| | #1 |

| RCC Addict Join Date: Mar 2008 Location: SSF

Posts: 1,614

|

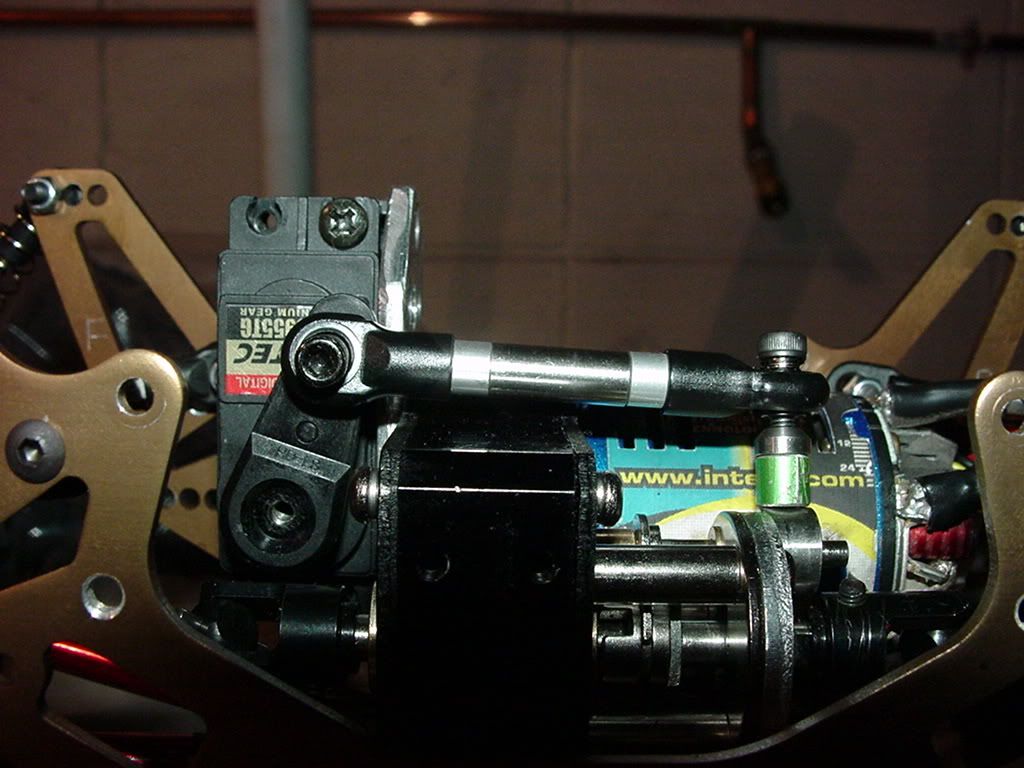

No comps, just a crawler that's all-around capable, that's my goal. My AX-10 is fun as hell, making mods and watching it perform better and better is a big rush. At a certain point mod options come to an end, atleast for me and my AX-10. So I started collecting parts for a natural evolution. R2D Mike Poulson axles Mayhem Double Fatties Panther Cougars Mamba Max CC BEC Hitek 5955tg TCS Edge chassis Of course there's a learning curve. I already know the R2D and Poulson axles don't make a great combo cause the lack of slipper. Mayhem Double Fatties don't lend to an easy fit on Poulsons cause of the larger spindle, wheel nut and drive hex. My ultimate goal is to make this rig light as hell. When I say that I don't mean 3lbs with a 3s lipo and 35t motor. I mean 5-5.5lbs but all the weight as possible. With that in mind the Edge chassis is only for mock up, it's too heavy, very nice but a similar chassis in aluminum will be made. Tons of fine detail work will be done in order to make components work well. To make the Fatties work on the Poulsons I used standard alum hexes, drilled them to fit the .1875" spindles, as well as the Fatties. Took a long 2mm set screw and turned and shank down half the length, similar to Traxxas yoke screws just smaller. This mod'd screw threaded thru the hex and into the Poulson spindle. No washers or spacers needed. Although unthreaded spindle still shows into the wheel. To cure this I'll make special wheel nuts that share the same nut driver my AX-10 does. I also made all the shock and link threads in the Poulsons metric, just trying to simplify things. Stock AX-10 wheels and tires are just rollers.  The next trick was getting the dig servo mounted for a nice low COG and straight linkage. I liked and wanted to copy the TCS mount, so I did but I put my own spin on it. Raised and flipped the servo, this made the linkage just perfect. I still need to make the linkage longer and lighter but you get the idea.  |

| |  |

| Sponsored Links | |

| | #2 |

| RCC Addict Join Date: Mar 2008 Location: SSF

Posts: 1,614

|

Other subtle mods are all the STRC links have big Revo ends with 4mm set screws. Upper links are carbon fiber and small traxxas 3mm ends. Traxxas big bores with internals. I'm making a different skid with better triangulation of the lower chassis ends. The chassis will be a stock AX-10 with alum tuber welded in. I'll post when more updates are available.  Last edited by JeepinDoug; 07-28-2008 at 10:38 PM. |

| |  |

| | #3 |

| Quarry Creeper Join Date: Mar 2008 Location: san pancho, ca

Posts: 224

|

nice to see you finally found a good use for those axial lizards your natural-evo build is going to be SICK...can't wait to see this thing crawl  Last edited by mr_manny; 07-28-2008 at 11:01 PM. |

| |  |

| | #4 |

| Pebble Pounder Join Date: Jun 2008 Location: UK

Posts: 137

|

Those axles are an interesting hybrid concept. Are they still available from somewhere, and if so how much were they?

|

| |  |

| | #5 | |

| I wanna be Dave Join Date: Sep 2005 Location: USA

Posts: 11,196

| Quote:

I also have a New Roller with Poulson axles for Sale. | |

| |  |

| | #6 |

| RCC Addict Join Date: Mar 2008 Location: SSF

Posts: 1,614

|

That's funny, I'm not getting email noti's from post replies. I spent some time experimenting tonight on a new skid. The existing one binds the rod ends, just too close to the chassis sides. Plus, just like lube, there could never be enough triangulation.  This is not the finished product, only a prototype (and no, I have no interest in producing, for sale, anything I make). This piece is black delrin and anyone who knows delrin knows it tough to drill long holes with HSS drills and keep the hole straight, whew!  In order to access the link screws the skid needs to be removed from the chassis. PITA but worth the effort. Also rather than using cap screws I'll be using long set screws. Counter boring the skid large enough for a 3mm cap screw head leaves little room for chassis mount screws. I really like the result.  The axles will have misaligning mount blocks as to not max out the rod ends. Last edited by JeepinDoug; 07-29-2008 at 09:36 PM. |

| |  |

| | #7 |

| RCC Addict Join Date: Mar 2008 Location: SSF

Posts: 1,614

| |

| |  |

| | #8 |

| RCC Addict Join Date: Apr 2007 Location: RAMBLIN

Posts: 1,713

|

hey Doug, rig looks great .

|

| |  |

| | #9 |

| Rock Stacker Join Date: Feb 2008 Location: Minnesota/Wisconsin

Posts: 63

|

interesting build, some of the sweetest axles I have ever seen on a crawler the skid plate is unique, hope to hear how it works for you |

| |  |

| | #10 |

| RCC Addict Join Date: Mar 2008 Location: SSF

Posts: 1,614

|

Thanks for the axles BILLYGOAT, a sweet deal, I'm having fun building them up. Thanks Joe. I made the first real skid today but I don't like it. Just like the black delrin one pictured but in PTFE impregnated delrin, awesome stuff. I need to make it longer, in turn my links will get shorter. I'm hoping I'll have an updated skid by friday night. |

| |  |

| | #11 |

| RCC Addict Join Date: Mar 2008 Location: SSF

Posts: 1,614

|

Update The skid is done, not exactly what I was shooting for but I think it'll work well.  A better overview of link placement.  My upper fronts are temps while JB Weld dries. The rear geometry looks good to me, the front needs a little help.  Still need to make a little longer dig link even though this one will work. Here's a better pic showing a nice link angle on the dig.  Cheesed up the dig servo plate with lightening holes, every little bit helps.  Gratuitous pic, I like how it looks so far. The CF upper links may not hang to well but I have delrin backups. I also plan on making some extensions to get the shock upper mounts more towards the axles. BTW, these Traxxas big bore shocks have axial shafts and mod'd caps for rod ends. I also play with homemade teflon shock pistons and variable valving options.  |

| |  |

| | #12 |

| I wanna be Dave Join Date: Mar 2008 Location: Pacific Ocean

Posts: 2,342

|

Looks great Doug.  Can't wait to see that thing run! Can't wait to see that thing run!

|

| |  |

| | #13 |

| Quarry Creeper Join Date: Mar 2008 Location: san pancho, ca

Posts: 224

|

I like the new skid, nicely done  I hope you don't mind If I make something similar :P what issues do you foresee with the carbon uppers? |

| |  |

| | #14 |

| RCC Addict Join Date: Mar 2008 Location: SSF

Posts: 1,614

|

Thanks Dave, Hope we'll see you in San Carlos tomorrow. Manny, I'm afraid the threads will pull out from the links. All the forces are push/pull besides maxing the articulation. The shocks hinder the artic, the saving grace to saving the links. We'll see. Your skid will be better than mine since I have some practice now in machining them. Just for the info the skid is Delrin impregnated with PTFE (teflon). This stuff is tough, not brittle at all, not as flexible as straight delrin and slipperier than snot. Almost as slippery as UHMV. |

| |  |

| | #15 |

| RCC Addict Join Date: Mar 2008 Location: SSF

Posts: 1,614

|

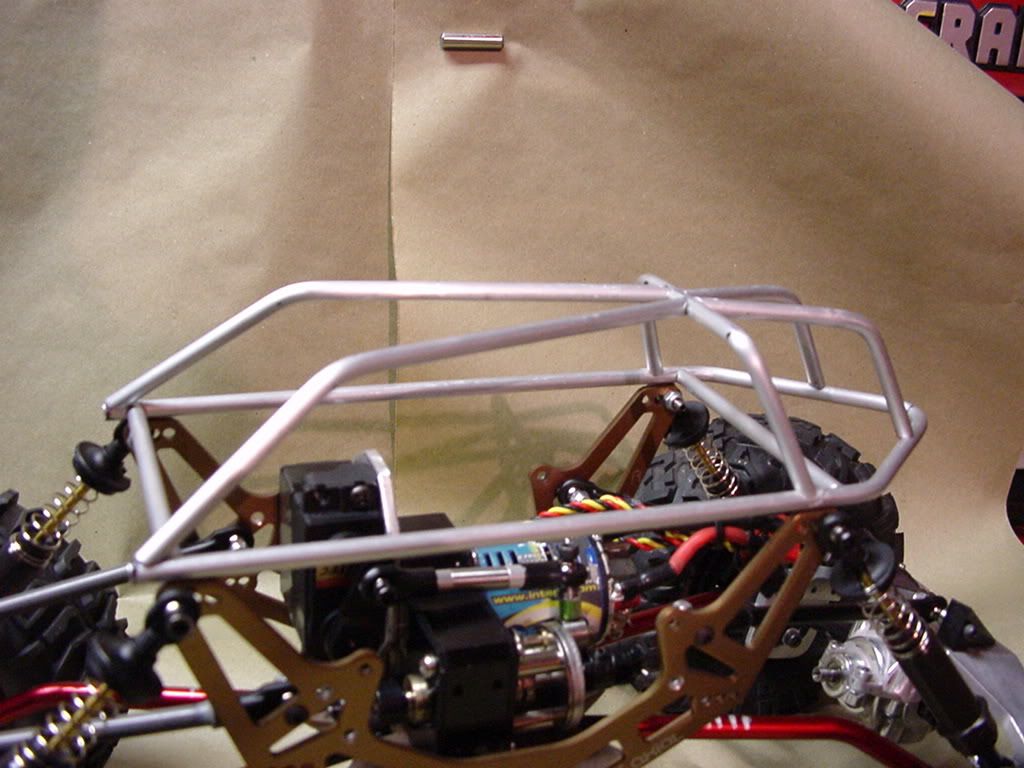

Playing around with some aluminum for the tuber section. I really don't know how well this will take when I get around to tigging it, gotta practice the small stuff again. A flux braze tank would be sweet but I dont have access to one. Bending with dowels in a board and coping with a rat tail file.   And last but not least the poser shot.  |

| |  |

| | #16 |

| I wanna be Dave Join Date: Mar 2008 Location: Pacific Ocean

Posts: 2,342

|

looking great! I ditched my Edge and went back to the stock Axial chassis too. Did you notice that the flat sections on the Edge sit lower then the Axial chassis?

|

| |  |

| | #17 |

| no talent hack  Join Date: Feb 2007 Location: Redwood City

Posts: 2,479

|

damn doug, the tube work kinda looks like your malvado grande btw you ever get that thing done? or are the rc's taking up too much time |

| |  |

| | #18 | |

| RCC Addict Join Date: Mar 2008 Location: SSF

Posts: 1,614

| Quote:

Dave, Yes, I noticed, the shock mounts are lower on the Edge. I might even ditch the tuber idea, depends on weight. I'm sure a poly lid will be lighter. | |

| |  |

| | #19 |

| I wanna be Dave Join Date: Mar 2008 Location: Pacific Ocean

Posts: 2,342

|

You could narrow the cage so that it sits down in between the chassis rails.

|

| |  |

| | #20 |

| RCC Addict Join Date: Mar 2008 Location: SSF

Posts: 1,614

|

Dave, I'm not sure the cage being higher or lower will effect the COG noticeably. I'm more interested if a polycarb body will be heavier than this alum cage. No update pics. I swapped in a Hitec 5645mg for the dig, swapped out the st.st. dig link for aluminum and finished the shock spring treatments. I wanted to machine a BTA system but I think hi-steer will have to be the choice. Dave, you hook up the new radio yet. I love mine!! |

| |  |

|

| |