| | #1 |

| RCC Addict  Join Date: Mar 2007 Location: Penngrove

Posts: 1,809

|

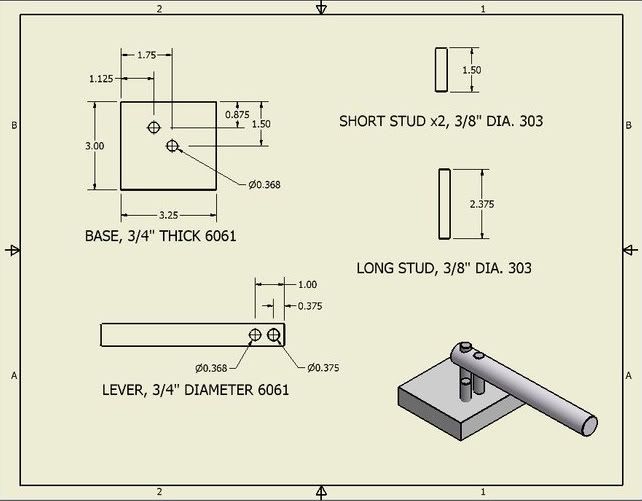

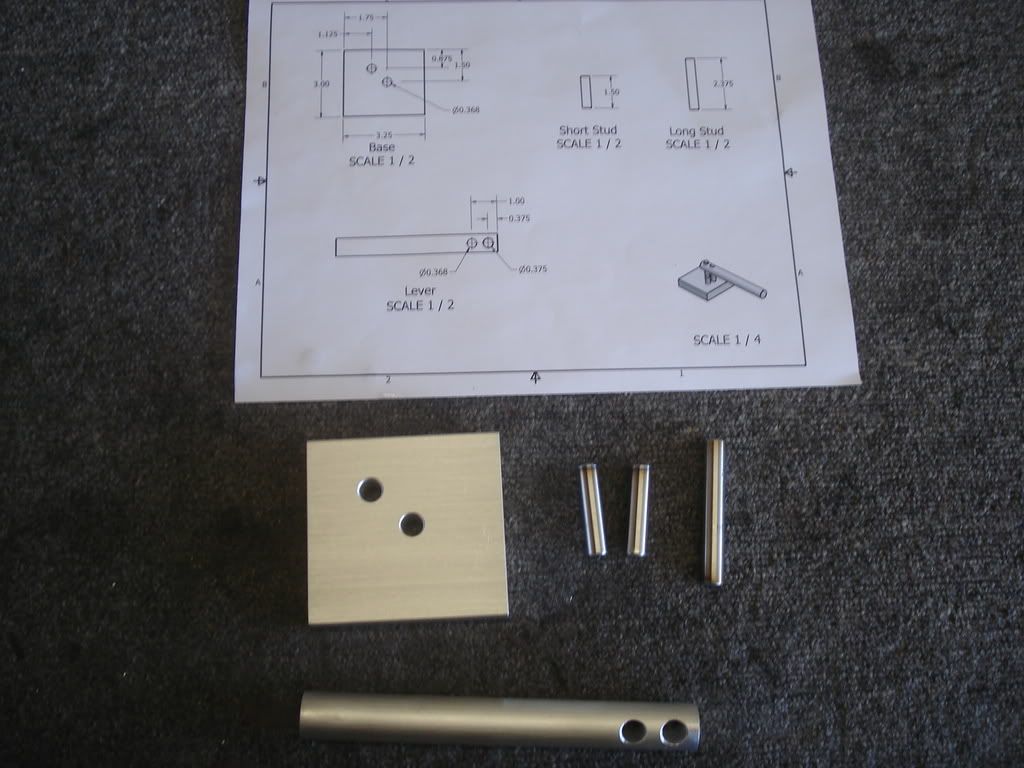

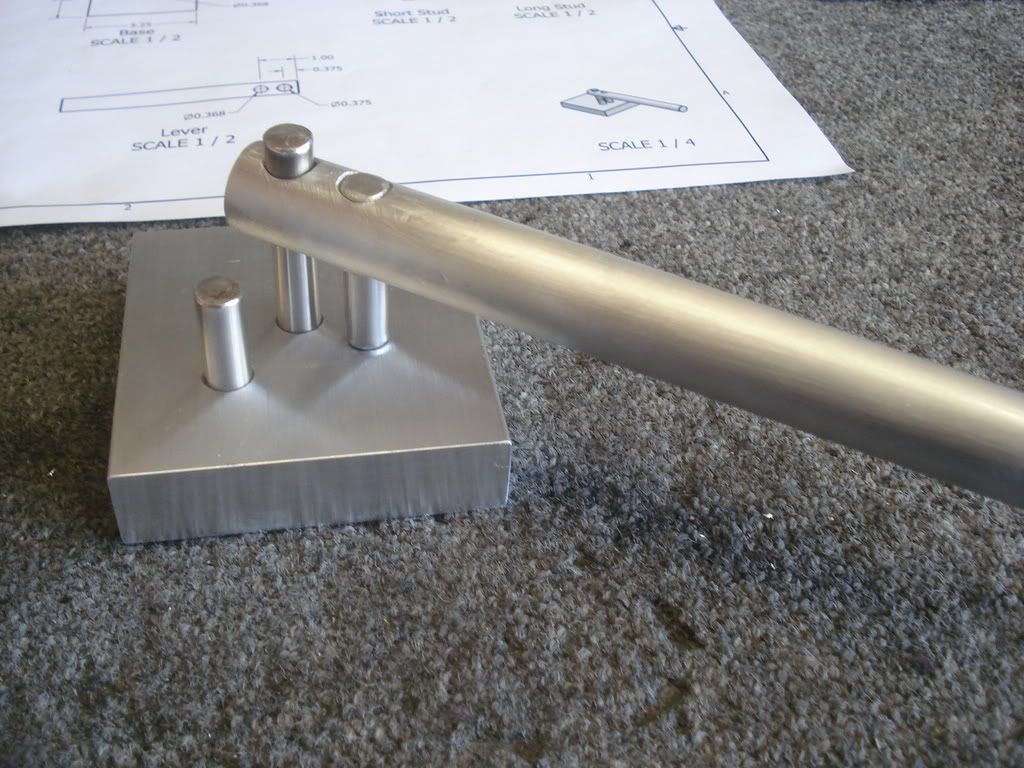

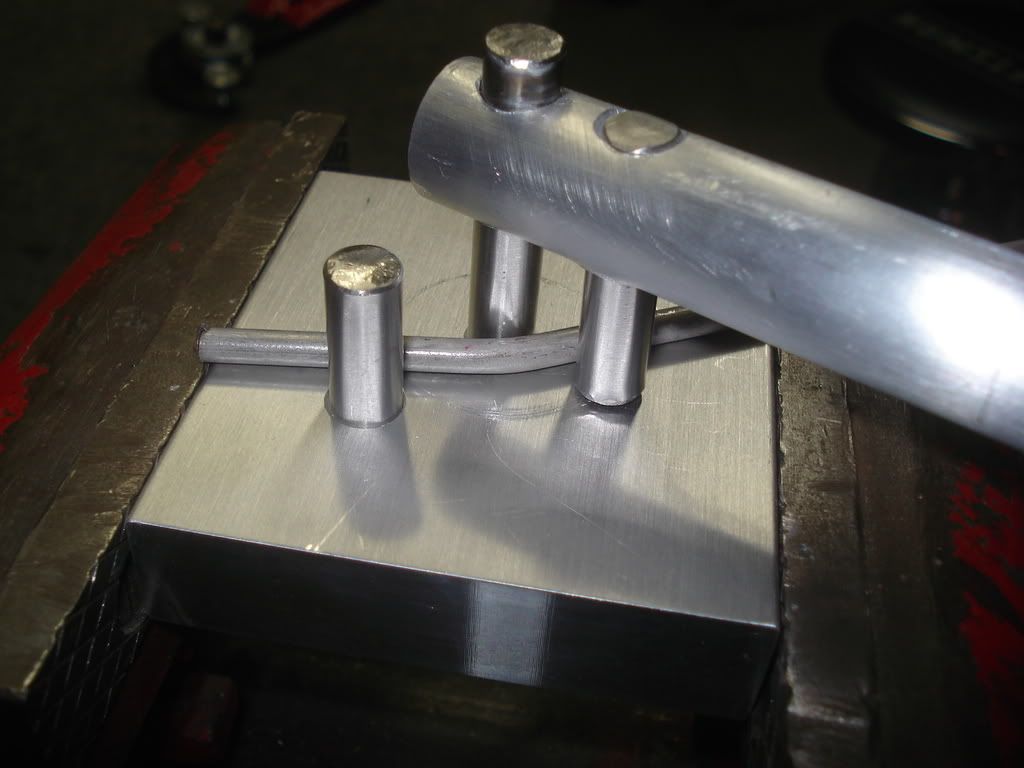

I decided to post my first How-To since there seems to be plenty of threads here about which tubing benders or methods yield the best results but no threads on how to build a bender. When I first started fabbing with tubing I bought a couple different benders that I found at the local autopart store. The following examples work well when you need large radius bends:   I have also used the bench vise but for me it only works well with solid rod. To give credit where due I designed the following bender off a pic I saw in an old build thread that I cant seem to find right now. This bender is meant to work with 1/8" through 1/4 tubing or solid rod. Care must be given when bending thin wall tube becasue it is easy to kink the tubing at the apex of the bend. Required Materials: - 3/4" thick x 3" wide 6061 Aluminum bar stock. - 3/8" diameter stainless steel rod stock (I guess colded rolled steel could be substituted) Required Tools: - Band or Hack saw - Drill press with vise - Cut off wheel, metal chop saw or lathe - "U" size drill bit - 25/64" drill bit - Oven - Freezer - Bearing Press or BFH (if you need to ask...) Step 1) Cut your material to the following dimensions using the appropriate tool above:  (Note: use the U size drill bit for the .368 hole and 25/64" bit for the .375)  Step 2) Put the lever and base into the oven at its lowest setting (approximatly 200 deg F). Also put all the studs into the freezer. Leave them both for a half hour or so. Step 3) Pull parts from oven / freezer and quickly press or pound the studs into the appropriate holes:  Step 4) Assemble handle onto base:  Now to use the bender there are few things to remember: A) Secure bender in bench vise:  B) Place material inbetween two studs on base:  C) Swing handle over tubing:  D) Bend to desired angle:  Here is a sample 90* I made from 3/16" Stainless tubing from McMaster:  Tricks to reduce kinkage are as follows: 1) MAKE THE BEND SLOWLY! This is the best thing to help reduce kinks. 2) Use sand or rice in the tube during the bend. 3) Hit tubing with a hammer when done to make it round again.  |

| |  |

| Sponsored Links | |

| | #2 |

| Rock Crawler Join Date: Jan 2006 Location: Colorado Springs

Posts: 606

|

Its about time...J/K Nice write up, I appreciate it. I think this is was a Juggster design, I remember seeing it in 1BJB's Clone build. I was always wondering how it worked!

|

| |  |

| | #3 |

| Quarry Creeper Join Date: Jan 2008 Location: marysville

Posts: 228

|

Mad4Rnr- Thanks for the insperation dude! Looky what I did Now I've got 12 ft of mat'l, a TIG, and no excuse EDIT: It bent up 5/16 and 3/8 solid Alum. rod like a coat hanger, and didn't deform the strait legs after bending. That just 1/4 next to the square. Last edited by BigRocks; 04-05-2008 at 03:53 PM. |

| |  |

| | #4 |

| Pebble Pounder Join Date: Nov 2007 Location: alpharetta

Posts: 139

|

nice trick man, btw where i can find that thick aluminum for lever and the base? Thanks

|

| |  |

| | #5 | ||

| RCC Addict  Join Date: Mar 2007 Location: Penngrove

Posts: 1,809

| Quote:

Quote:

Hard to say, I got mine from work, you can try Mcmaster or a local metal suppy store. | ||

| |  |

| | #6 |

| Pebble Pounder Join Date: Nov 2007 Location: alpharetta

Posts: 139

|

@mad4rnr are you willing to sell your homebrew tubing bender?? |

| |  |

| | #7 |

| Quarry Creeper Join Date: Jan 2008 Location: marysville

Posts: 228

|

x2. I got mine out of the scrap bin at work. I'll make you one for sale if you want. The base is 3/4". Check McMaster. The arm was tooling that got scrapped, and that started life as one big billet Last edited by BigRocks; 04-06-2008 at 03:53 AM. |

| |  |

| | #8 |

| Pebble Pounder Join Date: Nov 2007 Location: alpharetta

Posts: 139

| |

| |  |

| | #9 |

| I wanna be Dave  Join Date: Jun 2005 Location: drillin Holes for the man

Posts: 2,736

|

thanks bud! I will be making one of these next week! I will post up pics when I'm done!  edit:well I actually made it today! I hade a little free time at work so I gathered up the matereal and made it. I will post pics of it tonight! Last edited by bigflex; 05-21-2008 at 11:37 AM. |

| |  |

| | #10 |

| I wanna be Dave Join Date: Mar 2008 Location: Wayne county. PA

Posts: 2,507

|

where can one find small dia mandrell wheels like the first picture one in this thread that will fit 1/8", 3/16" and so tube and rods.................bob .... |

| |  |

| | #11 |

| I wanna be Dave  Join Date: Jun 2005 Location: drillin Holes for the man

Posts: 2,736

|

heres the one I built today at work!    Thanks for sharing the prints!  |

| |  |

| | #12 | ||

| RCC Addict  Join Date: Mar 2007 Location: Penngrove

Posts: 1,809

| Quote:

Quote:

| ||

| |  |

| | #13 |

| Newbie Join Date: Mar 2008 Location: transfer

Posts: 17

|

that is very nice bender but dose it have to be made out of alum. can it made out of any metal or alloy or dose the alum have somthing to do with the nice bends that it makes

|

| |  |

| | #14 | |

| RCC Addict  Join Date: Mar 2007 Location: Penngrove

Posts: 1,809

| Quote:

| |

| |  |

| | #15 |

| I wanna be Dave  Join Date: Dec 2005 Location: Tax Nation

Posts: 2,289

|

dragging this thread back up.... If you put the center stud in a mill or even a drill and "cut" a round groove at the same diameter as the material you are bending, wouldnt that work to support the material and keep it from kinking? Last edited by jetboat; 08-20-2008 at 07:44 AM. |

| |  |

| | #16 | |

| Quarry Creeper Join Date: Jun 2007 Location: Calgary, Alberta

Posts: 291

| Quote:

Im sure that would help. I could not get a nice 90 with tube with this bender. Solid on the other hand, it does it perfectly. | |

| |  |

| | #17 | ||

| RCC Addict  Join Date: Mar 2007 Location: Penngrove

Posts: 1,809

| Quote:

Quote:

| ||

| |  |

| | #18 |

| Quarry Creeper Join Date: Apr 2007 Location: St. Louis

Posts: 267

|

A good tubing bender will have a mandrel that will support the sides of the tubing to prevent kinking. Thin wall tubing is more prone to kinking than thick wall or solid. A good example would be the tubing benders used at a muffler shop, they support the sides of the tubing. Yes, there is a difference between tubing and pipe benders. Last edited by Flip; 08-20-2008 at 02:10 PM. |

| |  |

| | #19 |

| Rock Crawler Join Date: Sep 2007 Location: Denmark

Posts: 904

| I will show my boss the drawing tomorrow  We use 1/8" and 4mm copper tube at work Quote: and I have a lathe at work so I can make small rollers with grooves to fit the tube |

| |  |

| | #20 |

| Pebble Pounder Join Date: Aug 2008 Location: socal

Posts: 160

|

if anybody decides to start making these let me know. i will purchase one i have a mountaineer that needs some bumpers and other parts.  |

| |  |

|

| |