| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| RCC Addict Join Date: Mar 2007 Location: St. Louis (High Ridge)

Posts: 1,279

|

this will be my txt axled project  emaxx trans, I'll leave it 2 speed and shift it. slop is ok for bashing/crawling TXT axles, bottoms shaved and jb'd maxx shafts for now, hopefully this will be light enough, and they can be a readily available "sacraficial link" maxx rolcage, dovetailed on each end for the tube chassis. I'm making my own links (need a little lathe time) 3/8 aluminum rod with 8-32 all thread and jato ends. I'll use this stock for the tie rods too. I need to find some more MLST shocks. I like these, they are standard half inch in diameter, with about an inch of travel. I'm probably going to steal the plates and hitec 775's off my other txt for steering. I'm still trying to get around to making the larger plates to fit the huge tower pro servos for it. wheelbase should be around 13.5 inches still debating on wheels and tires. I want enough ground clearance and I want good traction but not so tall and grippy I break axles but I don't want it so wide the 199 oz. in. are over matched but not so narrow it hits the links and I don't want to spend any money. You know, PERFECT. |

| |  |

| Sponsored Links | |

| | #2 |

| RCC Addict Join Date: Mar 2007 Location: St. Louis (High Ridge)

Posts: 1,279

|

Well, I just won a set of max mashers on wheels for $25 to my door, so that is at least settled. links should hit the late tomorrow. |

| |  |

| | #3 |

| RCC Addict Join Date: Mar 2007 Location: St. Louis (High Ridge)

Posts: 1,279

|

Well one of the wheels had a chewed out hex that had been filled with JB and chseled to fit a cross pin. Messy. So I ran to the LHS and got a matching set of wheels and did a tire change. Links still aren't done, but the Al rod is at least sitting in my friend's basement waiting for him to get off his kiester and turn them. Just completed a tower order for some shocks. blue anodized and about 3.4" long at full extension. |

| |  |

| | #4 |

| Quarry Creeper Join Date: Jan 2007 Location: I live in my own world,they know me here

Posts: 402

|

let me know how the transmission wors out for you I was thinking of using one of those.

|

| |  |

| | #5 |

| PapaGriz Yo  Join Date: Apr 2004 Location: In the garage building the wife a crawler

Posts: 13,137

|

I've been wanting to build a basher with a 2 speed also. That cage actually looks pretty good. If you added some rear kickers to the back of the cab it would look better.

|

| |  |

| | #6 |

| RCC Addict Join Date: Mar 2007 Location: St. Louis (High Ridge)

Posts: 1,279

|

I have an emaxx trans in a WK rig. I just have a wrap of ducttape holding the shift fork in low range. It works well but there is about 4-5 inches of roll-back, or forward to contend with. not expecting it was a little unsettling running on the back side of a fjord style dam. By kickers are you refering to extra roll cage points from the top of the roof to the bed edge? or mid bed side? Its possible, but I can always throw a truck body on this cage later if I want. I'm still playing with Ideas. |

| |  |

| | #7 |

| I wanna be Dave Join Date: Aug 2006 Location: under a rock and a hard place

Posts: 5,443

|

I have found the gearing to be to tall with an e-max, thats locked in 1st with a 76/8 pinion combo. Sucks the juice right out of a 4200mh pak in 20 mins or so. I am going to try a RC4WD v twin tranns, that should give me some gearing options as I have maxed out the pinion spur combo. This is running 40 series slingers so you may have better luck wihth the smaller tires

|

| |  |

| | #8 |

| RCC Addict Join Date: Mar 2007 Location: St. Louis (High Ridge)

Posts: 1,279

|

Well I was looking at an 833kv brushless motor to help with wheelspeed too, but then I found this thing http://cgi.ebay.com/RC-Hobby-480Rpm-...QQcmdZViewItem With an 8mm output shaft it would have to be divorced from the trans. the mounts are a X brace on the back of the motor for airplane mounting, so it would literally bolt to the radiator core support. The output shaft is threaded for their prop adapter, so it could be turned down to 6mm easily enough and flatted to adapt to a maxx or better revo shaft. Then I guess I would have to figure out how to mount a knuckle to the emaxx motor plate to gear this thing. |

| |  |

| | #9 |

| RCC Addict Join Date: Mar 2007 Location: St. Louis (High Ridge)

Posts: 1,279

|

ok, I found a nice big brushless motor running 720kv, I have it coming as well as a Mamba max. I got some shocks in, but still haven't gotten the links turned out. I got the mashers mounted on the axles sitting under the chassis waiting for links. I'll mount the shocks once I see what kind of clearance I'll need for the mashers at full swing. Then I'll get some progress pics up. I was a little worried about wheel speed seeing as how I'm using an emaxx trans and txt axles with the stock 2:1 gearing. So I ran the numbers in my gearing spreadsheet, and compared it to the WK axle, emaxx trans rig I have now. the WK rig numbers: 833kv 7.4v 14p 66s emaxx (in first) WK axles 5.5" All-T gives me 3.06 mph which is a little fast but gives good wheel speed The Mid-size TXT stats: 720kv 7.4v 12p 72s emaxx TXT axles 6" mashers gives me 2.87 mph which will be pretty decent. 2nd gear will give me 4.6mph which will be a good trail top speed for bashing without suffering too much from fully locked diffs. Last edited by hairba11; 12-12-2007 at 07:08 PM. |

| |  |

| | #10 |

| I wanna be Dave Join Date: Aug 2006 Location: under a rock and a hard place

Posts: 5,443

|

What kind of spread sheet is it ? can you post it or e-mail it. I would like to find what my speed options are.

|

| |  |

| | #11 |

| Quarry Creeper Join Date: Nov 2004 Location: Fenton, MO

Posts: 236

|

HEY that tranny looks familiar. Have I seen it before? LOL Looks good man I cant wait till it warms up again so we can meet up with the group. I want to see this one in action. |

| |  |

| | #12 |

| Quarry Creeper Join Date: Nov 2004 Location: Fenton, MO

Posts: 236

|

Oh and if needed I have a set of 40 series mashers on proline outbacks that I'm selling or trading.

|

| |  |

| | #13 |

| RCC Addict Join Date: Mar 2007 Location: St. Louis (High Ridge)

Posts: 1,279

|

@ hotwheels, http://www.one18th.com/forums/showth...064#post371064 I made this originally for my 1:18th stuff to try and get top speed figures Instructions are on page one spreadsheet is page two and if it is version 4a there will be a gearing chart on page 3 @ elvis, yes, as a matter of fact you have seen that trans before. and if interested I have the set of 40 series moabs with some weight in them on the other 17" txt :edit: Ok, I went to my thread, and updated the gearing spreadsheet to the 4a version. Last edited by hairba11; 12-18-2007 at 04:56 PM. |

| |  |

| | #14 |

| RCC Addict Join Date: Mar 2007 Location: St. Louis (High Ridge)

Posts: 1,279

|

well, I haven't got links done yet, I put the wheels on, dropped a body on it for looks. got my motor and mamba max in. The motor peaks out at 1500W that's a hair over 2 horsepower. Now I just have to figure out how I want to mount the fool thing. The motor pics are next to a 55t integy motor for size comparison. *tim allen grunting here* here are some pics     |

| |  |

| | #15 |

| I wanna be Dave Join Date: Aug 2006 Location: under a rock and a hard place

Posts: 5,443

|

Thanks for the link.

|

| |  |

| | #16 |

| RCC Addict Join Date: Mar 2007 Location: St. Louis (High Ridge)

Posts: 1,279

|

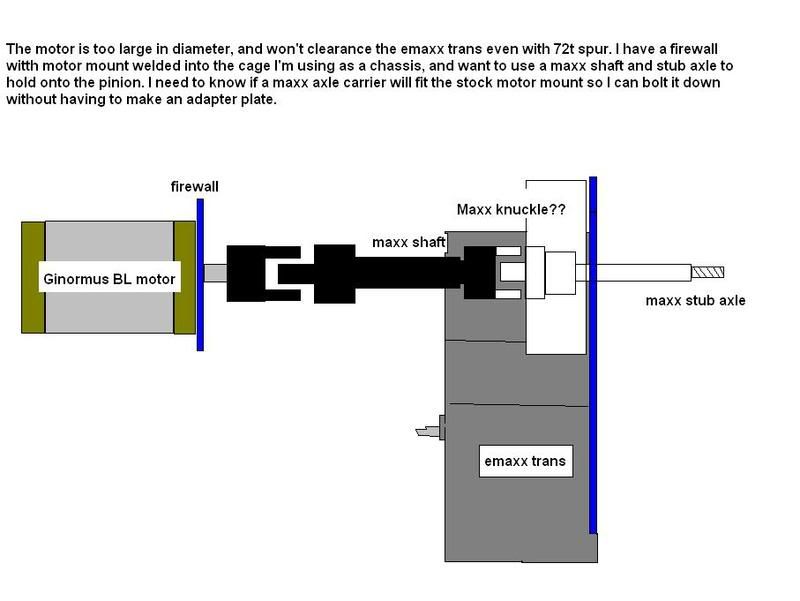

I got a firewall welded in place, with the mount for the motor. it will give me ECS mounting, and a mount position for the shift servo. I got the motor shaft flattened and drilled to accept maxx shaft ends, now I am going to make a trip to the LHS and see what I can come up with to try and mount a t/emaxx knucle to the motor mount plate of the emax trans so I can mount the pinion on an axle stub and mesh it with the spur. I got a 6 channel radio a couple of days ago, so I will have 4ws independant, throttle control, shifting, lights, and maybe something else. |

| |  |

| | #17 |

| RCC Addict Join Date: Mar 2007 Location: St. Louis (High Ridge)

Posts: 1,279

|

Here is what I'm looking at doing.  I got some measurement numbers from the maxx side of the site, and I'll be headed to the lhs probably today to look for parts. |

| |  |

| | #18 |

| Rock Crawler Join Date: Sep 2005 Location: IDK

Posts: 852

|

why not take off the spur and connectring the driveshaft to the output? like on scale builds wich use the tranny as a transfercase. Thinks that is the easyest and morst effective way. Like the build do far !  |

| |  |

| | #19 |

| RCC Addict Join Date: Mar 2007 Location: St. Louis (High Ridge)

Posts: 1,279

|

the txt axles are 2:1 the emaxx trans ratios are roughly 2.75 and 1.75. that is only a 5.5:1 ratio. Even with a gd-600 on the back of the motor, it might get to 10 or 15:1 which isn't low enough. putting the 12/72 combo in gives and extra 6:1 that puts me at about 33:1 at the motor I'm planning now on volt up gear down, so I am thinking of adding a gd-600 with a high ratio to the mix which should step that up to a good 40-45:1 by the time I push 45:1 through the mechanical disadvantage of 6" tall tires, it may be a little slow, but not by much. I had thought to do what you suggested, but the ratios are just to high without extra reduction. Last edited by hairba11; 12-30-2007 at 09:04 AM. |

| |  |

| | #20 |

| RCC Addict Join Date: Mar 2007 Location: St. Louis (High Ridge)

Posts: 1,279

|

OK, finally got the links done and got the motor mounted with driveshaft. only curmmy cell phone pics now, my computer died and i can't get the new one hooked up and can't bring media into the library computers. wheelbase is 13-5/8" right now. still working on permanent shock mounts.       I took it apart after the mockup Now I will have to wait till I get time to turn the maxx stub axle down to fit the pinion. Last edited by hairba11; 01-18-2008 at 04:45 PM. |

| |  |

|

| |