| | #1 |

| Quarry Creeper Join Date: Oct 2011 Location: Georgetown, On

Posts: 345

|

Hey guys, was looking at vanquish, and ordered some parts for my wraith. the thing i was wondering is making my own links for my scx10's. just want to confirm some info with the ppl who have done it. so it takes: 3/16 rod 10-24 die traxxas part number 5347 revo rod ends. that sound about right? thanks, just want to confirm before i buy anything, as ive searched and found a few different options. will be making upper and lower links for both my scx10's, and steering links for my scx10 and my wraith. i need to save as much money as i can! i have all the tools to do this kind of work, its just my first time giving it a go. |

| |  |

| Sponsored Links | |

| | #2 |

| Rock Stacker Join Date: Jul 2010 Location: crisfield

Posts: 56

|

u can use derlin rod its super easy and can get all ur bends with a little heat. or try ur hand at sum ti links but id highly suggest a vise and a map gas tourch to get the bends u want with little effort. its really up to u what u can afford and feel cofident working with. either way is a good route  |

| |  |

| | #3 |

| Newbie Join Date: Apr 2011 Location: Grass Valley

Posts: 15

|

I have used 8/32 all thread with the revo rod ends covered in macro line for a paintball gun. With the 8/32 you don't have to tap out your rod ends first just screw em in.

|

| |  |

| | #4 |

| Rock Stacker Join Date: Feb 2011 Location: Vancouver Island, B.C

Posts: 53

|

I used 8-32 all thread with 1/4 stainless steel tubing to sleeve it once I got the right lengths, you can also use 1/4 brake line but the stainless steel slides on the rocks better. I used revo rod ends part # 5347 and used an 8-32 tap to thread them. Super strong, havn't broken one yet. I built upper and lower links, and the whole steering assembly for my scx10 and my wraith. Very simple. Very strong. Follow this: http://www.scalebuildersguild.com/fo...ad.php?t=13579 It's probably found on this site too, I just know this one off hand. Last edited by jhedsy; 11-22-2011 at 03:59 PM. Reason: Added web page. |

| |  |

| | #5 |

| I wanna be Dave Join Date: Mar 2008 Location: Wayne county. PA

Posts: 2,507

|

i use the straight part of pail handles that are .144" and thread them 6-32 and use dubro rod ends.........bob .... |

| |  |

| | #6 |

| RCC Addict Join Date: Jun 2009 Location: Salmon Arm BC

Posts: 1,777

|

i use 8/32 all thread, 1/4" aluminum tubing and traxxas rod ends just to confuse you some more!!! the materials i use come in 3ft lengths and are like 3-4 bucks. so i bought 3 lengths of tubing, about eight 1ft lengths of 8/32 all thread and 24 rod ends.. you'll use roughly 3ft of tubing and 3ft of all thread for each crawler. thats 4 linked rear and the 2 lower links on the front. there's so many ways of making links its ridicolus. so write down all the possible materials from this thread onto a piece of paper take it into a store and buy what you can find. |

| |  |

| | #7 |

| Quarry Creeper Join Date: Oct 2011 Location: Georgetown, On

Posts: 345

|

I had the threaded rod setup on my scx10 with brake line, but it snapped on me. Im going to run 3/16 rod, die it so it threads in to the revo ends, and cann it a day. just wanted to double check those numbers made sense. when running 400 oz-in, i need something that wont break. threaded rod bent like rubber. gonna try and find some rod, and go from there. i have derlin for my esc mounting plate, but id never use it for links. id twist it in seconds. |

| |  |

| | #8 |

| RCC Addict Join Date: Jun 2009 Location: Salmon Arm BC

Posts: 1,777

|

hmmm interesting. i've pounded my steering link against rocks and never had a problem.

|

| |  |

| | #9 |

| Rock Crawler Join Date: Dec 2009 Location: Redding

Posts: 705

|

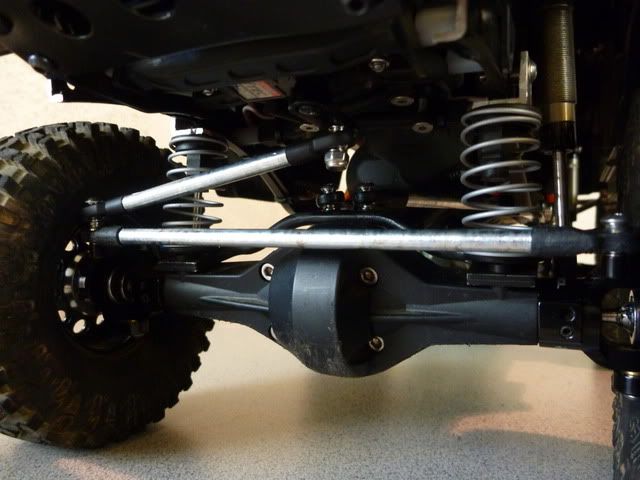

Here is my take on the links. Its a 1.9 scaler that weighs 7.5 pounds. My original links were 6/32 all thread with a 3/16 aluminum tube as a sleve. They bent the first time out.  My new links will require some new materials. Material List 6/32 all thread 6/32 tap 3/16 brake line Traxxas #2742 Rod Ends Tube cutter First I had to figure the length of my all thread pieces. Figured out how deep I ran my tap and also how deep the rod end would thread. Together I came to 18mm. I cut mine with a Dremel disc.  Cut your tube to length (make sure to consider your rod end lengths). Run your tap in both ends. Take your rod end and run the tap into it as well. Thread your rod end onto your all thead and then into the tube. You need to be very precise on your tube lengths since you want these snug and tight to eliminate any slop.  Side by side example  On the rig    Did my steering too while I was at it.  I havent bent the new links running yet. I do have to say that all my links are short. I have even hit the tierod hard and it hasnt bent yet. |

| |  |

| | #10 |

| Rock Stacker Join Date: Feb 2011 Location: Vancouver Island, B.C

Posts: 53

|

One good smack and you'll be sure to bend that steering link. Brake line bends to easy.

|

| |  |

| | #11 |

| RCC Addict Join Date: Jun 2009 Location: Salmon Arm BC

Posts: 1,777

|

im not talking about bending the tubing, im talking about bending the all thread. my alum tubing is beat to shit but i pulled it apart cut a piece of 1/4" all thread slowly tapped it through the tube with a hammer about an inch, pulled it out and repeated the process... straightens out the tube pretty good!!!! edit: damn dont have a good picture showing my tie-rod link. i'll get one though. Last edited by AX10wannabe; 11-22-2011 at 03:13 PM. |

| |  |

| | #12 |

| Quarry Creeper Join Date: Oct 2011 Location: Georgetown, On

Posts: 345

|

my scx10 had the all thread and brake line at the websters meet. tumble down the big hill and it snapped it like a pencil. got a tap and die set i can use... now for rod and a revo end set. |

| |  |

| | #13 |

| Pebble Pounder Join Date: Oct 2011 Location: Exeter Ontario

Posts: 156

|

I've been using 1/4" Solid Alum and using a drill bushing That I made on the lathe to center my taps for 3mm All Thread. Now I have 5/16" Solid Delrin and not sure if I like the Alum or the Delrin. |

| |  |

| | #14 |

| Rock Stacker Join Date: Feb 2011 Location: Vancouver Island, B.C

Posts: 53

| Was your "allthread" running all th way though the brake line? Or was it tapped into each end? Cause I can see that snapping.

|

| |  |

| | #15 |

| Rock Crawler Join Date: Oct 2010 Location: Abbotsford BC

Posts: 522

|

use 8/32 not 6/32. this is 8/32 with stainless sleeving compared to stock links  When I wanted to put a bend in a steering link I had to use a hydraulic jack against the frame of my real 1:1 truck in order to bend it. |

| |  |

| | #16 |

| Quarry Creeper Join Date: Oct 2011 Location: Georgetown, On

Posts: 345

| |

| |  |

| | #17 | |

| No idea what I'm doing Join Date: Oct 2008 Location: Underground, CO

Posts: 4,529

| Quote:

I do run Delrin lower links on my SCX, but don't do it with anything smaller than 5/16". I have 5/16" and have bent lower links in binds before. | |

| |  |

| | #18 |

| No idea what I'm doing Join Date: Oct 2008 Location: Underground, CO

Posts: 4,529

| Just curious, but have you run this truck for very long? I was wondering how strong those lower link mounts on the axle are, with the rod end just being bolted to one tab. Since you are on the insides of both tabs, wouldn't it be stronger if you ran the bolt through both, and used a spacer to take up the space where the shock used to be?

|

| |  |

| | #19 | |

| Rock Crawler Join Date: Dec 2009 Location: Redding

Posts: 705

| Quote:

Mud Puppy- I would use the 8/32 but it makes all my links look way too oversized. This is not a KOH rig or TTC rig. I built it to match what would be a daily driver/trail rig. My next project will represent a TTC tube style jeep. Everything will beef up. At that point the 8/32 will fit right in. More food for thought. In a bad tumble or bind something will always be a weak link. Not saying it has to actually be weak but things will always break or give. I dont mind broken links because you can make multiples and have them ready to swap out on the trail. But if you break an axle mount.....your day is toast. Or say a steering knuckle? Its just my thinking. Same reason in my drivetrain I leave my driveshafts to snap first. Saves big money and time. Just my opinion. Last edited by Propane; 11-23-2011 at 12:35 PM. | |

| |  |

| | #20 |

| RCC Addict Join Date: Jun 2009 Location: Salmon Arm BC

Posts: 1,777

|

i see what your saying Propane.. i swapped my plastic knuckles out for alum and kept the plastic ones as spares so i can swap out on the trail if i had to. but if i snap a c-hub im done for the day because they are plastic still and havent upgraded them yet. i personally went the 8/32 route because i dont carry spare links with me on the trail. i've never bent the all thread...yet... but i've beat the shit out of the tubing.. not worried if i do because i take a piece of 1/4" all thread and hammer it through the tubing and it straightens it just fine. Last edited by AX10wannabe; 11-23-2011 at 12:55 PM. |

| |  |

|

| |