| | #1 |

| Rock Crawler Join Date: Dec 2005 Location: West Omaha

Posts: 581

|

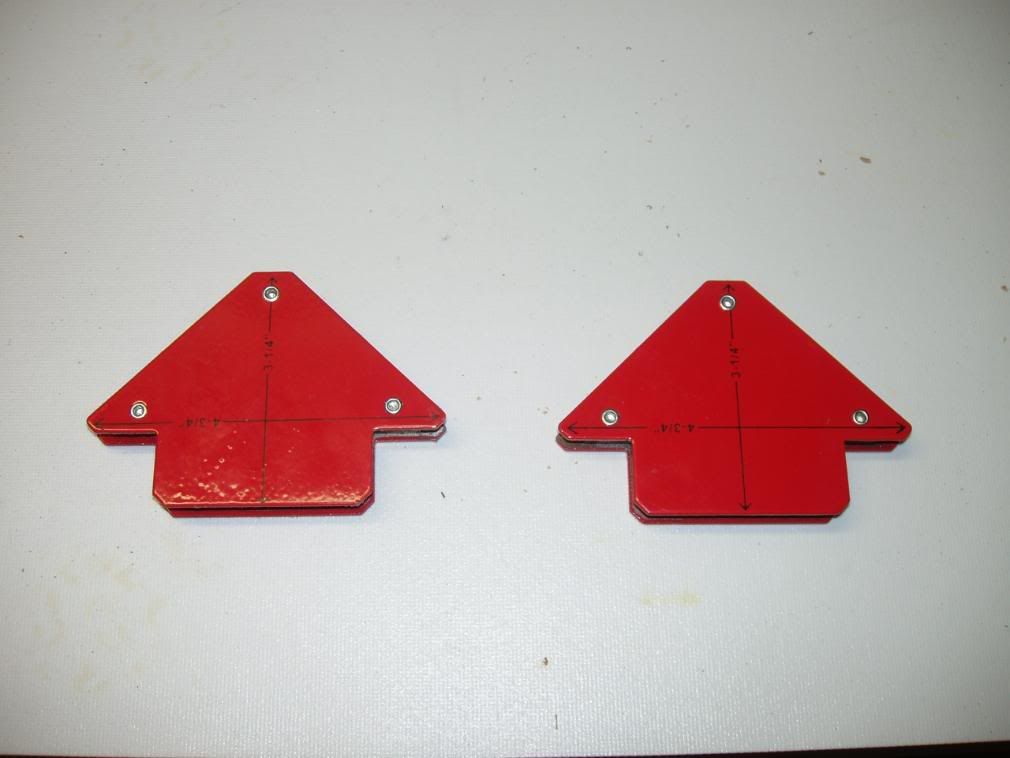

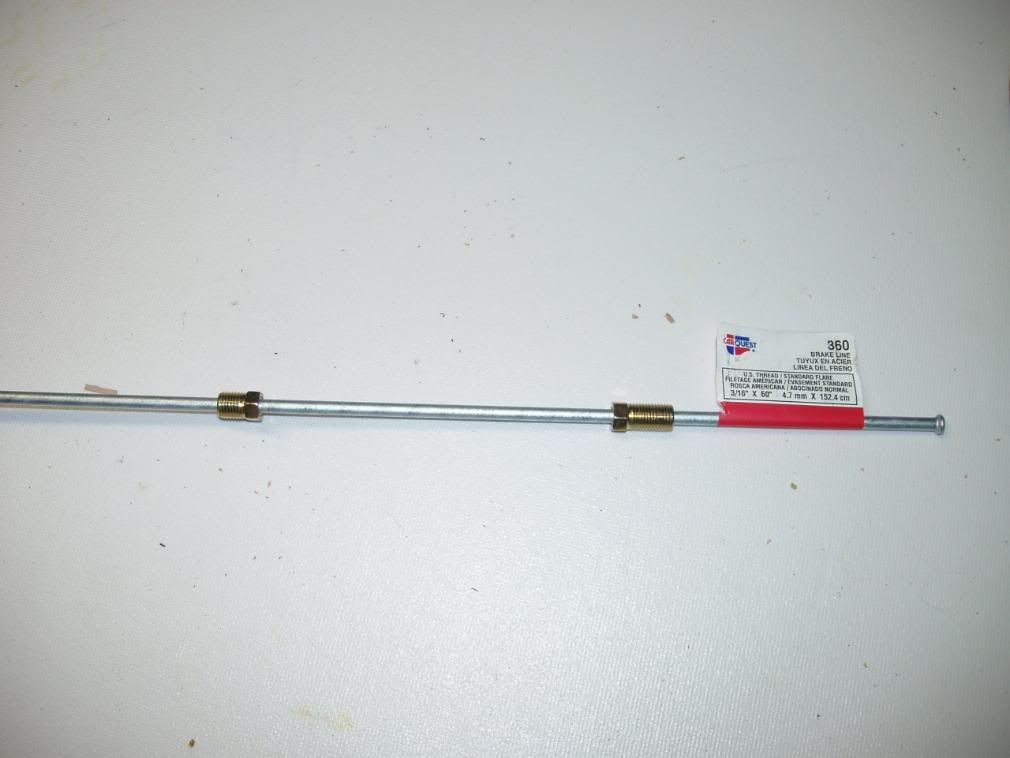

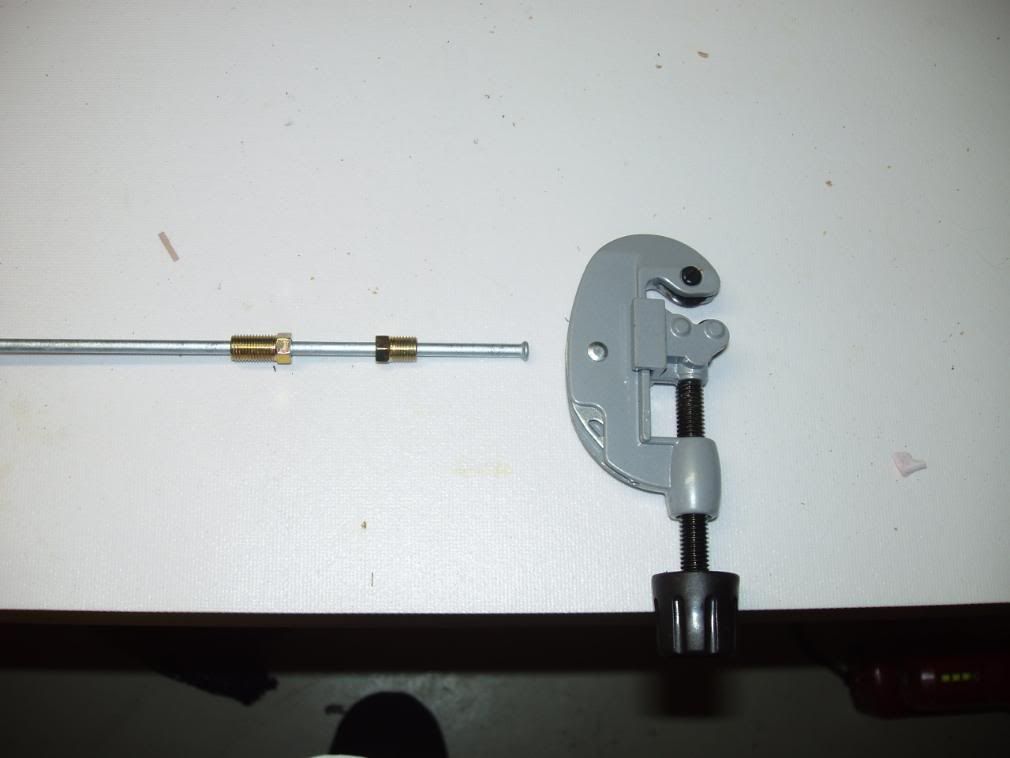

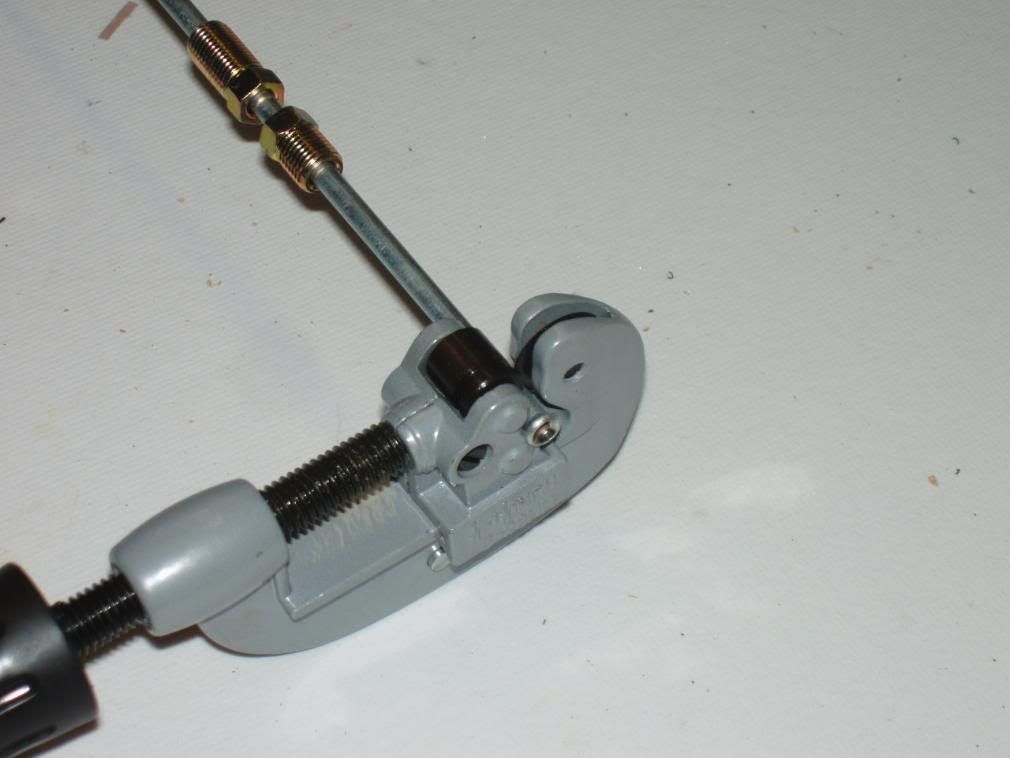

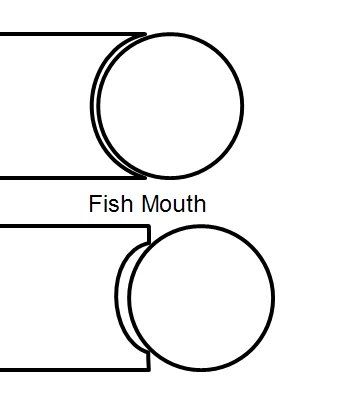

I wanted to make a thread with lots of pics to help everyone out with brazing. I constantly see questions that should mostly be answered here. First the disclaimer brazing is dangerous. Do it at your own risk. Lets begin. First the tools of the trade. Mapp gas torch  Silver Solder  Flux  Saftey Items  File,rotary file, tungsten carbide bit for fish mouthing tubing and rod  Pipe cutter  Magnets  3/16" Steel Brakeline  First thing to do is cut the flared end off you brake line and get the fittings that you don't need off.    Next you need to fish mouth the ends of the tube so it mates to the other tubes better. Fish mouth  Mated up  The next step is to sand off the galvanized coating. It is extremely toxic if you burn it, so sand it all off. Some people just do the end and call it good, but you are going to paint it later anyway right. Might as well sand it all now. I didn't take a pic of this because I am sure everyone knows what I mean. Next you apply a small amount of flux to the end of the tube.  Then you apply a small amount of flux to the joint itself. Note: this is too much flux.  You then apply heat using the torch. Use just the tip of the flame as it is the hottest. You want to get the tube just to a cherry red then move the flame aside and touch the solder to the joint. It will cool fast so you have to apply the flame quickly to keep it hot. You will see when the solder flows into the joint. When it flows stop or you will melt it out of the joint completely. Here is the finished product. Cold joint, not hot enough when solder applied and not heated back up soon enough. Try to avoid this. You can fix it though. Just heat it back up.  Completely bonded joint. My camera makes it look really rough, but it is not really that rough. Also that is a little to much solder, but I prefer to use a little to much and grind the extra off. It gives that welded look. Anyway here it is.  That about covers it. Between this and the already posted brazing video all bases should be covered for brazing. If anyone has anything else to add let me know. I am not the master I am still learning really. Last edited by CrawlinClodKiller; 02-03-2008 at 10:33 PM. Reason: fixed a typo is all |

| |  |

| Sponsored Links | |

| | #2 |

| I wanna be Dave Join Date: Jan 2006 Location: Albuquerque

Posts: 2,206

|

You don't need it to be cherry red, especially with safety silv. That's the one thing I don't like about the Home Depot brazing rods. They're so thick and the melting point so high, you do need to get to red hot. You can see here, top left is home depot rod in the corner of the door panel and windshield area, right (and all the smooth ones) is safety silv. Of course the whole thing is powder coated real shiny, but you can still see the underlying braze points.  |

| |  |

| | #3 |

| Pebble Pounder Join Date: Aug 2007 Location: london

Posts: 174

|

nice walkthorugh, may have to try it, love the name of the torch "bernz0matic" lol |

| |  |

| | #4 |

| Dirt Addict  Join Date: Jan 2004 Location: Stumblin' thru the parking lot of an invisible 7-Eleven

Posts: 1,053

|

Excessive flux isn't a problem. Getting the steel red hot can tend to burn the flux and ruin the smooth flow of the brazing material. Jay |

| |  |

| | #5 | |

| I wanna be Dave Join Date: Dec 2005 Location: between heaven and hell.

Posts: 3,367

|

Nice job. But you want to try and get your fishmouths to the edge of the tube. That may help with some of your gaps. You can see in the diagram the top fishmouth fits over the corosponding tube tighter than you showed in your pics. Also when your heating your tube, heat your safty silv holding it a little behind the flame. Then when the flux starts to melt away and becomes clear looking, apply the silv to the joint. When you get the joints cherry red it won't bond with the silve quite as well which can also cause it not to connect to parts of the tube also creating gaps. fishmouth diagram:  EDIT: Quote:

Agree Last edited by Double J; 02-05-2008 at 04:30 PM. | |

| |  |

| | #6 |

| Rock Crawler Join Date: May 2007 Location: Prescott

Posts: 796

|

Great info and pics. It makes me want to build my own. Just dont have time right now.

|

| |  |

| | #7 |

| Rock Crawler Join Date: Dec 2005 Location: West Omaha

Posts: 581

|

The fishmouth in the pics was a quick example one. It is not the one I used, and your right I did not notice that one was not done enough. The other joints you see in the pic are not mine by the way. This is a tuber someone else built that I am changing. I guess I should have been more specific with the whold red hot thing. My flux goes clear just as the metal starts to turn red. That is when I apply the solder. I have to keep it hot or it stops flowing almost immdiately.

|

| |  |

| | #8 | |

| Dirt Addict  Join Date: Jan 2004 Location: Stumblin' thru the parking lot of an invisible 7-Eleven

Posts: 1,053

| Quote:

This will get the tubes a little hotter overall and may prevent the rapid cooling you describe. Jay | |

| |  |

| | #9 |

| Pebble Pounder Join Date: Jan 2008 Location: Woodinville, Washington

Posts: 119

|

I've done both, but havent tried with either 3/16 or 1/4 break line, i used my mapp gass+oxy on 1/4 breakline and it did fairly well, would it just be easier to use plain mapp gass then mapp gas+oxy?

|

| |  |

| | #10 |

| Rock Crawler Join Date: Dec 2005 Location: West Omaha

Posts: 581

|

Well I am surprised more people have not comented on this with so many questions about brazing all the time. I think this is a good simple explanation of how to do it.

|

| |  |

| | #11 |

| On the lookout for Rocks  Join Date: Mar 2006 Location: Monroe, Louisiana

Posts: 3,711

| |

| |  |

| | #12 |

| I wanna be Dave Join Date: Jun 2007 Location: Canada, eh.

Posts: 2,919

| |

| |  |

| | #13 |

| Newbie Join Date: Jan 2008 Location: Brooklyn Park

Posts: 34

|

Ok, I have a question. You are using silver solder here and flux when you braze, correct? Couldn't you use a solder with the flux already in it like when you solder something? Or since brazing is done different and you want the solder to flow more, you should use seperate flux? |

| |  |

| | #14 |

| Rock Stacker Join Date: Apr 2006 Location: Cannon Falls

Posts: 74

|

This is silver soldering not brazing.

|

| |  |

| | #15 |

| Rock Crawler Join Date: Apr 2007 Location: LaSalle

Posts: 819

| |

| |  |

|

| |