| | #801 |

| Rock Crawler Join Date: Jul 2016 Location: Southern Oregon

Posts: 767

|

Just saw in email advert Monoprice has Open Box Maker Select V2s for $175 w/ a coupon code... Sent from my SM-G930V using Tapatalk |

| |  |

| Sponsored Links | |

| | #802 |

| Newbie  Join Date: Jan 2018 Location: Sugarland, Texas

Posts: 17

|

Just snapped up a gently used Robo 3D R2 for under 5 bills. |

| |  |

| | #803 |

| Rock Stacker Join Date: Sep 2018 Location: Monroe Township

Posts: 37

|

Thought I would update with how the Ender 3 turned out. Got it a couple weeks ago and have been playing with it like crazy. Got it set up in about an hour and had already printed some ribbon cable clips the same night. Since then, I've printed up a bunch of mods for the printer, i.e. filament guide, controller fan shroud, controller back plate, chain links, etc. I've also added a Raspberry Pi 3 B+ running Octopi and a Raspberry Pi camera. This allows me to remotely monitor the print job as well as send print jobs to it without having to fidget with the SD card or connect a USB cable to it. For some reason, Creality ships the printer with the thermal protection turned off in the FW. I used an Arduino Uno to load a bootloader and flash TH3D's latest Marlin based firmware onto it. Printed a 3Dbenchy and it turned out pretty good. I'm using Cura for slicing and it's working out pretty well. Overall, I can see why this printer is getting such good reviews and is touted as one of the best sub-$200 printers out there. Definitely a new addicting hobby. Want to try ABS and PETG eventually, but think I may need to move the printer somewhere with better ventilation for those materials. What is everyone using for modeling software? |

| |  |

| | #804 | |

| Moderator  Join Date: Sep 2008 Location: PA

Posts: 13,935

| Quote:

For 3D modeling I use SolidWorks because I can use my work software at home. Before that I was using AutoCAD Fusion360. It's great software that's held back by a horrible interface IMO. But I'm used to using SolidWorks throughout my career so YMMV. | |

| |  |

| | #805 | |

| Newbie  Join Date: Oct 2018 Location: Cleveland Heights

Posts: 12

| Quote:

I'd suggest printing with "supports" the drooping, sagging happened because you need to print with supports. I use simplify3d as my slicer program and you simply hit "add supports" and the program figures out where the print needs to be supported and adds a "z fold" typr of print that breaks off easily when the print is done. I run a maker gear M2 and can get much smaller layers, if printing with a fresh roll of PLA I can get almost smooth pieces. | |

| |  |

| | #806 | |

| Rock Stacker Join Date: Sep 2018 Location: Monroe Township

Posts: 37

| Quote:

Yeah. . I was thinking more of just moving the printer to my basement if I print ABS. Right now, it's in my office and I'd rather not be breathing any fumes. An alternative would be in my garage, but with the temps dropping, not sure how well that would do. I was looking at Fusion360 and Blender. I think I'll try Blender first as that looks to be a good open source software that is well supported. Haven't played with modeling software since Maya and 3D Studio Max over 20 years ago. | |

| |  |

| | #807 | |

| Moderator  Join Date: Sep 2008 Location: PA

Posts: 13,935

| Quote:

| |

| |  |

| | #808 | |

| Rock Stacker Join Date: Sep 2018 Location: Monroe Township

Posts: 37

| Quote:

I was reading about Fusion 360 last night and I believe it's free for 30 days, then you fill out some information and it's extended for a year. The documentation seemed to indicate that after that year extension that it was no longer free. Am I misinterpreting? | |

| |  |

| | #809 |

| Moderator  Join Date: Sep 2008 Location: PA

Posts: 13,935

| It was free last time I used it, but that may have changed. If it's no longer free that is news to me. Maybe somebody else can chime in as I now use SolidWorks.

|

| |  |

| | #810 | |

| Rock Stacker Join Date: Sep 2018 Location: Monroe Township

Posts: 37

| Quote:

I'm going by this article here: https://all3dp.com/2/fusion-360-free...-free-version/ According to that, it's only free for up to a year. . or 3 if you're a student. | |

| |  |

| | #811 | |

| Moderator  Join Date: Sep 2008 Location: PA

Posts: 13,935

| Quote:

https://www.autodesk.com/campaigns/f...-for-hobbyists I just make sure I download my models and store them on AutoCAD's cloud. If you only store them on AutoCAD's cloud there could come a day when they hijack them and suddenly make Fusion360 paid software for hobbyists. | |

| |  |

| | #812 | |

| Rock Stacker Join Date: Sep 2018 Location: Monroe Township

Posts: 37

| Quote:

I may try it out just to see how it works. Looks like they may have changed their license model though. The legal notice specifies 1 year for startups/hobbyists and 3 for educational. https://www.autodesk.com/company/leg...s-entitlements | |

| |  |

| | #813 | |

| RCC Addict Join Date: Nov 2014 Location: Nowhere

Posts: 1,326

| Quote:

| |

| |  |

| | #814 |

| Rock Stacker Join Date: Sep 2018 Location: Monroe Township

Posts: 37

| |

| |  |

| | #815 |

| Rock Crawler Join Date: Jul 2016 Location: Southern Oregon

Posts: 767

|

Just to throw in my $.02... I tried Fusion 360 and for some reason couldn't wrap my brain around it. OnShape has worked out well for me, and has a free option. The main downfall of the free version is all your files are public. I just try to use oddball names to try and hide the files from searches... Sent from my SM-G930V using Tapatalk |

| |  |

| | #816 |

| Rock Crawler Join Date: Mar 2016 Location: Murphy

Posts: 733

|

I'm trying to print a fontend that goes on a Tonka Bronco that I will be putting on a Traxxas Summit to use for FPV. I download the files from Thingverse for the frontend, designed by a guy on RCGroups he has the same frontend on his Tonka Summit. The issue as you will see in the pictures is the gap in the model after slicing. Does the samething weither or not I use supports. He sliced it with Flashprint and didn't have the same issue. I had the same issue with both Slic3r PE & Craftware. Downloaded the files again same issue. Resolution doesn't make a difference either.   The red circle is the problem area. |

| |  |

| | #817 | |

| Rock Crawler Join Date: Mar 2016 Location: Murphy

Posts: 733

| Quote:

[QUOTE] Some STLs aren't exported properly from the CAD software. Use a repair tool or service like https://modelrepair.azurewebsites.net . The repaired STL shouldn't have those issues anymore.[/QUOTE} Uploaded the file a few minutes later is was downloaded back to my PC, I then loaded it into Slic3r PE again and sliced it now looks good. I'll print it tomorrow and see what happens. | |

| |  |

| | #818 |

| ~THE SCALE SHOP~ Join Date: Apr 2006 Location: KILLEEN TX

Posts: 10,056

|

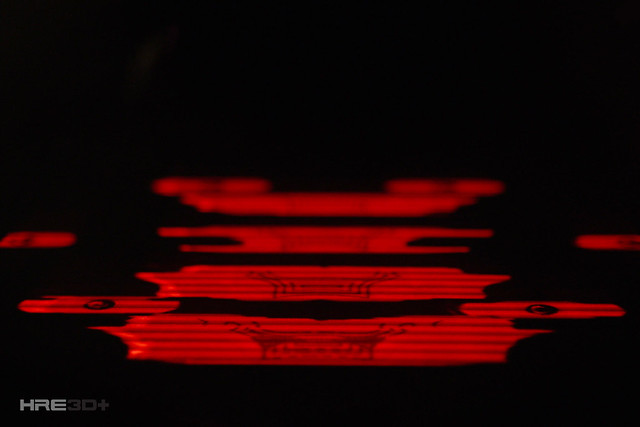

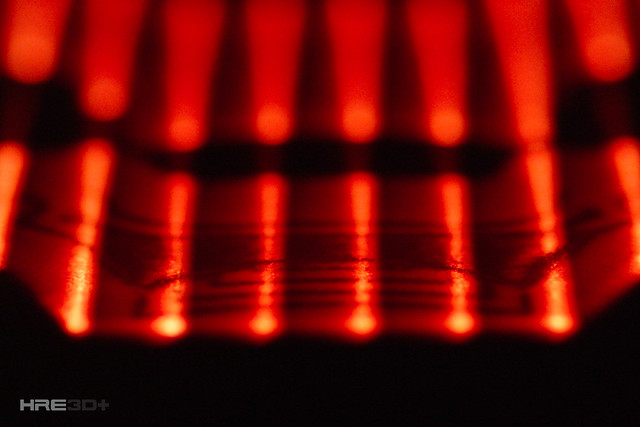

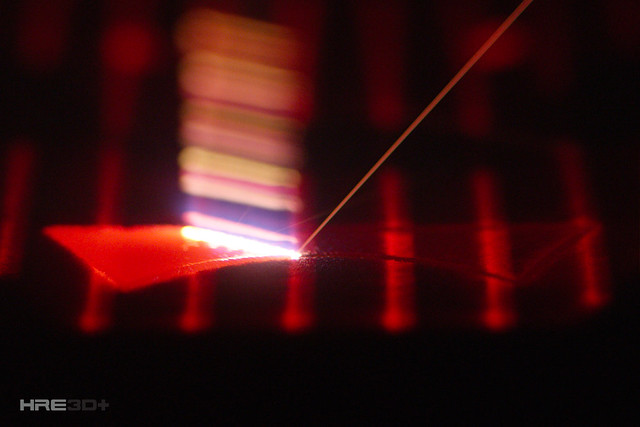

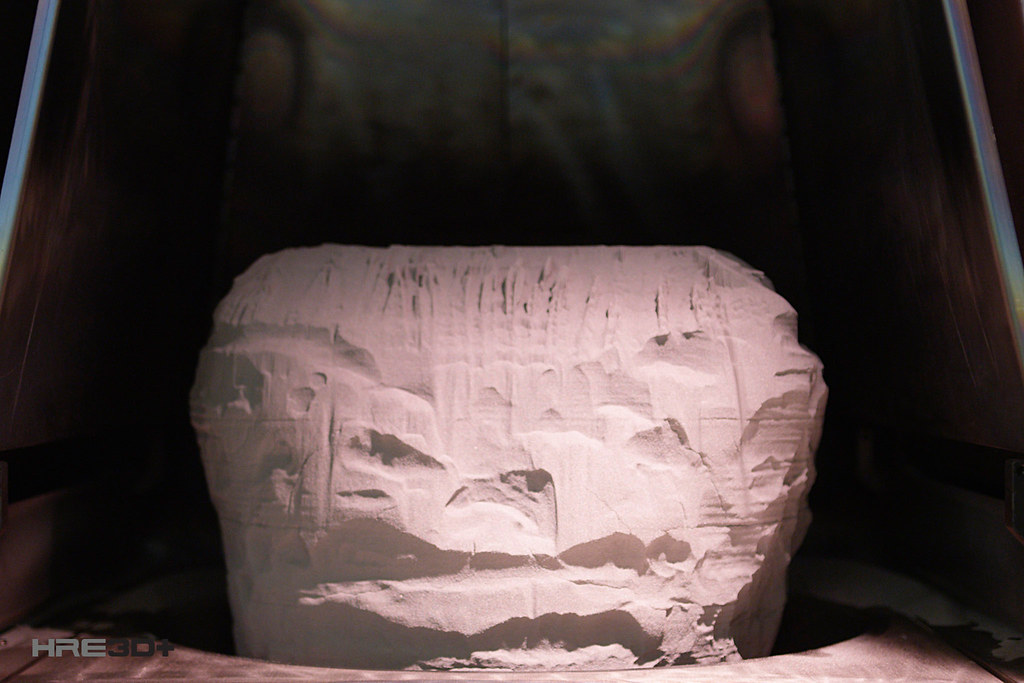

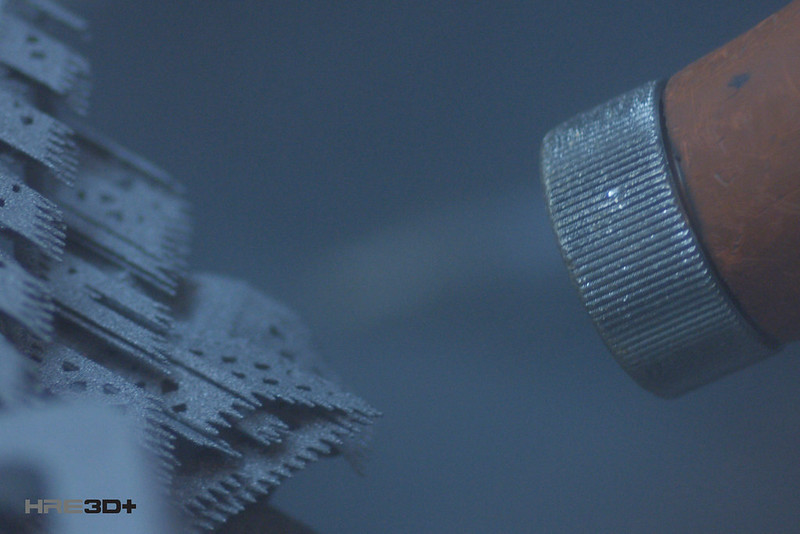

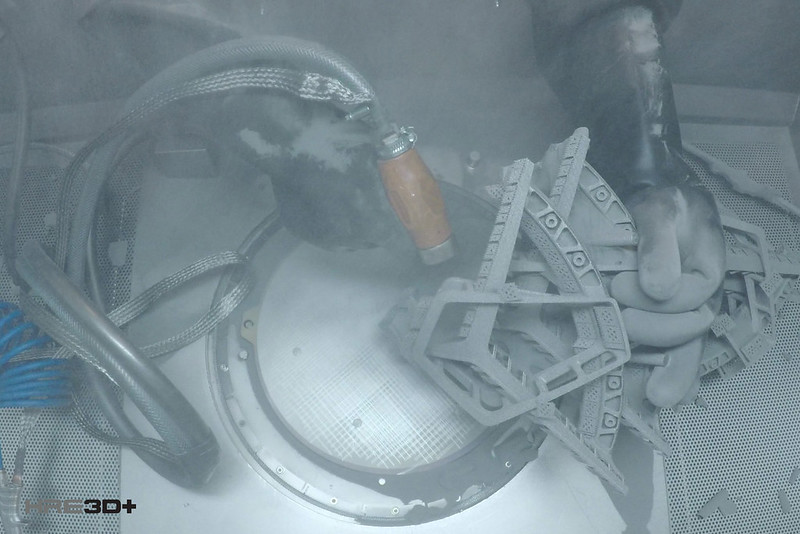

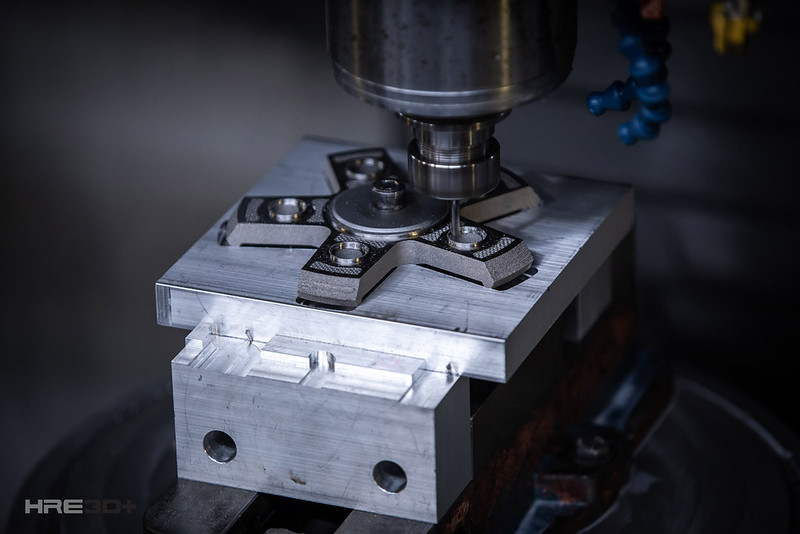

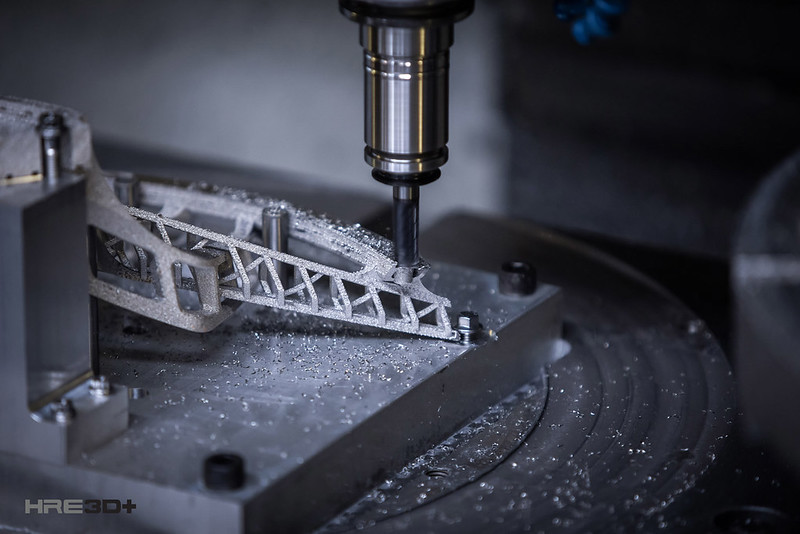

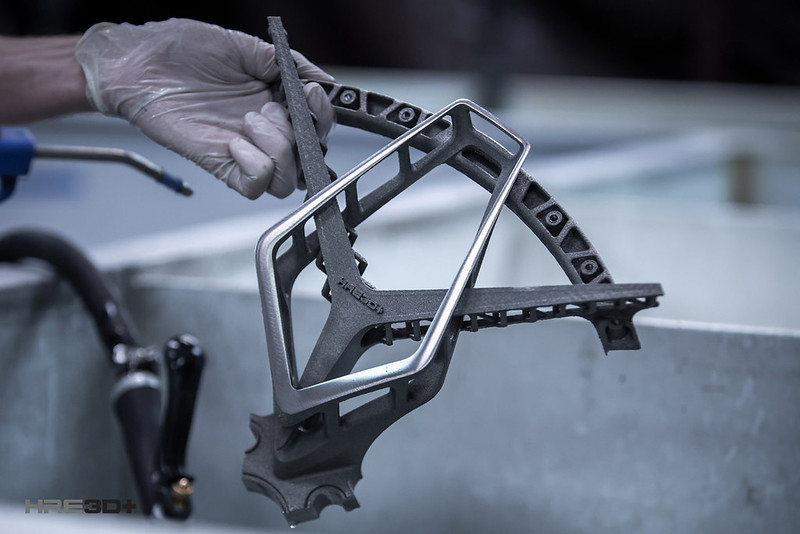

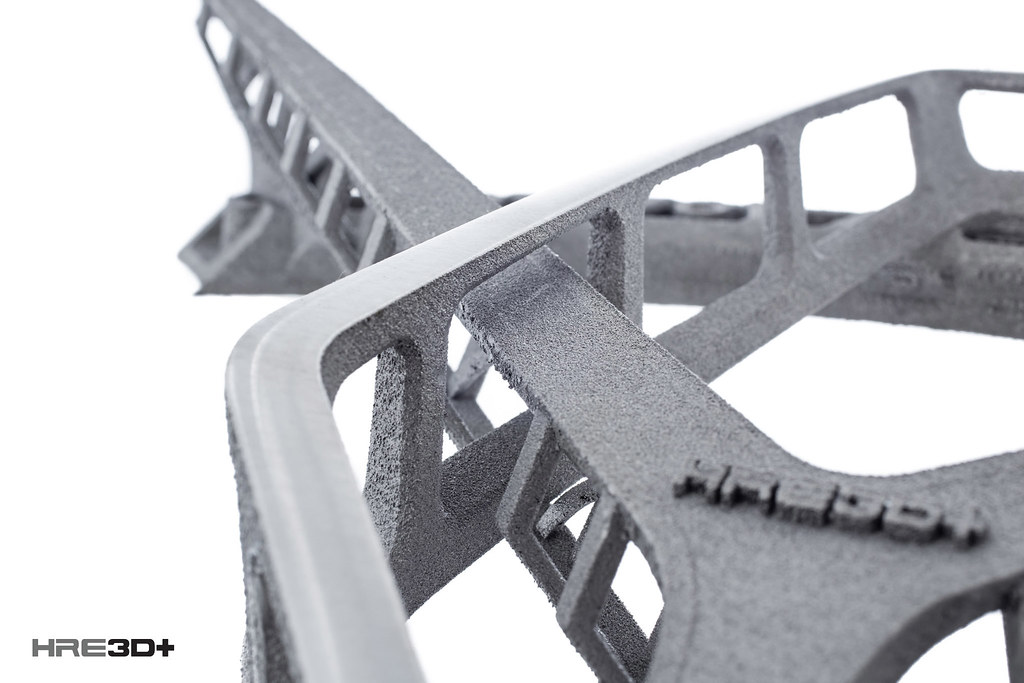

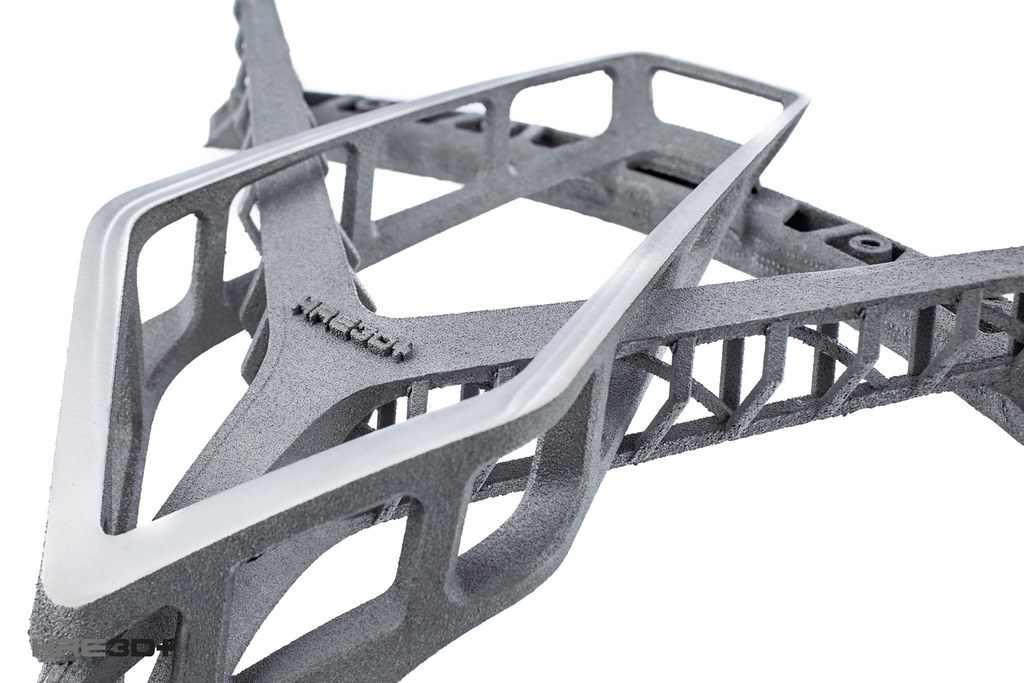

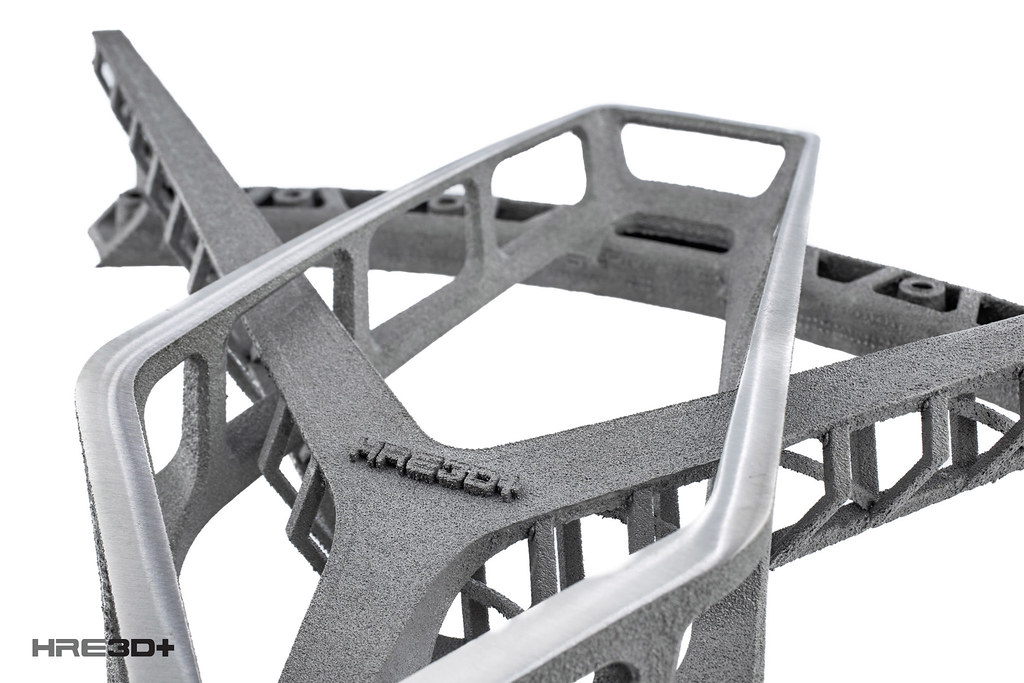

thought this was pretty cool   HRE WHEELS PARTNERS WITH GE ADDITIVE TO CREATE FIRST 3D-PRINTED TITANIUM WHEEL HRE and GE Additive’s AddWorks team have used Electron Beam Melting (EBM) technology to create a new prototype wheel made from an advanced titanium powder, unveiling the first automotive wheel to be made with this process. Vista, Calif. (November, 201 The goal of the “HRE3D+” project was to test the capabilities of additive manufacturing in a practical application and to create a highly-sophisticated wheel design with an elusive material like titanium. With a traditional aluminum Monoblok wheel, 80% of material is removed from a 100-pound forged block of aluminum to create the final product. With additive manufacturing, only 5% of the material is removed and recycled, making the process far more efficient. Titanium also has a much higher specific strength than aluminum and is corrosion resistant, allowing it to be extremely lightweight and to be shown in its raw finish. There was an intensive design collaboration between the Vista, California based team at HRE and the GE AddWorks team out of Ohio. Using design queues from two existing models of HRE wheels, the two companies worked together to create a stunning example of what is possible with additive manufacturing. The wheel was produced on two Arcam EBM machines - Q20 and a Q10 in five separate sections,, then combined using a custom center section and titanium fasteners. "This is an incredibly exciting and important project for us as we get a glimpse into what the future of wheel design holds,” said HRE President Alan Peltier. “Working with GE Additive’s AddWorks team gave us access to the latest additive technology and an amazing team of engineers, allowing us to push the boundaries of wheel design beyond anything possible with current methods. To HRE, this partnership with GE Additive moves us into the future.” “HRE prides itself on its commitment to excellence and superior quality in the marketplace. It was a natural fit for AddWorks to work on this project with them and really revolutionize the way wheels can be designed and manufactured,” said Robert Hanet, senior design engineer, GE Additive AddWorks [COLOR="]EBM Printing: Electron Beam Melting is an additive technology that uses and electron beam to melt and fuse fine layers of titanium powder into a solid. These fine layers are built up one at a time to create the full design.    Titanium Powder Bed: The additive design is built up in a bed of fine titanium powder which results in very little wasted material, unlike traditional subtractive methods like machining from a solid forging.  Powder Recovery: The excess titanium powder is removed to reveal the final design and recycled for future parts.   Support Removal: Temporary internal support structures are printed along with the part to provide support to the structure and to facilitate extremely complex designs. These are removed by hand and recycled after printing.  Post Machining: Mating surfaces and threads were CNC machined post-printing to ensure tight tolerances of assembly. Compared to traditional machining from forgings, this post-processing is minimal.   Hand Finishing: The tops of the spokes were hand brushed to create a beautiful decorative finish. Because Titanium has excellent corrosion resistance, no additional powder-coat or clear-coat was necessary.      Cleaning: Due to the minimal machining and finishing, cleaning is a simple process simply to remove any oils or remaining powder.   Assembly: All the parts were hand-assembled into a carbon-fiber rim barrel using titanium fasteners.[/COLOR]                         The “HRE3D+” wheel will be on display from November 13-16 on GE Additive’s booth (D30) at the form next tradeshow in Frankfurt, Germany. For more information on HRE Wheels, visit https://www.hrewheels.com/wheels/concepts/hre3d About HRE Performance Wheels: HRE designs, engineers and manufactures 3-piece and 1-piece forged aluminum alloy wheels for Racing, Performance & Luxury cars and SUVs in their San Diego, California-based, TÜV-approved facility. HRE’s built-to-order wheel sets offer a customized choice of offsets, widths and finishes, resulting in a uniquely personal style and performance solution for each customer’s application. HRE wheels are sold through select high-end car dealerships, specialty retailers and performance companies worldwide. For more information, visit www.hrewheels.com or call an HRE wheel expert at (760) 598-1960. About GE Additive: GE Additive – part of GE (NYSE: GE) is a world leader in additive design and manufacturing, a pioneering process that has the power and potential to transform businesses. Through our integrated offering of AddWorks additive experts, advanced machines and quality materials, we empower our customers to build innovative new products. Products that solve manufacturing challenges, improve business outcomes and help change the world for the better. GE Additive includes additive machine providers Concept Laser and Arcam EBM; along with additive material provider AP&C. EBM machines create dimensionally accurate parts quickly and efficiently by using a high-power electron beam for high melting capacity and productivity. The EBM process takes place in vacuum and at high temperature, resulting in stress-relieved components with material properties better than cast and comparable to wrought material. |

| |  |

| | #819 |

| Rock Crawler Join Date: Jul 2017 Location: BC, Canada

Posts: 742

|

Cool Sent from my SM-G960W using Tapatalk |

| |  |

| | #820 |

| Rock Stacker Join Date: Sep 2018 Location: Monroe Township

Posts: 37

|

That printer looks like one of those, "if you have to ask, you can't afford it" type deals. Very cool though.

|

| |  |

|

3d printer for rc parts - Similar Threads

3d printer for rc parts - Similar Threads | ||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Can your printer do this? | CREEPERBOB | Chit Chat | 19 | 10-14-2011 07:33 PM |

| Are you a printer in OH or know someone who is? | Phatmac | Ohio | 5 | 02-20-2009 02:14 PM |

| |