| | #1 |

| Rock Crawler Join Date: Dec 2008 Location: Appleton, Wi

Posts: 660

|

Ok I know this question has been asked a million times, but I searched and haven't come up with anything really usable. I couldnt find any instructions online to set up the dig, ie. servo placement and such. I saw the epa setup sheet. Thats not what I need. My real concern is how it seems to be a lot of side load on the little brass rod in the dig. Im looking to use some fuel tubing on a linkage to actuate it but I'd like to see some pics of installed digs so I know how this dang thing goes together! :ps: The spacers inbetween the servo and mounts are because of interference with the chassis plate.    Thanks for any pics and suggestions! |

| |  |

| Sponsored Links | |

| | #2 |

| I wanna be Dave Join Date: Jun 2007 Location: Earth

Posts: 2,488

|

I'm mobile but will link you to some setup when I get home. Flip your servo, the horn should be opposite the motor. Don |

| |  |

| | #3 |

| Rock Crawler Join Date: Dec 2008 Location: Appleton, Wi

Posts: 660

|

ok. Ill have to try that, but i'm still concerned about the side load tho. I greased the internals and it seems to stick a bit when shifting. I might have to go in and file the edges a little bit. Thanks for being so quick to reply Don!  |

| |  |

| | #4 |

| RCC Addict Join Date: Jun 2008 Location: Fresno

Posts: 1,464

|

do not file anything try moving the servno further back and use the longer servo horn so your shift link lines up here a quick sketch before i have to go back to work  |

| |  |

| | #5 |

| Rock Crawler Join Date: Dec 2008 Location: Appleton, Wi

Posts: 660

|

Ok, I understand now. Ill have to try that.  Thanks for the info! Keep it coming. Thanks for the info! Keep it coming.

|

| |  |

| | #6 |

| www.team3sixrc.com Join Date: Mar 2008 Location: Scalerville

Posts: 4,506

|

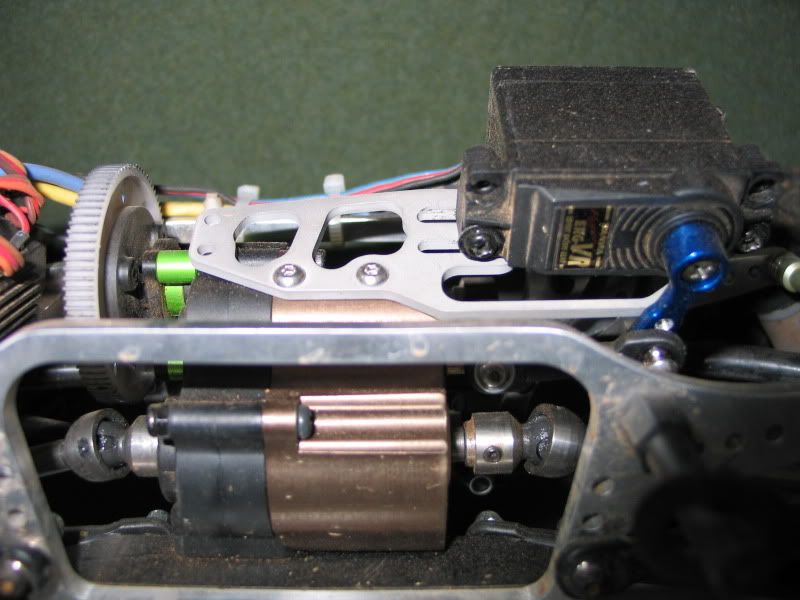

should be set up like this if you use the 645mg   |

| |  |

| | #7 |

| Rock Crawler Join Date: Dec 2008 Location: Appleton, Wi

Posts: 660

|

Does the fact that the servo is flipped make any difference? I fitted it like that but it seems like it sits too high.

|

| |  |

| | #8 |

| www.team3sixrc.com Join Date: Mar 2008 Location: Scalerville

Posts: 4,506

|

well the bracket is made to house all kinds of servo's. I like mine set up like that. it does make it a little top heavy, but i just add more to the wheels. M ine has been fine though. setting it up like that is the best way with that servo as it gives it the smoothest non binding action on the DIG

|

| |  |

| | #9 |

| Rock Crawler Join Date: Dec 2008 Location: Appleton, Wi

Posts: 660

|

ok. Ill have to do it up.

|

| |  |

| | #10 |

| RCC Addict Join Date: Nov 2008 Location: Greece, sun, sea and rocks

Posts: 1,242

|

I have it mounted like this:  just like team3six suggests. Servo orientation does not play any role at all. Also if you use a quality servo the weight differennce from the mini will be minimal. The VR I used was 11 grams heavier than the cs35 mg I previously had. |

| |  |

| | #11 |

| Rock Crawler Join Date: Dec 2008 Location: Appleton, Wi

Posts: 660

|

Well this is what I worked up. I had to mount the servo side of the linkage so close to the splines because I dont have the epa mod done in my tq3 yet, so I just did that to shorten up the overall throw of the servo. You cant see it well but I have a 3mm collar locked on the brass shaft with a 3mm x 10mm long grub screw. I then threaded on a shorter traxxas ball end on till it was tight to the collar. Even without epa's I was able to get the throw short enought to where all 3 positions work. The servo doesnt even hum when in 4wd, and free wheel. It does works a bit when the rears are locked, but the fuel tubing takes up quite a bit of the load. Any suggestions on improvements?  |

| |  |

| | #12 |

| www.team3sixrc.com Join Date: Mar 2008 Location: Scalerville

Posts: 4,506

|

well I would switch that round out for a servo horn so you get a more equal throw and the geometry is more effective. it lowers the stress on the servo and makes the switching more level and easier to pull and push your DIG postitions. It's the same situation on the steering servo, a more level geometry is less stress on the servo which is why a good percentage of guys blow servo's, wrong EPA's and wrong geometry. You got to remember whats tried is true and alot of the guys whom have been into it for a long time know what works best. as far as using fuel tubing, That will not work and the reason for this is if you know anything about crawling, rough terain and being able to run it is key to going forward in progress. as long as you set your EPA's correct and keep the geometry correct. You shouldnt place hardly any stress on the servo and when it comes time for you to use the DIG for the nessesary moves. it will stay in that place until you move it. one wrong rock or pedestal slip using your current set up will only give that link enough room to push or pull out of its position. meaning if you are on a downward path at a 85% grade and you need to make a sharp turn to make it through a gate, and upon hitting that gate there is a rock that throws your artiqulation to being 90%+ grade sideways. hitting that rock using the hose will jar it enough across the srive shaft to move the linkage to the DIG. then you are either stuck at a stop, free wheeling, or 4 wheelsing when you dont want to. |

| |  |

| | #13 |

| Rock Crawler Join Date: Dec 2008 Location: Appleton, Wi

Posts: 660

|

I would like to put a horn on it, but without epa's this is the only way to make the 3 positions functional. I plan on adding epa's later but right now Im needing to get the truck running for a comp on sunday. I have been running it around for a bit and it all is working ok. The dig seems to stick a little bit when I try to go from rear dig to free wheel. It all works perfect going from 4wd to free wheel to dig. If I go straight from dig to 4wd then it all dissengages. As soon as I get the epa's soldered into the tq3 Ill be switching to the servo horn.  |

| |  |

| | #14 |

| RCC Addict Join Date: Nov 2008 Location: Greece, sun, sea and rocks

Posts: 1,242

|

Try replacing the fuel tubing on the right side of the pic with a similar length spacer. Seems like the unit does not engage 100% in 4wd so that little give the tubing has, causes you to disengage.

|

| |  |

| | #15 |

| Rock Stacker Join Date: Jun 2009 Location: PT

Posts: 97

|

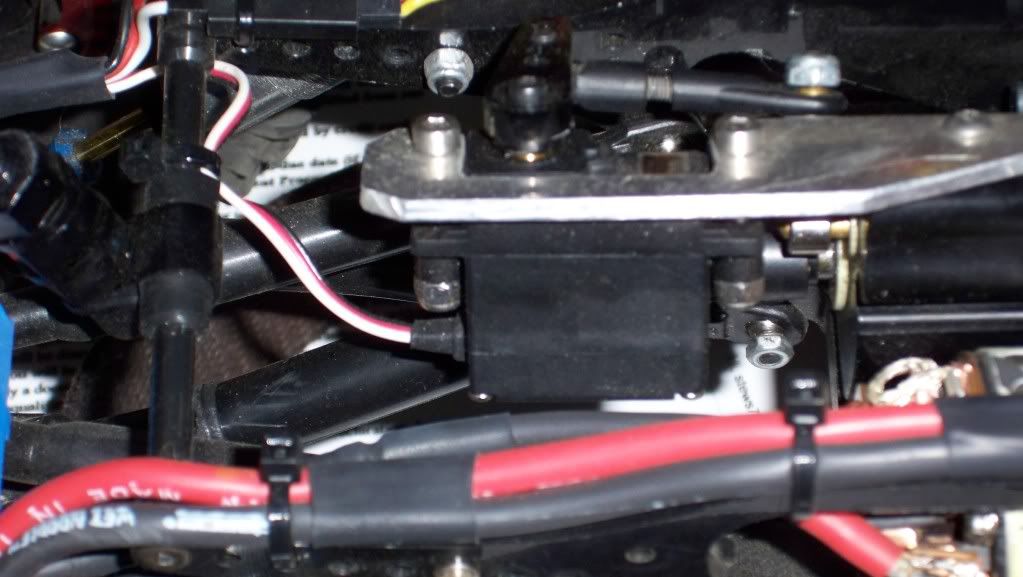

I have same problem , I didnīt known how to instal the servo , DNA instructions are to mount the servo like this , to have low GC   Only two screws , looks like a mess , so I make a new carbon servo mount this way :   |

| |  |

| | #16 |

| Rock Crawler Join Date: Dec 2008 Location: Appleton, Wi

Posts: 660

| Sorry, I misworded it. I meant it all works as needed.The only thing that is sticky is when it shifts from digging to free wheel. Im thinking once I have a chance to run it a bit more it will break in.

|

| |  |

| | #17 |

| Rock Crawler Join Date: Dec 2008 Location: Appleton, Wi

Posts: 660

|

I like how that is setup but ti still seems like there is gonna be alot of side load on the small brass actuating shaft. Ill have to look and see if I can set it up like that. Im not sure if i have enough room. |

| |  |

| | #18 |

| Quarry Creeper Join Date: Sep 2008 Location: Castro Valley

Posts: 214

|      I didnt like the way that DNA designed their mount for the dig servo either, so I made my own. I used a Futaba Micro Servo #S3102. It has just as much power as the Hitec mg225 and is also metal geared. It has more than enough power to move the dig while full throttle or light throttle. With this mount vitually everything is under the top of the chassis, so CoG is nice and low. |

| |  |

| | #19 | |

| Pebble Pounder Join Date: Aug 2009 Location: RuffNeck Build Lab.....

Posts: 173

| Quote:

| |

| |  |

| | #20 |

| Rock Crawler Join Date: Dec 2008 Location: Appleton, Wi

Posts: 660

|

that is the stock dna one.

|

| |  |

|

| |