| | #1 |

| Newbie Join Date: Nov 2005 Location: SWEDEN

Posts: 33

|

HI! i just wonder how it gonna be if i put in a brushless systen in my txt-1 and a GD600, does anyone of You done this before?  PLZ. only serious, mr Dirk Digler can sitt down and just listen.....:-P im a newbee. mr_svensson SWEDEN |

| |  |

| Sponsored Links | |

| | #2 |

| Rock Stacker Join Date: Sep 2005 Location: N.B. Canada

Posts: 73

|

I have one mounted to the gd600.. but I haven't put it in the truck yet honestly. With the snow coming I dont think I will actualy mount it to the truck for a good while. I need to keep my snow set up (wheel speed) I'm sure it will work out good. Should have all kinds of run time. I dont know if I would buy a brushless just for a txt though... unless money isnt a big deal. |

| |  |

| | #3 |

| Newbie Join Date: Dec 2005 Location: Portland

Posts: 9

|

Well, I just got done doing this very thing. I am running the SS-5800 in my TXT. The thing has excellent power, good runtime, but does lack the cog that you would get from a brushed motor. The biggest deal with making this setup work is getting the motor to turn the transmission the right way. The problem with the GD-600 is that is reverses the motor direction at the GD's output shaft. This is no biggie for a brushed motor, -simply reverse the polarity and make sure the timing is at zero. But on a sensored brushless like the Novak, it is NOT possible to reverse the motor electrically. This leaves only a couple of options, -reverse the throttle channel and run the Novak in reverse to go forward, or as Ozzy once put it "going forward in reverse".... (this doesn't work too well, -tried it, -and besides, the dynamic braking on the ESC only works when the truck is techically backing up, not going forward) so that sucked bigtime. The latest option I have found that seemed to work well was an "innerdrive" semi-planetary gear reduction setup. This solved the whole going forward in reverse thing, but it was only available in a 2:1, and quite honestly, the truck was just plain geared too high. The wheelspeed was pretty phenomenal, but I could get the ESC to go My latest solution is TWO GD-600's (in series) on the Novak. The primary box is 25/46, and the secondary box is 22/46, -which puts the reduction down to around 3.85:1. The low speed crawl is awesome, and motor cogging (braking) is no longer an issue because the lower gears really help that out a lot. The best part is, there's still plenty of wheelspeed. The ESC is much happier, and the motor is turning the trans the right way, so no half-A funky-doo reversed channel going forward in reverse crap. I will post a picture tonight when I get home, I must say, it looks pretty *****in'! I gotta get back to work before I get busted. C-ya. |

| |  |

| | #4 |

| Newbie Join Date: Dec 2005 Location: Portland

Posts: 9

|

Oh yeah, I forgot to tell you that I am just a NEWBIE. I did stay at a Holiday-Inn Express last night though................. Last edited by ratman572; 12-07-2005 at 11:12 AM. Reason: spelling |

| |  |

| | #5 | |

| I wanna be Dave Join Date: Jul 2005 Location: Cedar Rapids

Posts: 2,028

| Quote:

Sensored brushless motors are timed like brushed motors. On aveox motors you can switch the two outside wires. Then adjust the timing to get the motor running corectly. I've never opened a Novak motor up. But I would geuss it would be fixed so people can't change it. Since it is a lower end system. | |

| |  |

| | #6 | |

| Newbie Join Date: Dec 2005 Location: Portland

Posts: 9

| Quote:

However, our buddies at Novak informed me that the motor is timed via the firmware chip in the ESC, -and aside from programming another chip, -nada. :-( That's ok, because like I said, it REALLY likes the extra gear reduction of the two GD600's. Brushless motors in general seem to be happier turning more RPM with lower gears, -especially this one, -considering it is only a 195 watt setup (kinda weak as brushless stuff goes). I'm still lovin' it! In the TXT it is sweet! I'll post pic's when I get home. L8 | |

| |  |

| | #7 |

| Pebble Pounder Join Date: Sep 2005 Location: Canada

Posts: 171

|

ratman have you tried flipping the whole tranny for a reverse rotation with a single gd?

|

| |  |

| | #8 |

| Rock Crawler Join Date: Mar 2004 Location: BAY AREA

Posts: 557

|

Awsome info.. I will be awaiting more as I am on the hunt for a set up like your describing.. No clog, plenty of wheel speed, long run times, and something different.. I am an electric newbie here so this might be dumb... but can you use Lipo batterys with this brushless set up..? I ask because I am looking for a lightweight set up.. My truck is so light without electronics and a motor.. I would like to keep it as light as I can, even at the cost of my old ladies money.. HAHAH Thanks Casey |

| |  |

| | #9 | |

| Newbie Join Date: Dec 2005 Location: Portland

Posts: 9

| Quote:

I don't want you to think I'm bashing the idea, because if it wasn't for the weight bias, it would work pretty slick. So far so good with the current setup, I like it! | |

| |  |

| | #10 |

| Newbie Join Date: Dec 2005 Location: Portland

Posts: 9

|

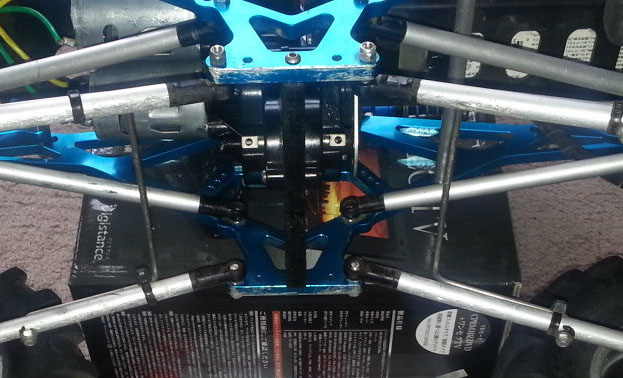

Here are some pics of the dual GD-600/SS5800 setup.  (ABOVE) the weight is way forward, -right where I wanted it in the first place. Yeah, it sticks out there pretty far, but it seems to be good and solid.  (ABOVE) The 4.84:1 reduction with this motor on 7 cells has plenty of wheel speed, and gobs of low speed torque.  (ABOVE) My 4 year old son really thinks it's quite the setup!! He has helped out a lot on the project. He helped put some of the screws in the wheels, as well as putting all the zipties on the front RX pack tray. This kid loves using the dremel, and I have already had nightmares about what I might find "dremeled-up" around the house! His solution to every problem we've encountered is "just use the dremel dad" -The dang kid is usually right! Those moab xl's haven't even hit the dirt yet, but I'll bet they do pretty well. L8 |

| |  |

| | #11 |

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

|

I am trying to find a cheaper solution than the novak for crawlers. The geardown of brushless is key, as they do like to turn high rpms. I know I could put together a 10 pound rig package for less than 200 bucks. Details to come as I get them.

|

| |  |

| | #12 | |

| Newbie Join Date: Dec 2005 Location: Portland

Posts: 9

| Quote:

Well, I'll admit, it certainly isn't the least expensive way to go, but when you consider what you would have wrapped up in a super rooster, rebel-2, or whatever, then it doesn't seem all that unreasonable, -especially when you consider the benefits. I've seen the SS-4300 at tower for $160 (esc and motor), -that ain't too bad. I'd rather have a SS-4300 than a super rooster and a 55T brushed anyday, and the price difference is negligible considering the benefits. I guess the bottom line is that all these cool toys cost money. Please do let us know what you come up with! Time for me to look for a second job................ | |

| |  |

|

| |