| | #1 |

| Quarry Creeper Join Date: Jan 2008 Location: Federal Way

Posts: 210

|

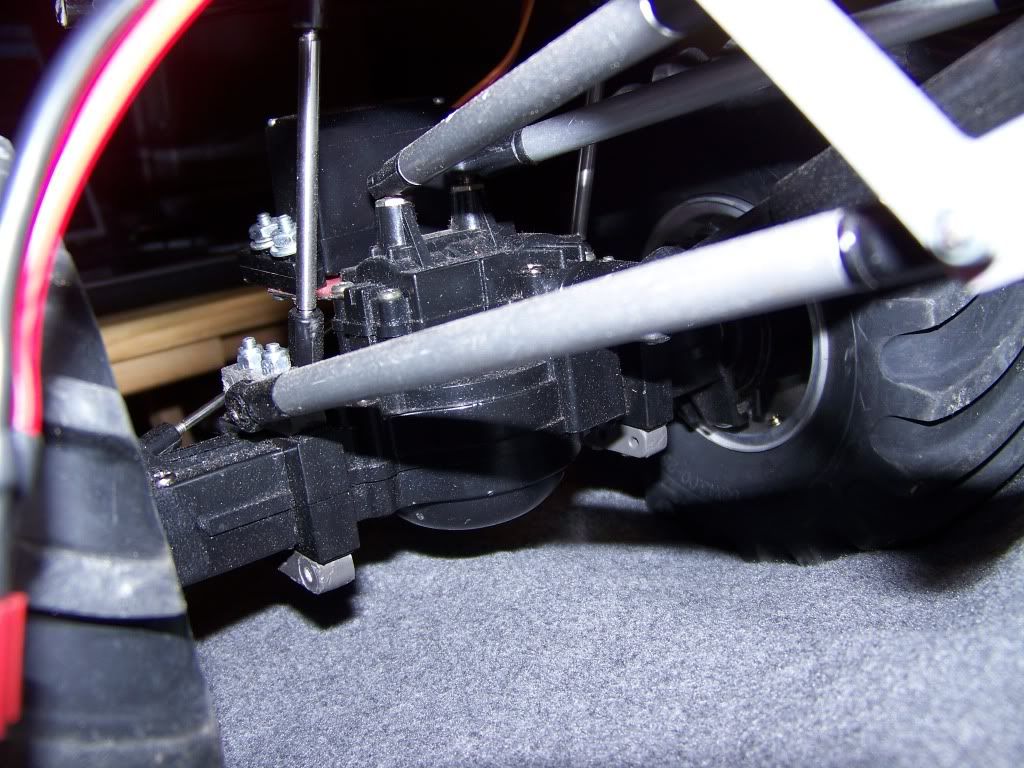

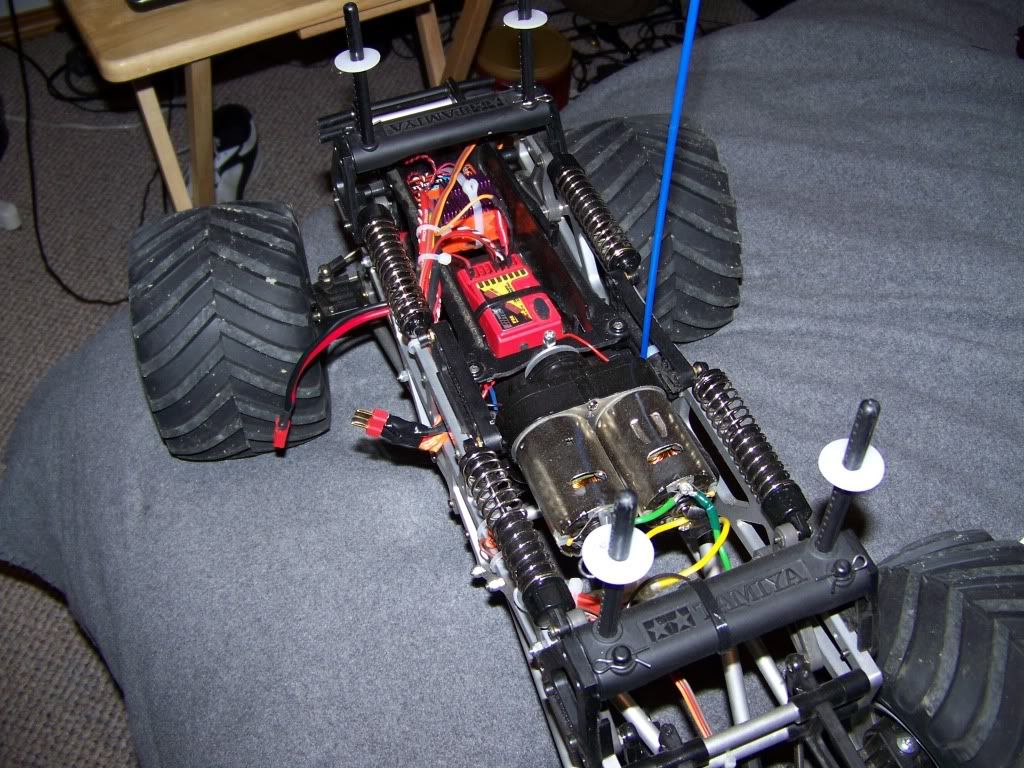

Here is mine. I have been working on it for years little by little. It has seen dirt twice lol. Stock motors, 9 tooth pinions, Home made servo mounts, lenthened to 15 inches, JB welded diffs, screwed tires to rims, wiring wiring wiring. I run it with a HiTec Laser 6 twin stick and that has been a PITA to get to work right. I drove it today and guess what? I'm not done!! Good thing I like to work on this lol. I have an RS10 to drive. I think I stripped my rear servo and the truck leans WAY over under throttle. I bought some aluminum to make suspension and steering links. I'm ditching the cantelevers next. I ran the stock shocks where the canti arms go and the arms where the shocks go. It helped the twist but lost the articulation so I switched it back...I need the middle ground. Here's some pictures. Also top heavy, needs wheel weight all that stuff. But it looks good        Thanks for looking! |

| |  |

| Sponsored Links | |

| | #2 |

| Pebble Pounder Join Date: Aug 2008 Location: marlborough, ct

Posts: 148

|

your title says review. Were you looking for thoughts and ideas? seems a different setup in each pic. (cantilever on one, shocks outside, shocks inside?) My first thought would be to lower your body as much as you can without it rubbing tires. If you are looking to improve the best way is to copy someone that already put the time in experimenting. Then tweak from there to personal preference. Tuning is addictive though. I have done sooo much research on suspension geometry it hurts my head. Squat, anti squat etc... worth your while though.. Torque twist can be fixed with just proper geometry.

|

| |  |

| | #3 |

| Quarry Creeper Join Date: Jan 2008 Location: Federal Way

Posts: 210

|

Good eye, Yes each has a different set up because I work on it alot. Copying someone elses truck I feel is a short cut and I will miss all of the knowledge gain in the process, I'm interested in learning the right way and why. The last three pictures are the current setup. I'm planning to cure torgue twist with springs and shock oil. Maybe new shocks and a different mounting place. I'm thinking of switching to 1/4 servos after doing some reading here. SO I may scrap the old mounts and start over there. I think what I like best about this truck is that all of the mods have to be thought up, fabricated and tried. Its a thinking mans game, I enjoy the experimentation both good results and bad. Any idea's are welcome and will be added to my long list of things to try. I will have this truck for a long time just because the possibliltes are endless. I have the body where I want it, If you notice some tasteful trimming had to be done. If anything I will have a different body to crawl with but just for looks this is how I want it. Thank for looking  Last edited by GreMonte; 02-11-2010 at 09:17 PM. |

| |  |

| | #4 |

| Pebble Pounder Join Date: Aug 2008 Location: marlborough, ct

Posts: 148

|

First you want to keep your lower links and lower shock mounts as close to the tire as possible. the farther out the more stable the chassis. And its not all about flex with a shaft rig. Sprung weight of a hanging tire to a certain degree keeps a rig from flipping over. For springs you want almost stiffest you can that will allow full travel of your shock. A good way to start with torque twist is by doing the rear first. When up hilling all the weight is on the rear. Lockout your front suspension. Put some sort of link so it wont move and is at ride height. Make a high traction steep incline (carpet works good). Start with your links parallel then close the gap up front by lowering your upper link mounts. Unfortunatly you will have to drill holes in that mint chassis. Which is why its good to have someone else go first. I could go on for days, but this is my favorite part of crawlin. Unfortunatly I do not have a txt so i cant completely help you on that. Someday i will.  |

| |  |

| | #5 |

| Quarry Creeper Join Date: Jan 2008 Location: Federal Way

Posts: 210

|

Thats what I'm looking for! Something to test, find the sweet spot thru testing. I want my soon to be wife to shake her head at me when I spend an entire Saturday driving up a carpet ramp over and over and over  Since I was planning a new servo mount to house some 1/4 scale servos I can remove the grey plastic mounts for the lower links and shocks. I can build the new mounts into the servo mount and can move the suspension where ever I please. I like your methods and they give me a great place to start, which I needed. I have seen guys on this site that mount the upper and lower links into the same hole on the chassis. I might start there. I bought 80 weight shock oil today but they didn't have the springs I was looking for. I think TXT-1 is code for Test X Tune - 1 more time I will take lot of pictures of the Fabrication, tests and finished modification, I love pictures and I know everyone else does also. Do you think the top picture is about what I should shoot for with articulation? Just a little more than a TXT tire. Last edited by GreMonte; 02-12-2010 at 06:34 PM. |

| |  |

| | #6 |

| Rock Crawler Join Date: Aug 2007 Location: Dela-where?

Posts: 501

|

you mentioned mounting top and bottom links in the same location... i really think you should keep the triangulation so you have more stability. ive never tried it with a txt, but my clod had nearly parallel links and it caused the axles to sway. i definitely prefer the og triangulated setup. however, id love to hear a review if you try it!  |

| |  |

| | #7 |

| Rock Stacker Join Date: Nov 2005 Location: woods cross

Posts: 51

|

hey man cool rig! as for your thoughts on shocks vs cantilevers , ditch the cantis and put 4-6 inch shocks in that spot, and it is awesome

|

| |  |

| | #8 | |

| Pebble Pounder Join Date: Aug 2008 Location: marlborough, ct

Posts: 148

| Quote:

| |

| |  |

| | #9 |

| Pebble Pounder Join Date: Aug 2008 Location: marlborough, ct

Posts: 148

|

i have never run cantilevers so i cant speak on that

|

| |  |

| | #10 |

| Quarry Creeper Join Date: Jan 2008 Location: Federal Way

Posts: 210

|

I agree about the canti's. I wanted to try it both ways that's why in one picture I have the shocks up top and another I have then on the axle. I have good articulation without the canti's. But I switched it back to make sure and now I have horrendous body roll. I bet if I try hard enough I can roll the truck with the throttle lol. I'm going back to the other way and will look into some of those 4-6 inch shocks also. Right now I'm going to switch out the radio from a 6 channel twin stick to a three of four channel pistol. I found after running my RS-10 that I have much more control. I also put the steering servo's from this onto my RS-10 and they're much more at home turning 2.2 tires, I'll get 1/4 scale servo's for this beast. I found some small screw-type clamps at work that I can use to test link placement without drilling a hundred holes in my frame.   Its stripped down now so I can start over. I have a better idea where I'm going this time. I want to get my electronics installed and fuctioning properly so I can get to tweeking the suspention. I'm switching to lipo for smaller batteries with more run time. My helicopter runs 11.1V 900's and there tiny. So I figure 3s 2000's would work here. Now I am waiting for servos and a radio, maybe a new ESC since I'm running the Super Rooster and I would like drag brakes but we'll see. I will update as I have updates  Last edited by GreMonte; 02-23-2010 at 03:01 PM. |

| |  |

| | #11 |

| Quarry Creeper Join Date: Jan 2008 Location: Federal Way

Posts: 210

|

Quick question. I'm thinking of bending my lower links. I know that I can bend them up for ground clearance but what about also bending then in for tire clearance? I might just try it for you guys  |

| |  |

| | #12 | |

| Newbie Join Date: Feb 2010 Location: New York

Posts: 43

| Quote:

| |

| |  |

| | #13 |

| Quarry Creeper Join Date: Jan 2008 Location: Federal Way

Posts: 210

|

Its not fast, I don't want it to look like those "low rider" rock crawlers, I have one of those. I like the holy sh*t! factor of this truck, I took it into the LHS and set it next to a guys AX10 and his attention was on mine as was everyone elses. The first thing I hear is lower, naw its as tall as I want it, I'm not going to comp with it I just think it would be cool after a comp to have a little fun. I'm doing crawler things to it but I want it to be easily recognized as a TXT-1 Monster truck, (that can crawl)

|

| |  |

| | #14 |

| I wanna be Dave Join Date: Oct 2007 Location: Scumrise, Flooriduh

Posts: 5,181

|

Looks good so far. I am about to part mine out to fund my 2.2 comp. If you have any interest in HR aluminum knuckles x4 front and rear, rc4wd r2HD tranny, gd600, egressor's 4:1 axle kit, or a set of 40 series rockster's with x-locs (99% tread left) drop me a PM.

|

| |  |

| | #15 |

| Quarry Creeper Join Date: Mar 2004 Location: Central NY

Posts: 387

|

You want to keep it looking fairly stock? Take a look at the pics on Tamiya's site; the body is lower. Where you have it just doesn't look good. Here's a thought on copying other people - research on this site to find what works is likely less time consuming that testing various iterations on the truck. I don't want to burst your creativity bubble but for some things going with what others have proven to work is cheaper in time and money. |

| |  |

| | #16 | |||

| RCC Addict Join Date: Apr 2004 Location: 5280

Posts: 999

| Quote:

So you don't want it looking like this one??? As that is a TXT super. I had a lot of fun with my TXT when it was set-up like yours. As mentioned go waay back, like end of the TXT forum way back, and work your way to newer posts. Lots of good tech on how to set it up and still keep it looking stockish like you want  Quote:

You got PM!! Quote:

Exactly, the body is a couple of notches lower. X2 on going waay back to find good tech for ya! | |||

| |  |

| | #17 |

| Quarry Creeper Join Date: Jan 2008 Location: Federal Way

Posts: 210

|

The body is where it is now because at one time I had way more articulation than I needed and this is as low as I good go with out having to cut anymore off the body. I think it adds to the overall hugeness of the truck. And if I was building it to the Picture on the box I would have been done five years ago. The last guys TXT-1 is awsome looking and I may end up there someday but like I said I have one like that already. Suggestions on how to improve preformance and what definately doesn't work are more than welcome. But like I said before I will only lower the truck as a last resort. I'll spool $100 bucks worth of solder wire into the wheels if I have too.

|

| |  |

| | #18 |

| Quarry Creeper Join Date: Jan 2008 Location: Federal Way

Posts: 210

|

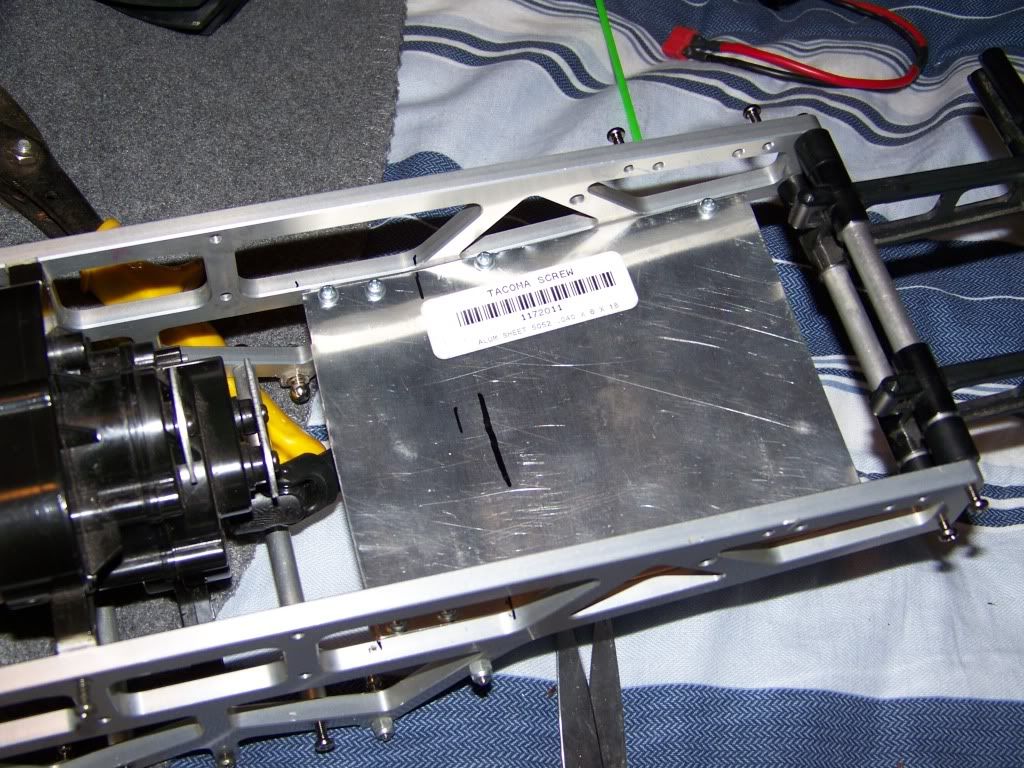

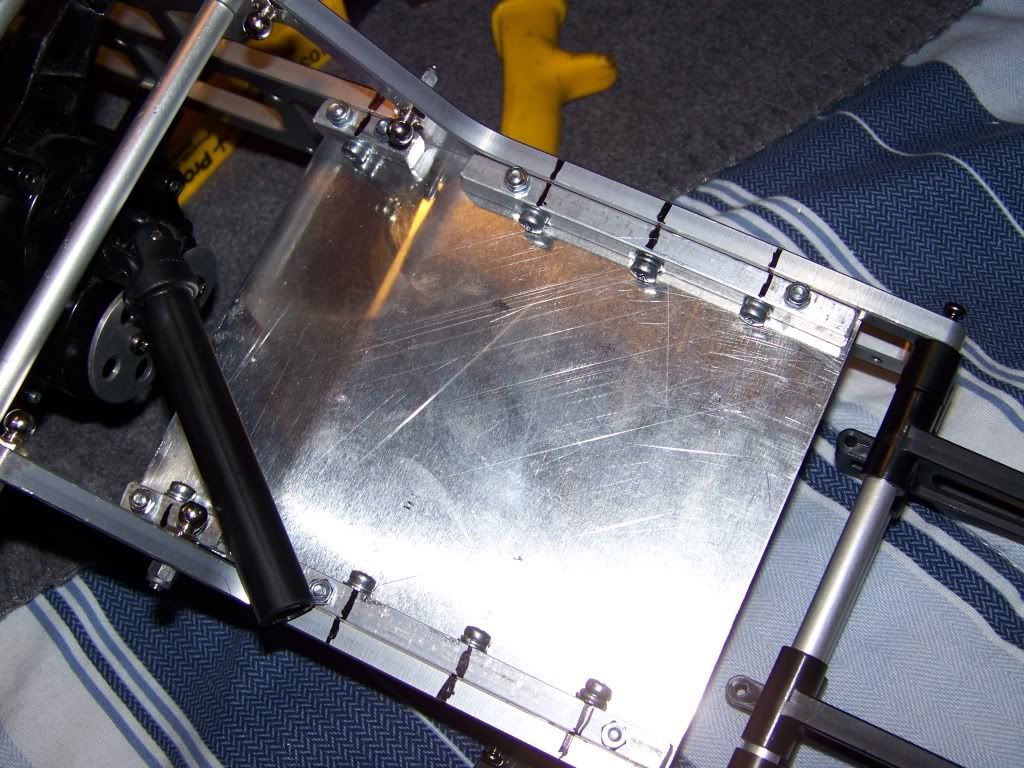

So I got tired of trying to squeeze all of the electronics into the confines of the stock battery holder. I was at Tacoma Screw buying some hardware and noticed the metal area, so I went to investigate and I found the perfect electronics mount! Well I found this..  But I made quick work of it  Here it is installed   Notice I drilled and tapped the mounting holes instead of drilling all the way thru and using a nut and bolt, just looking for a couple style points. After I finish all of my mock up I'm planning to hit everything aluminum with a polisher. I read on here that turning the motors to the rear and mounting the battery up front is the best way to do it, but I weight them and the motors weigh almost double what the battery pack does. So I spun the motors back to the front and am mounting all of the electronics to the rearish. I may make another panel for the far front of the truck and mount a pair of saddle type batteries up there, I still have plenty of aluminum. I took your advice and read what others have done and I have designed some servo/shock/link mounts. I will take pictures as I build once I get started. Thanks for talking with me about my truck.  Last edited by GreMonte; 02-26-2010 at 01:43 AM. |

| |  |

| | #19 |

| Quarry Creeper Join Date: Mar 2004 Location: Central NY

Posts: 387

|

Nice work on the plate. I used an electronics box to keep the ESC / receiver dry. Here's a couple reference pics with the body in the stock location; I'll leave it alone after this. With 6 7/8" tires an 3/4" wider wheels, stock shocks:  With 6.25" (near stock) tires and no wideners, shocks moved:  |

| |  |

| | #20 | |

| Newbie Join Date: Feb 2010 Location: New York

Posts: 43

| Quote:

As for a good location to mount your battery. I have my body mounted lower, if not lower than Mazlem's TXT-1. I will be running dual 7 cell battery packs that will be mounted along the outer frame rails, just under the sides of the door body panels. This way the weight will be lower than if it was mounted on top or within the chassis. I tried to find the link showing a similar truck and I seem to have lost it? | |

| |  |

|

| Thread Tools | |

| Display Modes | |

| |