| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| I wanna be Dave Join Date: Jul 2006 Location: The beautiful Pacific Northwest

Posts: 6,923

|

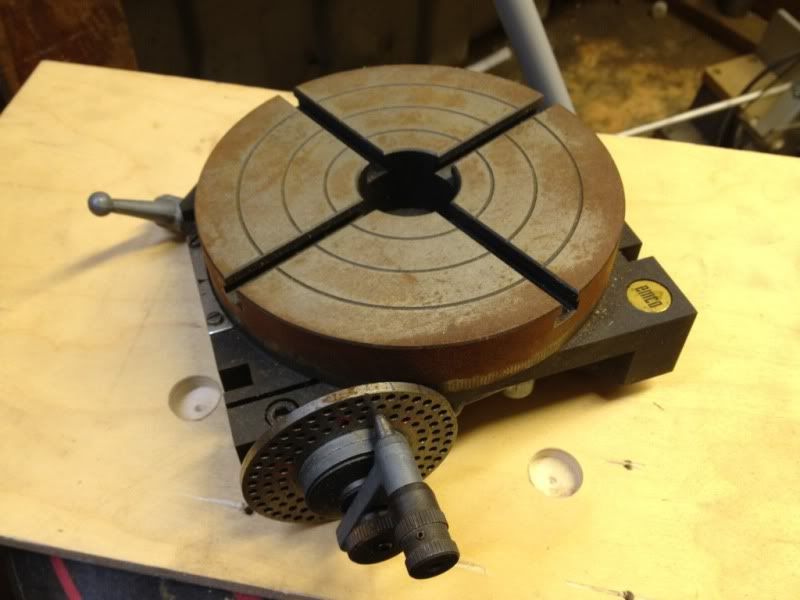

So, my dad has had this combo lathe/mill since the early '80's. I got it up and going a few years ago and have become fairly familiar with it, but I doubt I'm using it properly and to its full potential. First, can anyone tell me much about it? It's difficult to find much about it since I don't believe it's made anymore. It's a Maximat V10 made in Austria in the late '60's.      One thing is it has some wear close to the lathe head. If you take the slop out close to the head, it gets tighter the farther you travel to the right. Is there any way to fix that? Also would like to add a quick change tool holder. Not sure if just any will fit. I also have all these accessories, but don't know how to use most of them. The first ones I have used.    These, not too sure about.    Some various items that I either have bought (most of the end mills) or came with the machine.      Also wondering if any of you have used the Myford turning tools before? So, any info you can give me about tuning it up, basic safe and proper machining techniques, etc would be great. There seem to be quite a few knowledgeable and passionate machinist on here. Thanks for your time. Tim. |

| |  |

| Sponsored Links | |

| | #2 |

| RCC Addict Join Date: Oct 2009 Location: San Francisco

Posts: 1,927

|

Safety 101... Never EVER leave a chuck key in a chuck EVER... Never have anything loose around the machine, it can get sucked in... that's bad Treat metal chips with respect, they are SHARP and some are very HOT! A little oil goes a long way to keep things happy, just use whatever they recommend for it. I use Mobil Vactra #2 on my Sherline and friends Hi Torque mill. I like how it forms a FILM of oil, its sticky but that's a good thing. And sharp tools are key. If its dull, try and re-sharpen but if you can't... toss it. When a tap goes dull, toss it right away, they aren't worth fishing out of a part when they break Last edited by 666; 03-20-2012 at 02:37 PM. Reason: quoted pics.... |

| |  |

| | #3 |

| No idea what I'm doing Join Date: Oct 2008 Location: Underground, CO

Posts: 4,529

| Since you've already used the rotary table, the first is similar but with a dividing head on it. This is used to make accurate, quickly repeatable steps. You can probably look online and get some info on how many degrees each hole will give you. The second is a Steady Rest. It mounts to the bed and provides support to longer material. The third is a Follower Rest. It mounts to the carriage instead of the bed, and "follows" the tool as it's cutting. Most of time with small parts you won't have to worry about the rests, but that dividing head could come in real handy. I remember your post in your 34' thread about drilling the rotors...you could easily do it with that dividing head. Nice looking machine, but I'd cover those electrical outlets  edit: Here's a bit more information on it. And it looks like you can still get manuals for it on Ebay. Last edited by C*H*U*D; 03-20-2012 at 02:39 PM. |

| |  |

| | #4 | ||

| I wanna be Dave Join Date: Jul 2006 Location: The beautiful Pacific Northwest

Posts: 6,923

| Quote:

Quote:

Thanks for the info guys! | ||

| |  |

| | #5 |

| Suck it up!  Join Date: Mar 2008 Location: Arkansas

Posts: 11,652

|

This is a short course truck tire groover.  |

| |  |

| | #6 |

| Newbie Join Date: Mar 2012 Location: North

Posts: 8

|

The lathe also looks to have drive dogs with adjustable speeds. If so this lathe is capable of making threads. That grinder is not just a grinder, but I can't remember exactly what they are for. I will ask my boss. He is great with this stuff. I'm more in to CNC's. |

| |  |

| | #7 |

| I wanna be Dave Join Date: Jul 2006 Location: The beautiful Pacific Northwest

Posts: 6,923

|

It did have thread cutting capabilities, but the gears are stripped on the feed for cutting threads.....so no go on that.

|

| |  |

| | #8 | |

| I wanna be Dave  Join Date: Dec 2009 Location: San Francisco

Posts: 2,236

| Quote:

Assuming that it is only a couple thou I would get some lapping compound and work on your forearm muscles for a couple hours. Basically just lap the tight portion until it comes down and then lap the whole thing a bunch to even it out. If it is off more than that then you are SOL unless you want to pay someone to regrind them for you (probably not). You should be able to add a quick change post, generally you just need to buy one with the proper diameter through hole to match the screw coming out of the cross slide. Any tooling supplier should be able to supply you with the tool post and matching holders for your tools. If you are going to do it you will need to invest some coin in holders, a quick change post without 4 or more holders for your most used tools is a waste of money. On an unrelated note, how are you attaching your winch spools to the servo? Im trying to figure out an easy way to spline them so I dont have to use the dumb plastic circle horns as a base. | |

| |  |

| | #9 |

| I joined the Band! Join Date: Feb 2012 Location: bay area

Posts: 66

|

I believe the grinder is suppose to be attached to the carriage for precision grinding of tool steel. This might also explain why the ways are loose up by the lathe spindle. When you do grinding with a lathe the abrasives and metal grindings get between the ways and saddle and cause friction and wear that will ruin the tolerances.

|

| |  |

| | #10 |

| I joined the Band! Join Date: Feb 2012 Location: bay area

Posts: 66

|

heres a pic of the grinder in use

|

| |  |

| | #11 |

| Newbie Join Date: Mar 2012 Location: North

Posts: 8

|

That would be it (for the grinder). We have one at our shop but we never use it. On the saddle there should be some adjustments to take the slop out. Mine has two bolts that are attached to a plate next to the rear way. Last edited by ~thrasher~; 03-21-2012 at 06:10 AM. |

| |  |

| | #12 |

| I wanna be Dave Join Date: Mar 2008 Location: Wayne county. PA

Posts: 2,507

|

drool, drool, green with envy you have a nice piece of old iron there  ........bob ........bob.... |

| |  |

| | #13 |

| Rock Crawler  Join Date: Apr 2008 Location: Albany

Posts: 640

|

A Tim. Nice lathe very cool. You have some very neat and expensive tooling. Tim If you want to I can come up to your house and we can do a question and answer thing. This is my passion. Let me know. Anyway nice lathe/mill combo. Evan |

| |  |

| | #14 | |

| No idea what I'm doing Join Date: Oct 2008 Location: Underground, CO

Posts: 4,529

| Quote:

There's also a lot of info online about how to use one. Last edited by C*H*U*D; 03-21-2012 at 09:15 AM. | |

| |  |

| | #15 |

| Quarry Creeper Join Date: Jun 2007 Location: Sandy,Oregon

Posts: 354

|

I'll say it again. I can come play when you need me. I can show you how to use the dividing head. At least I used to be able to use one. CNC has turned me into a lousy manual machinist.

|

| |  |

| | #16 |

| I wanna be Dave Join Date: Jul 2006 Location: The beautiful Pacific Northwest

Posts: 6,923

| I'll have you come over when you're not so busy at work. I'm sure the last thing you want to do in your spare time is come show me how to use lathe, mill, and tooling.

|

| |  |

| | #17 |

| Rock Crawler  Join Date: Apr 2008 Location: Albany

Posts: 640

| |

| |  |

|

Tell me a little about my lathe and mill. - Similar Threads

Tell me a little about my lathe and mill. - Similar Threads | ||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Discovered this mill/ lathe | stubb | Tools, and Procedures | 2 | 04-27-2009 07:07 AM |

| Possible ideas for someone with lathe/mill | Zapper2003 | General Crawlers | 10 | 08-20-2005 02:26 PM |

| micromark lathe/mill? | braceysdad | Tools, and Procedures | 3 | 08-15-2005 12:58 PM |

| Mill or lathe? | BeadLock | Tools, and Procedures | 4 | 07-03-2005 04:57 PM |

| |