| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Rock Stacker Join Date: Oct 2010 Location: ireland

Posts: 52

|

Hello, my names Adam, I'm 16 and doing technology and design for A-level, for my course I have to improve on a product that I have. I chose my XTM RC tools. I plan on improving the handle to a material that allows more grip, I plan on making the hex bits interchangeable also I hope to make the hex bits adjustable in length. My question is, what else would you want your RC hex tool to do? Something that i will be able to do in a school work shop. Thank you all very much |

| |  |

| Sponsored Links | |

| | #2 |

| Quarry Creeper Join Date: Oct 2011 Location: Georgetown, On

Posts: 345

|

sounds like a plan, but dynamite makes a set that does all that, and its $23. 1.5, 2.0, 2.5 and 3.0 perfect for anything axial. |

| |  |

| | #3 |

| Quarry Creeper Join Date: Jul 2004 Location: Arkie-Saw

Posts: 284

|

Thats not the point. He just wants to know what you would do so he can get a good grade in class. Not re-invent the wheel nor have someone tell him where to buy one.

|

| |  |

| | #4 |

| Rock Crawler Join Date: Sep 2005 Location: Duncan, BC, Canada

Posts: 750

|

Sound like a good plan ... check your bit thickness as with the right diameter, you may be able add the function of hex drivers as well. I would say whatever the Turnigy or Integy sets use would net you that extra as they both offer decent low cost drivers in both hex and nutdrivers. A good sized handle would be a considerable improvement, maybe add a rotating top pad to it (shouldn't be to difficult in the shop class). Or add bit storage in the handle ... bit storage with a rotating base would be the best improvement overall. The length adjustment is all in the handle's insert hole and a set screw (but if you want to add bit storage it may be a one or the other thing here). That's probably the extent of it though, after all, it is just a hex tool. But should be a fairly decent project for school. Good luck Damn, now I want someone to actually make the thing, my tools just don't seem adequate any more/ Last edited by Rockfrog; 11-29-2011 at 10:47 AM. Reason: I can't spell for crap when I type. |

| |  |

| | #5 | |

| Quarry Creeper Join Date: Oct 2011 Location: Georgetown, On

Posts: 345

| Quote:

id make the drivers similar to screwdriver setup they sell. it would be cool to see the end of the handle have a different size socket in it, like the tire wrenches. that way one set will have everything you need. make the handle out of aluminum to keep it light, and you could make it so the driver has a standard 1/4 inch socket in the end of the handle, that is held in by a set screw like the hex shaft. this would eliminate the need for a second set of drivers to hold nuts and such. just dont put the hex and driver that are needed for one bolt in the same driver. you could put one of the u joint attachments in there as well, to get a socket into a tight place. | |

| |  |

| | #6 |

| RCC Addict Join Date: Aug 2009 Location: Earth?

Posts: 1,698

|

Some type of small grip area on the hex shaft where it comes out of the handle. The point would be, some times with long screws I will spin/turn the shinny hex instead of turning the larger handle to increace the turning speed.

|

| |  |

| | #7 |

| Rock Crawler Join Date: Sep 2009 Location: Temecula Ca

Posts: 566

|

Maybe make some a little longer for the hard to reach areas, stronger magnets so thy the hex screw don't fall off, A light sources so we can see |

| |  |

| | #8 |

| RCC Addict  Join Date: May 2008 Location: Green Bay

Posts: 1,138

|

I think a nice comfy handle that would ratchet would be a great idea along with the interchangeable tips for both nuts and socket head cap screws.

|

| |  |

| | #9 |

| No idea what I'm doing Join Date: Oct 2008 Location: Underground, CO

Posts: 4,529

|

Turn them into Torx  Seriously though, I've always liked the grip area of some Phillips screwdrivers out there. Not sure how you would do that in class though. Basically if you can keep them from stripping out the screw they are removing, I'm sold.  |

| |  |

| | #10 |

| Rock Crawler Join Date: Jun 2011 Location: San Diego

Posts: 698

| This! Even with a rotating top pad I still do this regularly.

|

| |  |

| | #11 |

| Rock Stacker Join Date: Oct 2010 Location: ireland

Posts: 52

|

Thanks everyone for the replies I was thinking of a wooden handle with some sort of rubber grip material, but someone mentioned aluminium which would be very nice to work with, how about a cylinder shaped aluminium handle, with a lot small holes in it for grip? Or would you prefer wooden with rubber grip? For the extendable bits I was thinking a magnetised hexagonal shaped tube through the center of the handle, the same shape as most interchangeable screw driver ends. Which I presume are the same size as the nut and hex drivers already available. And to stop the bit sliding back when applying force there will be a series of holes for a grub screw to tighten into, maybe 0.5cm gaps between them. The turning cap on the top, I like this idea and will hopefully include it in my project. To all those that suggested ideas for the actual bits, I appreciate your input but as mentioned before I won't be making new bits. Thank you all so much, this has been a great help but please keep the ideas coming! Also, would you like me to post pictures through out the construction of it? |

| |  |

| | #12 |

| No idea what I'm doing Join Date: Oct 2008 Location: Underground, CO

Posts: 4,529

| |

| |  |

| | #13 |

| Newbie Join Date: Sep 2008 Location: Burtonsville

Posts: 47

|

Good luck with your project man sounds like fun. I actually like the sound of a wooden handle. Sent from my MB860 using Tapatalk |

| |  |

| | #14 |

| Quarry Creeper Join Date: Jul 2008 Location: fremont

Posts: 265

|

i would like a strong magnetic hex bit

|

| |  |

| | #15 |

| RCC Addict Join Date: Nov 2009 Location: Tulsa

Posts: 1,667

|

A wooden Handel would be nice. I like the drivers that on the end of the Handle spins helps u to keep pressure on the screw wile u adjust ur hand to turn.

|

| |  |

| | #16 |

| Rock Stacker Join Date: Oct 2010 Location: ireland

Posts: 52

|

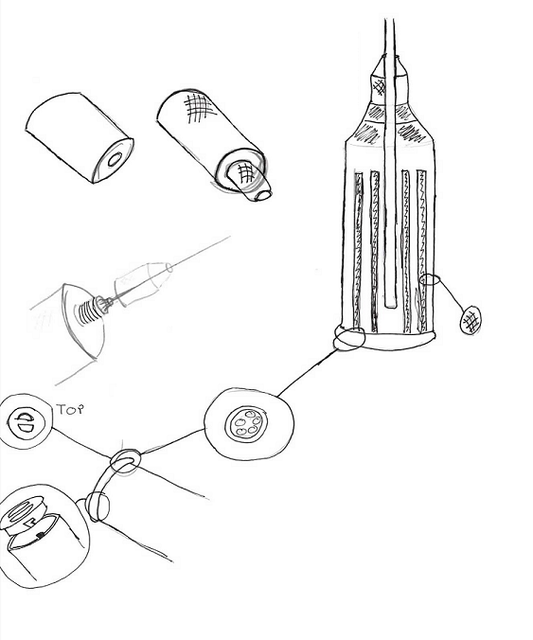

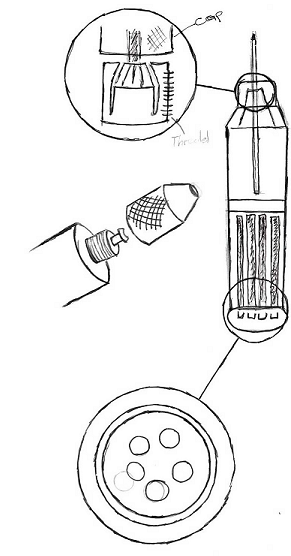

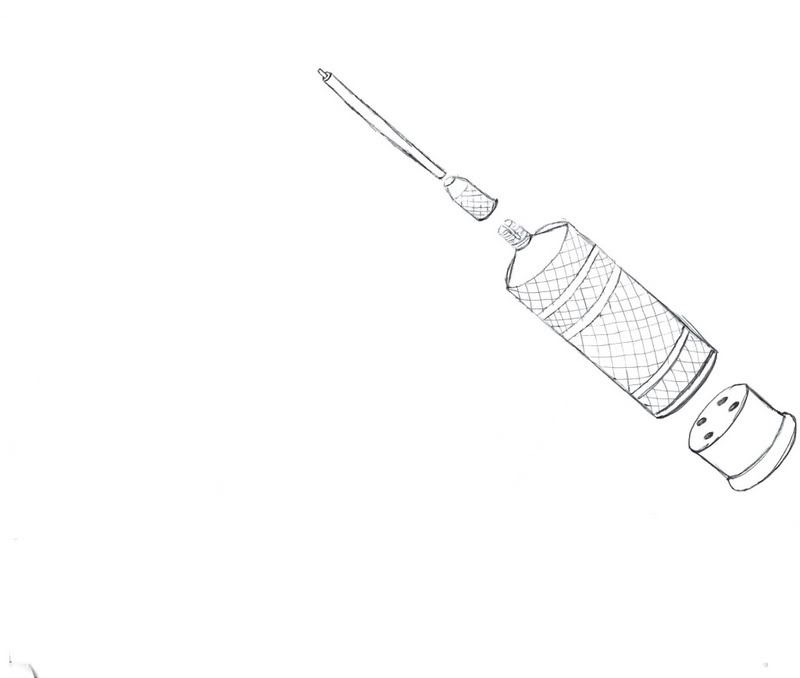

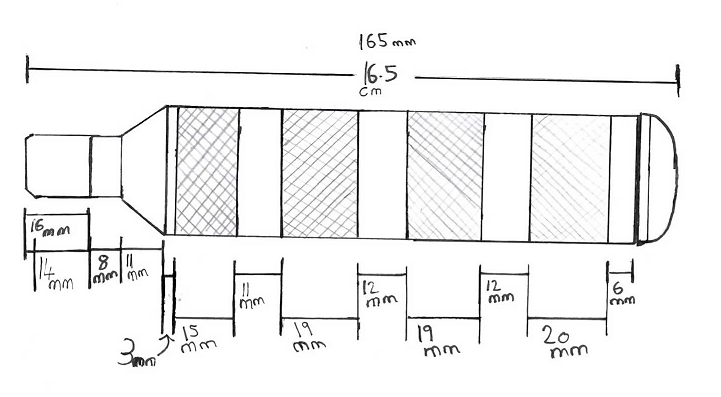

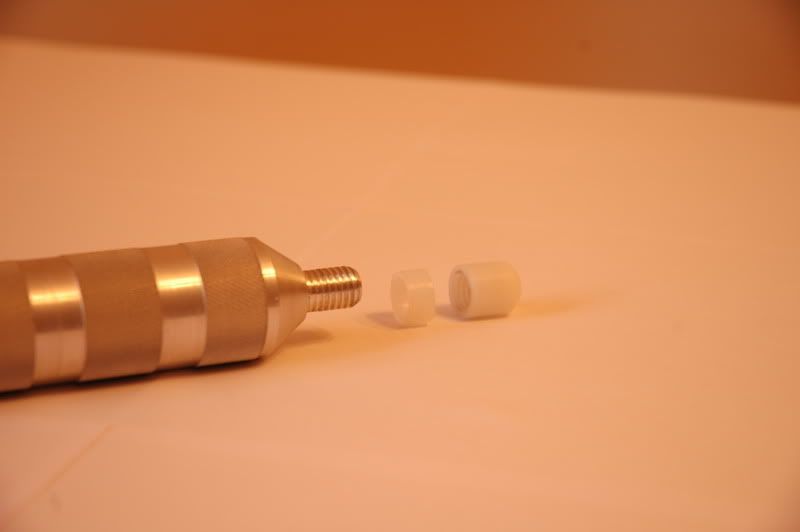

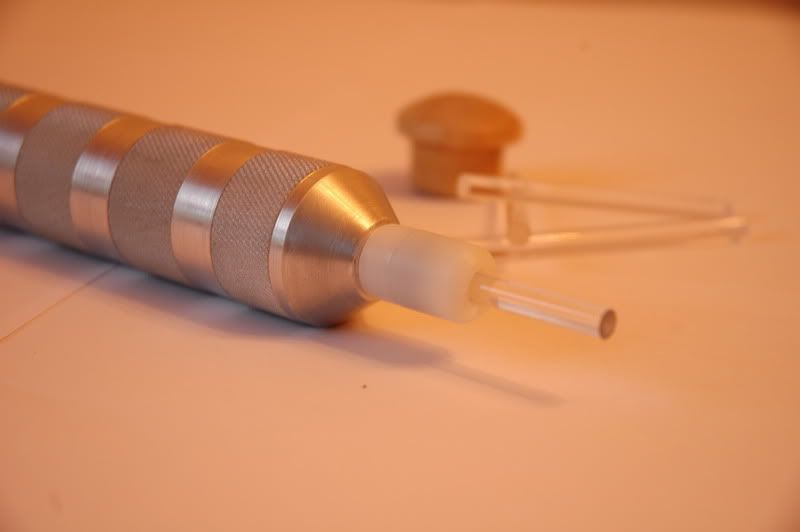

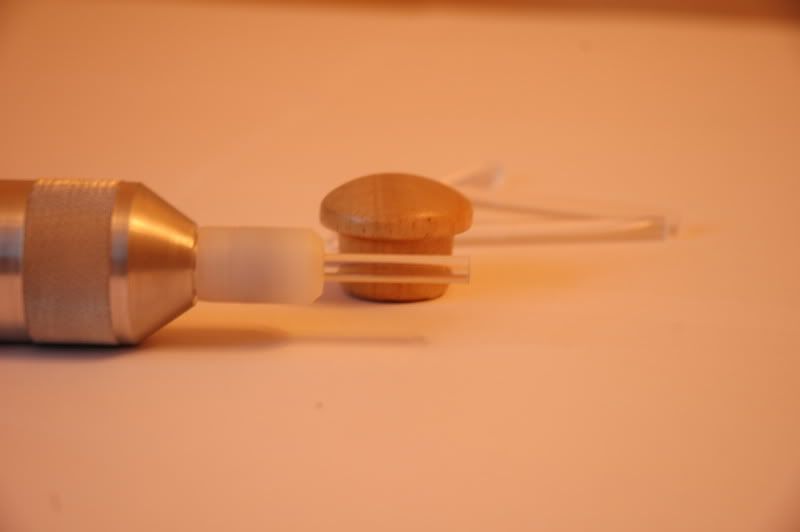

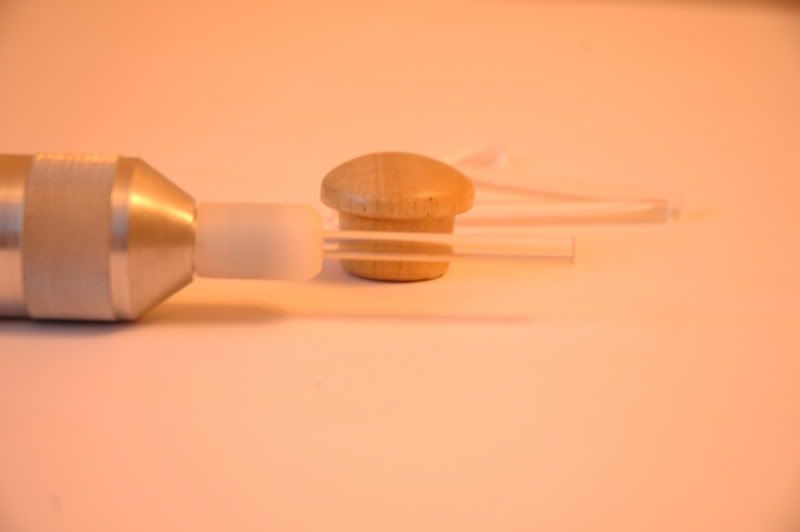

OK so I guess I didn't do a good job of keeping you guys informed as the project has actually been completed Because of time and the machines available I couldn't do some of the things I wanted to but it was only meant to be a model and didn't have to function completely as a production model would. I'll show you some pre-manufacturing planning drawings (they're kinda bad, dont judge) then i'll show you some finished model pictures and try to explain what is going on in the pictures lol Onto the pics!     Now for the finalised pictures, I wont bore you with manufacturing lol    The acrylic rod represents hex bits.       This is it with a real hex bit to give you guys an idea of how it would actually look   This was my first time on a lathe, metal and wood, I would have liked to complete the front section that holds the bits in, then it would have allowed me to correctly adjust the length of the tips but hey what'cha gunna do! thanks for looking guys! |

| |  |

| | #17 |

| RCC Addict Join Date: Oct 2006 Location: crawlifornia

Posts: 1,612

|

bravo dude!!!! nicely done, and I love the overall diameter of these, as they seem a little bigger than most for hobbyists with big hands eh!!!   Dude you totally learned how to Knurl!!! |

| |  |

| | #18 |

| Quarry Creeper Join Date: Apr 2006 Location: sweethome

Posts: 452

|

Looks good is the bit ajustable in the handle for the length.Now if i could find a tool that would get a job to help pay for the builds or so i could stay home .LOL  |

| |  |

| | #19 |

| I wanna be Dave  Join Date: Nov 2008 Location: Chillin in Utardia

Posts: 2,561

|

This is how an engineer Is born.....keep up the great work  |

| |  |

| | #20 |

| Newbie Join Date: May 2012 Location: brattleboro

Posts: 8

|

great job! knurled handle and i would also knurl the top of the tool shaft...

|

| |  |

|

| |