| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #101 | |

| Rock Crawler  Join Date: Nov 2009 Location: Commiskey

Posts: 585

| Quote:

If you go to the storm door area you can find replacement rollers for storm doors that'll work as dies in both steel and brass. Your just going to have to use smaller bolts or drill out the center of the roller/die. If drilling is not your thing you can get away with "1/4 grade 8 bolts.  The ones I found fit 1/8th/3/16 tube really well, the one's that fit "1/4 tube fit kinda loose but should still work. The ones I found fit 1/8th/3/16 tube really well, the one's that fit "1/4 tube fit kinda loose but should still work.

| |

| |  |

| Sponsored Links | |

| | #102 |

| I wanna be Dave Join Date: Mar 2008 Location: Wayne county. PA

Posts: 2,507

|

the reason i went with the tube on the bolts over the screen door rollers is that there dia was to big....i'm thinking bout adding a 1/4" hole on my plate and use a 5/16" tube on a 1/4" bolt for a smaller radius bend........bob .... |

| |  |

| | #103 |

| Quarry Creeper Join Date: Feb 2012 Location: Fort Worth

Posts: 237

|

Is there any reason why 3/16" .014 walled brass tubing won't work when bending in this kind of a bender? Cause I built one with a 2x4, a 1/4" bolt, and a screen door roller.  No matter what I try the tube kinks. The funny this is is that it doesn't flare out on the sides because I have a washer tightened down on it. The inside of the bend just caves in. Is the tubing wall too thin?  Please help me out guys. I've ruined probably 3 or 4 feet of tube thinking it might be technique and I'm tired of going to Lowe's and Ace Hardware everyday trying to make this work. |

| |  |

| | #104 |

| Quarry Creeper Join Date: Feb 2012 Location: Fort Worth

Posts: 237

|

On second thought... Does anyone have a good bender that lives in Houston? I'll just come use yours.  |

| |  |

| | #105 |

| Rock Stacker Join Date: Oct 2012 Location: Canberra, Australia

Posts: 58

|

I am about to start making a "Bob's Bender". I will make bending dies for 3/16" and 1/4" tubing a la brandonwalsh420 to minimise flattening on the inside of the bends. My first project will be a roll cage for an open JK (1: |

| |  |

| | #106 |

| I wanna be Dave Join Date: Mar 2008 Location: Wayne county. PA

Posts: 2,507

|

i would say yes to thin of brass tube, i get that little indent on 1/4" steel tube as well. just not as bad and don't look bad either.... I made the pin on my handle close as I did to have the bend go easier without much pressure needed.... |

| |  |

| | #107 |

| Pebble Pounder  Join Date: Sep 2010 Location: Far from you

Posts: 176

|

Great post mate thank I for sharing;)

|

| |  |

| | #108 | |

| I wanna be Dave Join Date: Aug 2006 Location: under a rock and a hard place

Posts: 5,443

| Quote:

| |

| |  |

| | #109 | |

| RCC Addict Join Date: Mar 2007 Location: Turn the mayflower around.. it will never work

Posts: 1,588

| Quote:

^^^ this! I would listen..... His brass cage work is always awesome, Prolly uses it to bend rules too...who knows ..... It cheats a lot or it gets the hose again... | |

| |  |

| | #110 |

| Quarry Creeper Join Date: Apr 2017 Location: Melbourne Australia

Posts: 404

|

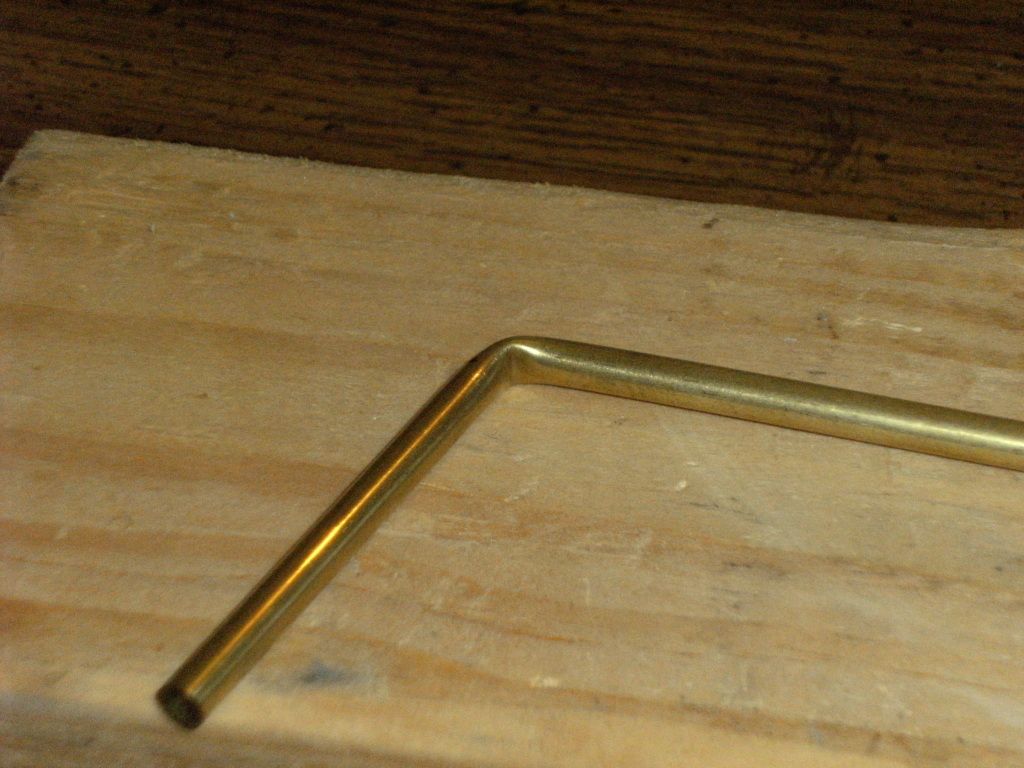

My take on a Bob bender. I remixed it a bit and turned down some m8 nuts and hex couplers to approximately round using a drill and file. Pretty happy for 4 bolts, 2 hex couplers, few nuts and couple of random brackets from the hardware store. Got no kink on a 180° 3/16" brakeline quick bend. Photos of bends are tube and rod respectively.      Sent from my LYA-L09 using Tapatalk |

| |  |

|

| |