| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| RCC Addict Join Date: May 2010 Location: The heart of the south

Posts: 1,138

|

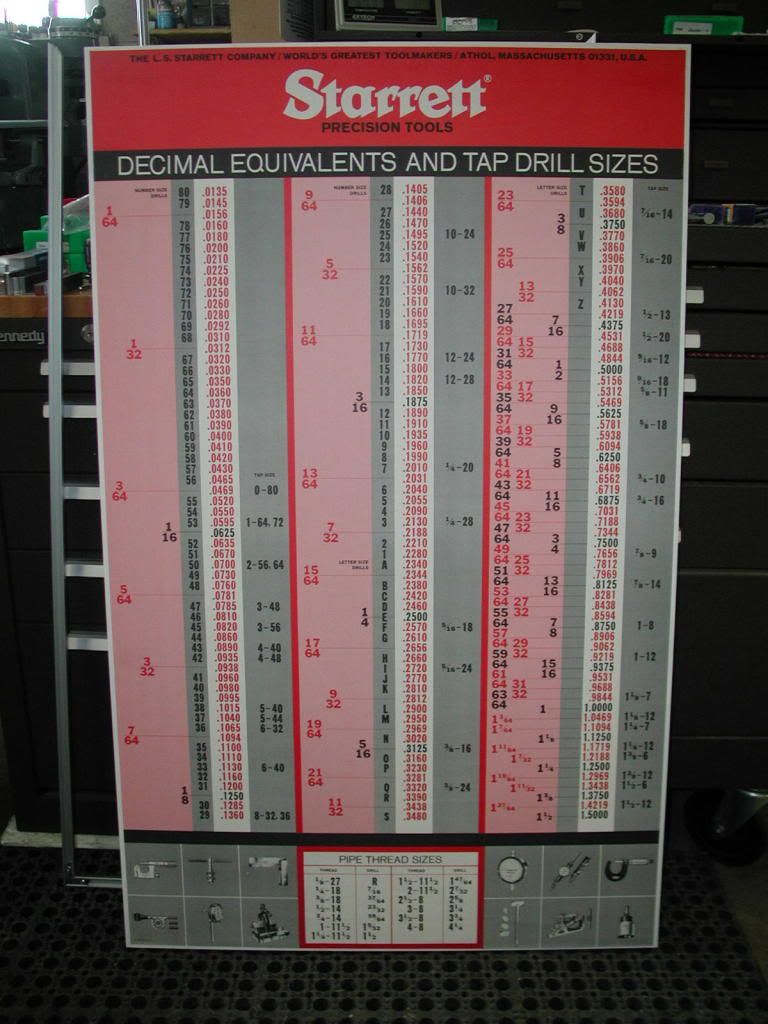

For us that don't work in the metal machining world, this chart is of great help. At least it was to me. http://www.physics.harvard.edu/servi...HREADCHART.pdf |

| |  |

| Sponsored Links | |

| | #2 |

| I wanna be Dave Join Date: May 2008 Location: Baltimore

Posts: 4,442

|  Thanks for the link, this is a good to use as well. |

| |  |

| | #3 |

| Suck it up!  Join Date: Mar 2008 Location: Arkansas

Posts: 11,652

|

What, no metric system?  Last edited by Duuuuuuuude; 07-01-2011 at 08:53 PM. |

| |  |

| | #4 |

| Quarry Creeper Join Date: Apr 2009 Location: sandia park, nm

Posts: 263

|

good info, thanks. might help in the day to day as well.

|

| |  |

| | #5 |

| I wanna be Dave Join Date: Nov 2010 Location: 07456 N. NJ USofA

Posts: 8,314

| Nice, but doesn't cover the small stuff we use..... try this.... http://www.engineersedge.com/manufac...rill-chart.htm   |

| |  |

| | #6 |

| RCC Addict Join Date: Nov 2006 Location: Lowell, Arkansas

Posts: 1,307

| |

| |  |

| | #7 |

| I wanna be Dave Join Date: Nov 2010 Location: 07456 N. NJ USofA

Posts: 8,314

| |

| |  |

| | #8 |

| I wanna be Dave Join Date: Aug 2008 Location: Deep in Swing Town

Posts: 3,011

|

I found that an 1/8" clearance hole for a 3mm is too big...

|

| |  |

| | #9 |

| Suck it up!  Join Date: Mar 2008 Location: Arkansas

Posts: 11,652

| |

| |  |

| | #10 |

| RCC Addict Join Date: Nov 2006 Location: Lowell, Arkansas

Posts: 1,307

| |

| |  |

| | #11 |

| RCC Addict Join Date: Nov 2010 Location: England

Posts: 1,603

|

when i was an apprentice many years ago the best reference for threads and other machining know how was the Zeus book of tables. plastic coated flip book. i still have my 1976 edition somewhere http://cgi.ebay.co.uk/ws/eBayISAPI.d...m=310187580240 someone has converted them to PDF format here http://www.green-oval.com/data/zeus.pdf Last edited by M1tch; 07-02-2011 at 06:29 PM. |

| |  |

| | #12 |

| Got Worms? Join Date: Jun 2009 Location: Golden, CO

Posts: 6,116

| |

| |  |

| | #13 |

| RCC Addict Join Date: Nov 2010 Location: England

Posts: 1,603

|

i like that...... a lot  |

| |  |

| | #14 | |

| Quarry Creeper Join Date: Apr 2005 Location: Malaysia

Posts: 374

| Quote:

| |

| |  |

| | #15 | |

| I wanna be Dave  Join Date: Dec 2009 Location: San Francisco

Posts: 2,236

| Quote: | |

| |  |

| | #16 | |

| TEAM MODERATOR  Join Date: May 2004 Location: Tennessee

Posts: 10,855

| Quote:

Very true. Allot of times at work, material, tolerances, and application plays a part in what size hole I drill for a threaded hole. What style of tap also plays a big part in what drill I use. | |

| |  |

| | #17 |

| Newbie Join Date: May 2011 Location: San Diego Ca

Posts: 20

|

0-80 .500 deep in SS is easy. Don't bother even trying lol.

|

| |  |

| | #18 |

| I wanna be Dave Join Date: Nov 2010 Location: 07456 N. NJ USofA

Posts: 8,314

| |

| |  |

| | #19 |

| TEAM MODERATOR  Join Date: May 2004 Location: Tennessee

Posts: 10,855

| We typically use rolled threads (form taps) when taping a smaller size like 3mm or #6 and smaller...in aluminum. Can't do that in steel, stainless or anything hard. In hard material, a hole a few thousandths bigger will be allot easier on your taps. Using spiral flute cut taps help in hard material since they pull the chips out of the hole instead of pushing them down into the hole. From my limited experience, the chips coming off the tap in the hole is what breaks allot of taps.

|

| |  |

| | #20 | |

| I wanna be Dave Join Date: Nov 2010 Location: 07456 N. NJ USofA

Posts: 8,314

| Quote:

As to chips breaking taps, having them go to the bottom of a blind hole can bind the tap & break it. Not backing the tap off to break chips can be as bad (in 3/4-1 turn, back 1/2 turn.....). Bending taps also breaks them off. Funny story....one place I worked, we ordered TiN taps for a job, our purchasing dept bought HSS taps & had them sent out for Tin coating. They couldn't figure out why we were pissed when they came in.   | |

| |  |

|

| |