| | #81 |

| RCC Addict Join Date: Sep 2015 Location: Southern Maine

Posts: 1,024

|

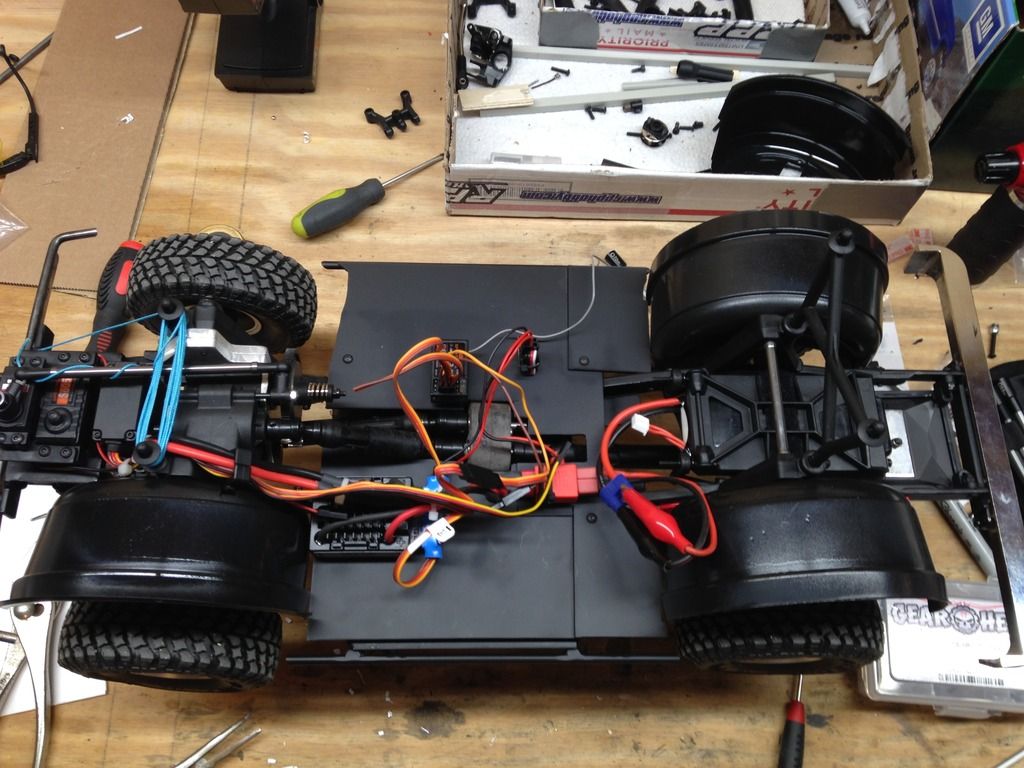

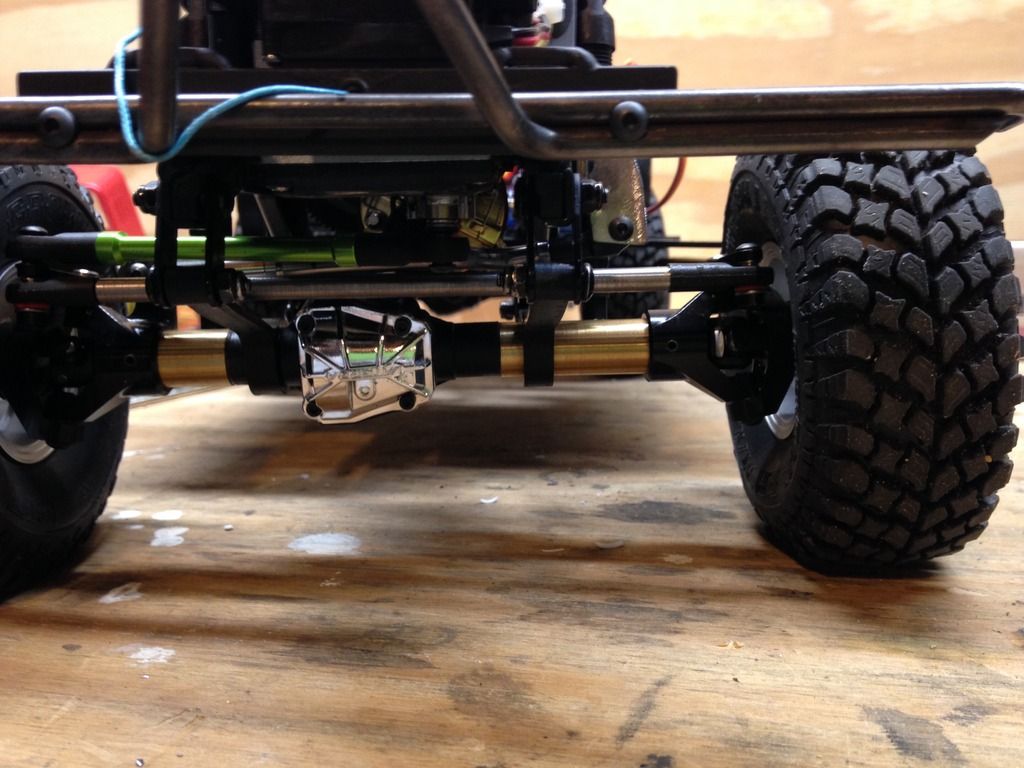

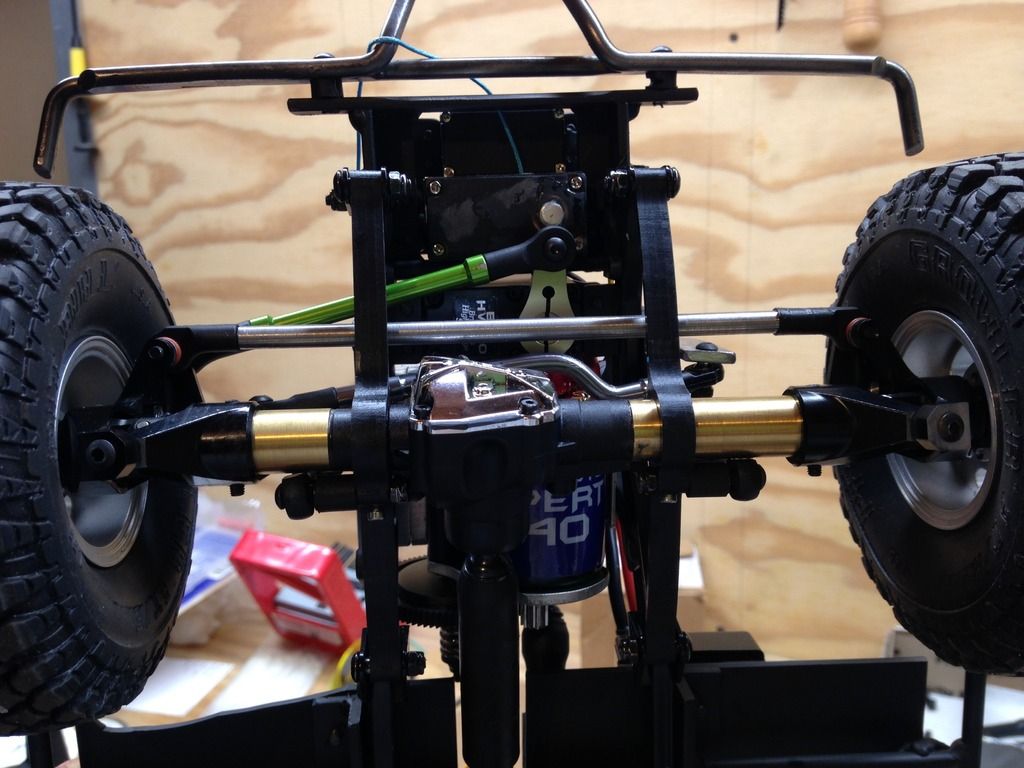

Finally a little update. IT'S ALIVE!!!!!!!!!!!!!!!!!!!! I finally got my sliders painted, made my floor up from styrene, and started wiring things together. I ran out of servo connectors to make my servo extensions. BUT, I did get my BEC wired up and ESC so I could at least start playing with the steering and setting up the servo. I'm a little bummed with the amount of bump steer I'm getting. I can't really take advantage of the crazy steering angle the axle is capable of. First off, like Nate suggested posts ago, I probably should have a longer servo horn. I'm having a hard time getting full steering to the left, and when the right side suspension is compressed, it pulled the steering from left toward center. I can get full turn to the left but when the suspension is compressed, it'll drive the right tire into the spring and bind the axle u-joint. No big deal that way, I'll just have to remember to not turn the wheel all the way to the right while flexin' but still a nuisance. I tried using my steering stops, but it'll just pull the left side suspension up when it hits and I try to steer more. Any suggestions to a really low profile servo horn that's longer than the axial clamping one? Also, are any offset at all like the draglink end is lower than the servo output shaft end? I put my servo winch super close to the servo horn and if the horn is any longer, it'll hit the shaft on the winch unless it's offset. I can raise my winch but ya know, it's already mounted... I've also maxed out my travel adjustment on my radio so I think a longer horn will help out. I did clock the horn more to the left and set my sub trim to center the wheels and that did allow me to get much more left steering but it drives me NUTS seeing my trim so far off from center lol. I'm like flat broke so it'll be a while until it's done. Still need to get the $20 ebay special ECS that'll run on 3s for the winch, need more wire to extend the ECS battery power wires to my rear mounted battery tray and more servo wire and connectors so I can finish making my servo extensions and what not, and tire glue. Then, the body work! Oh boy. Think i'll mount up my original RTR Blazer body for the time being so I can at least enjoy the truck this summer. Back to the steering, can I run a pan hard bar on spring suspension with out it binding or being a problem? My mom had a 93 jeep wrangler and it had a pan hard bar on the rear axle with leafs. Just wondering. I tried moving the axle side to side and it really has no play so I'm thinking a pan hard bar, even set properly at ride height will cause binding. I do have the drag link very close to level at ride height and straight up and down suspension travel bump steer it's bad, but when it's just the right side where the drag link attaches to the knuckle, it's definitely noticeable. I'm open to suggestions and feedback. On to a few pictures...     |

| |  |

| Sponsored Links | |

| | #82 |

| I wanna be Dave Join Date: Jan 2006 Location: Corruptifornia

Posts: 12,107

|

Hudy makes servo horn that is offset towards the servo, I've got a picture of it in my thread somewhere, don't remember how long it is though. I can measure it if you like. Starting with servo horn offset to one side and then using sub-trim to center like you've done is often the only way to get steering properly setup, don't worry about the knobs setting. Panhard with leaves can be done, but not ideal and has to be set just right. 1:1 trucks also rely on rubber suspension bushings that flex around, we use solid ball rod-ends. I"m looking back through your thread for pictures of front end at full compression, ride height and full droop to see again what is going on with your steering. Definitely drive it with the Blazer body this summer, I also think that would help you figure the steering more. Sometimes just gotta drive it a bit and watch what's happening. |

| |  |

| | #83 |

| RCC Addict Join Date: Sep 2015 Location: Southern Maine

Posts: 1,024

|

Nate thanks. I though about it more last night and your right on with the pan hard bar on 1:1's. I'm scrapping the idea for this one too. Plus, it's too much work for most likely just another problem like binding. I need a servo horn offset away from servo mount if I don't want to move my servo winch. I'm also thinking I can make an extension for my current servo horn using the threaded holes and add one more threaded hole past the end of the horn for more throw and it'll be offset away from the servo, and Itll drop the drag link down just a bit more and probably be perfect for a level drag link at ride height. I'm going to look into that. I forgot to mention that this truck has ZERO torque twist (I was thinking it wouldn't but now I know for sure. Also, the Holmes hobbies esc and motor are literally SILENT. it's amazing. Super duper smooth and I haven't even played with any esc settings yet. On the level the steering is a bit ratchety at full steering lock but that's just the nature of such steering angl plus the front axle is overdriven .18%. Thanks Nate! Ben |

| |  |

| | #84 |

| RCC Addict Join Date: Sep 2015 Location: Southern Maine

Posts: 1,024

|

So after looking at my steering and suspension for a bit I scrapped the pan hard idea. I decided I needed a little longer servo horn so I can get full steering throw and turn down the radio end points from max so I'll have some adjustability. But like I said before, the servo winch is super tight to the current servo horn and I really hate moving things after I like where they are. I didn't want to spend hours online trying to figure out horn lengths and splines yadda yadda yadda, so, I just made my own horn. Well, sorta. I made this plate to bolt to current horn. It is just a bit longer, offset to clear servo winch and also drop the drag link down so it will be level at ride height. I'll hopefully get it on tonight or so and see how it goes.    Last edited by Itali83; 05-11-2017 at 10:44 AM. |

| |  |

| | #85 |

| I wanna be Dave Join Date: Jan 2005 Location: Raleigh-ish vicinity

Posts: 3,846

|

It would mess up your nicely designed setup but I think you could get much better steering geometry if the steering servo was mounted in the position of the servo winch with the horn pointing towards the rear of the truck. That would bring the drag link much more inline with the steering travel and give you some more out of the servo throw.

|

| |  |

| | #86 |

| RCC Addict Join Date: Sep 2015 Location: Southern Maine

Posts: 1,024

|

You are totally correct. I spent way too much time just staring at it last night in rage but yeah, the drag link is on too much of an angle front to back to meet with the servo horn. When I installed my longer servo horn last night, I'd only get about 30-40 degrees of wheel turn then the servo tried to pull the axle sideways because it was a straight line from steering knuckle to servo horn if that makes any sense. So I can't use that. Ben |

| |  |

| | #87 |

| I wanna be Dave Join Date: Jan 2005 Location: Raleigh-ish vicinity

Posts: 3,846

|

Just eyeballing things from the pictures, it looks like rearranging the servos could take care of everything. Move the servo winch to the front, put the steering servo in the middle, and the shift servo in the back. With most of the truck being custom, it may not be a quick solution but it wouldn't require an extensive redesign either.

|

| |  |

| | #88 |

| RCC Addict Join Date: Sep 2015 Location: Southern Maine

Posts: 1,024

|

I think your right, but what really makes me mad about this is the fact that the steering servo is in the stock location the bronco and K10 is in. That's the only thing on this whole truck that's stock and it isn't working!!!!!!! My mind is blown. I actually went ahead and made a pan hard bar to tame bump steer and axle shift while steering and I'm happy with it. Only the slightest bit of binding at full right side compression with left side unloaded but the benefits outweigh that so I'm going to keep it on for now. It at least gives me a few more steering degrees to the left I was loosing by axle shift. I don't know what to do about the servo not turning as many degrees by power as by hand. If it weren't for this I'd have it mostly done except battery connectors and wire. Ben |

| |  |

| | #89 | |

| I wanna be Dave  Join Date: Apr 2010 Location: Oakridge

Posts: 3,305

| Quote:

Just kind of thinking out loud.  Ernie | |

| |  |

| | #90 |

| RCC Addict Join Date: Sep 2015 Location: Southern Maine

Posts: 1,024

|

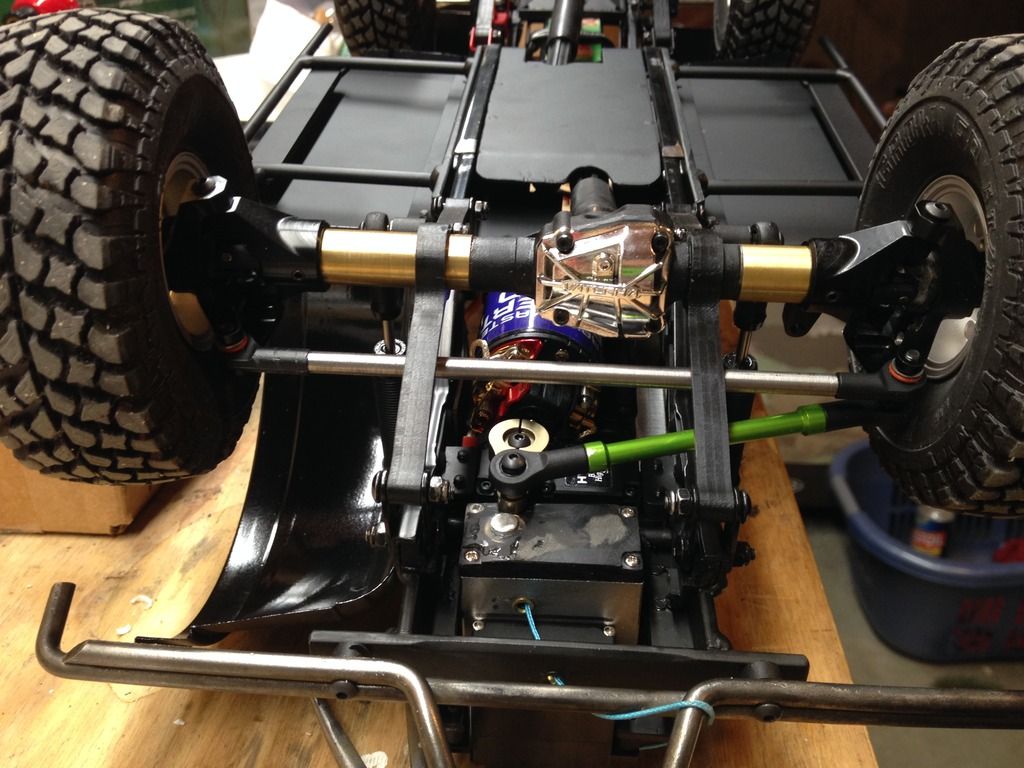

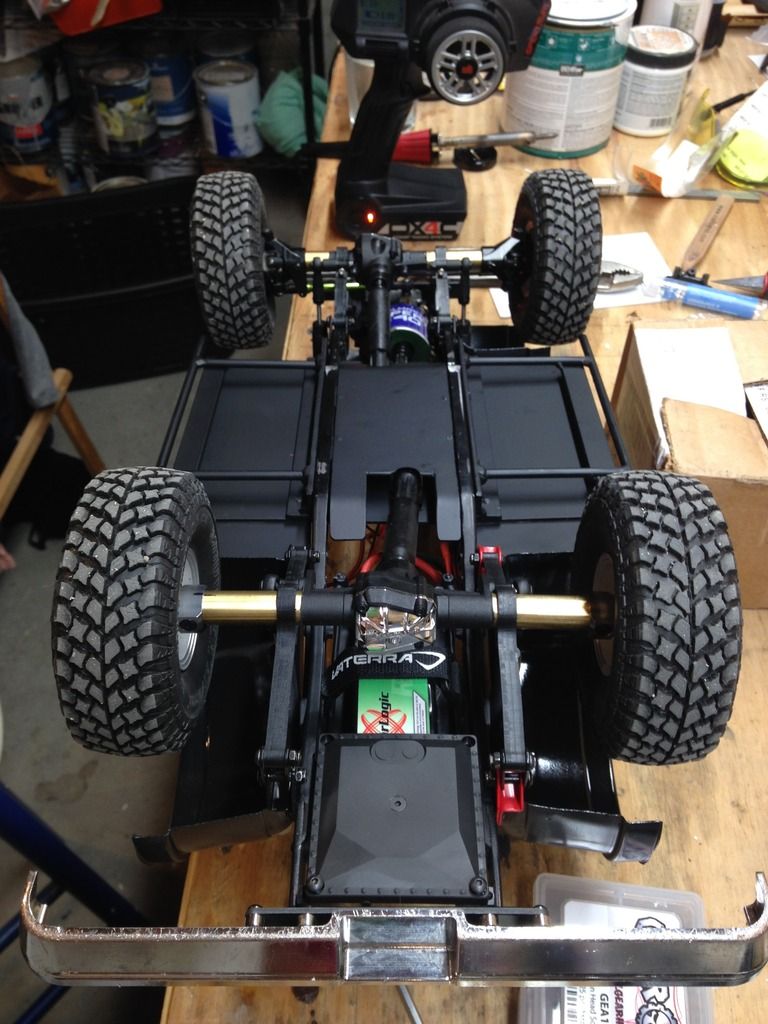

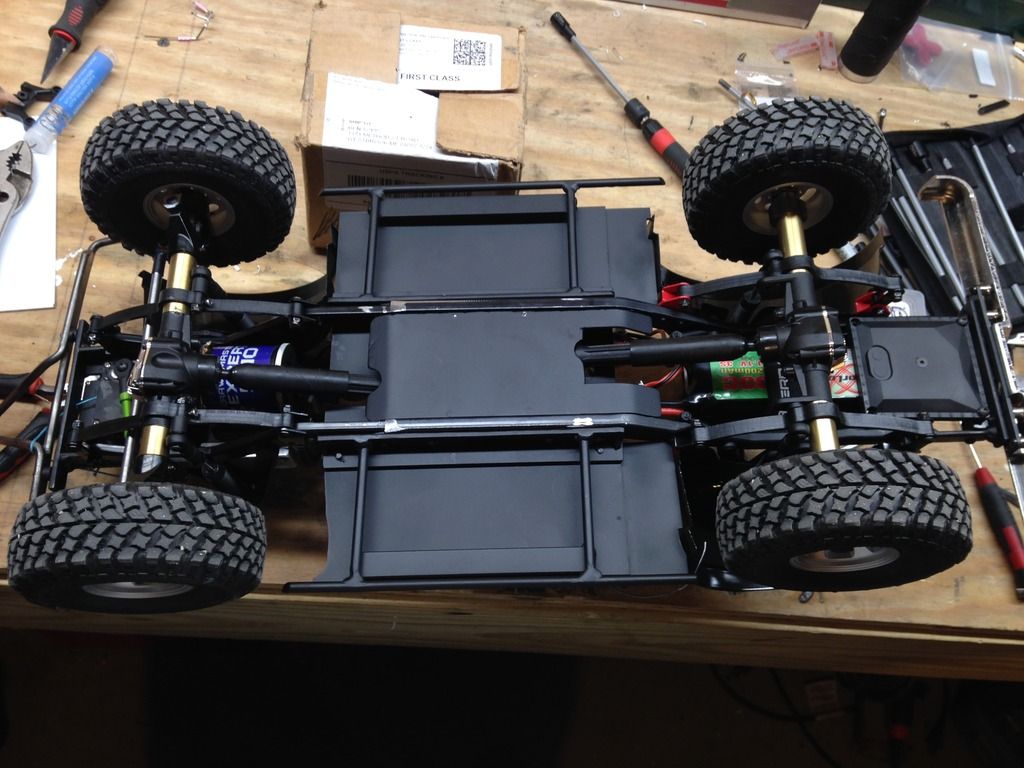

So, like I posted in the electronics section, my mind is blown why a servo can physically turn 180 degrees but only do about 90 degrees powered. I tried everything I possibly can to see if it's the servo, radio, receiver or whatever. All combinations that I have do the same thing so I'm stumped. I do have an e-mail into Holmes to see if I can program more steering into their servo. Like my last post says, I did make up a pan hard to keep the axle from shifting when trying to steer and the tires have some drag or traction to them. Up in the air, it wasn't a problem, but if I put the truck down on the ground, I'd loose the last bit of steering due to axle shift. Flex of the springs, little play in shackles etc etc etc. SO, I said screw my last thoughts of no pan hard bar and made one up from left over suspension links. Made my own frame mount as I'd already cut the stock one off ages ago. Whoopsie! I had to put a bend in it to clear the motor but it just clears the tie rod in all situations. It is as close to even with the angle of the drag link as possible and 99% of my bump steer is gone, and there is virtually no suspension binding or issues. Only the last 1.5mm or so of up travel of the right side does it start to want to slightly bind but that's really me just being fussy. I've also got a lot of my steering angle back, and I'd say I'm a bit beyond the 45 degree stock steering angle. Closer to 50-55ish I'd say. So, I'm happy with that. No steering binding or getting into the leafs with the tires so whatever. It's a bummer but hopefully I can somehow program more steering in the servo then everything will be right again. I also got my shift servo wired up and adjusted and it shifts smooth as butter. I just need to get more servo connectors and wire to wire up the winch. I'm also thinking about putting the castle sidewinder ESC into my first blazer, taking the stock esc out of that and using that esc for my winch control. I want something that'll run on 3s so that'd be perfect. I found a cheap 1/18 scale esc on ebay that runs on 3s and good for like 80amps which is obviously WAY more than the servo can pull but it's only $12. But, I like the sidewinder and think it'd be good in my blazer and then I can use that esc for free. Here's the pictures of my panhard bar and mount. Hard to see with everything that's going on up front but I think you'll get the idea.     Some flex shots to show the front suspension does work...   |

| |  |

| | #91 | |||

| I wanna be Dave Join Date: Jan 2006 Location: Corruptifornia

Posts: 12,107

| Quote:

Rearranging servos as you suggested might help geometry and steering, by placing draglink closer to parallel with the tie-rod.  Quote:

Assuming that you've tried dialing in more than 100% steering servo travel, but it doesn't make the servo travel farther? I've not had a servo/radio combo yet that this doesn't work on, assuming the radios had the ability to extend servo travel. Assuming that you've tried dialing in more than 100% steering servo travel, but it doesn't make the servo travel farther? I've not had a servo/radio combo yet that this doesn't work on, assuming the radios had the ability to extend servo travel.Quote:

| |||

| |  |

| | #92 |

| RCC Addict Join Date: Sep 2015 Location: Southern Maine

Posts: 1,024

|

Nate, agree with the pitman arm and steering knuckle arms racing the the same way. I wanted that on this truck but wasn't willing to put the servo in the stock blazer position because of motor placement. Plus, I figured since the k10 and bronco have the servo in the position I put mine and with the drag link mod like I did I figured it'd be fine. As for servo travel, if I put my travel at 0, the servo barely moves in either direction, as I go up all the way to max, 150, the servo gains throw but not to the full 180 degrees that is physically available if I do it by hand. But there is no point where the servo stops and I still have adjustment on my radio if that makes sense. It's just like the amount of adjustment on the radio isn't proportional to the amount of throw that the servo has. I dunno. I've got it to a good place now. Plus, I just got an idea of using a bent drag link (I know I know, not my favorite idea either) but I've seen pictures of other crawlers with big power servos using them so what the heck. I may try it too. That may fix the out of line angle my drag link is at and actually pull/push more on the steering link arm. It turns tighter than my other blazer already so I guess I should be happy. Still waiting on a reply from HH to see what they have to say about the servo travel. Ben |

| |  |

| | #93 |

| RCC Addict Join Date: Sep 2015 Location: Southern Maine

Posts: 1,024

|

Just double checked because I wasn't having a moment, my servo horn/pitman arm IS facing the same way as the steering knuckle arms. The axle is in the same position as stock, the servo is in the same position as the stock K10's and Bronco's, and I did the extended drag link to the steering knuckle arm, not the vaterra funky knuckle thingy in the tie rod. So I don't think I did anything wrong with servo set up.... just sayin' Ben |

| |  |

| | #94 | ||

| I wanna be Dave Join Date: Jan 2006 Location: Corruptifornia

Posts: 12,107

| Quote:

Quote:

Yes, good job putting draglink straight to top of steering knuckle.  | ||

| |  |

| | #95 |

| RCC Addict Join Date: Sep 2015 Location: Southern Maine

Posts: 1,024

|

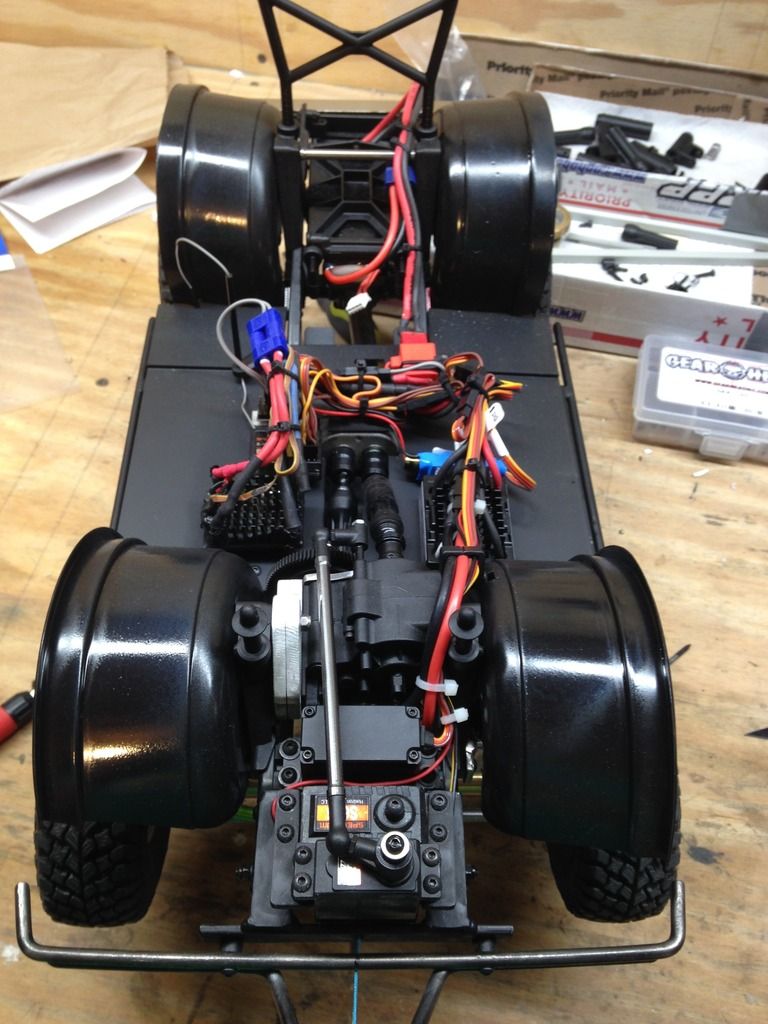

Ok guys, here it is. Got it for christmas and finally got it running under it's own power and basically complete. I'm running my original RTR body for the time being. I want to paint and detail the new body to be just like my first truck. 1987 GMC Jimmy but I can't wait any longer! I've got the steering pretty well sorted out, may try my longer servo horn now that I have the pan hard bar set up and the axle shift won't be an issue but I've got to say this thing steers great already. I had to glue the tires which was a first for me. Went to the local hobby shop, picked up some glue, forgot what kind off the top of my head, a little extra of the tiny applicator tube and went to town. I did trim the foams that I had, I have the CI dual stage foams but the outer stage was too wide for me, couldn't keep it centered on the inner layer and the tire would be lumpy. Can't have lumpy tires on my truck! So I just trimmed about 1/4"-3/8" off each outer foam and was happy with that. I did wire wheel the bead groove of the wheels to get the shiny polish off and hope that the glue will stick better. I do think these growlers will do the job well. They aren't the alien compound but seem to be quite sticky and soft already. I didn't quite run a complete 2200mah pack through the truck but they've already left some tread on the rocks. This truck is another heavy one so traction will be needed. The foams are stiff enough so far with side hilling but soft enough to form around obstacles so I'm very happy. I'm very very happy with the leaf springs I got from Guisseppe in Italy. Time will tell with their strength and durability but I already love them much more than the metal leafs the ford had. They flex very well and smooth. No binding or jerking. I do have to drive it differently than a 4 link truck because if things get in a bind, they will wrap up some obviously. I do need to adjust my rear pinion angle because I do get some axle wrap and the pinion climbs up to a not so nice angle while climbing. No big deal though. I have a few ideas for anti-wrap helpers, I spin on drag racing traction bars but won't hang down like them. I've got to say I'm blown away with the electronics on this truck. The Holmes Hobbies stuff is just awesome. I LOVE the low end speed and control this thing has. I can literally watch the teeth turn on the PINION while under a load it's that smooth. In high gear and wide open, the truck is quite fast too, a very brisk walk light job speed. I might swap out the 88T losi spur gear for the 86 vaterra just because I'm a slow and steady guy but think the difference will be marginal. The servo is super nice too. Gobs of power, I've got the BEC set to 8.0 volts, the servo is good fo full 2s power so 8.4 volts but figured a neat 8.0 is good enough for me. Very quick too. Both the servo and ESC are so quiet. I ended up using my castle side winder esc to power the servo winch. Overkill but I had it and the wiring was a bit funky so I rewired it to fit the bill on this truck. It's nice to not have to touch the truck to power up the servo winch like I have to on the other two ascenders. Thats because I was too cheap to buy a winch controller and just used an on-off switch to cut power to winch to prevent drift. Over all driving experience: it just gets it done. Only thing I noticed from my other trucks is that this is a pumpkin dragger because of the tires. I will get some measurements but with the flat skid and custom front bumper, the actually has better approach angle and belly clearance than my RTR K5 blazer. The rear bumper is a bit of an anchor but I've already done a big of "massaging" to it with a grinder and file today at work. I'm leaving it on there purely for looks and a place to put my licence plates. This seems to side hill great and climb as vertical as traction will allow and not flip over. I will be putting it to the limits at my favorite crawl spots for comparison soon hopefully. Enough jibber jabber, here's a few pictures and a video of it done for now. Like I said, I will be doing a fresh body for it with a little more detail than I've done in the past but that'll be a ways down the road. Here's the wiring and such. Wiring is a little messier than I had in my head but I'm mostly happy with it.  On the bench ready to go. It's amazing the slight differences in bodies, the sliders fit like crap on this body compared to my new unpainted one. So please, don't mind the final fit and finish of bumpers and sliders to this body, they weren't set up using this body.     Up on the rocks for some real world flex shots, truck was driven to this spot. Good view on my licence plate, same one I had on my first vehicle, 1987 GMC Jimmy. I was a Drummer all through school and professional for 3 years before starting a family.     Hope you enjoy. Thanks!. Ben |

| |  |

| | #96 |

| RCC Addict Join Date: Sep 2015 Location: Southern Maine

Posts: 1,024

|

Here's a link to the video I took one handed driving it up my "test rock". The one where I've got to hang a wheel over the 8 foot cliff to get a little weight transfer for traction. You can see I snagged my rear pumpkin mostly from not paying attention but also from the tires. I just love this truck though! https://youtu.be/0zNdlp-hzmw Also, I just want to thank all the guys on this board for all of your help and ideas. I've stolen so many tricks and tips from you it's not even funny. Ernie, you are a class act and I appreciate all of your help with the many questions and free answers. Thank you! Nate, your eye for setting things up and details have been very helpful. For everyone else, your comments and ideas have helped me build my first truck and I think I'm going to enjoy it very much. Thank you! I will be updating this thread with new crawling pictures and any changes done to the truck. I'll gladly help anyone who has questions about their ascender the best I can. I've learned quite a few out of the box tricks with this build for sure. Thanks for following along, hope you enjoyed as much as I have building it. Ben |

| |  |

| | #97 |

| RCC Addict Join Date: Sep 2015 Location: Southern Maine

Posts: 1,024

|  Trying to figure out how to get pics on here after the photobucket dump. Gotta keep working on it I guess but at least that's a teaser on how it looks now. Very happy with it and how it handles. I'll try to figure out the picture thing because I've got a lot of great pictures from last weekend's crawl. Ben Last edited by Itali83; 08-24-2017 at 10:43 AM. |

| |  |

| | #98 |

| RCC Addict Join Date: Sep 2015 Location: Southern Maine

Posts: 1,024

| |

| |  |

| | #99 |

| RCC Addict Join Date: Sep 2015 Location: Southern Maine

Posts: 1,024

|     Im back!! With pictures now. Ben Sent from my iPhone using Tapatalk |

| |  |

| | #100 |

| RCC Addict Join Date: Sep 2015 Location: Southern Maine

Posts: 1,024

|

So, now I'm back with pictures, figured I might as well talk about how the truck goes since it's now complete and has a few runs under its belt. I love it. It's slow, low, heavy, and pretty scale. The leaf springs are so cool to watch bounce and flex like a real truck would do. I do have quite the axle wrap "problem" in the rear I'm still thinking of how to fix. It hasn't become a problem on the trail or rocks but it bugs me. May swap to some steel tamiya springs or so a helper spring set up to keep current delrin springs. I do have a spare set of springs after a freak scenario where I got a loose rock stuck between my rear wheel and bumper which instantly snapped my rear leaf spring. The Holmes electronics are amazing. This truck is almost completely silent, except transfer case which has a little 32p gear noise. Super smooth and just great. This thing side hills great, especially with the new 1.55 rock beasts with the stick pit bull foams which are quite stiff. This truck needs that. See the major sidehill picture below.  It's not as point and shoot as my 1.9 ascender for obvious reasons, but I love the challenges it gives me to make the same lines that the 1.9 does. My rear bumper is the big issue but it's the look I was going for with the build so it stays. My front bumper height and approach and skid guard is almost the same as my 1.9 truck so that's not the issue with obstacles. I painted this truck to match my first vehicle that I still have. Sadly it's only a plow truck as the Maine winters have left the body and frame quite soft from rust. But back in its day when I was driving it through high school, I had it polished and clean all the time.       So overall this isn't a truck I could comp with if we had them because I feel the leaf springs couldn't take being bound up but I know the metal ones bend too so that's just my thought. But I love driving it and seeing how well it keeps up with linked trucks. Hopefully I'll get it out this weekend for some more testing. Ben Sent from my iPhone using Tapatalk |

| |  |

|

My little Jimmy... lol - Similar Threads

My little Jimmy... lol - Similar Threads | ||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Don't Touch My Jimmy: GMC Jimmy build by CFM | CarterFab | Vaterra Ascender | 31 | 11-01-2015 12:33 AM |

| Jimmy-Yeti | jrkilburn | Axial Yeti | 2 | 08-29-2014 06:36 PM |

| Jimmy Fallon | hotrodsonoma | Chit Chat | 1 | 06-10-2014 10:56 AM |

| can Jimmy do it THIS time? | emaxxjeremy | Chit Chat | 3 | 11-18-2006 12:28 PM |

| Wheel Chinamans..lol had Carnage..lol | UPNOVER | General Crawlers | 0 | 02-27-2006 08:03 AM |

| |