| |  |

| | #25 |

| Quarry Creeper Join Date: Jan 2006 Location: Winston-Salem

Posts: 200

|

Just slapped mine together real quick for a test fit. Need to fabricate some aluminum standoffs. Right now I'm using the factory bottom standoff spaced with an Associated body post spacer for now. You can see the t-plate I had to make out of carbon fiber to mount the Stealth trans. I also used different upper link chassis mounting points. It ended up 0.850" above the lower link point (Factory spacing is ~1"). So far, torque twist isn't nearly as bad as I thought it would be with the shocks layed down pretty good. I'm gonna fabricate some L-bracket extensions of my own.  For $15, shipped, I sure as heck have no regrets with this chassis! Those things are THICK! |

| |  |

| | #26 |

| Newbie Join Date: Jul 2006 Location: LA,CA

Posts: 35

|

those things look friggin awesome. 15 buck is a steal.

|

| |  |

| | #27 |

| Quarry Creeper Join Date: Jan 2006 Location: Winston-Salem

Posts: 200

|

The way the trans slid in there actually places it 1/4" lower than it sat in the stock chassis, and over an inch lower than the motor sits in the TLT trans. The motor centerline is approx 2" from the bottom edge of the chassis. Laying the tranny down would bring it down another inch, which I might give a try.

Last edited by SammyXp; 09-06-2006 at 07:02 AM. |

| |  |

| | #28 |

| Rock Stacker Join Date: Jan 2006 Location: Citrus Heights

Posts: 70

|

Looks good, nice work. You could use some thick threaded rod to space the two chassis plates apart, with a lock nut on each side of the shock tower, kinda like a tie rod?? You might want to make a lexan skid plate for the bottom, mine snagged a lot till I made one. |

| |  |

| | #29 |

| Quarry Creeper Join Date: Jan 2006 Location: Winston-Salem

Posts: 200

|

I just ordered some K&S 1/4" .049 wall aluminum. I'll cut it to length, tap it with an 8-32 tap and just bolt the two halves together with those. The skid plate is a good idea, though. Gotta find some scrap lexan.

|

| |  |

| | #30 |

| Newbie Join Date: Aug 2006 Location: OUT WEST

Posts: 7

|

You can use 1/4 in cutting board for the skid as well. I am in the process of putting one together woth the shock towers and I am going to drill the skid on each corner then just run the bolt for the link into the skid plate. The skid plate is made from a cutting board you can buy at the dollar store. Just a thought |

| |  |

| | #31 |

| Quarry Creeper Join Date: Jan 2006 Location: Winston-Salem

Posts: 200

|

Cutting board sounds like a great idea. Most likely made of either Nylon or a Delrin material that would be slick on the rocks, and self-healing. I'm not sure I can picture how you're suggesting it would mount to the chassis, though. Pics of someone who has done it? By the way, the 1/4" OD .049 wall standoffs came out awesome. The 8-32 tap was much easier to work than a 4-40 tap into 3/16" .049 tubing. A lot less fragile! I'll post pics later. |

| |  |

| | #32 |

| I wanna be Dave Join Date: Jul 2005 Location: Cedar Rapids

Posts: 2,028

|

Cutting board is polyethylene medium or high density depending on what you get. I think he is talking about running a long bolt through the lower ball links. That way it would hold the links and skid plate on. |

| |  |

| | #33 |

| Newbie Join Date: Aug 2006 Location: OUT WEST

Posts: 7

|

I am talking about the lower end link mounts to where they go to the frame. I just drilled a slightly under sized hole and let the stainless screw tap itself (word of caution it is a pain to screw in but it will not back out). I used this on the first TLT chassis I built and it worked very well. I had originally bought inserts to epoxy into the board but it wasn't required as the screws will not back out. The cutting boards I bought at the dollar store were 1/4 in thick and a pain to cut my band saw wasn't very happy. I cut it oversized and then used the table sander to get final size as the band saw is a very ruff cut on the cutting board. |

| |  |

| | #34 |

| Quarry Creeper Join Date: Jan 2006 Location: Winston-Salem

Posts: 200

|

I like the idea of self-tapping right into the cutting board. Might need to dremel out some clearance for the driveshafts, though, since the steatlh trans is sitting way low.

|

| |  |

| | #35 |

| Newbie Join Date: Aug 2006 Location: OUT WEST

Posts: 7

|

I had to cut out a horse shoe cut out of mine but I am using a old RC-10 tranny in mine.

|

| |  |

| | #36 |

| I lost my vendor privileges Join Date: May 2006 Location: TOP OF THE HILL

Posts: 3,014

|

just bought a tlt kit from brando and the cutting board sounds like a good idea. probably wont use it but good call.

|

| |  |

| | #37 |

| Quarry Creeper Join Date: Jan 2006 Location: Winston-Salem

Posts: 200

|

Fabbed up some "shock towers" yesterday...   More pics in my TLT Build thread... My First Crawler (56k - don't bother) Last edited by SammyXp; 09-06-2006 at 07:09 AM. |

| |  |

| | #38 |

| Newbie Join Date: Aug 2006 Location: OUT WEST

Posts: 7

|

Looks good SammyXp. I have been slacking on my TLT. My daughter wanted a truck to go play so I am putting together a clod axled crawler for her. I am trying to use the shcok towers for hers as well. I bought 3 sets while they were on sale at tower. We'll see how it turns out.

|

| |  |

| | #39 |

| Rock Stacker Join Date: Jan 2006 Location: Citrus Heights

Posts: 70

|

You might want to brace between the "shock towers" with a rod and sleeve to prevent excess flex or snapping one off...

|

| |  |

| | #40 |

| Rock Stacker Join Date: Jan 2006 Location: Citrus Heights

Posts: 70

|

But looks good, mine worked a lot better after I raised the angle of the shocks..

|

| |  |

|

| |